1Energy Centre, Maulana Azad National Institute of Technology,

2Mechanical Engineering Department, Maulana Azad National Institute of Technology Bhopal (M.P),

462051, India

Article Publishing History

Received: 26/11/2016

Accepted After Revision: 27/12/2016

Microalgae hold assurance for the sustainable substitution of fossil fuels due to its high growth rates, ability to grow on non-arable land and biochemical compositions that can be easily converted to fuels using existing technology. The three major macromolecular components that can be extracted from microalgal biomass are lipids, carbohydrates, and proteins. These chemical components can be converted into a variety of fuel options such as alcohols, diesel, methane, and hydrogen. Open ponds and photobioreactors are used as standalone production systems or in combination as a two-stage process in the production of algal biomass. A novel method of plastic bag technology can be adopted for reducing investment and the production cost of microalgae. In the present work an integrated approach of micro-algae cultivation is proposed to ultimately address the sustainable production and environmental issues .The state-of-the-art of algal production for food, feed and biofuels is presented with emphasis on sustainable and economical approaches. The various sustainable cultivation techniques to enhance lipid and protein yields are listed. The optimum proportions of organic nutrients required for microalgae growth to is also presented. This integrated and economically viable approach of microalgae production has the potential to save India from malnutrition and fuel scarcity.

Microalgae, Sustainable Production, Spirulina, Open Pond, Photobioreactors, Plastic Bags

Soni R. A, Sudhakar K, Rana R. S. Sustainable Biomass Production from Microalgae for Food, Feed and Biofuels: An Integrated Approach. Biosc.Biotech.Res.Comm. 2016;9(4).

Soni R. A, Sudhakar K, Rana R. S. Sustainable Biomass Production from Microalgae for Food, Feed and Biofuels: An Integrated Approach. Biosc.Biotech.Res.Comm. 2016;9(4). Available from: https://bit.ly/2QQkNrS

INTRODUCTION

The global energy demand is expanding with rapid population growth. Almost 1.4 billion people of our planet face daily shortage of energy. Estimate shows that the world would require 50% more energy in 2030 than it does today. Although feeding the biofuel production residues to animals presently is an economically viable and may also results in balancing the energy and environmental cost of feed production, but it may not be a

perfect solution if biofuels are to replace the majority of the liquid fuel used today. Initial evaluation of microalgae as the potential source for biofuel production began in 1970, but it was temporarily waived due to technical and economic issues. Later on, subsequent studies from 1980 onwards showed high potential in microalgae biofuel production, (Ugwu et al 2008, Komerath and Komerath 2011, Huo et al 2012 and Sani et al 2013).

Microalgae find its major application in producing lipid based fuels as biodiesel. Their growth rate and doubling time is high as compared to plants, and their cell walls are rich in protein rather than cellulose, in comparison with terrestrial plants. Moreover, releasing protein from algal biomass may be an easier bioconversion process rather than breaking down lignocellulosic plant matter to fermentable sugars. Despite these potential advantages, economic analyses have suggested that any highly engineered process for cultivating microalgae and producing commodities such as diesel or jet fuels results in very expensive products in the present scenario. New integrated cultivation techniques have been introduced for better mixing efficiency, cost effective materials of enclosed photobioreactor (Jonathan 2011, Naqqiuddin et al 2014, Jiang et al 2016).

|

Figure 1: Shows the plastic bag technology for cultivation of microalgae which could be economically beneficial |

|

Figure 2: SFossil fuel reserves with time (CIA Factbook, 2010). |

There is a strong potential for co-production of energy and high-value added compounds from algae, but the present productivity or availability of the latter is much too low to achieve so as to achieve an substantial volume of biofuel co-production. The only advantage of microalgae production in photobioreactor for producing pure microalgae as compared to other systems other than cost, complicated designs and difficulties in maintenance making it at disadvantage. Therefore, algal productivity in bulk-volume is needed for a large-scale co-production or integrated concept. The possibility of co-producing food and fuel, self-sufficiency, combating malnutrition and hunger, reducing the negative health effects of using traditional biomass sources for cooking and heating can be other advantages. Traditional cultivation systems such as open ponds and photobioreactors have inherent drawbacks. Though open pond system has been used for long time, the major drawback is the low productivity and contamination. Hybrid or integrated cultivation system may bring out some positive and improved results. There is big time to fulfill or accommodate the global demands for biofuels. An emphasis should be laid on improving the quality, scope, depth, and translation of research.

CONCEPT OF SUSTAINABLE FOOD AND BIOFUEL PRODUCTION

Till date, researches on developing advanced technologies in microalgae cultivation systems have been contributive especially for enclosed photobioreactors. Most photobioreactor are land based designed, with some drawbacks as sophistically complicated, difficulties in maintenance, high initial cost, expensive preservation, and normally reserved to culture high value microalgae. To a certain extent of open systems, culture purity might decline distress after few generations of algae cultivation cycle (Medipally 2015).

|

Figure 3: Integrated approach of food, feed and biofuel production from Spirulina species |

Different climatic factors may influence the growth and productivity of microalgae. Waste-grown algae have widely varying lipid contents, and the technologies for lipid extraction are still under development. Excessive or extreme agitation or aeration could affect the growth of microalgae cell particularly for Spirulina. Bubbles arising during aeration could break the long chained filament of Spirulina cells into short though it promotes other microalgae species to grow inside the photobioreactors. Spirulina have considerable potential for development as a small scale crop for nutritional enhancement, livelihood development along with environmental mitigation. To ensure water environment and water ecology security, designing of green watershed with low emissions, high self-purification ability, ecosystem healthy, and excellent service functions is required, (Abdel-Raouf 2012 and Liu et al 2016).

An adequate energy supply has been identified as a key prerequisite for economic, cultural and social development in complex societies. For sustainable food production, plastic bag technology integrated with open pond and green house can be implemented. Microalgae are the most promising next-generation biomass feedstock. Conventional production systems did not result in cost-effective cultivation of microalgae. Issues were high contamination risk, very low biomass production, high capital expenditures and increasingly high operational costs. These can be overcome by bringing out new technologies.

Though the cultivation of algae using manmade or natural open pond system was initially simple, turning it into a viable feedstock has always been problematic. So there is a need for a system that could enable higher production levels, lower capital and operating costs, greater biomass concentration, better environmental control, and above all, industrial scalability.

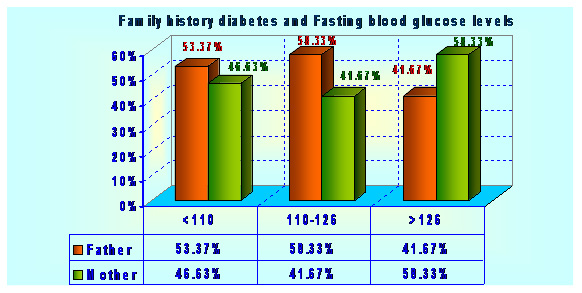

To make a difference when it comes to renewable energy or byproducts made from microalgae, cost effectiveness is a major role to be bring about in concern. For producing microalgae feedstock, it should be further refined in order to get biofuels or biochemical. Many experiments and research is in process for biofuels and chemical industries along with agricultural industries for producing high value added products and proteins. Table 1 shows the comparison between different cultivation system and validates that plastic bag technology can be more beneficial in terms of daily productivity (Rao et al 2014; Arto et al 2016 and Soni et al 2016).

| Table 1: Comparison of open pond, PBR and Plastic Bag techniques for algae cultivation. | |||

| Open Pond | PBR | Plastic Bag Technology | |

| Water Media(tons) | 100 | 100 | 100 |

| Area Requirement (m2) | 250 | 250 | 1200 |

| Daily Production (Kg Dry Weight) | 35 | 35 | 60 |

| Areal Productivity (Kg/m2/day) |

0.14 | 0.14 | 0.05 |

The energy history and profile of a country is a major factor to consider in assessing their current and future journey towards a sustainable energy path, particularly for developing countries. Spirulina has a high nutritional value and micronutrients which can be used as healthy food, animal feed, nutraceuticals and pharmaceuticals. It is considered as an excellent food, with minimal or no toxicity and having immunitive properties against viral attacks, anaemia, and especially malnutrition. It has been reported as animal and fish food supplements, (Soha and Nour 2013 and Edomah 2016)

Spirulina seems to have considerable potential for development, especially as a small-scale crop for nutritional enhancement, livelihood development especially for women, children and environmental mitigation. In particular, the sustainable production and consumption of spirulina has the following advantages:

- It provides an easily digestible protein product with high levels of â-carotene, vitamin B12, iron and trace minerals and the rare essential fatty acid ã-linolenic acid (GLA).

- It’s healthy for human consumption with no negative effects.

- Its production is done with considerable efficiencies in terms of water, land use and energy consumption when compared to traditional terrestrial crops;

- Its production is highly suitable to saline and alkaline water conditions that are often unfavourable to traditional crops and are frequently occupied by disadvantaged people suffering from natural disasters;

- The production of algae is simple and easy which can be easily cultivated from household “pot culture” to intensive commercial development over large areas. Table 2 summarizes the nutritional components of different microalgae species. Among these spirulinais having maximum protein content and chlorella vulgaris is having maximum lipid content.

| Table 2: Comparison of microalgal species | |||

| Species | Proteins | Carbohydrates | Lipids |

| Spirulina maxima | 60-71 | 13-16 | 6-7 |

| Spirulina plantesis | 46-63 | 8-14 | 4-9 |

| Scenedesmus obliquus | 50-56 | 10-17 | 12-14 |

| Chlorella vulgaris | 51-58 | 12-17 | 14-22 |

| Spirogyra sp. | 6-20 | 33-64 | 11-21 |

Advancing a strategy for sustainable development of biofuels that meets concerns for availability, cost effectiveness, green house gas reductions, food competition, and ecosystem protection will be a knowledge intensive activity. Very little is going into research on agricultural and natural resource systems needed to sustainability “scale -up” a significant biofuel production system, into the limits of sustainable expansion, or into the ways that biofuel production interacts with the environment at global, regional and local scales, (Lee et al 2008). Biofuels have a limited ability to replace fossil fuels and should not be regarded as a ‘silver bullet’ to deal with transport emissions. Biofuels cannot support a sustainable transport system on their own so it must be developed as part of an integrated approach. Emphasis is needed in the development of hybrid and fuel cell vehicles, public transport, and better town and rural planning, (Mohr et al 2015, Sudhakar and Premalatha 2015; Hassan 2016).

Globally – every year an equivalent of over 11 billion tonnes of oil is consumed. Crude oil reserves are vanishing at the rate of 4 billion tonnes a year – At this rate of consumption without any increase for our growing population or aspirations, the known oil deposits will be exhausted by 2052. We’ll still have gas left, and coal too. But if we increase gas production to fill the energy gap left by oil, then those reserves will only give us an additional eight years, taking us to 2060. But the rate at which the world consumes fossil fuels is not standing still, it is increasing as the world’s population increases and as living standards rise in parts of the world that until recently had consumed very little energy. Fossil Fuels will therefore run out earlier.

| Table 3: Comparison of different sources of biofuels, summarizing the different biofuel sources | ||||||

| Country | Biofuel Source | Impact Boundaries | Oil Yield (Lt/oil/ha) | Land Use (m2/GJ) | Energy (GJ/ha) |

Water Required (m3/GJ) |

| Argentina | Soyabean | Use of non-renewable energy sources, GHG emissions (CO2), hydrocarbons (HC), CO, particulate matter (PM), NOx, SOx | 446 | 689 | 15 | 383 |

| Brazil/India | Rapeseed | GHG emmisions | 1190 | 258 | 39 | 383 |

| Malaysia | Palm Oil | GHG emmisions | 5906 | 52 | 192 | 75 |

| India | Jatropha | Use of non-renewable energy GHG emissions (CO2, CH4, N2O) Pollutants (SO2, NOx, NH3, HCI, NOx, NH3, POCP) Ozone | 1896 | 162 | 62 | 396 |

| U.S | Microalgae | Utilises CO2 from atmosphere through photosynthesis | 24355-136886 | 2-13 | 793-4457 | <379 |

It’s often claimed that we have enough coal to last hundreds of years. But if we step up production to fill the gap left through depleting our oil and gas reserves, the coal deposits we know about will only give us enough energy to take us as far as 2088. And let’s not even think of the carbon dioxide emissions from burning all that coal, (Piyushi 2014).

Out of the world’s twenty largest oil fields, sixteen have already reached their peak level of production, whilst the discovery of oil field discovery was nearly 50 years ago (CIA Factbook, 2010). Biofuels have the potential to be a useful element of the overall approach to the issues of climate change and energy supply. While improvements can be made in the environmental performance of the existing supply of biofuels, many of the technologies and production systems are at early stages of conception and development.

CONCEPT OF INTEGRATED FOOD AND BIOFUEL PRODUCTION

Current biorefinery schemes are suboptimal for several reasons such as reduced efficiencies or high cost. Microalgae do not compete for land with crops used for food production, fodder and other products (Huang et al, 2010). Microalgae can be grown on farms or in bioreactors, or in plastic bags. The most common microalgae have oil levels in the range of 20 to 50% by weight of dry biomass, but still higher productivities can be attained through research (Mata et al, 2010). Microalgae have the doubling time of 24hrs which is one of their greatest advantages in terms of productivity Firstly, algae have limited efficiency because cultures used for biofuel production must be starved so that they produce lipid feedstocks, resulting in less cell growth and less total CO2 fixation. The growth of algae requires CO2 as one of its main nutrients. There is an opportunity to sequester CO2 by using flue gas emissions from industrial sources as the feed for algae cultivation (Ahmad et al, 2011; Sudhakar and Premalatha, 2012; Rinanti et al 2014, Arita et al 2015, Cheah et al 2015 and Sharon et al 2016)

- Secondly, sugar-based or cellulosic biorefining, lead to the accumulation of protein by-products, but there are no such strategies to convert these by-products into lipids and then to liquid fuels. These protein by-products are now mainly used as animal feed. But despite the current profitability of animal feed, the feed market has a limited ability to absorb the increasing protein by-products from the fast-expanding biorefinery industry (Sani et al 2013). Thirdly the main concern is the accumulation of the reduced nitrogen which increases the green house gas emission leading to more destruction than carbon dioxide (Jonathan, 2011). Moreover, the unused or lost reduced nitrogen must be reintegrated by enriching future crops with reduced fertilizer nitrogen, which is being produced by the environmentally unfriendly and energy-intensive Haber-Bosch process. Re-tracing the potential of Spirulinato fulfill both their own food security needs as well as a tool for their overseas development and emergency response efforts. Integrated food and energy systems are designed to integrate, intensify, and thus increase the productivity of food and energy simultaneously through sustainable land management. The intensification of specific productions of energy and other coproducts such as food, feed and biochemicals is achieved in two ways. Carbon dioxide (CO2) emissions are a particular problem and an attempt to reduce atmospheric CO2 concentration is inevitable worldwide. (Raoof et al 2006, USEPA 2014, Mickey et al 2016)

- Multiple resource use through the diversification of land use and productivity, i.e. by combining the production of food and fuel feedstock on the same land, through mixed cropping and or some advance techniques.

- Multiple resource use and full utilization of products and byproducts or the residues, i.e. multiple products which may be derived from a crop or from livestock. By feeding the by-products of one production stream into the next line of production, waste is reduced or eliminated. This leads to low- or zero-waste systems.

The rationale and concept of the Integrated production schemes are elaborated below

Economic viability and Environmental sustainability

The relationship between energy consumption and economic growth, as well as economic growth and environmental pollution, has been one of the most widely investigated topics in the economic literature during the three last decades. Microalgae biofuel production is commercially feasible because it is cost competitive with fossil based fuels, does not require extra lands, improves the air quality by absorbing atmospheric CO2, and utilizes nominal water. However, microalgae biofuels have some limitations such as low biomass productivity, low lipid content in the cells, and small size of the cells that makes cultivation and harvesting process highly priced. These drawbacks can be overcome by improving the technologies for harvesting and drying and by genetic engineering of metabolic pathways for high growth rate and doubling time and increased lipid content.

Conversion of algae to biofuels circumvents many problems presented by land based crops, but also presents its own challenges. Firstly, photosynthetic microbes produce negligible levels of cellulosic polysaccharides. The difficult task of degrading lignocellulose does not exist and will not limit overall energy efficiency. Secondly, photoautotrophic organisms may be grown in plastic lined ponds which reduce environmental runoff from unused fertilizer. An analogous setup cannot be established for terrestrial crops. Thirdly, photosynthetic microbes fix carbon at a much higher rate than terrestrial plants. The fastest carbon fixation rate measured in an algae pond was 40 g/m2/day , while that of terrestrial plants has not risen above 1 g/m2/day (Huo et al, 2012) . Rise in algal biodiesel scale will expand the global nitrogen unevenness with further protein-rich by-product creation. (Emeish 2013; Singh et al 2011; Roy et al 2013; Ali et al 2014; Lee 2016)

Algal productivity has a strong influence on the economics of the process, as it determines how much product the cultivation system produces. If the market price of the product is known, the money available for producing the algae and extracting the products can be calculated. Realistic estimates for dry microalgal biomass yield may vary from 40 to 80 tons per year per hectare depending on the technology used and the location, despite common claims of higher yields, (Gallagher et al 2011, Nagarajan et al 2013, Sani et al, 2013, Soha and Nour 2013, Brownbridge et al 2014, Sghari et al 2016).

| Table 4: Comparison of different parameters with algae cultivation systems | |

| Parameter | Relative Advantage |

| Capital / Operating Costs | Plastic Bags< Open Ponds< |

| Biomass Concentration | Plastic Bags< Open Ponds |

| Oxygen Inhibition | Open Ponds> PBRs~ Plastic Bags |

| Contamination risk | Open Ponds> PBRs~ Plastic Bags |

| Water losses | Open Ponds> Plastic Bags> PBRs |

| Carbon dioxide losses | Open Ponds~ Plastic Bags~ PBRs |

| Space Required | Open Ponds~ PBRs< Plastic Bags |

The location of the production system is of major notability for the economics, as it determines the costs of land, labour, CO2, nutrients supply and other factors that have a major impact on the process. By assessing the vitality of algae projects from a market perspective, it is clear that total installation, operation and maintenance costs will be a major obstacle to future commercialization but technologies are being developed to further reduce costs and increase yields. Table 3 shows the advantages of adapting plastic bag technology with different parameters.

Although the upcoming innovative technologies are a long way from commercialization, it opens up a new pathway for producing higher carbon alcohol fuels while offering a co-product for conventional biomass biorefineries. It may also stimulate development of sustainable algal systems for protein production. Currently it is too expensive to be commercialized. The long term potential of this technology can be improved by the following approaches. Economical growth technologies of oil – rich as well as protein rich algae which can contribute to food supplement, should be developed. Integrated concept for food and biofuel concept should be adopted. Enhancing algal biology by genetic modifications and metabolic engineering leads to great impact on improving the economics of microalgal production. International organizations working with Spirulina algae should prepare a practical guide to small scale Spirulina production that could be used as a basis for extension and development methodologies.

This small-scale production should be orientated towards:

(i) Providing Spirulina products as nutritional supplements in rural and urban communities especially for women and children where the staple diet is poor or inadequate;

(ii) Instead of growing variety of traditional crops, more emphasis should be laid on monitoring Spirulina production and its different products.

(iii) To develop clear guidelines on food safety and toxicity aspects of Spirulina production and processing.

(iv) Production of Spirulina for human consumption should specifically take into account the potential risks of contamination of Spirulina with toxin producing blue-green algae.

(v) Culture should be encouraged only in controlled ponds or photobioreactors or in plastic bags where single cell culture is feasible.

CONCLUSION

Biofuel development is facing urgency due to the rising challenges of climate change and carbon balance accounting concepts as carbon footprints. The technology for cultivating, harvesting and processing of algal biomass should be customized, standardized, simplified and economized. Theoretically, microalgae have been a potential source to produce biofuels because of their many pros as a sustainable feedstock for biofuel production; however their production needs more research to identify the most suitable microalgae species and improve their oil yield as well there use as food supplement. Based on the overview presented, the search for beneficial microalgae sources should focus on appropriate strain for food and biofuel production without much impact on land-use and water consumption. There is a need for more research on the biosynthesis of algal lipids, especially triglycerides and fatty acids. The algae having major portion of proteins can also be converted and further used for biofuel production. No other potential sources of biofuels compete to microalgae in being realistic sustainable production for food, feed and

biofuels.

ACKNOWLEDGEMENTS

We are very thankful to Ex-Director, Dr. K. K. Appukuttan, Maulana Azad National Institute of Technology Bhopal, India for his continued support and guidance to complete this research work.

REFERENCES

Ahmad A.L Yasin N.H., Derek C.J.C, Lim J.K (2011), Microalgae as a sustainable energy source for biodiesel production: A review, Renewable and Sustainable Energy Reviews 15, 584–593

Arita, C. Peebles, T.H. Bradley (2015) Scability of combining microalgae-based biofuels with wastewater facilities: a review Algal Res., 9 (160) p. 169

Arto I, Capellán-Pérez I, Lago R, Bueno G., Bermejo R (2016) The energy requirements of a developed world, Energy for Sustainable Development 33, 1–13

Brownbridge G., Azadi P., Smallbone A., Bhave A., Taylor B., Kraft M., (2014) The future viability of algae-derived biodiesel under economic and technical uncertainties, Bioresource Technology 151, 166–173.

Cheah W.Y., Show P.L., Chang J.S., Ling T.C., Juan J.C.(2015) Biosequestration of atmospheric CO2 and flue gas-containing CO2 by microalgae Bioresource Technology 184, pp. 190–201

Edomah N,(2016) On the path to sustainability: Key issues on Nigeria’s sustainable energy development, Energy Reports 2, 28–34

Emeish S., (2013) Production of Biodiesel from Microalgae, Journal of Energy Technology and Policy, vol. 3, no. 10, pp. 58–69.

Gallagher B.J, (2011) The economics of producing biodiesel from algae, Renewable Energy 36, 158e162

Homaidan A.A.A, Houri H.A, Hazzani A.A.A, Elgaaly G, Moubayed N.M.S, (2014) Biosorption of copper ions from aqueous solutions by Spirulina platensis biomass, Arabian Journal of Chemistry 7, 57–62

Huang G, Chen F, Wei D, Zhang X, Chen G. (2010) Biodiesel production by microalgal biotechnology. Appl Energy; 87:38–46.

Huo Y X , Wernick D.G. and Liao J.C, (2012) Toward nitrogen neutral biofuel production, Current Opinion in Biotechnology, 23:406–413

Jiang G, Wang C, Chris Le X., (2016) Rapid growth of environmental research in China, Journal of environmental sciences 39, 1–3.

Komerath N. M. Komerath P. P, (2011) Terrestrial Micro Renewable Energy Applications of Space Technology, Physics Procedia, 20, 255-269.

Lee D.H. (2016) Cost-benefit analysis, LCOE and evaluation of financial feasibility of full commercialization of biohydrogen Int J Hydrogen Energy, 41 (7), pp. 4347–4357

Lee H., Clark W.C., Devereaux C. (2008) Biofuels and Sustainable Development, Venice.

Liu H, Wang D, Yuan B. (2016) Sustainable water environment and water use: A perspective on water resource utilization, Journal of Environmental. Sciences., http://dx.doi.org/10.1016/j.jes.2016.11.005

Mata TM, Martins AA, Caetano NS. (2010) Microalgae for biodiesel production and other applications: a review. Renew Sust Energy Rev 14:217–32.

Medipally, S. R., Yusoff, F. M., Banerjee, S., & Shariff, M. (2015). Microalgae as Sustainable Renewable Energy Feedstock for Biofuel Production. BioMed Research International, 2015, 519513. http://doi.org/10.1155/2015/519513

Mickey H. Wu a, Thomas S. Nga, Martin R. Skitmore (2016) Sustainable building envelope design by considering energy cost and occupant satisfaction, Energy for Sustainable Development 118–129.

Mielenz J. R,( 2011) Biofuels from protein, Nature Biotechnology Volume 29 number 4 April

Mohr SH, Wang J, Ellem G, Ward J, Giurco D. (2015) Projection of world fossil fuels by country. Fuel;141:120–35.

Nagarajan S, Chou S. K., Cao S., Wu C., Zhou Z., (2013) An updated comprehensive techno-economic analysis of algae biodiesel, Bioresource Technology 145, 150–156

Naqqiuddin M. A, Nor N.M, Omar H. & Ismail A (2014) Development of simple floating photobioreactor design for mass culture of Arthrospira platensis in outdoor conditions: Effects of simple mixing variation, Journal of. Algal Biomass Utilization., 5 (3): 46- 58

Nautiyal P, Subramanian K.A, Dastidar M.G, (2014) Kinetic and thermodynamic studies on biodiesel production from Spirulina platensis algae biomass using single stage extraction–transesterification process, Fuel 135 228–234.

Nautiyal P, Subramanian K.A., Dastidar M.G., (2014) Production and characterization of biodiesel from algae, Fuel Processing Technology 120, 79–88

Rao ND, Riahi K, Grubler A. (2014) Climate impacts of poverty eradication. National Climatic Change; 4(9):749–51.

Raoof B,. Kaushik B.D,, Prasanna R, (2006) Formulation of a low-cost medium for mass production of Spirulina, Biomass and Bioenergy 30, 537–542

Raouf N.A, Al-Homaidan A.A, Ibraheem I.B.M, (2012) Microalgae and wastewater treatment, Saudi Journal of Biological Sciences 19, 257–275

Rezaei H., (2016) Biosorption of chromium by using Spirulina sp., Arabian Journal of Chemistry 9, 846–853

Rinanti A, Kardena E, Astuti DI, Dewi K. (2014) Improvement of carbon dioxide removal through artificial light intensity and temperature by constructed green microalgae consortium in a vertical bubble column photobioreactor. Malaysian Journal of Microbiology. 10(1): 29–37.

Roy J.J., Sun L., Ji L.(2013) Microalgal proteins: a new source of raw material for production of plywood adhesive J. Appl. Phycol., 26 , pp. 1415–1422 http://dx.doi.org/10.1007/s10811-013-0169-2

Sani Y.M., Ashri W M,. Abdul Aziz A.R, (2013) Solid acid-catalyzed biodiesel production from Microalgal oil-The dual advantage, Journal of Environmental Chemical Engineering,1, 113-121.

Sghari M B A, Hammami S. (2016) Energy, pollution, and economic development in Tunisia, Energy Reports 2, 35–39

Sharon J.W. Klein N, Coffey S., (2016) Building a sustainable energy future, one community at a time, Renewable and Sustainable Energy Reviews 60, 867–880

Singh A., Nigam P. S., and. Murphy J. D, (2011) Mechanism and challenges in commercialisation of algal biofuels, Bioresour. Technol., vol. 102, no. 1, pp. 26–34.

Smith A, Hargreaves T, Hielscher S, Martiskainen M, Seyfang G. (2015) Making the most of community energies Three perspectives on grass roots innovation. Environ. Plan. A. http://dx.doi.org/10.1177/0308518X15597908.

Soha S.M. Mostafa and Nour Sh. El-Gendy, (2013) Evaluation of fuel properties for microalgae Spirulina platensis bio-diesel and its blends with Egyptian petro-diesel, Arabian Journal of Chemistry – http://dx.doi.org/10.1016/j.arabjc.2013.07.034

Soni R A, Sudhakar K.,Rana R.S (2016) Biophotovoltaics and Biohydrogen through artificial photosynthesis: an overview Int. J. Environment and Sustainable Development, Vol. 15, No. 3,

Sudhakar K. and Premalatha M. (2012), Micro-algal Technology for Sustainable Energy Production: State of the Art, Journal of Sustainable Energy & Environment 3 59-62

Sudhakar K., Premalatha M. (2015) Characterization of micro algal biomass through FTIR/TGA/CHN analysis: Application to Scenedesmus sp. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects; 37(18):1-8. DOI:10.1080/15567036.2013.825661

The CIA World Factbook (2010), Central Intelligence Agency, Skyhorse Publishing Inc., 2009, United States

Ugwu, C.U., Aoyagi, H. & Uchiyama, H. (2008) Review-Photobioreactors for mass cultivation of algae. Bioresources Technology 99: 4021-4028

USEPA (2014). Green building—basic information. U.S. Environmental Protection Agency; http://www.epa.gov/greenbuilding/pubs/about.htm].