1Department of Home Science, Barkatullah University, Bhopal, M.P

2Department of Home Science, Rani Laxmibai Girls College, Bhopal, M.P

3Department of Food Science & Technology, JNKVV, Jabalpur, M.P.

Corresponding author email: tikleashwin@gmail.com

Article Publishing History

Received: 05/10/2019

Accepted After Revision: 30/11/2019

Cookies are produced from blends of chickpea, wheat, soybean, sorghum and oat flours, which is extremely important as there are important crops, which are good source of protein, minerals and trace elements. Chickpea flour was prepared from four different varieties i.e. two Kabuli varieties -Kripa (Phule G-0517) and RVKG- 101 and two desi- JAKI-9218 & JG-130. Blend was prepared by homogenously mixing chickpea with other flours in the proportions of 60:10 (60% chickpea & 10% of each other flours used to bake cookies). The study was carried out to evaluate the varietal effect of these blended flours on physical, microbial and sensory qualities. Bacterial and Fungal growth were evaluated using standard form. Consumer preference was also determined using a taste panel list. The main quality scores of bacterial count on the cookies from 0 to 90 days of four varieties ranged (0.28-14.03 x 104 and 0.21-8.19 x 104 cfu/100g) for total viable count on PDA & NAM. For fungal count on PDA & NAM medium ranges (0.06-0.85 x 107 and 0.03 -0.74 x 107 cfu/100g) were estimated. The counts were minimal and within acceptable limits. In sensory evaluation of cookies it was carried out in 20-35, 35-50 & 50-65 age groups. In all the age groups cookies made from flours of different varieties were found significantly different (p<0.05) exist in color, texture, taste and mouthfeel. Cookies made form kabuli gram had overall higher ranking than those made form desi gram varieties.

Cookies, Chickpea flour, Physical analysis, Microbial, Sensory.

Tikle A, Mishra A. Physical, Microbial and Sensory Qualities of Cookies Produced from Composite Flour. Biosc.Biotech.Res.Comm. 2019;12(4).

Tikle A, Mishra A. Physical, Microbial and Sensory Qualities of Cookies Produced from Composite Flour. Biosc.Biotech.Res.Comm. 2019;12(4). Available from: https://bit.ly/34oRNeq

Copyright © Tikle and Mishra This is an open access article distributed under the terms of the Creative Commons Attribution License (CC-BY) https://creativecommns.org/licenses/by/4.0/, which permits unrestricted use distribution and reproduction in any medium, provide the original author and source are credited.

INTRODUCTION

In the present day economic scenario, emerging globalization, consumers have changed the perception of their foods. Most of the consumers demand convenient food, ready to eat snacks which add to bulk and satisfy their appetite (Kumar et al., 2016). In this era of industrialization and technological advancement, the life style of people has changed (Udaybeer et al., 2018). The diet consumed by a vast majority of people is deficient in proteins, minerals etc. Therefore, one of the great challenges today is to develop inexpensive foods that are nutritionally superior and at the same time highly acceptable to intended consumers. The consumption of cereals and legumes all over the world gives them an important position in International Nutrition (Goliya et al., 2018).

Chickpea seed has high digestible protein and complex carbohydrate with low glycemic index and is relatively free from anti-nutritional constituents increased cancer prevention as well as protection against cardiovascular disease due to their dietary fiber content. A multigrain snack helps in high intake of fiber and health enhancing components (Regaee and Abddel Aal, 2006 Wang et al., 2010, Wallace et al., 2016, Parca et al., 2018, Raza et al., 2019).

Wheat is the world’s number one cereal supplying major portion of energy and protein in the Indian diets (Shewry and Sandra 2015). Soybean being the richest, cheapest and easiest source of best quality protein and fat and having a vast multiplicity of uses as food and industrial products is sometimes called a wonder crop (Rana et al., 2013). Oats are high in fibre, specifically beta-glucan, which reduces blood cholesterol level by increasing the excretion of bile in the body (Jenkins and Kendall, 2012; Varma et al., 2016; Grundy at al.,2018). Millets are being recognized as potential future crops because of relatively high dietary fiber, antioxidants, micro-nutrients, sulphur containing amino acids and essential fatty acids besides macro-nutrients. Particularly in the develop countries, there is a growing demand for gluten-free foods and beverages for people with celiac disease (Rao et al., 2017). Indians consume 42 per cent of the millets produced globally (Anonymous, 2007). India is the largest producer of many kinds of millets, which are often referred as coarse cereals (Michaelraj Shanmugam, 2013).

The sensory evaluation of the product improves the consumer appeal which helps in marketing and dissemination of the product (Aziah et al., 2012). Sensory evaluation helps customer to reduce risks, improve their product’s appeal and enhance quality characteristics as a result of different process such as packaging, storage, new processing or changing ingredients (Bala et al., 2015). Microbiological changes are primary important for short-life products, whole chemical and sensory changes for medium to long life products. Microbial spoilage is the major problem causing deterioration in bakery products. It is caused mainly by molds and yeasts and occasionally by bacteria (Saranraj and Geetha 2012).

The purpose of the study is to evaluate Shelf-life studies of products of chickpea cultivars through microbial load and to study the impact of selected recipes on various age groups -College girls and elders.

MATERIAL AND METHODS

Raw Material & cookies preparation

Four released varieties 2 kabuli and 2 desi of chickpea (Cicer arietinum L.) were procured from Department of Plant Breeding and Genetics, Rafi Ahmed Kidwai College of Agriculture, Sehore while local grains of Soybean, Wheat, Sorghum and Oat were procured from local market. Butter, sucrose, baking powder etc. were purchased from grocery store.Cookies were prepared from the composite flour according to the method of (Giami et al., 2004) (Table-1, Fig.-1). The composite flour and baking powder are added to the sugar-butter-egg mass and mixed to get homogenous mass. Baking was carried out at 2250C for 13 minutes. The biscuits were cooled at room temperature for 15 minutes. The cookies were allowed to cool for 30 minutes and stored in polyethylene bags before further analysis.

Table 1: Basic formulation of cookies

| Ingredients | Quantity in (gram) |

| Flour/composite flour | 500 gm |

| Sugar | 250 gm |

| Ghee/butter | 250 gm |

| Eggs (White) | 3 (Nos.) wt. 60 gm each |

| Baking Powder | 10 gm |

|

Figure 1: Cookies of four different gram varieties. |

Determination of Physical properties

Physical properties of the cookies were determined according to AACC (2000) methods. Six cookies were weighed on an electronic (Mettler Toledo, India) weighing balance. The diameter was determined by placing six cookies edge to edge using a ruler. The cookies were rotated at an angle of 900 for duplicate readings. The height was measured by placing six cookies on top of one another using a ruler. The spread factor was expressed as the ratio of the diameter to the thickness of the cookies. All measurements were carried out in triplicate.

Sensory Evaluation

The sensory evaluation of the cookies samples was carried out for consumer acceptability and preference using 150 untrained and semi-trained panelists comprised of students, staff of agriculture and home science departments and different age group (20-35, 35-50 & 50-65) people. They were to evaluate the sensory properties based on Taste, Flavor, Crispiness, Appearance and Overall acceptability using a nine point Hedonic scale where 1 represents “extremely dislike” and 9 “extremely like” respectively.

Storage Studies/Microbial observation

For microbial estimation of cookies, PDA & NAM medium mixtures were sterilized in an autoclave at 1210C for 20 minutes. The molted medium was poured in pre-sterilized Petri-plates. The samples were ground to fine powder and stored in polypropylene bags for 0, 30, 60 and 90 days. The ground powder of respective samples were spread on petri-dishes and incubated at 30 ± 200C temperature for 48 hours. The fungal and bacterial colonies were counted over PDA and NAM after 48 hours of incubation.

Statistical Analysis

Three replicated measurements were taken for each analysis and the results were expressed as the mean of values ± standard deviation. The significance of treatments were observed by calculating F ratio compared with Fisher’s Table F value. Significance of difference were tested using the Duncan Multiple Range Test at 5% level of probability.

RESULTS AND DISCUSSION

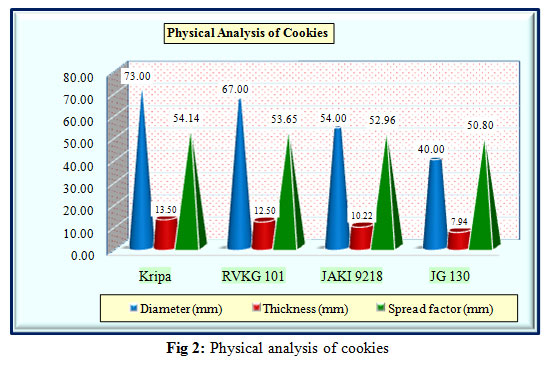

Results of these studies indicate that there is a significant difference (p < 0.05) between diameter and thickness of cookies made from four different varieties, while, no differences were observed for spread factor. There was an increment in kabuli gram varieties by about 48% for diameter in cookies than desi gram varieties. The diameter of the cookies ranged from 40.00 to 73.00 mm with the mean of 58.50 + 3.60 mm. The diameter of cookies made from Kripa was the highest one (73 mm) as compared to the cookies of other three varieties. The thickness of cookies made from the kabuli gram was in general significantly of higher magnitude than those made from desi gram varieties. However, in general, spread factor of cookies was higher in Kripa variety (5.41), but no significant differences were observed either in cookies made from different gram varieties (Table-2, Fig.-2).

The increase in thickness of multi-grain cookies might be due to the fact that baking powder acts as chemical leavening agent. The carbon dioxide, ammonia gas and steam produced during baking process increases the thickness and crispness of cookies. Vishwakarma, (2016) and Goliya (2017) also reported the similar findings. The result of increase in diameter of composite flour cookies are in close agreement with the result of (Siddiqui et al., 2003) and (Kukade, 2017) who reported increase in diameter with increasing level of soy flour in biscuits. (Sanaa et al., 2006) reported that the substitution of wheat flour with 30% of barley, millet or sorghum whole grain meal had no significant effects on the quality (i.e. cookie height and diameter) of cookie products.

Table 2: Physical analysis of Cookies of gram varieties

| Variety | Kripa | RVKG 101 | JAKI 9218 | JG 130 | General Mean | SEm | C.D.

5% |

| Diameter | 73.00 | 67.00 | 54.00 | 40.00 | 58.50 | 1.04 | 3.60 |

| Thickness | 13.50 | 12.50 | 10.22 | 7.94 | 11.04 | 0.33 | 1.15 |

| Spread factor | 5.41 | 5.36 | 5.28 | 5.04 | 5.30 | 1.73 | 6.01 |

|

Figure 2: Physical analysis of cookies |

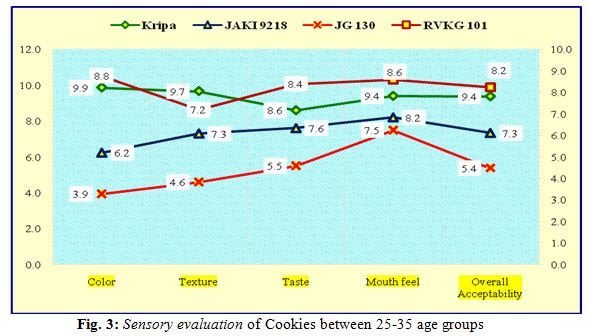

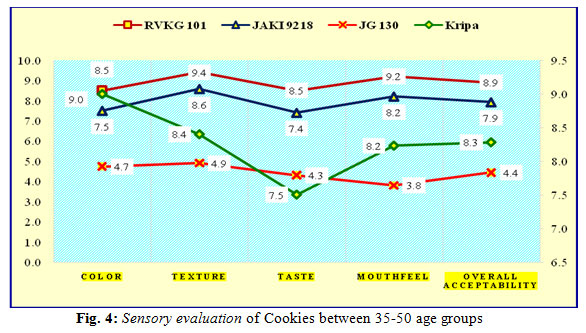

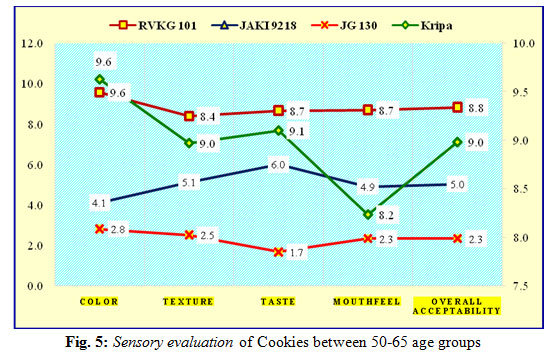

In all the age groups, cookies made from flours of different varieties were found significantly different for color, texture, taste, mouth feel (Table- 3, Fig-3, 4 & 5).

Cookies made from kabuli variety Kripa ranked first (9.38) closely followed by cookies made form RVKG 101 (8.24). The lowest ranked cookies were those made from the flour of JG 130 (5.38). Likewise, in the age group of 35-50 as well as of 50-65, the most liked cookies ranking highest point were those made from kabuli gram variety Kripa followed by RVKG 101 and to certain extent cookies of JAKI 9218. Cookies made form kabuli gram had overall higher ranking than those made form desi gram varieties.

Similar findings have been reported by (Mridula et al., 2007). This finding was also agreed with the results of (Maha et al., 2012) who reported that addition of sorghum to wheat flour decreased sensory quality of biscuits. (Singh et al., 2000) reported decrease in taste score of biscuits containing 20 per cent defatted soy flour when stored at ambient condition. (Kukade, 2017) and (Vaijapurkar et al., 2013) and (Chavan, 2013) reported the similar results after supplementing pearl millet flour with wheat flour to prepare cookies. This kind of evaluation was also been reported of the cookies made from different blends of Wheat Flour Fortified with Termitomyces robustus flour by (Giwa et al., 2012) and cookies made from blends of wheat/cassava/cowpea flour by (Adekunle et al., 2014).

Table 3: Sensory Evaluation of cookies of different gram varieties

| Age Grp. | Variety/

Parameter |

Kripa | RVKG 101 | JAKI 9218 | JG 130 | General Mean | SEm | C.D.

5% |

| 20-35 | Color | 9.87 | 8.77 | 6.23 | 3.93 | 7.20 | 0.15 | 0.54 |

| 35-50 | 9.00 | 8.50 | 7.50 | 4.73 | 7.43 | 0.19 | 0.67 | |

| 50-65 | 9.63 | 9.57 | 4.10 | 2.80 | 6.53 | 0.19 | 0.69 | |

| 20-35 | Texture | 9.67 | 7.20 | 7.30 | 4.60 | 7.19 | 0.28 | 0.98 |

| 35-50 | 8.40 | 9.40 | 8.57 | 4.90 | 7.82 | 0.16 | 0.55 | |

| 50-65 | 8.97 | 8.40 | 5.13 | 2.50 | 6.25 | 0.20 | 0.67 | |

| 20-35 | Taste | 8.60 | 8.40 | 7.60 | 5.50 | 7.53 | 0.22 | 0.76 |

| 35-50 | 7.50 | 8.50 | 7.40 | 4.30 | 6.93 | 0.095 | 0.33 | |

| 50-65 | 9.10 | 8.67 | 6.00 | 1.67 | 6.36 | 0.29 | 1.01 | |

| 20-35 | Mouthfeel | 9.40 | 8.60 | 8.20 | 7.50 | 8.43 | 0.11 | 0.40 |

| 35-50 | 8.23 | 9.20 | 8.20 | 3.80 | 7.36 | 0.28 | 1.00 | |

| 50-65 | 8.23 | 8.70 | 4.90 | 2.33 | 6.04 | 0.23 | 0.81 | |

| 20-35 | Overall Acceptability | 9.38 | 8.24 | 7.33 | 5.38 | 7.59 | 0.082 | 0.28 |

| 35-50 | 8.28 | 8.90 | 7.92 | 4.43 | 7.38 | 0.12 | 0.44 | |

| 50-65 | 8.98 | 8.83 | 5.03 | 2.33 | 6.29 | 0.087 | 0.30 |

|

Figure 3: Sensory evaluation of Cookies between 25-35 age groups |

|

Figure 4: Sensory evaluation of Cookies between 35-50 age groups |

|

Figure 5: Sensory evaluation of Cookies between 50-65 age groups |

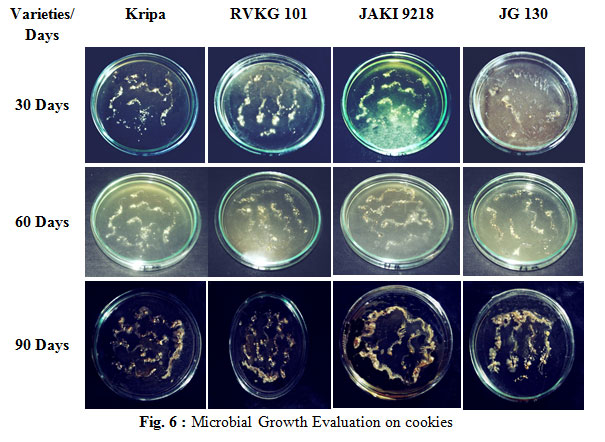

The Bacterial population on PDA at 60 days was found lowest (3.75) on the cookies made of kabuli gram variety Kripa, while it was significantly higher on the cookies made from desi gram JG 130 (6.98). The linear growth was observed in 90 days also (Table-5 Figure-6). In the study of bacterial growth on NAM medium on cookies was also found to be significantly higher on 30,60 & 90 days on the cookies made from desi chickpea JG 130 while, it was lowest on the cookies made form kabuli chickpea Kripa. While, compared to other three varieties, fungal population of cookies of Kripa was found to be the lowest one.

It has been observed that growth of fungus and bacteria on PDA & NAM media observed on cookies had significant preference from which they are prepared. Cookies made from the flour of desi gram JG 130 are more prone to the higher bacterial population than those of products prepared from other three varieties because of their high protein and fiber content in the flour and cookies.

The similar kind of finding has been reported by (Yousufu et al., 2016). Results show that the spoilage organisms grow faster in a medium that is highly nutritious. It indicated that the varietal differences exist in making the product suitable or unsuitable for the shelf life. In the present investigation, it has also been observed that the protein and fiber content of the cookies are positively correlated with the bacterial and fungal count at 60 & 90 days in both the media (Table 4).

Table 4: Association of prox. components with bacterial & fungal counts in cookies.

| Proximate Character | PDA

60 days |

PDA 90 days | NAM 60 days | NAM 90 days | PDA 60 days | PDA 90 days | NAM 60 days | NAM 90 days |

| Bacteria | Fungal | |||||||

| Protein | 0.87 | 0.86 | 0.83 | 0.89 | 0.52 | 0.88 | 0.78 | 0.84 |

| Crude fiber | 0.97 | 0.99 | 0.99 | 0.87 | 0.64 | 0.87 | 0.92 | 0.91 |

Table 5: Microbial (Bacterial & Fungal) population of Cookies of different gram Varieties.

| Variety | PDA- Bacterial(104cfu/100g) | NAM- Bacterial (104cfu/100g) | ||||||

| 0 days | 30 days | 60 days | 90 days | 0 days | 30 days | 60 days | 90 days | |

| Kripa | 0.32 | 1.71 | 3.75 | 12.43 | 0.28 | 0.55 | 2.15 | 7.18 |

| RVKG 101 | 0.16 | 1.73 | 4.90 | 13.71 | 0.11 | 0.64 | 2.48 | 7.31 |

| JAKI 9218 | 0.28 | 1.59 | 6.26 | 14.80 | 0.21 | 0.71 | 2.72 | 8.73 |

| JG 130 | 0.35 | 2.38 | 6.98 | 15.19 | 0.22 | 1.14 | 2.88 | 9.52 |

| General Mean | 0.28 | 1.85 | 5.47 | 14.03 | 0.21 | 0.76 | 2.56 | 8.19 |

| SEm | 0.062 | 0.25 | 0.408 | 0.151 | 0.086 | 0.056 | 0.142 | 0.118 |

| C.D.5% | 0.214 | 0.87 | 1.41 | 0.524 | 0.299 | 0.196 | 0.492 | 0.409 |

| Variety | PDA- Fungal (107 cfu/100g) | NAM- Fungal (107 cfu/100g) | ||||||

| 0 days | 30 days | 60 days | 90 days | 0 days | 30 days | 60 days | 90 days | |

| Kripa | 0.03 | 0.07 | 0.18 | 0.60 | 0.00 | 0.11 | 0.36 | 0.61 |

| RVKG 101 | 0.02 | 0.05 | 0.15 | 0.64 | 0.02 | 0.26 | 0.41 | 0.66 |

| JAKI 9218 | 0.05 | 0.08 | 0.19 | 0.97 | 0.03 | 0.34 | 0.48 | 0.79 |

| JG 130 | 0.13 | 0.20 | 0.39 | 1.19 | 0.06 | 0.46 | 0.59 | 0.91 |

| General Mean | 0.06 | 0.10 | 0.23 | 0.85 | 0.03 | 0.29 | 0.46 | 0.74 |

| SEm | 0.022 | 0.020 | 0.017 | 0.053 | 0.004 | 0.033 | 0.015 | 0.055 |

| C.D.5% | 0.076 | 0.071 | 0.059 | 0.183 | 0.014 | 0.116 | 0.054 | 0.192 |

|

Figure 6: Microbial Growth Evaluation on cookies |

CONCLUSION

Demand and consumption of snack foods is increasing day by day. Therefore, the monitoring of newly developed genotypes and advanced breeding material of chickpea for various quality characteristics should be emphasized and suitable genotypes be identified through chickpea improvement programs. Information on the quality of snacks made from newly developed varieties of chickpea is important so as to overcome resistance encountered by the plant breeder from the consumers, when new varieties are introduced in the market. The overall diameter & spread of cookies made from kabuli gram has larger appearance which favors its acceptability. In sensory evaluation, it is concluded that cookies & crackers made form kabuli gram varieties have higher acceptability by most of the age groups. The longevity because of least microbial growth on cookies or crackers made from the flour of kabuli gram is higher which increases its shelf life.

REFERENCES

AACC (2000). Approved methods of the American Association of cereal chemists 10th edition, American Association of Cereal Chemist press, St Paul, MN.

Anonymous (2007). Millet Network of India-Deccan Development Society-FIAN, India.

Adekunle O.A. and A.A. Mary (2014). Evaluation of cookies produced from blends of wheat, cassava and cowpea flours. International Journal of Food Studies IJFS., 3:175-185.

Aziah Noor A. A., Mohamad Noor A.Y. and Ho L.H. (2012). Physico-chemical and organoleptic properties of cookies incorporated with legume flour. International Food Research Journal 19 (4) : 1539-1543.

Bala A., Gul K and Charanjit Singh Riar (2015). Functional and sensory properties of cookies prepared from wheat flour supplemented with cassava and water chestnut flours. Cogent Food & Agriculture 1 : 1-7.

Chavan Swapnil Kumar (2013). Development of Technology for Production of Multi Grain Cookies. B.Tech. Thesis, Vasantrao Naik Marathwada Krishi Vidyapeeth, Parbhani (Maharshtra).

Giami, S.Y., Amasisi T. and G. Ekiyor (2004). Comparison of bread making properties of composite flour from kernel of roasted and boiled African breadfruit (Treculia africana decna) seeds, J. Mat. Res. 1 (1): 16 – 25.

Giwa O. E., Babalola, R.O. and S. A. Kolawole (2012). Microbial, Physical and Sensory Attribute of Cookies Produced from Wheat Flour Fortified with Termitomyces robusts and Spiced with Curry Leaves (Xylopia aethiopica). Journal of Natural Sciences Research, 2, No.3.

Goliya K.N. (2017). Development and Therapeutic multigrain cookies; JNKVV, Food Science and Technology. JNKVV, Jabalpur. http://krishikosh.egranth.ac.in.

Goliya K. N.; Mehra M and Priyanka Goswami (2018). Nutritional quality of the developed multigrain flour and cookies. Journal of Pharmacognosy and Phytochemistry. 7 (SP1) : 2886-2888.

Grundy M.L, Fardet A., Tosh S.M., Rich G.T and Peter J. Wilde (2018). Processing of oat: the impact on oat’s cholesterol lowering effect. Food Function 9 (3): 1328–1343.

Jenkin D.J. and Kendall C.W. (2012). Oat fibre beta-glucan reduces blood cholesterol. Am. J. Clin. Nutr.,75 : 834-839.

Kukade A.G (2017). Development and quality evaluation of composite flour cookies. Vasantrao Naik Marathwada Krishi Vidyapeeth, Parbhani, http://krishikosh.egranth.ac.in.

Kumar S., Grewal R and Varsh Rani (2016). Standardization and quality evaluation of ready to eat extruded snacks developed using maize-oat blends and processed cowpea. International Journal of Food and Nutritional Science 5 (4): 121-129.

Maha A. H. and Fizah M. M. 2012. Production of biscuits from different sorghum varieties assay digestibility protein to weanling rats. Journal of American Science. 8 (12): 996-1002

Michaelraj P.S and A. Shanmugam (2013). A Study on Millets Based Cultivation and Consumption in India. International Journal of Marketing, Financial Services & Management Research 2 (4): 49-58.

Mridula D. Gupta R.K. and M.R Manikantan (2007). Effect of incorporation of sorghum flour to wheat flour on quality of biscuit fortified with defatted soy flour. Am. J. Food Technol., 2 (5): 428-434.

Parca F., Koca Y.O and Aydın Unay (2018). Nutritional and Anti-nutritional Factors of Some Pulses Seed and Their Effects on Human Health. International Journal of Secondary Metabolite 5 (4): 331-342.

Ragaee S and E.S.M. Abddel Aal (2006). Pasting properties of starch and protein in selected cereals and quality of their food products. Food Chemistry, 95 (1):9-18.

Rana M., Pathania P. and S. L. Khaswan (2013). Effect of bio-fertilizers and phosphorus on productivity and nutrient uptake of soybean (Glycine max L.) College of Agriculture, CSK Himachal Pradesh Krishi Vishvavidyalaya, Palampur. 34 (3) : 245-247.

Rao D.B., Bhaskarachary K., Arlene Christina G.D., Sudha Devi G and Vilas A. Tonapi (2017). Nutritional and Health benefits of Millets. ICAR_ Indian Institute of Millets Research (IIMR) Rajendra Nagar, Hyderabad, PP 112.

Raza H., Zaaboul F., Shoaib F and Lianfu Zhang (2019). An Overview of Physicochemical Composition and Methods used for Chickpeas Processing. International Journal of Agriculture Innovations and Research. 7 (5) : 2319-1473.

Sanaa R., El-Sayed, M. and A. Abdel (2006). Pasting Properties of Starch and Protein in Selected Cereals and Quality of their Food Products. Food Chemistry 95: 9-18.

Saranraj P. and M. Geetha (2012). Microbial Spoilage of Bakery Products and Its Control by Preservatives. International Journal of Pharmaceutical & Biological Archives. 3 (1):38-48

Siddiqui NR, Hassan M, Raza S, Hameed L, Khalil S. (2003). Sensory and physical evaluation of biscuits supplemented with soy flour. Pakistan J Food Sci. 13 (1-2), 45- 48.

Singh R., Singh G. and G.S. Chouhan (2000). Nutritional evaluation of soy fortified biscuits. Journal Food Science Technology, 37 (2):162-164.

Shewry P.R and Sandra J. Hey (2015). The contribution of wheat to human diet and health. Food and Energy Security 4 (3): 178–202.

Udaybeer Khan M.A., Rajput LPS and Shriram Godase (2018). Physical parameters of low gluten cookies and different flour combination (wheat, soybean and pearl millet flours). International Journal of Chemical Studies 6 (4): 1814-1817.

Udaybeer Vishwakarma (2016). Process Standardization and Development of low Gluten Cookies. MSc. Thesis, JNKVV, Jabalpur, (Madhya Pradesh). http://krishikosh.egranth.ac.in.

Vaijapurkar K. R., Rudr Stone awar B. D., Dambalkar V. S. and Poojari V. R. (2013). Development And Standardization of Bajara Biscuits (Pennisetum glaccum) with Added Pomegranate Peel Powder and their Physical and Sensory Attributes. International Journal of Science and Research. 4 (10): 952-956.

Varma P., Bhankharia H and Shikha Bhatia (2016). Oats: A multi-functional grain. Journal of Clinical and preventive Cardiology 5 (1): 9-17.

Wallace T.C., Murray R. and Kathleen M. Zelman (2016). The Nutritional Value and Health Benefits of Chickpeas and Hummus. Nutrients. 8: 2-10.

Wang X., Gao W. and J. Zhang (2010). Subunit, amino acid composition and in vitro digestibility of protein isolates from Chinese kabuli and desi chickpea (Cicer arietinum L.) cultivars. Food Res Internl, 43: 567-572.

Yusufu P.A., Netala J. and Opega J.L (2016). Chemical, Sensory and Microbiological Properties of Cookies Produced From Maize, African Yam Bean and 04 Plantain Composite Flour. Indian J Nutri. 3 (1) : 122.