1Department of Food Science and Nutrition, Periyar University, Salem, Tamil Nadu, India.

2Department of Nutrition and Dietetics, Periyar University, Salem, Tamil Nadu, India.

Corresponding author email: bhuvana123jb@gmail.com

Article Publishing History

Received: 25/06/2021

Accepted After Revision: 23/09/2021

Millets have great nutritional properties and health benefits, and can thus be utilized as a pasta supplement. Thus, for the health-conscious genre of the present world, minor millet especially foxtail millet is perhaps one more addition to the proliferating list of healthy foods, owing to its nutritional superiority. They are convenient, easy to make, quick to cook, relatively inexpensive, and have a long shelf life. The extrusion process was chosen for making pasta which comprises foxtail millet and green pea flour to improve nutritional value, particularly in terms of protein level. The objective of the study is to formulate foxtail millet and green pea incorporated pasta and to evaluate for its physicochemical, textural profile analysis, colour analysis, and sensory analysis. Four variants of pasta were developed by mixing the following flours like foxtail millet (30-60%), green pea (10%), and wheat flour (30-60%) at different ratios. The developed pasta physiochemical, textural, colour, and sensory parameters were assessed using standard procedure.

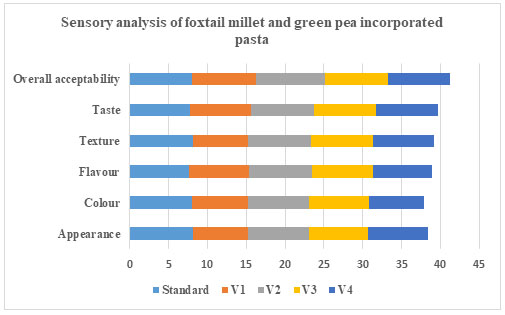

The results of the study revealed that chemical analysis, colour, textural, and sensory analysis of pasta showed a 1% level of substantial difference (p<0.01) as compared to the standard as the level of flour addition was increased. The pasta made with 40% foxtail millet and 10% green pea flour achieved the highest sensory scores as compared to regular pasta. The sensory assessment of the pasta samples showed that the variations differed significantly. This study concluded that pasta has a universal demand and is a strong carrier of nutrients for a segment of the population that is health-conscious. Foxtail millet and green pea flour were a good replacement for wheat flour in terms of improving the nutritional properties of pasta manufacture and use.

Colour, Foxtail Millet, Green Pea, Physiochemical And Sensory.

Bhuvaneswari, P. Nazni. On the Sensory, Colour, Texture and Physiochemical Characteristics of Foxtail Millet and Green Pea Pasta. Biosc.Biotech.Res.Comm. 2021;14(3).

Bhuvaneswari, P. Nazni. On the Sensory, Colour, Texture and Physiochemical Characteristics of Foxtail Millet and Green Pea Pasta. Biosc.Biotech.Res.Comm. 2021;14(3). Available from: <a href=”https://bit.ly/3zvgt4H“>https://bit.ly/3zvgt4H</a>

Copyright © Bhuvaneswari This is an open access article distributed under the terms of the Creative Commons Attribution License (CC-BY) https://creativecommns.org/licenses/by/4.0/, which permits unrestricted use distribution and reproduction in any medium, provide the original author and source are credited.

INTRODUCTION

Millets stand out among cereals due to their high calcium, dietary fibre, polyphenol, and protein content. Millets are gluten-free, making them a good choice for celiac disease sufferers who are bothered by wheat and other gluten-containing cereal grains. The sixth-highest yielding crop, foxtail millet (Setaria italica (L.)), has been established as a major millet in terms of global output (Gélinas, 2008; Saleh et al. 2013; Devi 2014). Like most millets, foxtail millet is high in crude fibre, which aids in digestion and induces bowel movement, resulting in a laxative effect that is useful to a healthy digestive system.

In China, foxtail millet is used to make noodles, nourishing gruel or soup, brewing alcoholic beverages, cereal porridges, and pancakes due to its nutritional characteristics (Krishna 2013; Yang et al. 2013). Aside from its nutritional value, foxtail millet has been found to provide several health benefits, including cancer prevention, hypoglycemic, and hypolipidemic effects (Zhang et al. 2015).

Green pea (Pisum sativum) is the second most important highly nutritious crop in terms of production. Peas are known for being a low-fat (3%), high-protein (24%), high-carbohydrate (58%), and high-dietary fibre (12%) carrying food (Iqbal et al. 2006). Pea containing a significant amount of vitamin A, vitamin C, vitamin B complex, iron, calcium, copper, zinc and manganese. No significant value of anti-metabolites or toxicity has been reported in pea (Garg et al. 2015; Narayanan et al. 2015; Ettoumi and Chibane 2015; Laureati et al. 2020).

Solubility, emulsifying and foaming characteristics, gelling ability, and water holding capacity are some of the functional qualities of pea flour and pea protein. These functional qualities are desirable in a variety of foods to improve shelf life and stability. Pasta products are well-known in many countries, and they are consumed and enjoyed worldwide. Researchers and food producers are becoming more interested in developing pasta products that are high in minerals, vitamins, fibre, and have a low glycemic index as a result of increased demand from health-conscious customers.

Pasta is considered an effective medium for the incorporation of nutrition supplements by the World Health Organization (WHO) and the Food and Drug Administration (FDA) (Chillo et al. 2008; Ettoumi and Chibane 2015). According to Bustos et al. (2015), pasta is an ideal vehicle for the advancement of health among functional foods due to its low cost, long shelf life, and widespread consumption. These studies show that consumers are becoming more interested in using pasta as a functional meal. The addition of healthy ingredients to the pasta will lower the glycemic index and provide customers with additional health benefits (Bustos et al. 2015; Laureati et al. 2020).

Foxtail millet and green peas play an important role in the preparation of pasta due to their nutritional value. The study’s goals were to identify the best combinations as well as to investigate the physical, chemical, textural, colour properties, and sensory analysis of pasta made with foxtail millet and green pea flour. The goal of this research is to develop pasta and assess it for physicochemical, textural profile, colour, and sensory properties.

MATERIAL AND METHODS

The raw materials such as foxtail millet (Setaria italica), wheat, and green pea (Pisum sativum) were received from the local market in Salem, Tamil Nadu. To exclude foreign materials, the collected materials were thoroughly washed. The cleaned grains such as foxtail millet, wheat, and green peas were grounded well into fine flour for future usage.

For extrusion of pasta, the following flours like foxtail millet flour were mixed at different levels of 30 (V1), 40 (V2), 50 (V3), and 60% (V4) were used to replace with wheat flour at the level of 60 (V1), 50 (V2), 40 (V3) and 30% (V4). About 10% of green pea flour was in every four variations of the mixture. A 150ml of water was added and 0.2g of salt was added according to its taste. Totally 5 variations (4 variants with 1 standard) of pasta were formulated. All the grounded flours (100g) were mixed with the optimum amount of water containing 2% salt and were mixed in the pasta extruder chamber for 10minutes to distribute water uniformly throughout the flour particles.

The moist flour aggregate was placed in a metal extruder attachment of the pasta machine fitted with an adjustable die-size. After the preparation of pasta, the formulated pasta was dried in a food-grade dryer at 60°C for about 3hours. The developed pasta was analyzed for Energy by Parr Oxygen Bomb Calorimeter Method, Protein by micro Kjeldahl procedure, crude fat using Soxhlet extraction, Carbohydrate by anthrone method, iron by colourimetric method, calcium by colourimetric method, and vitamin C by 2,6 di-chlorophenolendophenol.

All the analyses were carried out in triplicate using standard procedures of (AOAC, 2000). The hardness, strength, stringiness, and adhesiveness of dry pasta and cooked pasta were evaluated by a texture profile analysis (TPA). A 35 mm diameter cylindrical probe (dry pasta) and 75 mm cylindrical probe (cooked pasta) was used to compress single pasta at a constant deformation rate of 1 mm/s to 80% of the thickness.

The measurement mode settings for double-cycle compression (pre-test, test, and post-test) were set to a speed of 1.0 mm/sec; trigger type at auto-10 g; and data rate: 200 PPS. The colour profile was measured for dry and cooked pasta using the Lovibond tintometer. The measurements determined chromatic coordinates of L*, a*, and b*. In the range of 0 to 100, a coordinate L* described the brightness (black to white). The yellowness-blueness balance was specified by a coordinate b*, which was in-minus for blue and in-plus for yellow.

The yellowness-blueness balance was specified by a coordinate b*, which was in-minus for blue and in-plus for yellow. Measurements were taken in five replicates for each sample. All the developed pasta were evaluated for sensory quality based on appearance, colour, flavor, taste, texture, and overall acceptability using a 9-point Hedonic scale by a panel of 10 judges scorecard with scores ranging from 9 to 1, where 1 = dislike extremely, 5= neither like nor dislike and 9= like extremely was used.

Samples were coded and presented in a random sequence to the panelists. All experiments in the present analysis were conducted in triplicate and mean values were reported. Data were subjected to analysis of variance (ANOVA), and the means were compared using Duncan’s Multiple Range Test at 0.05% significance to find the best variations. Paired t-test was used to compare the standard with that of the variants of pasta.

RESULTS AND DISCUSSION

Chemical analysis of foxtail millet and green pea incorporated pasta: The chemical composition of pasta indicates that the energy content was ranged from 346.7 to 357.7kcal, in this high energy content was noticeable in V4 (357.7kcal) and the lowest energy content was observed in V1 (346.7kcal) pasta sample compared to standard pasta (p<0.05) (Table-1). The protein content was showing an increasing level where the incorporation level increases and it ranged from 10.07 to 13.89g. V2 pasta had a higher protein level than regular pasta, with a protein value of 13.89g.

The high protein content of semolina led to the formation of a strong protein-starch matrix in pasta, which determined the cooking and quality criteria (Rizkalla et al. 2004). Few investigations have concentrated on expanding the dietary benefits of pasta in terms of protein content (Fuda et al. 2010; Adegunwa et al. 2012). Cooking loss is a critical metric for determining the quality of pasta products. The high quality of pasta is associated with less cooking loss. Cooking loss is caused by the gluten-starch network’s ability to maintain the physical uprightness of pasta throughout cooking (Lu et al. 2016).

Table 1. Chemical analysis of pasta

| Standard | V1 | V2 | V3 | V4 | |

| Energy (k.cal) | 345.9±1.79a | 346.7±1.89b | 348.7±2.14a | 356.7±1.82de | 357.7±2.04a |

| T value | – | 4.85 | 7.62 | 5.35 | 3.67 |

| Significance | – | 0.00** | 0.02** | 0.41NS | 0.06 NS |

| Protein (g) | 10.07±0.74b | 13.27±0.64c | 13.89±1.81b | 12.39±0.55f | 13.87±0.71d |

| T value | – | 8.85 | 12.35 | 9.58 | 9.54 |

| Significance | – | 0.00** | 0.02** | 0.00** | 0.34NS |

| Fat (g) | 2.84±0.64a | 2.44±0.64ac | 2.58±0.55c | 2.84±0.31bc | 3.13±0.32e |

| T value | – | 11.62 | 6.58 | 9.72 | 8.87 |

| Significance | – | 0.00** | 0.02** | 0.39NS | 0.56 NS |

| Zinc | 1.7±0.43a | 1.7±0.53bc | 1.82±0.85bc | 1.90±0.52a | 1.94±0.87ac |

| T value | – | 11.39 | 15.38 | 16.38 | 9.45 |

| Significance | – | 0.00** | 0.35NS | 0.41NS | 0.089 NS |

| Calcium (mg) | 43.6±0.54bc | 44.17±0.74b | 44.19±0.64ac | 44.82±0.63b | 44.95±0.41f |

| T value | – | 3.67 | 6.47 | 5.66 | 4.14 |

| Significance | – | 0.36NS | 0.02** | 0.91NS | 0.76 NS |

| Phosphorus (mg) | 243.5±2.41a | 153.5±2.41d | 158±1.77ac | 142.5±2.45a | 247±1.14bc |

| T value | – | 5.31 | 2.35 | 3.35 | 4.65 |

| Significance | – | 0.00** | 0.00** | 0.00** | 0.46 NS |

| Iron (mg) | 3.63±0.75a | 3.33±0.35ab | 2.84±0.21b | 2.35±0.55ac | 2.86±0.8a |

| T value | – | 6.22 | 3.65 | 4.26 | 5.38 |

| Significance | – | 0.00** | 0.01** | 0.68NS | 0.97 NS |

Values are the means ± standard errors of means (SEM) of 3 determinants. Means with same superscript are not significantly different using Duncan’s Multiple Range Test (p < 0.05)

As reported by Santos et al. (2015), the lipid content was 2.44 kg 100kg-1, in pasta prepared with refined wheat flour, eggs, and salt, which is similar to this study. The protein network of pasta can be strengthened by thermal protein denaturation to improve the firmness of cooked pasta. Pasta is a healthy food that contains protein, vitamins and is an important source of carbohydrates with virtually no fat (Malcolmson 2003; Krishnan et al. 2012 and Foschia et al. 2015; Santos et al. 2015). The high amount of zinc content, calcium, phosphorus, vitamin A and iron content was detected in V4 1.94mg/100g, 44.95mg, 247mg, 4.45mcg, and 2.86mg respectively. The proximate analysis and the formulated pasta samples showed a significant difference at the 0.05% level, according to Duncan’s Multiple Range test results.

Textural properties of foxtail millet and green pea incorporated pasta

Table 2a. Textural properties of Dry pasta

| Textural properties | Variations | Mean SD | T value | Significance |

| Hardness (N) | Standard | 12.74±2.34a | – | – |

| V1 | 11.47±1.503bc | 8.75 | 0.00** | |

| V2 | 15.40±1.50 ac | 11.35 | 0.01** | |

| V3 | 13.19±0.43de | 13.68 | 0.00** | |

| V4 | 17.70±0.78e | 19.54 | 0.00** | |

| Strength (N/mm) | Standard | 6.37±1.21a | – | – |

| V1 | 5.73±0.75c | 7.80 | 0.00** | |

| V2 | 7.70±0.75bc | 12.35 | 0.01** | |

| V3 | 6.59±0.22f | 11.57 | 0.00** | |

| V4 | 8.85±0.39de | 13.25 | 0.87NS |

Values are the means ± standard errors of means (SEM) of 3 determinants. Means with the same superscript are not significantly different using Duncan’s Multiple Range Test (p < 0.05)

Texture profile analysis of the pasta is presented in Table-2a and 2b. Compare with standard pasta, V4 pasta shows high hardness and strength where the pasta samples showed a significant difference at (p<0.01) level. As time moves, the dryness of the pasta was changed due to the protein matrix and the surface moisture was also evaporated too quickly. According to Jayasena and Nasar (2012) and Bustos et al.

(2015), the use of chemicals in the production of pasta, particularly high-protein pasta, can alter not only the culinary characteristics but also the texture. The firmness and minimal stickiness of pasta are significant attributes for customers (Susanna and Prabhasankar 2013). According to the literature, protein additions used in the making of pasta, such as egg and broad bean protein, increase stiffness, which is in line with the results found (Laleg et al. 2007; Jayasena and Nasar 2012; Bustos et al. 2015; Camelo et al. 2016).

The hardness and strength of green pea incorporated pasta showed a significant difference at a 5% level while comparing to a standard one. During pasta cooking, the gelatinization of starch and denaturation of proteins causes the main structural changes in pasta’s texture (Aravind et al. 2012; Camelo et al. 2016). A decrease in the cohesiveness or an increase in the adhesiveness of the pasta indicates changes in the texture quality of the pasta made with unripe apple flour or oat bran, and it can be used to determine the product’s consumer acceptability.

Various texture studies have been reported in spaghetti-type pasta added with different types of flour (Hernández et al. 2009; Osorio et al. 2014). Hatcher et.al. (2005) stated in their study that amylopectin content and retrogradation rate and although it has been reported that addition of gluten content may decrease significantly adhesiveness values of noodle.

The stringiness of cooked pasta samples ranged from 6.15mm to 6.94mm. The high stringiness was found in V1 (6.94mm). There was a significant difference (p<0.01) between the stringiness of the samples in variations than standard. The adhesiveness of the pasta samples ranged from 0.08J to 2.03J and showed a statistically significant.

Table 2 b. Textural properties of cooked pasta

| Textural properties | Variations | Mean SD | T value | Significance |

| Hardness (N) | Standard | 13.65±0.46a | – | – |

| V1 | 9.70±0.13 bc | 3.67 | 0.00** | |

| V2 | 9.48±0.20d | 15.62 | 0.01** | |

| V3 | 9.69±0.11f | 11.47 | 0.00** | |

| V4 | 9.66±0.08b | 12.32 | 0.89NS | |

| Stringiness (mm) | Standard | 6.69±0.23a | – | – |

| V1 | 6.94±0.12ac | 22.41 | 0.00** | |

| V2 | 6.15±0.75gh | 2.85 | 1.35NS | |

| V3 | 6.98±0.10ab | 3.64 | 0.00** | |

| V4 | 6.90±0.10d | 5.68 | 0.97 NS | |

| Adhesiveness (J) | Standard | 2.03±0.23a | – | – |

| V1 | 1.60±0.60b | 7.98 | 0.00** | |

| V2 | 0.08±0.04ac | 8.65 | 0.01** | |

| V3 | 1.05±0.373de | 5.69 | 0.00** | |

| V4 | 1.01±0.37g | 7.12 | 0.36 NS |

Values are the means ± standard errors of means (SEM) of 3 determinants. Means with the same superscript are not significantly different using Duncan’s Multiple Range Test (p < 0.05)

Lee et al. (2005) found no substantial variations in the adhesiveness of Chinese fresh noodles made from wheat flours as the percentage of garbanzo bean substitutions increased from 0 to 30%. Chen et al. (2005) found significant associations between amylose content and the adhesiveness of Chinese fresh noodle made from wheat flours. Results on Duncan’s Multiple Range test showed that there was a significant difference between all the pasta samples developed using foxtail millet and green pea flour. Cohesiveness and springiness parameters indicated how the sample holds together upon cooking, which interpreted the higher values recorded for the chickpea fortified pasta than the control sample (Lee et al. 2005; Chen et al. 2005; Kosovićet al. 2016).

Colour analysis of foxtail millet and green pea incorporated pasta

Table 3 a. Colour analysis of dry pasta

| Colour | Variations | Mean SD | T value | Significance |

| L* | Standard | 70.3±0.24b | – | – |

| V1 | 67.1±1.20ac | 6.74 | 0.00** | |

| V2 | 74.9±2.12ab | 7.52 | 0.01** | |

| V3 | 71.7±0.97a | 6.38 | 0.00** | |

| V4 | 71.9±0.75d | 9.65 | 0.99 NS | |

| a* | Standard | 4.4±1.40a | – | – |

| V1 | 4.0±0.97b | 8.56 | 0.00** | |

| V2 | 4.7±0.82d | 5.64 | 0.01** | |

| V3 | 4.1±0.75ac | 5.67 | 0.68NS | |

| V4 | 4.0±1.04b | 6.58 | 0.021* | |

| b* | Standard | 15.6±0.87a | – | – |

| V1 | 16.6±0.41b | 1.38 | 0.00** | |

| V2 | 15.0±0.85ac | 5.69 | 0.01** | |

| V3 | 15.9±0.94a | 7.65 | 0.031* | |

| V4 | 15.7±0.72ab | 9.45 | 3.37NS |

Values are the means ± standard errors of means (SEM) of 3 determinants. Means with the same superscript are not significantly different using Duncan’s Multiple Range Test (p < 0.05)

Lei et al. (2004) have reported that elasticity was significantly related to TPA’s springiness. Tang et al. (1999) also reported that adding gluten into soft wheat flour could improve the elasticity of noodles. The elasticity decrease in wheat-SPF noodles might result from the dilution of gluten in noodle dough. Laleg et al. (2016) reported in his literature indicate that protein additives used in the production of pasta, such as egg and broad bean protein, increase the firmness, which is consistent with the obtained results (Tang et al. 1999; Lei et al. 2004; Laleg et al. 2016).

Table 3 b: Colour analysis of cooked pasta

| Colour | Variations | Mean SD | T value | Significance |

| L* | Standard | 56.5±0.41a | – | – |

| V1 | 55.5±0.88ac | 8.64 | 0.00** | |

| V2 | 56.5±0.67ab | 5.64 | 0.01** | |

| V3 | 57.1±0.73d | 7.61 | 0.002** | |

| V4 | 55.4±0.75c | 6.39 | 0.004** | |

| a* | Standard | 2.4±0.27b | – | – |

| V1 | 1.8±0.14c | 8.94 | 0.00** | |

| V2 | 1.7±0.34a | 7.41 | 0.01** | |

| V3 | 1.8±0.26b | 6.58 | 0.41NS | |

| V4 | 1.7±0.22ac | 8.94 | 0.01** | |

| b* | Standard | 11.3±0.84a | – | – |

| V1 | 12.7±0.67bc | 9.47 | 0.00** | |

| V2 | 12.6±0.51d | 7.65 | 0.01** | |

| V3 | 13.2±0.81b | 8.56 | 0.00** | |

| V4 | 12.8±0.34a | 7.14 | 0.01** |

Values are the means ± standard errors of means (SEM) of 3 determinants. Means with the same superscript are not significantly different using Duncan’s Multiple Range Test (p < 0.05)

The colour of pasta is one of the foremost basics discriminates of its quality. It depends mainly on the raw materials used for the development of pasta. In considering the results of the dry and cooked pasta colour coordinates (Table -3a and 3b). Colour changes in food ingredients (including noodles) can be known based on the values L* a* and b. The L* value donates the brightness level of the noodle, the a* value donates the greenish colour while the b* value represents the yellow colour (Ginting et al. 2015; Sirichokworrakit et al. 2015).

As suggested by Güler et al. (2002), changes in starch during high-temperature drying have been shown to influence the consistency of cooked pasta. As pierced out by Chanu and Jena (2015) in pasta incorporating wholemeal rye flour, this kind of monotony occurred due to the higher concentration of fibre, pigments, and other structural components that are naturally present on external corn layers (Güler et al. 2002; Chanu and Jena 2015).

As the legume components in the pasta increased, the lightness (L* value) of all raw and cooked samples declined. This result is in agreement with studies conducted in the past. (Zhao et al. 2005; Wood 2009; Petitot et al. 2010). The darker colour of the legume-supplemented pasta may be attributed to the higher content of ash and the specific colour of the legume flour. After cooking, the redness and yellowness of legume-fortified pasta decreased, whereas the brightness (L*) increased, according to Petitot et al. (2010). Cooked pasta samples using 30-60% foxtail flour and wheat flour with 10% green pea flour had a significant increase in colour parameter a*.

Sensory analysis of foxtail millet and green pea incorporated pasta: The sensory evaluation was carried out based on colour, flavour, taste, appearance, and overall acceptability of the developed product. The sensory evaluation of the pasta samples revealed that there were significant differences among the variations for the organoleptic qualities compare with the standard. Overall acceptability of pasta ranged from 7.90 to 8.80. The V2 (8.80) incorporated pasta has got the highest overall acceptability than standard (figure-1). Regarding appearance, colour, flavor, texture, taste, and overall acceptability of the pasta incorporated levels of 40% foxtail millet and 10% green pea flour has appeared to have the highest overall acceptability score than standard pasta.

Figure 1

Yilmaz and Buket (2012) stated that sensory evaluation (SE) has been used to evaluate the products sensory characteristics and consumer acceptance. Hence, determination of the consumer expectations and the expression of consumer demands are classified into scientifically sound sensory descriptors. It allows for the description and comparison of food samples, as well as the matching of consumer requests. It is a complex sensory dimension that includes tactile, visual, and auditory perceptions and plays a key role in defining consumer responses (Yilmaz and Buket 2012; Laureati et al. 2020).

CONCLUSION

The findings of the present study suggests that pasta mixed with foxtail millet and green pea flour forms a pasta variant that is satisfactory in terms of physiochemical, colour, texture, and sensory aspects. Increased foxtail millet incorporation resulted in a significant change (p<0.05) in proximate and overall acceptability of the pasta samples, although textural properties reduced when compared to the standard, with a 5% level of significant difference. Increasing the amount of nutrient-dense foods significantly improves the health of the great majority of health-conscious people.

The findings revealed that cereals have the ability and functionality to enrich wheat-based pasta for the manufacture of dietetic pasta with high protein content and all nutritional benefits. As a result, foxtail millet and green pea flour are being used in innovative pasta products aimed at health-conscious customers who always promote cereal-based foods as the greatest nutritional supplement.

Conflict of Interests: Authors declare no conflicts of interests to disclose.

REFERENCES

Adegunwa MO, Bakare HA and Akinola OF (2012) Enrichment of noodles with soy flour and carrot powder Nigerian Food Journal Vol 30 No 1 Pages 74–81.

Aiyesanmi, AF and Oguntokun MO (1996) Nutrient composition of Dioclea reflexa seed an underutilized edible legume Rivista Italiana delle Sostanze Grasse Vol 73 No 4 Pages 521–523 https://doi:10.15680/IJIRSET.2015.0402097.

AOAC (2000) Official methods of analysis Gaithersburg MD The Association of Official Analytical Chemists Methods Ed (17) 954.11, 999.10b.

Aravind N, Sissons M, Egan N et al. (2012) Effect of insoluble dietary fibre addition on technological, sensory and structural properties of durum wheat spaghetti Food Chem Vol 130 No 6 Pages 299–309.

Bustos G T, Perez and AE Leon (2015) Structure and quality of pasta enriched with functional ingredients Rsc Advances Vol 5 No 39 Pages 30780–30792.

Bustos MC, Perez GT and Leon AE (2015) Structure and quality of pasta enriched with functional ingredients RSC Adv Vol 5 Pages 30780–30792.

Camelo-Méndez GA, Ferruzzi MG, González-Aguilar GA et al. (2016) Carbohydrate and phytochemical digestibility in pasta Food Eng Rev Vol 8 No12 Pages 76–89.

Chanu SN and Jena S (2015) Development of millet fortified cold extruded pasta and analysis of quality attributes of developed pasta products _e International Journal of Science and Technoledge Vol 3 No 1 Page 132.

Chen DS, Kiribuchi-Otobe C, Xu ZH et al. (2005) Effect of Wx-A1, Wx-B1 and Wx-D1 Protein on Starch Properties and Chinese Fresh Noodle Quality Scientia Agricultura Sinica, Vol 38 No 8 Pages 865–873.

Chillo S, Civica V, Iannetti M et al. (2010) Influence of repeated extrusions on some properties of non-conventional spaghetti Journal of Food Engineering Vol 100 No 15 Pages 329-335.

Crosbie GB, Ross AS, Moro T et al. (1999) Starch and protein quality requirement of Japanese alkaline noodle (ramen). Cereal Chem. Vol 76 No 6 Pages 328–334.

Devi PB, Vijayabharathi R, Sathyabama S et al. (2014) Health benefits of finger millet (Eleusine coracana L.) polyphenols and dietary fiber: a review Journal of food science and technology Vol 51 No 6 Pages 1021-1040.

Ettoumi LY and M Chibane (2015) Some physicochemical and functional properties of pea chickpea and lentil whole flours Int Food Res J Vol 22 No 3 Pages 987-996.

FAO (2007) Protein and amino acid requirements in human nutrition Report of joint WHO/FAO/UNU Expert consultation WHO Technical Report Series 935.

Foschia MM, Peressini D, Sensidoni A et al. (2014) Mastication or masceration: Does the preparation of sample affect the predictive in vitro glycaemic response of pasta? Starch/Starke Vol 66 Pages 1096-1102.

Fuad T and Prabhasankar P (2010) Role of ingredients in pasta product quality: a review on recent developments Critical Reviews in Food Science and Nutrition Vol 50 No 8 Pages 787–798.

Garg M (2015) Nutritional Evaluation and Utilization of Pea Pod Powder for Preparation of Jaggery Biscuits Garg J Food Process Technol Vol 6 No 12 Pages 1-4.

Gélinas P (2008) Gluten contamination of cereal foods in Canada International Journal of food science & technology Vol 43 No 7 Pages 1245-1252.

Ginting E, Dan R and Yulifianti (2015) Characteristics of Noodle Prepared from Orange-fleshed Sweet Potato and Domestic Wheat Flour J Procedia Food Science Vol 3 No 2 Pages 289–302.

GPO Access (2002) Food and drugs Code of Federal Regulations, U.S. Government printing Office via GPO Access, Title 21 Vol 2 Pages 385-386.

Guinard JX and Mazzucchelli R (1996) The sensory perception of texture and mouthfeel Trends Food Sci Technol Vol 7 No 4 Pages 213–219.

Güler S, Köksel H and Ng PKW (2002) Effects of industrial pasta drying temperatures on starch properties and pasta quality Food Res Int Vol 35 No 6 Pages 421-427.

Hatcher DW, Lagasse S, Dexter, JE et al. (2005) Quality characteristics of yellow alkaline noodles enriched with hull-less barley flour Cereal Chemistry Vol 82 No 3 Pages 60–68.

Hernández-Nava RG, Berrios JDJ, Pan J et al. (2009) Development and characterization of spaghetti with high resistant starch content supplemented with banana starch Food Sci Tech Int Vol 15 No 5 Pages 73–78.

Iqbal A, Khalil IA, Ateeq N et al. (2006) Nutritional quality of important food legumes Food Chem Vol 97 No 3 Pages 331 – 335.

Jayasena V and Nasar-Abbas SM (2012) Development and quality evaluation of high-protein and high-dietary-fiber pasta using lupin flour J Texture Stud Vol 43 No 3 Pages 153–163.

Kosović I, Jukić M, Jozinović A et al. (2016) Influence of chestnut flour addition on quality characteristics of pasta made on extruder and minipress Czech J Food Sci Vol 34 No 3 Pages 166–172.

Krishna K R (2013) Agroecosystems: Soils Climate Crops Nutrient Dynamics and Productivity Apple Academic Press Inc page 123.

Krishnan JG, Menon R, Padmaja G et al. (2012) Evaluation of nutritional and physico mechanical characteristics of dietary fiber-enriched sweet potato pasta European Food Research and Technology Vol 234 No 12 Pages 467-476.

Laleg K, Barron C, Santé-Lhoutellier V, et al. (2016) Protein enriched pasta: Structure and digestibility of its protein Network Food Funct Vol 7 No 3 Pages 1196–2007.

Laureati M, Sandvik P, Almli VL, et al. (2020) Individual differences in texture preferences among European children: Development and validation of the Child Food Texture Preference Questionnaire (CFTPQ) Food Qual Prefer Vol 80 No 11 Pages 103828

Lee SY, Woo KS, Lim J, et al. (2005) Effects of processing variables on texture of sweet potato starch noodles prepared in a non-freezing process Cereal Chemistry Vol 82 No 4 Pages 475–477.

Lei J, Zhang Y, Wang D, et al. (2004) Methods for evaluation of quality characteristics of dry white Chinese noodles Scientia Agricultura Sinica Vol 37 No 1 Pages 2000–2005.

Lu XMA, Brennan L, Serventi S, et al. (2016) How the inclusion of mushroom powder can affect the physicochemical characteristics of pasta International Journal of Food Science & Technology Vol 51 No 11 Pages 2433–2439.

Malcolmson LJ (2003) Pasta and macaroni-dietary importance In B Caballero PM Finglas & L 418 Trugo (Eds.) Encyclopedia of food sciences and Nutrition Academic Press Pages 4738-4380.

Moss R, Gore PJ and Murray IC (1987) The influence of ingredients and processing variables on the quality and microstructure on Hokkien Cantonese and instant noodles Food Microstructure Vol 6 No 3 Pages 63-74.

Nalle CL, Ravindran V and Ravindran G (2010) Evaluation of faba beans white lupins and peas as protein sources in broiler diets International Journal of Poultry Science Vol 9 No 4 Pages 567-573.

Narayanan BS, Sandiya R and Muthaiah NS (2015) Anxiolytic effects of Pisum sativum seed extracts in animal models Res J Pharm Biol Chem Sci Vol 6 No 2 Pages 443-447.

Osorio-Díaz P, Islas-Hernández JJ, Agama-Acevedo E, et al. (2014) Chemical starch digestibility and sensory characteristics of durum wheat/unripe whole banana flour blends for spaghetti formulation Food Nutr Sci Vol 5 No 2 Pages 264.

Petitot M, Boyer L, Minier C et al. (2010) Fortification of pasta with split pea and faba beans flours: pasta processing and quality evaluation Food Res Int Vol 43 No 5 Pages 634–641.

Rizkalla SW, Taghrid L, Laromiguiere M et al. (2004) Improved plasma glucose control whole-body glucose utilization, and lipid profile on a low-glycemic index diet in type 2 diabetic men: A randomized controlled trial. Diabetes Care Vol 27 No 4 Pages 1866–1872.

Saleh ASM, Zhang Q, Chen J et al. (2013) Millet grains: Nutritional quality, processing, and potential health benefits. Compr Rev Food Sci Food Saf Vol 12 No 4 Pages 281–295.

Santos JL, Santos JK, Santos EF et al. (2015) Sensorial and physicochemical qualities of pasta prepared with amaranth Acta Scientiarum Maringá Vol 37 No 1 Pages 69-75.

Sirichokworrakit SJ, Phetkhut AD and Khommoon (2015) Effect of partial substitution of Wheat Flour with Riceberry Flour on quality of Noodles J Procedia-Social and Behavioral Sciences Vol 197 No 3 Pages 1006–1012.

Susanna S and Prabhasankar P (2013) A study on gluten free pasta and its biochemical and immunological validation LWT-Food Sci Technol Vol 50 No 2 Pages 613–621.

Tang C, Hsieh F, Heymann H et al. (1999) Analysing and correlating instrumental and sensory data: a multivariate study of physical properties of cooked wheat noodles Journal of Food Quality Vol 22 No 1 Pages 193–211.

Wood AJ (2009) Texture processing and organoleptic properties of chickpea-fortified spaghetti with insights to the underlying mechanisms of traditional durum pasta quality J Cereal Sci Vol 49 No 4 Pages 128–133.

Yang, XS, Wang LL, Zhou XR, et al. (2013) Determination of protein fat starch and amino acids in foxtail millet (Setaria italica (L.) Beauv) by Fourier transform near-infrared reflectance spectroscopy Food Sci Biotechnol Vol 22 No 6 Pages 1495–1500.

Yilmaz E and Buket A (2012) Sensory Evaluation and Consumer Perception of Some Commercial Green Table Olives British Food Journal Vol 114 No 8 Pages 1085-1094.

Zhang A, Liu X, Wang G, et al. (2015) Crude fat content and fatty acid profile and their correlations in foxtail millet Cereal Chem Vol 92 No 5 Pages 455–459.

Zhao YH, Manthey FA and Chang SKC (2005) Quality characteristics of spaghetti as affected by green and yellow pea, lentil, and chickpea flour. J Food Sci Vol 70 No 6 Pages 371–376.