1Nutrition and Dietetics, Shri Sakthikailassh Institution, Salem, India.

2Nutrition and Dietetics, Periyar University, Salem, India.

Corresponding author email: karunafsnthara@gmail.com

Article Publishing History

Received: 07/10/2021

Accepted After Revision: 17/12/2021

Traditional cuisine has risen to the top of the consumer’s list of preferences. Many traditional cereal-based dishes have been processed, and instant mixes such as instant upma, idli, and dosa have been made. Comfort foods are foods that require little or no processing or cooking before consumption, making them more convenient for the user. Ready to Cook (RTC) and instant foods have grown highly popular as a result of increased urbanization and industrialization, owing to today’s lifestyle and the need for quick-to-serve cuisine.The study’s goal is to develop an RTC upma mix and evaluate its physicochemical, texture, sensory, and in vitro glycemic index. The millet was collected and pre-processing was done to develop the ready-to-cook mixes. The levels of millet incorporation ratio were 60% (V1), 70% (V2), and 80% (V3) levels.

Standard procedures were used to determine the physicochemical, textural, sensory, and in vitro glycemic index. The nutritional composition of V3 was found to be high, with moisture, carbohydrate, protein, fat, fibre, soluble fibre, and insoluble fibre content of 6.4 percent, 73.6g, 8.5g, 6.2g, 6.6g, 2.4g, and 0.56g, respectively.The textural profile showed a significant difference (p<0.05) between variations in comparison with the standard. Results on sensory evaluation showed that 70% foxtail millet upma mix shows high acceptable than other. The mean in vitro glycemic index of the control upma mix was 68.7 ± 0.12, while the mean estimated glycemic index value of V1, V2, and V3 was50.5 ± 0.5, 49.8 ± 0.4, and 49.2± 0.6 respectively. Thus, the result evident that all the developed RTC upma mixes exhibited a low glycemic index and were useful for Diabetic subjects and easy to carry as a journey food.

Foxtail Millet, Glycemic Index, Organoleptic, Ready-Mix, Upma.

Thara D. K, Nazni P. Formulation and Quality Evaluation of Foxtail Millet and Semolina Incorporated Ready-To-Cook Upma Mix. Biosc.Biotech.Res.Comm. 2021;14(4).

Thara D. K, Nazni P. Formulation and Quality Evaluation of Foxtail Millet and Semolina Incorporated Ready-To-Cook Upma Mix. Biosc.Biotech.Res.Comm. 2021;14(4). Available from: <a href=”https://bit.ly/2YG7P6j“>https://bit.ly/2YG7P6j</a>

Copyright © This is an Open Access Article distributed under the Terms of the Creative Commons Attribution License (CC-BY) https://creativecommons.org/licenses/by/4.0/, which permits unrestricted use distribution and reproduction in any medium, sources the original author and sources are credited.

INTRODUCTION

The Indian Ready to Cook (RTC) food market has progressed from its humble beginnings as a flimsy substitute for a home-cooked meal or dining out.A rapidly urban lifestyle, rising disposable income, and a growing percentage of continent Indians with a sophisticated palate are all favorable demographic variables driving the adoption of RTE and RTC foods in India. Diversification of food production must be encouraged at the national and household level with improved yields and household techniques (Singh and Raghuvanshi 2012).

Some of the highly nutritious agricultural foods are not being used as human foods because of the unawareness of people. Millets are one of them. Millets are being used as bird and animal feed. Millet has many nutritional and medical properties reported (Yang et al. 2012). Millets are rich sources of phytochemicals, micronutrients, and antioxidants, such as phenolic acids and glycated flavonoids (Stanly et al. 2013).

Millets also contain water-soluble gum-glucans, which help with glucose metabolism. As a result, millets can be included in a diabetic diet to help with glucose control. Foxtail millet (Setaria italica L.) is important underutilized minor millet that sustains well in adverse conditions. Nutritionally it’s superior to rice and wheat, and therefore provides proteins, minerals, and vitamins to the poor hooked into such grains (Tylor and Emmanbux 2008). In hyperlipidemic rats, foxtail consumption lowers plasma triglycerides, perhaps preventing cardiovascular disease (Lee et al. 2010; Stanly et al. 2013).

In humans with type 2 diabetes, high consumption of millet-based dietary fibre improves glycemic control, lowers hyperinsulinemia, and lowers plasma lipid contents (Jali et al. 2012; Kamatar 2013). Upma is a popular South Indian breakfast or snack cuisine that may be made in a short amount of time. Upma is a thick porridge made from dry roasted semolina and is typical Indian breakfast food. In both Asian and Western cuisines, semolina is a primary ingredient. Semolina made from foxtail millet could be a novel product made from small millets that can provide consumers with the natural health benefits of foxtail millet while also allowing millet products to be used in new ways (Dharmaraj et al. 2016).

The millet’s widespread use was still limited, owing to the lack of a variety of food products available on the market. Because millet semolina does not contain gluten protein, it might be used in place of wheat semolina, which could be beneficial to diabetes people. So yet, no one has used foxtail millet to make semolina or use it in the formulation of instant upma mix. With all these considerations in mind, the goal of this study is to develop a ready-to-cook (RTC) upma mix and assess its physicochemical, textural, sensory, and in vitro glycemic index.

MATERIAL AND METHODS

The physical properties of foxtail millet such as thousand-grain weight, thousand-grain volume, hydration capacity and index, swelling capacity and index and cooking quantity/characteristics millets and the functional properties such as bulk density, water absorption capacity, oil absorption capacity, swelling power, solubility, the solid loss were analyzed in foxtail millet. The analysis procedure of the AOAC method (2007) was used to examine millet nutritional qualities such as pH, total titratable acidity, moisture, carbohydrate, and energy value, crude protein, crude fibre, Ash, total starch, Amylose content, total sugar, dietary fibre, and mineral composition.

The anti-nutritional parameters such as tannin, total phenolics, and trypsin inhibitor were determined using standard procedures. For the creation of the upma mix, basic materials such as foxtail millet, semolina, Bengal gram dhal, mustard seeds, salt, green chili, carrot, beans, peas, and curry leaves were purchased from the local market. Millet was cleaned and washed under running water before being soaked for 30 minutes. After draining the grains and parboiling them for 10-15 minutes, the boiled grains were dried in the dryer to 14% moisture. Foxtail millet was converted into suji using a pulverizer and sieved (700mesh) as Millet suji. Dried vegetables were made by placing them in boiling water for 3 minutes and then cooling them immediately. At 60°C, carrots, chiles, and curry leaves were dried. Three variations of upma mixes were prepared by incorporating foxtail millet and semolina at different levels. Semolina in the ratios 0:100 (standard), other three variations of Upma mixes at 60%, 70%,80% levels of millet suji. Below table-1shows the composition of different ingredients for Upma mix preparation. The foxtail millet suji was roasted in a non-stick pan on slow flame with constant stirring till (5-7 min). The samples were cooled, packed in a container, and stored in normal condition.

According to the method of Basantpure et al. (2003), the physical properties of the upma mix were analysed. Moreover, the rehydration ratio (RR), which is a measure of the dehydrated product’s water absorption was determined. Dry foxtail millet suji-based upma mixes (100 g) were reconstituted with a measured amount of hot water (150-200 ml) and whisked on a low flame until the desired consistency was achieved. By using the AOAC technique (2000), all varieties of RTC upma were analysed for nutritional content, such as availability of carbohydrate, protein, fat, total fibre, soluble and insoluble fibre content, and the changes in nutritional quality on drying were documented. All the variations of millet upma mix with the respective control product were subjected to texture analysis using a Texture Analyser (TVT-300XP, Perten Instruments, Sweden) after the preparation.

The following Texture Profile Analysis (TPA) was used to determine the hardness, adhesiveness, springiness, and stickiness. All texture analysis measurements were repeated at least three times for each sample, and the mean values were calculated. The acceptable level of variations studied for sensory quality based on appearance, colour, flavour, taste, texture, and overall acceptability using a 9-point Hedonic scale by a panel of 10 judges scorecard with scores ranging from 9 to 1, in which 1 = dislike extremely, 5 = neither like nor dislike, and 9 = like extremely was used. Granfeldt et al. (1992) described a method for determining the in vitro starch digestibility of the formulated RTC upma mix. After that, the estimated glycemic index was determined using Goñi et al. (1997). The data was compiled and analysed using statistical methods such as mean, SD, ANOVA. All these were performed and the results separated, using the Multiple Range Duncan Test (p< 0.05) and using the statistical software of SPSS 16.

RESULTS AND DISCUSSION

The results and discussion of this study were discussed in the following heading like physical and functional, nutritional and anti-nutritional, rehydration ratio, textural, organoleptic, and in vitro glycemic responses of the RTC upma mixes.

Table 1. Physical and functional properties of foxtail millet

| Parameters | Foxtail millet |

| Thousand-grain weight (g) | 2.64±0.005ab |

| Thousand grain Volume (ml) | 2.96±0.05b |

| Hydration Capacity (g/1000 seeds) | 2.01±0.02ac |

| Hydration Index (%) | 76.9±0.05c |

| Swelling Capacity (ml/1000 seeds) | 0.21±0.02b |

| Swelling Index (%) | 6.72±0.02ab |

| Cooking Quantity | 193.3±11.9a |

| Cooking time (minutes) | 15±0.24ab |

| Bulk Density (g/ml) | 0.52±0.005a |

| Water Absorption Capacity (g/g) | 1.18±0.05b |

| Oil Absorption Capacity (g/g) | 1.06±0.02a |

| Swelling Power (g/g) | 5.23±0.4c |

| Solubility Per gram (%) | 6.2±0.55b |

| Solid Loss Per gram (%) | 29.3±0.86a |

Values are the means ± standard errors of means (SEM) of 3 determinants. Means with the same superscript are not significantly different using Duncan’s Multiple Range Test (p < 0.05).

The table-2 depicts the physical and functional properties of foxtail millet. In here the physical properties like thousand-grain weight, thousand-grain volume, hydration capacity, hydration index, swelling capacity, swelling index, cooking quantity, and cooking time showed the values of 2.64g, 2.96ml, 2.01g/1000seeds, 76.9%, 0.21ml/1000seeds, 6.72%, 193.3g, and 15min respectively. The functional properties of foxtail millet were bulk density, water absorption capacity, solubility per gram and solid loss per gram was 0.52g/ml, 1.18g/g, 1.06g/g, 5.23g/g, 6.2%, and 29.3%. Thilagavathi et al. (2015) found that pearl millet has the highest thousand-grain weight (11.39g), followed by Kodo millet (2.45g), and small millet (2.45g) (2.23g).

In this study, the selected foxtail millet grain weight was found to be more or less linked to Kodo millet grain based on the above literature. Thilagavathi et al. (2015) compared WAC of various types of millet with wheat and soybeans flour and found out that it ranged from 74.08 to 76.83 ml/100 g, 74.08 to 78.83 ml/100g, and (58.17- 60.02 ml/100g) for millet, wheat, and soybean flour respectively (Thilagavathi et al. 2015).

Butt (2010) also observed some variation in different millet flours and this may be due to different protein concentrations, their degree of interaction with water, and conformational characteristics. The oil absorption capacity according to Amir et al. (2016) on finger millet flour was found to be 1.93g/g and that of pearl millet flour is 1.60g/g. There is an advantage for the best organoleptic characteristics of a meal that the high water and oil absorption capacity of the flour can positively influence the flavor, moisture, and fat content in food.

The bulk density (798.10 kg.m-3) of foxtail millet were comparable with Subramanian and Viswanathan (2007). According to Ojediran et al. (2010) the bulk density, true density and porosity of pearl millet varied from 646.40-811.40 kg.m-3, 953.26-960.59 kg.m-3 and 15.17-32.64 per cent, respectively. The 1000 kernel weights of foxtail millet were observed as 2.45g in the past (Sunil et al. 2016).

The table-3shows that the nutrient content such as protein (6.8g), high fibre content (4.9g), and calcium (43mg). The iron content was 9.2g and the amylose content was 28.4g.Aconsiderable amount of energy source was noticed in foxtail millet (333.5kcal). Protein synthesis was attributed heavily to the germination process due to the involvement of microbial organisms in the flour. Sambavi et al. (2015) and Punia et al. (2003) revealed similar results in the production of cookies using a mix of foxtail millet and wheat flour and the nutritional evaluation of kangni (Setaria italic).The anti-nutrient compositions of foxtail millet were 0.36g of tannin, 65.6g of phenolics, and 0.24g of trypsin inhibitors. As a result changes in tastes and lifestyles backed by urban living will significantly impact food demand and consumption patterns (Goyal and Singh 2007; Sambavi et al. 2015).

Table 2. Nutritional and Anti-Nutritional properties of foxtail millet.

| Parameters | Foxtail millet |

| Nutritional parameters | |

| pH | 7.0±0.10a |

| Ash(g) | 2.1±0.015ab |

| Total titrable Acidity | 0.54±0.01a |

| Moisture(g) | 15±0.15c |

| Crude Protein(g) | 6.8±0.01bc |

| Crude Fibre(g) | 4.9±0.04c |

| Carbohydrates(g) | 70±1.10a |

| Fat(g) | 2.9±0.60ab |

| Energy (Kcals) | 333.3±0.77abc |

| Total Starch(g) | 18.5±0.01c |

| Amylose content(g) | 28.4±0.1b |

| Sodium(mg) | 16±1.0ac |

| Potassium(mg) | 347±1.0ab |

| Iron (mg) | 9.2±0.1a |

| Calcium(mg) | 43±1.00b |

| Phosphorus(mg) | 265±1.00ac |

| Anti-Nutritional parameters | |

| Tannin (mg) | 0.36±0.010a |

| Total Phenolics (mg) | 65.6±0.20b |

| Trypsin (mg) | 0.19±0.010ac |

Values are the means ± standard errors of means (SEM) of 3 determinants. Means with the

same superscript are not significantly different using Duncan’s Multiple Range Test (p < 0.05).

Balasubramanian et al. (2014) used pearl millet semolina to make upma dry mix. Before the preparation of semolina, pearl millet grains were hydrothermally treated to reduce anti-nutritional factors and inactivate lipase activity. Pasrija and Punia (2000) reported that both pressure-cooking and solar-cooking significantly reduced the phytic acidand polyphenol contents of cowpea cultivars. The reduction was greater when the seeds were soaked or dehulled prior to cooking (Pasrija and Punia 2000; Balasubramanian et al. 2014).

Table 3. Rehydration ratio of upma mix

| Variation | Rehydration ratio | |

| Initial weight | Final weight | |

| Standard | 30g | 40g |

| V1 | 30g | 50g |

| V2 | 30g | 60g |

| V3 | 30g | 80g |

In comparison to the standard sample in the table, the V3 sample shows a high rehydration ratio with a higher ability to reabsorb the water content. Among the three variations, low rehydration was noticed in V1 (50g). Amount of water adsorption was also affected by bulk and particle’s surface composition, particle size, porosity, and internal molecular structure of powder (Bhandari et al. 2013). Yadav and Sharma (2008) did their study in soy fortified upma. The incorporation of vanaspati and spices in pre-cooked dried Kabuli channa increased the re-constitution time due to the production of a hydrophobic oil coating, which hindered water penetration in the grain. Balasubramanian et al. (2014) showed similar rehydration ratios (2.4 to 3.3) in pearl millet semolina (Balasubramanian et al. 2014).

Table 5. Nutrient analysis of RTC upma mix

| Variations | Moisture | Carbohydrate (g) | Protein (g) | Fat (g) | Fibre (g) | Soluble fibre(g) | Insoluble fibre(g) |

| Standard | 3.74±0.05a | 79.79±0.05ab | 5.38±0.01ac | 6.8±0.01c | 5.0±0.01ab | 2.4±0.01b | 0.28±0.01c |

| V1 | 5.2±0.01ab | 74.3±0.01a | 8.6±0.01b | 6.1±0.01c | 6.2±0.01a | 2.0±0.01ab | 0.32±0.01b |

| V2 | 6.2±0.01ac | 73.1±0.01ab | 8.2±0.01b | 6.4±0.01c | 6.4±0.01ac | 2.3±0.01ab | 0.42±0.01b |

| V3 | 6.4±0.01b | 73.6±0.01c | 8.5±0.01a | 6.2±0.01ac | 6.6±0.01a | 2.4±0.01ac | 0.56±0.01c |

Values are the means ± standard errors of means (SEM) of 3 determinants. Means with the same

superscript are not significantly different using Duncan’s Multiple Range Test (p < 0.05).

From this table -5, it was predicted the nutrient analysis of RTC upma mix. In comparison to the standard, V3 had a high nutrient composition upma mix, with moisture, carbohydrate, protein, fat, fibre, soluble fibre, and insoluble fibre content of 6.4 percent, 73.6g, 8.5g, 6.2g, 6.6g, 2.4g, and 0.56g. The nutritional content of the selected fibre rich food items was determined to be good, and the fibre rich product was discovered to be a good source of minerals (Bora and Kulshrestha 2014). There was a substantial difference between the standard and the three variations upma mix in moisture, carbohydrate, and fibre at the 5% level, according to Duncan’s multiple range test. During decortication, milling, soaking, heating, roasting, germination, and fermentation are just a few of the traditional/household processing methods employed in food formulations (Aisoni et al. 2018).

Table 6. Textural characteristics of RTC upma mix

| Sample | Cohesiveness (N) | Stickiness (N) |

| Standard | 0.52±0.01a | -2.5±0.01ab |

| V1 (60%) | 0.43±0.01c | -1.6±0.10b |

| V2 (70%) | 0.05±0.01ac | -1.6±0.10a |

| V3 (80%) | 0.00±0.00b | -3.1±0.15c |

Values are the means ± standard errors of means (SEM) of 3 determinants. Means with the same

superscript are not significantly different using Duncan’s Multiple Range Test (p < 0.05).

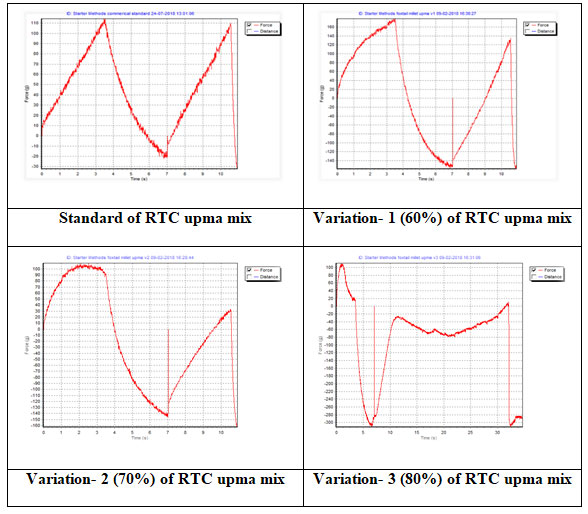

Compare with the standard high cohesiveness was found in V1 and maximum stickiness was noticed in the V3 upma mix. Fig-1 illustrates the textural profile curves of RTC upma mix variation and its standard. Duncan’s multiple range test showed that there was a significant difference (p<0.05) between the standard and the variations. Shivli et al. (2013) found that adding durum wheat semolina (SSCSBS) to cooked Multigrain Semolina Blend reduced hardness and springiness while increasing cohesiveness, gumminess, and chewiness (MSB).

Cohesiveness is defined as the ratio of the positive force area during the second compression for that during the first compression. The lowest cohesiveness was observed inV3 (0.00N) and the lowest stickiness was noticed in V1 and V2 (-1.6N). Stickiness was the important factor that affects the texture of the upma due to the presence of the soluble fibre content (Shivli et al. 2013; Aisoni et al. 2018).

Figure 1

Table 7. Mean sensory analysis of RTC upma mix

| Variations | Appearance | Colour | Flavour | Texture | Taste | Overall acceptability |

| Standard | 8.10±0.55b | 8.20±.52b | 8.90±.30d | 7.75±.55b | 8.05±.39b | 8.20±.52b |

| V1 | 8.20±0.78efg | 8.00±0.66cde | 8.10±0.73bc | 7.30±0.94abc | 7.80±1.03ab | 8.30±0.31fg |

| V2 | 7.60±1.42cdefg | 7.20±1.31abcd | 7.00±1.24ab | 6.50±1.08a | 6.60±1.07a | 8.90±0.67a |

| V3 | 7.20±0.78abc | 7.30±1.05bcde | 6.90±0.99ab | 7.10±0.87abc | 6.90±0.87ab | 8.00±0.66de |

Values are the means ± standard errors of means (SEM) of 3 determinants. Means with the same superscript are not significantly different using Duncan’s Multiple Range Test (p< 0.05).

When compared to other adjusted combinations, the V2 upma formulation made with 70% foxtail millet suji received the highest sensory ratings for colour (7.60), appearance (7.60), taste (6.60), flavour (7.00), texture (6.50), and overall acceptability (8.90).This could be owing to the use of fine foxtail millet semolina in the right proportions, resulting in an upma with pleasing colour, flavour, and texture. Similarly, Itagi et al. (2012) and Adegunwa et al. (2014) found that the acceptable levels of foxtail millet flour in readymade foxtail millet mix for diabetics, multigrain semolina blend for upma, and composite millet-wheat were 80 percent, 50 percent, and 100 percent, respectively, in readymade foxtail millet mix for diabetics, multigrain semolina blend for upma (Itagi et al. 2012; Adegunwa et al. 2014).

Table 8. In vitro glycemic response of RTC upma mix

| Variations | Glycemic Index | Glycemic load |

| Standard | 68.7±0.12a | 13.7±0.06ac |

| V1(60%) | 50.5±0.5ab | 10.1±0.1ab |

| V2(70%) | 49.8±0.4c | 9.9±0.1b |

| V3(80%) | 49.2±0.6b | 9.8±0.1c |

Values are the means ± standard errors of means (SEM) of 3 determinants. Means with the

same superscript are not significantly different using Duncan’s Multiple Range Test (p < 0.05).

Table -8 shows the glycemic responses of the formulated RTC upma mixes. Compare with standard, V1 (50.5), V2 (49.8), and V3 (49.2) had low GI values which indicate the addition of foxtail increases will decrease the GI value. As a result, all of the low GI values reported for various upma mixes were around 50, showing that all of these products have a low GI and are suitable for diabetic diets. According to Grandfeldt et al. (2000), limited grain processing and the manufacture of thicker flakes may aid in the development of flakes with reduced glycemic and insulinemic properties. Studies in this direction may be helpful for the preparation of finger millet flakes with a lower glycemic response. Livesey et al. (2008) stated in their meta-analysis study that foods with low GI caused significantly lower postprandial glycaemic response, they are considered better for people with diabetes. Monro (2014) suggests that the integrity of the dietary fibre is important to impart the desirable functional benefits like lower digestibility (Monro 2014).The effect of foxtail millet intervention on blood glucose might be explained by the slow digestion of carbohydrate and moderate glycemic index (Ren et al. 2016). In addition, the bioactivated fibers, flavonoids, polyphenols and other phytochemicals in foxtail millet might be other contributors to its glucose lowering effect (Sharma et al. 2018).

CONCLUSION

The findings of the present study determined that incorporating varying degrees of foxtail millet and semolina improved the quality of the RTC upma mix in terms of nutritional, textural, sensory attributes, and glycemic response. Variation 3 (80:20) RTC upma mix showed high nutritional composition than other variations with a 5% significant difference level. Based on textural characteristics, variation 1 showed a significant difference (p<0.05) than variations. Through the glycemic response of the RTC upma mix showed a low glycemic response (GI less than 55) for all the three variations (V1, V2, and V3) when compared with standard. As a result of the current study, it was concluded that foxtail millet has a higher nutritional value grain than rice and wheat, and will almost certainly improve glycemic control in diabetic patients.

Data Availability Statement: The database generated and /or analysed during the current study are not publicly available due to privacy, but are available from the corresponding author on reasonable request.

Conflict of Interest: Authors declare no conflicts of interests to disclose.

REFERENCES

Adegunwa MO, Ganiyu AA, Bakare HA et al. (2014) Quality evaluation of composite millet-wheat chinchin. Agriculture and Biology Journal of North America, Vol 5 No 1 Pages 33-39.

Aisoni J E, Yusha’U M and Orole OO (2018) Processing effects on physicochemical and proximate composition of finger millet (Eleusine coracana). Greener Journal of Biological Sciences, Vol 8 No 2 Pages 014–020.

Amir G, Kamlesh P and Pradyuman K (2016) Physico-chemical, Functional and antioxidant properties of millet flours conceptual frame work and innovations in agroecology and food sciences Vol 2 No 3 Pages 585- 589.

AOAC (2000) Official Methods of Analysis, Association of Official Analytical Chemists Washington DC (18).

AOAC (2007) Official Methods of Analysis, Association of Official Analytical Chemists Washington DC (18).

B Bhandari, N Bansal, M Zhang et al. (2013) Handbook of food powders: Processes and properties. Cambridge: Woodhead Publishing 379-402.

Balasubramanian S, Yadav DN, Kaur J et al. (2014) Development and shelf-life evaluation of pearl millet based upma dry mix J Food Sci Technol Vol 51 No 6 Pages 1110-1117.

Basantpure D, Kumbhar BK and Awasthi P (2003) Optimization of level of ingredients and drying air temperature in development of dehydrated carrot halwa using response surface methodology J Food Sci Tech Vol 40 No 2 Pages 40–44.

Bora P and Kulshreshtha K (2014) Development of low glycaemic index green gram husk incorporated fibre rich food products and their intervention for health benefits. International Journal of Food and Nutrition Sciences Vol 3 No 6 Pages 197-203.

Butt MS and Batool R (2010) Nutritional and functional properties of some promising legumes proteins isolates Pakistan Journal of Nutrition Vol 9 No 4 Pages 373–379.

Dharmaraj U, Rao BVS, Sakhare SD and Inamdar AA (2016) Preparation of semolina from foxtail millet (Setaria italica) and evaluation of its quality characteristics Journal of Cereal Science Vol 68 No 21 Pages 1-7.

Goñi, I, Garcia-Alonso A and Saura-Calixto F (1997) A starch hydrolysis procedure to estimate glycemic index Nutrition Research Vol 17 No 3 Pages 427-437.

Goyal A and Singh N P (2007) Consumer perception about Ready-to-eat in India: Food Journal Vol 109 Iss. 2 Pages 182-195.

Granfeldt Y, Björck I Drews A et al. (1992) An in vitro procedure based on chewing to predict metabolic responses to starch in cereal and legume products Eur J Clin Nut Vol 46 No 23 Pages 649–660.

Granfeldt Y, Eliasson A C and Björck I (2000) An examination of the possibility of lowering the glycemic index of oat and barley flakes by minimal processing J Nutr Vol 130 No 4 Pages 2207-14.

Handa V, Kumar V, Panghal A, et al. (2017) Effect of soaking and germination on physicochemical and functional attributes of horse gram four J Food SciTechnol Vol 54 No 13 Pages 4229–39.

Itagi S, Naik R, Bharati P et al. (2012) Readymade foxtail millet mix for diabetics International Journal of Science and Nature Vol 3 No 1 Pages 47-50.

Jali MV, Kamatar MY, Jali SM, et al. (2012) Efficacy of value-added foxtail millet therapeutic food in the management of diabetes and dyslipidamea in type 2 diabetic patients Recent Research in Science and Technology Vol 4 No 7 Pages 03-04.

Kamatar MY, Hemalatha S, Meghana DR, et al. (2013) Evaluation of Little Millet Landraces for Cooking and Nutritional Composition Current Research in Biological and Pharmaceutical sciences Vol 2 No 1 Pages 7-10.

Lee SH, Chung IM, Cha YS et al. (2010) Millet consumption decreased serum concentration of triglyceride and C-reactive protein but not oxidative status in hyperlipidemic rats Nutr Res Vol 30 No 4 Pages 290-296.

Livesey G, Taylor R, Hulshof T et al. (2008) Glycemic response and health–a systematic review and meta-analysis: relations between dietary glycemic properties and health outcomes Am J ClinNutr Vol 87 No 11 Pages 258S-268S.

Monro JA (2014) Polysaccharide based structures in food plants: Gut and health effects Polysaccharides Natural Fibers in Food and Nutrition In: Benkeblia, N (ed.) Boca Raton: CRC Press Pages 347-366.

Ojediran J O, Adamu M A and Jim D L (2010) Some physical properties of pearl millet (Pennisetum glaucum) seeds as a function of moisture content African Journal of General Agriculture Vol 6 No 1 Pages 39-46.

Pasrija, M., and Punia, D. (2000). Effect of pressure and solar cooking on phytic acid and polyphenol content of cowpeas. Nutrition and Food Science, 30(3), 133–137.

Punia D, Dalal A and Sindhu S (2003) Nutritional evaluation of kangni (Setaria italica): An underutilised millet and sensory evaluation of value-added products from kangni In: Recent Trends in Millet Processing and Utilization CCS Hisar Agricultural University Hisar India Pages 32-37.

Ren X, Chen J, Molla MM, et al. (2016) In vitro starch digestibility and in vivo glycemic response of foxtail millet and its products Food Funct Vol7 No 4 Pages 372–379.

Sambavi A, Sabaragamuwa RS and Suthakaran R (2015) Development of cookies using a combination of foxtail millet and wheat flour International Journal of Scientific and Technology Research Vol 4 No 10 Pages 294- 295.

Sharma N and Niranjan K (2018) Foxtail millet: Properties processing health benefits and uses Food Rev IntVol 34 No 4 Pages 329–363.

Singh P and Raghuvanshi RS (2012) Finger millet for food and nutritional security Afr J Food Sci Vol 6 No 4 Pages 77–84.

Srichuwong S, Suharti C, Mishima T, et al. (2005) Starches from different botanmical sources: Contribution of starch structure to swelling and pasting properties Carbohydrate polymers Vol 62 No 3 Pages 25-34.

Srivastava S, Sakhare SD and Indrani D (2014) Preparation of Multigrain Semolina Blend for Upma Its Formulation Rheology Physicochemical Textural and Nutritional Characteristics Indrani, Journal of Texture Studies Vol 45 No4 Pages 452–461.

Stanly JMP and Shanmugam A (2013) A study on millets-based cultivation and consumption in India. International Journal of Marketing Financial Services and Management Research Vol 2 No 4 Pages 49–58.

Subramanian S and Viswanathan R (2007) Bulky density and friction coefficients of selected minor millet grains and flours Journal of Food Engineering Vol 81 No 1 Pages 118-126.

Sunil C K, Venkatachalapathy N, Shanmuga S S, et al. (2016) Engineeering properties of foxtail millet (Setaria italica) International Journal of Science, Environment and Technology Vol 5 No 2 Pages 632-637.

Taylor JRN and Emmanbux MN (2008) Millets. Handbook of gluten free cereal products and beverage In A Arend and FD Bello (Eds.) Amsterdam and London: Academic Press 119-148.

Thilagavathi T, Banumathi, P, Kanchana S et al. (2015) Effect of heat moisture treatment on functional and phytochemical properties of native and modified millet flours Plant Arch Vol 15 No 1 Pages 15-21.

Thilagavathi T, Kanchana S, Banumathi P, et al. (2015) Physico-chemical and functional characteristics of selected millets and pulses. Indian Journal of Science and Technology Vol 8 No 7 Pages 147–155.

Yadav DN and Sharma GK (2008) Optimization of soy-fortified instant upma mix ingredients using response surface methodology J Food Sci Tech Vol 45 No 4 Pages 56–60.

Yang X, Wan Z, Perry L, et al. (2012) Early millet use in northen China Proc Natl AcadSci USA Vol 109 No 6 Pages 3726-3730