1Department of Mechanical Engineering, National Institute of Technology, Raipur, India.

2Dr. Babasaheb Ambedkar College of Engineering and Research, Nagpur, India.

Corresponding author email: bnkale.phd2018.me@nitrr.ac.in

Article Publishing History

Received: 20/06/2021

Accepted After Revision: 25/09/2021

In the current competitive situation, microalgae are the finest prominent alternative of biodiesel among all the other available sources. Microalgae are non-eatable and doesn’t require crop land for its cultivation which makes the microalgae most attractive source to study. This paper is aimed to investigate experimentally the competency of novel, less considered biodiesel from microalgae species, which will be developed as an alternative fuel in place of traditional diesel. In this study, the most common chemical process, transesterification was used to extract biodiesel from microalgae. As per the requisite of experimentation five microalgae blends (MAB) were prepared on volumetric basis.

The experimentation was performed on single cylinder variable compression ratio diesel engine to investigate the impact of microalgae biodiesel and its blends on performance as well as exhaust emission characteristics. All the experiments were carried out as per standard operating procedure and with due precautions. Brake power, brake specific fuel consumption and brake thermal efficiency were the performance characteristics focused during the experimentation. Microalgae blends indicated reduction in torque and hence brake power which resulted in average reduction of 7.14 % in the brake thermal efficiency. Brake specific fuel consumption increased by 11.54 % for microalgae as equated to traditional diesel.

As a need of time emission characteristics must be evaluated along with performance. So, the main emission characteristics were also investigated in this work. As blending ratio increased, considerable reduction in exhaust emission characteristics of carbon monoxide (CO) plus hydrocarbon (HC) were recorded. Conversely, for all microalgae biodiesel blends, nitrogen oxides (NOx) and carbon dioxide (CO2) increased little which was compatible and in acceptable range. The performance as well as emission characteristics using microalgae biodiesel were found satisfactory.

Algal Biodiesel, Emission Characteristics, Fuel Properties, Performance Characteristics, VCR Diesel Engine.

Kale B. N, Patle S. D, Khawale V. R, Lutade S. V, Mungale N. P. Experimental Investigation on Performance and Exhaust Emission Characteristics of Variable Compression Ratio Diesel Engine Fueled with Microalgae Biodiesel Blends. Biosc.Biotech.Res.Comm. 2021;14(3).

Kale B. N, Patle S. D, Khawale V. R, Lutade S. V, Mungale N. P. Experimental Investigation on Performance and Exhaust Emission Characteristics of Variable Compression Ratio Diesel Engine Fueled with Microalgae Biodiesel Blends. Biosc.Biotech.Res.Comm. 2021;14(3). Available from: <a href=”https://bit.ly/3AVKHyk“>https://bit.ly/3AVKHyk</a>

Copyright © Kale et al., This is an open access article distributed under the terms of the Creative Commons Attribution License (CC-BY) https://creativecommns.org/licenses/by/4.0/, which permits unrestricted use distribution and reproduction in any medium, provide the original author and source are credited.

INTRODUCTION

The current status of traditional energy sources is quite fickle and the world economy depends upon it. Rapidly depleting petroleum derivatives, on the other hand percentage increase in their cost likewise with disturbing increase in pollution levels are significant points of concerns for the general public in this scenario. To counter this situation, lots of biodiesel alternative are identified but they denied complete replacement for traditional diesel. This may be due to their unattractive physiochemical properties (Tayari et al. 2020).

In addition to this an enormous number of vehicles is being offered on the roads regularly which increase stress on petroleum industries and environment. So as per BP Statistical Review of World Energy, it is a need of time for offering new varieties of alternative fuel to rout the exhaustion of petroleum products and expansion in environment pollution.

World Energy 2020 Statistical Review by BP pointed towards a gap of 4287 thousand barrels per day between oil utilization and its supply for our country. Considering the food sock for mankind, it is always desirable to go with non-edible sources because of its several advantages over edible sources. As per the report of petroleum ministry, the yearly measured petroleum products consumption in India is nearly 120 million tonnes, and it is increasing (Kale et al. 2021).

MATERIAL AND METHODS

Raw Algae sample was collected from river outskirts at Salai (Mendha) Nagpur district, Maharashtra (Figure 2a). This raw alga was washed very clearly (Figure 2b). After washing these algae were grounded in a motor mixer to form homogeneous paste (Figure 2c). The grounded homogeneous algae paste was dried out at 800C for emancipating water (Figure 2d). 20ml Hexane plus 20 ml ether solution were mixed with this dried grounded homogeneous alga.

This mixture was set aside for 24 hours to get settle down. After total settlement, the mixture was filtered to separate biomass and after separation it was measured. The filtered biomass contained hexane and ether so it was evaporated in vacuum to make it free from hexane and ether. Afterwards 0.25 grams of NaOH (as a catalyst) was mixed with this extracted methanol. Proper stirring using magnetic stirrer was carried out to achieve uniform mixing.

Then this mixture of catalyst plus methanol was dispensed into the algae oil. The standard operating procedure given by American society for testing and materials standards (ASTM) was adopted during this biodiesel production. The most popular transesterification chemical reaction was implemented to get decent quality of microalgae biodiesel (Kale et al. 2021).

The conical flask containing solution of methanol, catalyst and algae oil was shaken at 300rpm and then set aside to settle down. The biodiesel was separated from sedimentation and remaining amount of residue, containing glycerine, was assessed through colours. Biodiesel was washed by 5% water and then dried using dryer to make it totally water free. Biodiesel production was measured and stored safely.

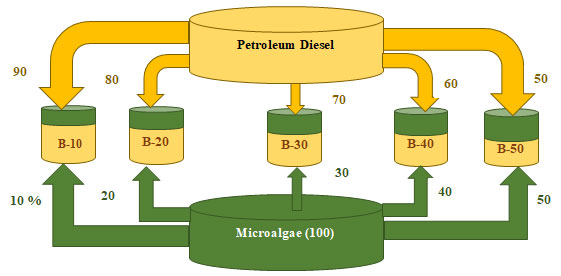

For experimentation purpose, microalgae biodiesel was blended with diesel on volume basis to get microalgae biodiesel blends as represented in figure 4 (Kale et al. 2020). Implementing above methods with precision, the microalgae biodiesel blends MAB10, MAB20, MAB30, MAB40, and MAB50 were prepared as shown in Figure 5.

RESULTS AND DISCUSSION

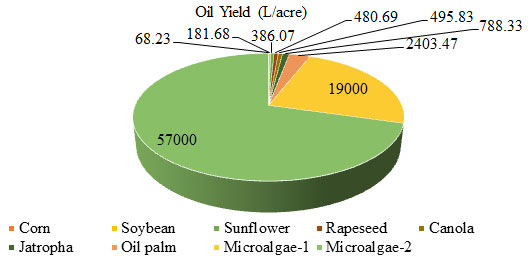

The oil yield from some edible and non-edible biodiesel sources are presented in figure 1. From the figure, one thing is very clear that, for a yield like soybean or palm, a colossal level of crop land is needed to substitute petroleum diesel entirely. Hence, the use of this assessable land for biodiesel purpose was not feasible.

On the other hand, while considering microalgae oil yield per acre, it has been prophesied that nearby 02 to 03 % of entire crop land is sufficient for providing sufficient microalgae biodiesel to supersede all petroleum diesel concern of our country. Undoubtedly, microalgae feedstock is major option for vast biodiesel production (Subhaschandra et al. 2019).

Figure 1: Comparison of oil yield (L/acre) from various sources of biodiesel

The steps followed in biodiesel preparation are given in figure 2.

Figure 2: Steps in microalgae biodiesel extraction (Kale et al. 2021).

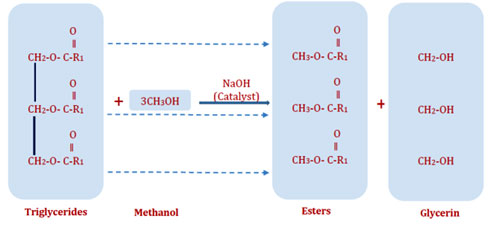

The chemical reaction used for biodiesel preparation is provided in figure 3.

Figure 3: Transesterification reaction for biodiesel extraction (Kale et al. 2021).

The techniques used for blends formation is illustrated in figure 4.

Figure 4: Microalgae biodiesel blends preparation on Volume basis

Figure 5 shows the actual photographs of microalgae blends prepared on volumetric basis.

Figure 5: microalgae biodiesel blends with petroleum diesel (Actual photographs)

Properties of Test Fuel: It is very important to know the physical plus chemical properties of biodiesel and its blend fuel so as to avoid any harm to engine and proper reading (Tayari et al. 2020). Following the ASTM Standard, the key properties found out in institute laboratory that were viscosity, cetane number, density, flash point, fire point and heating value. These properties were put forth in table 1.

Table 1. Microalgae blends chemical and physical properties

| Properties | Petroleum diesel | Algae Biodiesel | MAB10 | MAB20 | MAB30 | MAB40 | MAB50 |

| Kinematic Viscosity

at 104 oF (mm2/s) |

2.7 | 3.160 | 2.746 | 2.792 | 2.838 | 2.884 | 2.930 |

| Cetane Number | 49 | 48 | 48.8 | 48.72 | 48.66 | 48.59 | 48.52 |

| Density @ 150C (kg/m3) | 830 | 881 | 835.1 | 840.2 | 845.3 | 850.4 | 855.5 |

| Flash point (0C) | 64 | 150 | 72.6 | 81.2 | 89.8 | 98.4 | 107 |

| Fire point (0C) | 71 | 83 | 72.2 | 73.4 | 74.6 | 75.8 | 77 |

| Heating Value (MJ/kg) | 42 | 40.5 | 41.85 | 41.83 | 41.78 | 41.73 | 41.69 |

Experimental Test Rig: Variable compression ratio CI Engine test rig situated in thermal engineering laboratory of Institute is shown in figure 6. This test rig was used for experimentation. A single cylinder engine was coupled with eddy current dynamometer for loading. The setup was with facility of changing compression ratio from 12.5 to 18:5. The detailed specification of experimental setup were brief in table 2.

Figure 6: Actual photograph of experimental test rig

Table 2. Technical specification of Experimental Test Rig

| Parameter | Specification |

| Model | TV1 |

| Manufacturer | Kirloskar Oil Engines |

| Form | 4-Stroke |

| Total No. of cylinder | 01 |

| Bore Diameter (m) | 0.0875 |

| Stroke Length (m) | 0.11 |

| Cubic capacity (cm3) | 661 |

| Standard CR | 17.5:1 (Variable) |

ARAI Approved MARS Multi Gas analyser (Model: MN-05,) as shown in figure 7 was used for emission parameters measurement. Measurement range along with its accuracy was also provided in table 3.

Figure 7: Actual photograph of multi gas analyser (MARS, Model: MN-05)

Table 3. Measurement Range Resolution of Multi Gas analyser

| Parameter | Range | Accuracy |

| CO | 0 to 9.99% Volume | 0.001% Volume |

| CO2 | 0 to 20% Volume | 0.01% Volume |

| HC (propane) | 0 to 15000 ppm | 01 ppm |

| O2 | 0 to 25% Volume. | 0.1% Volume |

| NOx | 0 to 5000 ppm | 1 ppm Volume |

| Engine RPM | 500 to 6000 rpm | 1 rpm |

| Lambda | 0.200 to 2.000% | 0.001 |

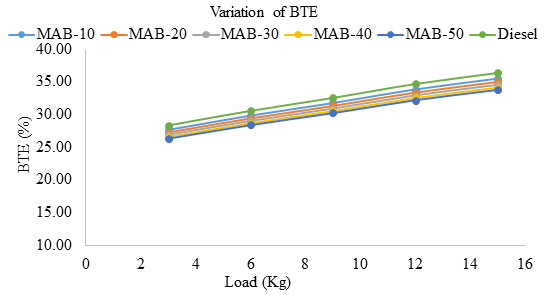

Performance characteristics: Brake Thermal Efficiency (BTE) Figure 8 represents the variation of brake thermal efficiency with respect to load applied. As the load on engine increased the brake thermal efficiency also increased but it declined with fuel blends when compared with petroleum diesel.

Specific fuel consumption (SFC) increased for microalgae biodiesel blends because of its lower calorific value. This obviously decreased the brake thermal efficiency. With an increase in blending proportion, there was a reduction in the rate of heat release which finally declined the brake thermal efficiency of the engine (Kalsi et al. 2017; Tayari et al. 2020).

According to the experimental results brake thermal efficiency obtained was 32.09% for diesel fuel conversely 31.32%, 30.87%, 30.49%, 30.10% and 29.80% for MAB10, MAB20, MAB30, MAB40 and MAB50 microalgae biodiesel blends respectively.

On an average, the reduction was observed in case of brake thermal efficiency for MAB10 by 2.41% and MAB50 by 7.14 % in comparison with diesel fuel. As the loading on engine increased, it was observed that brake thermal efficiency also increased. Analogous results trends were attained by earlier researchers in their work (Elsanusi et al. 2017; Datta et al. 2017; Srihari et al. 2017: Can et al. 2017; Tayari et al. 2020).

Figure 8: Brake Thermal Efficiency (BTE) variation with respect to load

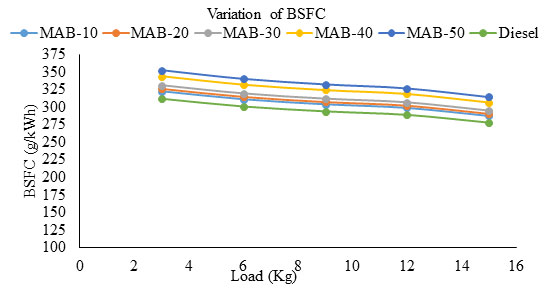

Brake specific fuel consumption (BSFC): Brake specific fuel Consumption was subjected directly on energy value (Calorific /Heating Value) of the fuel. The heating value significantly affected the complete combustion process of the fuel. Because of inferior heating value, biodiesel and its blends directly influenced the increase in brake specific fuel consumption values (Elsanusi et al. 2017; Datta et al. 2017). Moreover, the variation in brake specific fuel consumption in accordance to engine ran on different loading was represented in figure 9. BSFC was minimum for diesel fuel, trailed by all microalgae biodiesel blends at applied loads.

In overall, there was an increase in BSFC for MAB10 by 3.43 % and MAB50 by 11.54 % compared with diesel fuel. For Individual microalgae biodiesel blends, BSFC was decreasing with higher load since combustion efficiency increased and this was also proved from the figure 9. The analogous propensity of result was also observed in a referred study (Srihari et al. 2017: Can et al. 2017; Tayari et al. 2020).

Figure 9: Brake Specific Fuel Consumption (BSFC) variation with respect to load

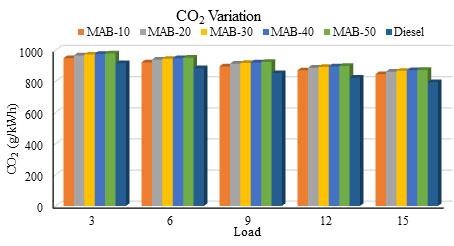

Emission Characteristics: Engine exhaust emission characteristics such as CO, CO2, HC, NOX, emissions in accordance with various loads provided on test engine were found experimentally for microalgae biodiesel blends and equated it with petroleum diesel fuel. Carbon dioxide (CO2) exhaust emissions, viscosity, process of atomization, compression ratio, oxygen, rpm of engine etc.

were the factors which influence CO2 emissions from engine exhaust (Muralidharan et al. 2011; Rahman et al. 2013; Celik et al. 2017; Gharehghani et al.2017 Shrivastava et al. 2019). Figure 10 depicts CO2 emissions variation in accordance to engine loading. CO2 was obtained to be higher for microalgae biodiesel blends in comparison with diesel. From the figure 10, it can be stated that, CO2 emission was increasing with an increase in blending proportion i.e. From B10 to B50 and decreased with engine load increase.

The CO2 exhaust emissions was 853.96 g/ kWh for petroleum diesel whereas it was 896.47g/kWh for MAB10 microalgae biodiesel blend. There was an increment of 4.74 % for B10 microalgae biodiesel blend in CO2 exhaust emissions, 6.52 % for MAB20, 7.07 % for MAB30, 7.43 for MAB40 and 7.70 % for MAB50 microalgae biodiesel blend. Though the CO2 Emissions were higher but quite compatible with diesel fuel.

Figure 10: CO2 exhaust Emissions Variation with respect to load

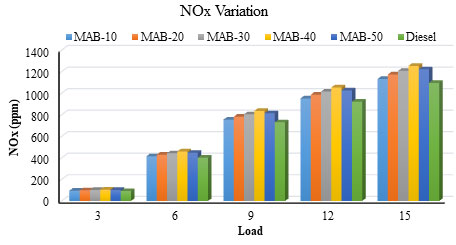

Nitrogen oxides (NOX) Exhaust Emissions: Combustion temperature, oxygen contents of the test fuel and the actual space of combustion zone were the aspects which directly dominated NOX exhaust emissions (Zehra et al. 2014). Stoichiometry, flame temperatures, delay in ignition, composition of fatty acids for fuel, rate of heat removal (HRR), premixing, combustion space, fuel cetane number, injection timing and thermo-physical properties of the fuel were different aspects which influence NOX exhaust emissions (Rajak et al. 2018; Shrivastava et al. 2019; Subhaschandra et al. 2019).

Fig. 11 illustrates the NOX exhaust emission variations for microalgae biodiesel blends and petroleum diesel fuel in accordance with engine loads. It was witnessed that, as the engine load increased, NOX exhaust emission also gradually increased. The average measured values for NOX emissions were 648 ppm for petroleum diesel fuel, 669.77 ppm for MAB10,694.20 ppm for MAB20, 714.09 ppm for MAB30, 741.37 ppm for MAB40, and 722.19 ppm for MAB50.

This may correlate to the greater content of oxygen level in case of microalgae biodiesel as well as its various blends which increased the combustion gas temperature and resulted in increasing NOx development by giving surplus oxygen (Song et al. 2002; Shrivastava et al. 2019).

Figure 11: NOX exhaust emission Variation with respect to load

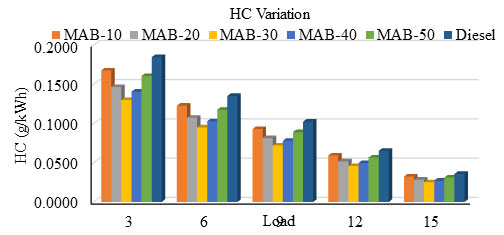

Hydrocarbon (HC) Exhaust Emissions: Figure 12 depicts hydrocarbons (HC) exhaust emissions variations for all the microalgae biodiesel blends fuels as well as petroleum diesel in accordance with engine load. The average HC emissions were found as 0.1045 g/kWh in case of petroleum diesel fuel, whereas for MAB10 it is 0.0949 g/kWh, 0.0830 g/kWh for MAB20, 0.0736 g/kWh for MAB30, 0.0796 g/kWh for MAB40, and 0.0909 g/kWh for MAB50 microalgae biodiesel blends.

The average reduction in HC emissions with respect to diesel fuel was 9.2% for MAB10, 20.58% for MAB20, 29.62% for MAB30, 23.84% for MAB40, and 13% for MAB50 Microalgae biodiesel blends. This might be correlated with the greater kinetic viscosity of biodiesel blends, impeding in fuel atomization and therefore benefits the HC emissions (Celikten et al. 2012; Shrivastava et al. 2019).

Figure 12: HC exhaust emission Variation with respect to Load

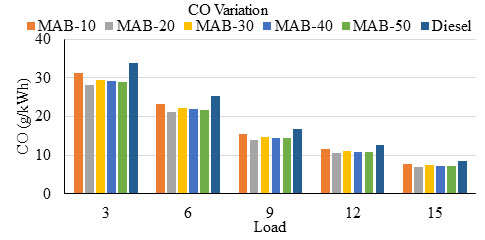

Carbon Monoxides (CO) Exhaust Emissions: Figure 13 illustrates CO exhaust emissions variations for all tested microalgae biodiesel blends and petroleum diesel fuel with respect to the different engine loading conditions. A massive reduction in CO emissions at higher engine load was witnessed for microalgae biodiesel blends. The average CO emissions were found as 19.41 g/kWh for petroleum diesel fuel, 17.92 g/kWh for MAB10, 16.15 g/kWh for MAB20, 16.96 g/kWh for MAB30,16.83 g/kWh for MAB40 and 16.59 g/kWh for MAB50.

This reduction in CO emission might be explained in linkage with fact that microalgae Biodiesel and its blends were an oxygenated fuel and they had additional oxygen atoms which comforts the complete combustion reaction, thus transforming CO to CO2 molecules, consequently a noteworthy amount of drop in CO emission was observed in case of Biodiesel Blends with diesel (Celikten et al. 2012; Shrivastava et al. 2019).

Figure 13: CO exhaust emission Variation with respect to load

CONCLUSION

The findings of the present study illustrated that the brake thermal efficiency and brake specific fuel consumption were increased for all microalgae biodiesel blends. Increment of in CO2 emissions in case of all microalgae biodiesel blends was recorded. Moreover, it was witnessed that, with an increase in engine load, NOX exhaust emission also gradually increased. The average reduction in HC and specific CO emissions with respect to diesel fuel was observed. Microalgae biodiesel blend MAB30 gave the finest results in terms of performance plus exhaust emission characteristics are concerned.

Conflict of Interests: Authors declare no conflicts of interests to disclose.

REFERENCES

Can O, Ozturk E and Yucesu SH (2017). Combustion and exhaust emissions of canola biodiesel blends in a single cylinder DI diesel engine. Renewable Energy Vol 109 Pages 73-82.

Celik M. and Ozgoren YO (2017). The determination of effects of soybean and hazelnut methyl ester addition to the diesel fuel on the engine performance and exhaust emissions. Applied Thermal Engineering Vol 124. Pages 124-135.

Çelikten İ, Mutlu E and Solmaz H (2012). Variation of performance and emission characteristics of a diesel engine fuelled with diesel, rapeseed oil and hazelnut oil methyl ester blends, Renewable Energy Vol. 48(C) Pages 122-126.

Datta A and Mandal BK (2017). Engine performance, combustion and emission characteristics of a compression ignition engine operating on different biodiesel- alcohol blends. Energy Vol 125 Pages 470-483.

Elsanusi OA, Roy MM and Sidhu MS (2017). Experimental investigation on a diesel Engine fuelled by diesel-biodiesel blends and their emulsions at various engine operating conditions; Applied Energy Vol 203 Pages 582-593.

Gharehghani A, Mirsalim M and Hosseini R (2017). Effects of waste fish oil biodiesel on diesel engine combustion characteristics and emission. Renewable Energy Vol 101 Pages 930-936.

Kale B, Patle S and Kalambe S (2021) Microalgae biodiesel and its various diesel blends as promising alternative fuel for diesel engine, Materials Today: Proceedings, Vol 44P2 Pages 2972-2977.

Kalsi SS and Subramania KA (2017). Effect of simulated biogas on performance combustion and emissions characteristics of a bio-diesel fuelled diesel engine. Renewable Energy Vol 106 Pages 78-90.

Muralidharan K and Vasudevan D (2011). Performance, emission and combustion characteristics of a variable compression ratio engine using methyl esters of waste cooking oil and diesel blends. Applied Energy Vol 88 Pages 3959-3968.

Rahman SMA, Masjuki HH, Kalam MA, et al. (2013). Production of palm and Calophyllum inophyllum based biodiesel and investigation of blend performance and exhaust emission in an unmodified diesel engine at high idling conditions. Energy Conversion and Management Vol 76 Pages 362-367.

Rajak U and Verma NT. (2018). Effect of emission from ethylic biodiesel of edible and nonedible vegetable oil, animal fats, waste oil and alcohol in CI engine. Energy Conversion and Management Vol 166C Pages 704-718.

Shrivastava P, Verma TN and Pugazhendhi A. (2019). An experimental evaluation of engine performance and emisssion characteristics of CI engine operated with Roselle and Karanja biodiesel. Fuel Vol 254.

Song J, Cheenkachorn K, Wang, J, et al. (2002). Effect of oxygenated fuel on combustion and emissions in a light-duty turbo diesel engine. Energy & Fuels Vol 16 No 2 Pages 294 -301.

Srihari S, Thirumalini S and Prashanth K (2017). An experimental study on the performance and emission characteristics of PCCI-DI engine fuelled with diethyl ether-biodiesel diesel blends. Renew Energy Vol 107 Pages 440-447.

Subhaschandra ST and Verma TN (2019). Biodiesel production from Momordica charantia (L.): extraction and engine characteristics. Energy Vol 189.

Tayari S, Abedi R and Abedi A (2020), Investigation on physicochemical properties of wastewater grown microalgae methyl ester and its effects on CI engine, environmental and climate technologies Vol 24 No 1 Pages 72-87.

Zehra S and Orhan NA (2015). Experimental investigation of the effects of using low ratio nbutanol/ diesel fuel blends on engine performance and exhaust emissions in a turbocharged DI diesel engine. Renewable Energy Vol 77. Pages 279-290.