Jawaharlal Nehru Agricultural University, Jabalpur (M.P.) India-482004

Corresponding author Email: akrai_jnau@yahoo.co.in

Article Publishing History

Received: 19/03/2018

Accepted After Revision: 10/06/2018

With the increased mechanization of harvesting operation, crop is harvested at high moisture and cannot be stored for longer period unless it is dried. Thus there is a need of equipment for determining moisture of grain. The same equipment may be used for determining moisture at the time of harvest also. The importance of grain-moisture and the use of electrical moisture meters for measurement are discussed briefly. References to earlier work with such moisture meters are cited (Young 1983, Nelson 2000), and a brief description of variation of electrical or dielectric properties with grain moisture are discussed. The information available in the literature on the dielectric properties of grain is reviewed from the viewpoint of its usefulness in grain-moisture measurement. Factors other than moisture that influence the dielectric properties of grain are elaborated. The authors have designed an in situ grain moisture meter for major crops like wheat, paddy, soybean. Most of the moisture meters available are desk type and are designed for in situ moisture measurement (Rai et al 2005). At present moisture meter and samplers are not integrated. In this design sensor and grain sampler are integrated in one unit. It will be low cost, portable and easy to use.

Moisture Content, Capacitance, Dielectric Properties, Sensor, Desiccant, Distillation. Gravimetric, Probe

Rai A. K, Dass B, Tiwari V. K. Design of a Probe Type in Situ Electronic Grain Moisture Measurement System. Biosc.Biotech.Res.Comm. 2018;11(2).

Rai A. K, Dass B, Tiwari V. K. Design of a Probe Type in Situ Electronic Grain Moisture Measurement System. Biosc.Biotech.Res.Comm. 2018;11(2). Available from: https://bit.ly/2ZboInU

Introduction

Moisture is an important criterion for pricing and procurement (at minimum support price) of agriculture produce. Farmers with high moisture produce is penalized directly by a lower price for excess moisture and farmer with low moisture produce is penalized indirectly for supplying dry matter instead of water to the purchases.

Inexpensive method with ease and sufficient accuracy for determining moisture content of grain is not available for farmers. In most of the cases farmer relies upon his experience to estimate the moisture content. Farmers normally used observation by biting or feeling. Regardless of the method used for determining the moisture content, there are possibilities of error in making the determination. The major problem is that of securing a sample which is representative of the entire lot of material. To reduce the possibilities of error several samples should be obtained from different location in the bin, container or bag. Usually a large sample is obtained which is taken to the laboratory for determining the moisture content. Moisture content determination within one percent accuracy is sufficient to establish storage period for grains, as considerable money is lost each year because of over drying (Rai et al 2005).

The authors have theoretically designed a hand held grain moisture meter for exclusive use at farmers level, Krishi Upaj Mandi, ware houses and Food Corporation of India during procuring and storage. The aim is to develop a device for measuring grain moisture, based on the principle of capacitance measurement. At present moisture meter and sampler are not integrated. It is proposed that a digital hand held battery operated portable moisture meter with integrated grain sampling unit and display unit will be designed. This unit will be tested rigorously at mandi with paddy, soybean and wheat at large scale. The sensor would be of capacitance type either in the cylindrical shape or miniature parallel plates to be integrated in the sampling device. The principle of operation will be based on dielectric method i.e. Capacitance (Dass et al 2010).

The sensor and measurement device will be internally connected on a single module. Attempts will be made to make the system compact and rigid.

Usually farmers bring their produce to Mandi for its sell. The keeping quality of grain largely depends on the moisture content. Therefore, moisture measurement at Mandi will be helpful in finalizing drying process for safe storage of food grains.

Moisture Measurement Techniques

Various grain moisture measurement techniques are available i.e. direct as well as indirect methods. The direct method includes oven method, drying with desiccant and distillation method (Rai et al 2005, Hall 1970, Zeleny 1960). Direct methods involve either gravimetric or volumetric procedures. Such methods are cumbersome and time consuming. Other methods such as infrared and microwave (Nelson 2004) are very costly and needs elaborate calibration from variety to variety. It is thought to use capacitance (dielectric) measurement method as it is easy, simple and low cost (Nelson 1987).

Proposed Device

The proposed device will be fabricated along with capacitive probe type sensor. The device will be developed consisting following components:

- The size and shape of grain sampler will be optimized.

- The sampled grain will be directly taken into sensor for better accuracy and instant measurement.

- A sampling probe for insertion into grain heaps/bags will be developed and standardized.

- A LCD based digital display integrated with the sampler and sensor for quick measurement of moisture.

- The Geometry of probe will be optimized / redesigned.

- The sample holder may be in the form of Auger (parkhi). Various sizes of parkhi’s will be fabricated and the capacitance response in the moisture range 8-25% will be studied.

- Sizes, shape and capacity of sensor will be optimized for best result in above range.

- If needed some modular arrangement will be made to incorporate grain collector of miniature size to increase the sample volume.

- The circuit will be designed using Op Amps, Analog and Digital ICs having LCD Display (Theraja 1980).

- Additional feature of above system will be equipped with graphical display system of the moisture indicators.

- Initially the meter will be calibrated for wheat, paddy and soybean crop. Thereafter, depending on the requirement and accuracy obtained other commodities may be taken for calibration (Rai et al 2005).

Operating Principle

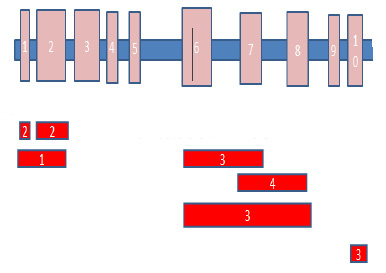

A coaxial type sensor (fig. 1) will be developed using dielectric properties of grain moisture.

Capacitance of Coaxial type sensor is given by

Where å = dielectric constant, K2 = constant for fixed geometry (R,r,H)

|

Figure 1: Coaxial Type Sensor |

Different sizes of coaxial type sensor will be fabricated for the purpose. Since a capacitor is physical device, a change in its capacitance is due to dielectric constant K2. The ratio of dielectric constants of water, dry grain and air is 80:5:1 respectively (Nelson 1982, Nelson 1991). Calibration curve will be obtained (Gough 1983). Various grain samples with different moisture levels will be collected for each crop. Measurement will be performed at length with different shape/size of sensors and will be excited in the range of radio frequency i.e. 1-50 MHz and frequency optimization will be carried out. Signal Conditioning and amplification will be carried out as per requirement. Initially it will be calibrated for paddy, soybean and wheat. A conceptual sampling probe is shown in fig 2.

|

Figure 2: Parakhi (Grain sampling device) |

Process Scenario

The circuitry will consist of RF Oscillator, Signal conditioning circuit, Amplification and Display units etc (Mathur 2002, Hall 1986, Gaonkar 1989). The process diagram is shown in fig 3 and excitation circuit in fig 4 (Kant 2010).

|

Figure 3: Block diagram of the System |

|

Figure 4: Bridge circuit for measurement of grain |

Materials and Methods

The following methodology is proposed:

- The present status of moisture measurement will be visualized by visiting FCI, SWC, farmer’s field, Krishi Upaj Mandi etc.

- The standard procedure laid down by Association of Analytical Chemist (AOAC) method will followed during calibration and testing of unit at different moisture levels (8-25%).

- Once relationship of the sensor output and correlation factor for other variable is established, the design of the sensor in respect of size, shape etc will be freeze.

- The design work of electronic circuit consisting of oscillator, signal conditioning, A to D conversion etc (Mottershead, 1985) will be taken into account.

- The integration of sensor and other measuring unit will be done.

Calibration and Testing of the Device

The relationship between the electrical properties and grain moisture content vary with grain type, variety, temperature, packing density etc. For calibrating the device, samples of known moisture content will be prepared (Gough 1983).

- Long duration performance of the system will be tried in Mandi / Warehouses.

- Moisture range will be 8-25% with accuracy of +/-1 % and will be calibrated for Wheat, Paddy and Soybean in the first phase.

- Testing and field trial will be conducted (Gough 1983).

Result And Discussion

This device will facilitate easy, simple and accurate insitu measurement of grain moisture of different crop. This will be useful for monitoring moisture migration of grain stored at Food Corporation of India, central and state warehouses, farmer’s field, Krishi Upaj Mandi, etc.

Before harvest during each Rabi and Kharif crop season, the Government of India announces the minimum support prices (MSP), to facilitate procurement of food grains. Government establish a large number of purchase centres at various mandis and key points. For paddy maximum limit of moisture content is notified as 17 percent on wet basis (GoI 2017).

For Wheat procurement more than 18,000 procurement centers are operating in Rabi Market Season (RMS) 2018-19 & for Rice procurement more than 35,000 procurement centres are operating in Kharif Market Season (KMS) 2017-18.

Its utility will be extended to these centers for ensuring procurement as per schedule of specification notified by Government of India (GoI 2017) i..e. .moisture content 17 % (wet basis). Thus there is need and demand of thousands of moisture meters to decide the condition of crop falling under uniform specification, to avoid unnecessary rejection of lot due to over moisture.

References

Young J.H. Instrumentation and Measurement for Environmental Science, Editor: B.W Mitchell, American Society of Agricultural Engineers, Special Publication, 1983, pp 7.01-7.10 (1983).

Nelson S.O. Sensing moisture content in grain. IEEE Instrumentation and Measurement Magazine. pp17-20, (March 2000).

Rai, A.K., K. Sivadasan and S.N. Murty. 2005 ‘A low cost field usable portable digital grain moisture meter with direct display of moisture (%)’ African Journal of Science and Technology, Science & Engineering Series. Vol 6, No. 1, PP 97-104

C.W. Hall.1970 Drying Farm Crops.C.W Hall, Drying Farm Crops, Lyall Book Depot., Ludhiana, India, pp 75-94

Zeleny, 1960 Moisture Measure-ment in Grain Industry, Cereal Science Today, Vol 5, pp 130-136,

Nelson S.O. and Samir Trabelsi. 2004 Principle for microwave moisture and density measurement in grain and seed. Journal of Microwave Power and Electromagnetic Energy, Vol 39(2), pp107-117,

Nelson, S.O .1987 Dielectric properties of cereal grain and their use in moisture sensing applications. International symposium on agricultural mechanization and international cooperation in high technology era – proceedings, April 3, The university of Tokyo, pp 289-298

Nelson, S.O. 1952 A method for determining the dielectric properties of grain. M.S. Thesis, Univ. Nebr. Libr.

Theraja B.L. 1980 A Text Book of Electrical Technology, Publication Division of Nirja Construction and Development Co. (P) Ltd., New Delhi, pp 98-99

Nelson, S.O. 1982 Factors affecting the dielectric properties of grain. Transaction of the ASAE, Vol.25(4), pp 1045-1049 and1056,

Nelson, S.O.1991 Dielectric properties of agricultural products measurements and applications. IEEE Transactions on Electrical Insulation 26(5):845-869.

M.C. Gough. 1983 Moisture Meter Calibration: A Practical Guide, Tropical Stored Product Information, Vol. 46, pp 17-24,

Mathur, A.P., 2002 Introduction to Microprocessor, TMH Publishing Company Ltd., New Delhi 139-145

D.V. Hall, 1986 Microprocessor interfacing programming and hardware, McGraw Hill Publisher

Gaonkar R.S. 1989 Microprocessor architecture, programming and application with 8085/8080A. Wiley Eastern Limited

Kant Krishna. 2010 Microprocessor Based Agri Instrumentation, Printice – Hall of India Pvt. Ltd., New Delhi,

Allen Mottershead. 1985 Electronic Devices and Circuits – an introduction, Prentice – Hall of India Pvt. Ltd., New Delhi, pp 50-59

Dass Bharati, A.K. Rai, Vinay Jharia and Deepak Sahu. 2010 Microcontroller Based Grain Moisture Measurement System Using Near Infrared Technology National Conference on Sensor Technology & Applications (STA’10), Feburary 22nd – 23rd Jabalpur Engineering College, Jabalpur, Madhya Pradesh, India

Government of India (GoI). 2017 Notification of Ministry of Consumer Affairs, Food and Public Distribution, Department of Food No 8-2.