1PG and Research Department of Microbiology, Sri Sankara Arts and Science College, Kanchipuram, Tamil Nadu, India

2Department of Biotechnology, School of Bio and Chemical Engineering, Sathyabama Institute of Science and Technology, Chennai, Tamil Nadu, India

3Department of Zoology – DDE wing, Annamalai University, Cuddalore District, Tamil Nadu, India

4Centre for Drug Discovery and Development, Sathyabama Institute of Science and Technology, Chennai, Tamil Nadu, India

5Senior Research Scientist (Biomarker) Department of Environmental Health Engineering Sri Ramachandra Institute of Higher Education and Research, Chennai, Tamil Nadu, India

Corresponding author email: kumarun23@gmail.com

Article Publishing History

Received: 10/10/2019

Accepted After Revision: 26/11/2019

Over the past decades, the feather waste degradation is one of the emerging problems due to the enormous wastes generated from poultry farms. In addition to poultry farms, the leather and wool industries are frequently producing million tons of keratin waste that have a negative impact on the environment. It emphasizes the critical need for research around the world on feather keratin hydrolysates. Therefore, nowadays the feather keratin hydrolysis product plays a significant role in the field of environmental research. Keratin is a tough protein and it is insoluble in nature and not easily degradable due to its chemical structure and the presence of various protease based enzymes. Thus, it creates inherent problems to the overall environment making it an ideal reason for the conversion of feather keratin into various protein hydrolysates which can be reusable. To avoid this issue, the feather keratin hydrolysates have been employed in divergent sectors such as chemical, cosmetic, pharmaceutical, agricultural and biomedical sector. In this review, we have explained the role of keratin in the production of biogas, plant promoting growth hormone, removal of hazardous industrial effluents, wound healing and various other biomedical applications.

Keratin; Feather waste; Degradation, Reuse

Santhiyaa RV, Aruni A. W, Suresh G, Balaji N. P, Barathi S, Pugazhvendan SR, Rajasekar T, Karthikeyan DR, Kumaran S. Applications of Feather Keratin Hydrolysate in Divergent Fields. Biosc.Biotech.Res.Comm. 2019;12(4).

Santhiyaa RV, Aruni A. W, Suresh G, Balaji N. P, Barathi S, Pugazhvendan SR, Rajasekar T, Karthikeyan DR, Kumaran S. Applications of Feather Keratin Hydrolysate in Divergent Fields. Biosc.Biotech.Res.Comm. 2019;12(4). Available from: https://bit.ly/2N2wNnS

Copyright © Santhiyaa et al., This is an open access article distributed under the terms of the Creative Commons Attribution License (CC-BY) https://creativecommns.org/licenses/by/4.0/, which permits unrestricted use distribution and reproduction in any medium, provide the original author and source are credited.

INTRODUCTION

Keratin protein has recently engrossed extensive interest owing to its ability to develop by-products using sustainable and renewable sources. It exists in various kinds of sources such as nails, wool, horn-hoof, hairs and feathers. Keratin is a major component of the discarded keratin, which belongs to the scleroprotein group and is made up of a chain of small amino acids with 10,500 Da molecular weight. The nature of this protein is greatly resistant to physiological, biological and chemical agents. It is insoluble in water due to the chemical structure of hydrogen bond, hydrophobic interaction and cross-linked disulfide bonds. In specific, the chicken meat processing industry is at a great focus towards sustainable market growth all over the world. Based on USA Foreign Agricultural Service post reports, consumption of chicken was about 59kg in US; 48 kg in Saudi Arabia, 67.1 kg in Hong Kong and 35.4 kg in Canada as a total domestic per capita (USDA Foreign Agriculture Service, 2014 Sharma et al., (2017). Inappropriately, the feathers thrown out are in low demand and most of them burned, landfilled or converted into feather meal and fed to livestock or used as fertilizers.

Discarded feathers cause major impend to human health diseases like fowl cholera and chlorosis. Every year, about 4 million tons of chicken feathers were generated by poultry processing industries (Xia et al., 2012).The disposable of chicken feathers in the environments causes pollution issues. In India, million tones of chicken feather wastes are generated every year from the poultry processing industries causing significant solid waste problems. The chicken feather does not degrade reluctantly due to the existence of β-Keratin. The β-Keratin is the chief constituent which exists in the chicken feathers. The chicken feather mainly comprises of 91% keratin, 1% fat and 8% of water (Shanmugasundaram et al., 2018).

It is tough to degrade even by the existence of proteases such as pepsin, trypsin and papain (Paul et al., 2013). Habitually, the disposal of these feathers is followed by few methods like incineration, alkali hydrolysis, steam pressure cooking and waste disposal sites. However, all of the above such methods not only make waste of highly rich amino acids present in the keratin but also cause production of greenhouse gases utilizing enormous amounts of energy ( Xia et al., 2012, Paul et al., 2013 Chen et al 2017).To circumvent these issues, keratin is regenerated into another form by chemical methods that may provide an alternative resolution. The cross- linked disulfide bonds are converted into non-cross linkage forms through oxidation and reduction methods. In reduction process, reductive agents such as sodium metabisulfite and mercaptoethanol are used to cleave the disulfide bonds into cysteine thiols, (Yang, Yao, & Wang, 2018).

The keratin can be hydrolyzed into keratin by the oxidation process, oxidative reagents such as peracetic acid are used to convert the disulfide bonds into cysteic acids whereby, the oxidized keratin is referred to as keratose (Yang et al., 2018). The feathers can also be biologically degraded by the action of microbial keratinase. The presence of disulfide bonds in keratin is reduced using the enzyme disulfide reductase due to the action of proteolytic keratinases that degrades the keratin into the byproducts of oligomeric and monomeric polymers (Paul et al., 2013). The enzyme keratinase can also be generated by a few microorganisms such as Bacillus sp, Rhizomucor, Aspergillus, Absidia, Tricophyton rubrum, Tricophyton mentagrophytes, Tricophyton gallinae, Microsporum gypseum, Microsporum canis, Streptomyces pactum and Streptomyces albus (Paul et al., 2013). The keratin which exists in the chicken feather have been degraded by various microorganisms such as thermophilic Bacillus species P-001A, Fervidobacterium pennavorans, Thermoactinomyces candidus, Pseudomonas aeruginosa, Aspergillus niger, Bacillus licheniformis, Microsporum fulvum IBRL SD3 and Streptomyces pactum DSM40530, (Santha et al., 2019).

The high quality keratins films are fabricated for the biomedical applications. The keratin obtained from the chicken feather can also act as a drug delivery system for the regeneration of bone. Typically, the biomaterials synthesized from the keratin were used to generate the drug delivery system and medical devices. The biomaterials are mainly utilized for the tissue regeneration applications such as cell proliferation, biocompatibility, promotion of cell growth etc. The keratin exhibits a good biocompatibility among the living organisms was proved by the clinical trials on animal models. Hence, the keratins were utilized for divergent biomedical applications. The keratin protein was also utilized for the various productions such as animal feed, keratin films, biodiesel, biogas and bioplastics. The combination of keratin and biopolymer viz gelatin, chitosan and alginate were blended to use for the development of 2D and 3D nanofibrous scaffold for the divergent applications such as skin regeneration, bone tissue engineering, biomedical, wound healing and cartilage tissue engineering (Shanmugasundaram et al., 2018).

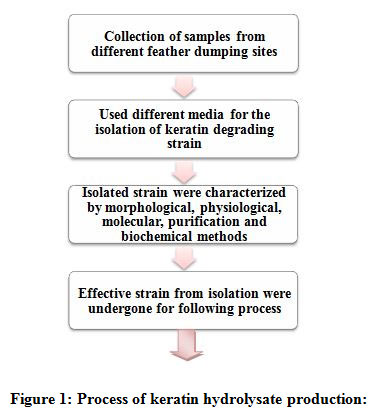

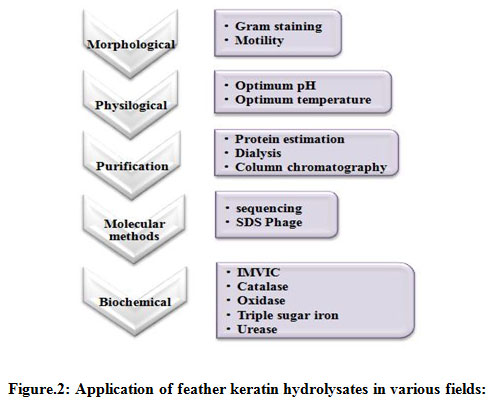

Fundamentally, these feather wastes are used as feed production for animals and are not economically feasible and its high cost. Nowadays, the utilization of such by-products of animal feed for animal production is also highly restricted. Therefore, the anaerobic digester is an alternative method due to it has material recovery and energy production (Forgács, Alinezhad, Mirabdollah, Feuk-Lagerstedt, & Horváth, 2011) (Xia et al., 2012). Exclusively, the keratin extracted from chicken feathers comprises of beta sheets and alpha helices and loops. It exhibits high concentration of nonessential amino acids like alanine, cysteine, glycine, serine, and valine even as essential amino acids such as tryptophan, methionine and lysine were exhibits at low concentration (Sharma et al., 2017) (Onifade,1998). Based on those treasured details, keratin is now widely employed in a variety of industries akin to medical, cosmetic, pharmaceutical and biotechnological industry (Sharma et al., 2017). The major keratinase productions and characterizations are given in Figure 1 & 2.

|

Figure 1: Process of keratin hydrolysate production |

|

Figure 2: Application of feather keratin hydrolysates in various fields |

Keratin in Biogas production

Keratin-rich chicken feather waste plays a dynamic role in the biogas production using a two-stage system. This stage comprises of two steps involved in the biogas production. Firstly, the pretreatment step was carried out proceeding to the biogas production. In this pretreatment step, the recombinant strains were employed to degrade the waste chicken feathers. Secondly, the acquired divergent feather hydrolysates following by various pretreatments were implemented for the biogas production. Vidmar and Vodvnik (2019) published an article according to regulation (EC) 1774/2002 of the European parliament, the third category of animal products with explicate meanings: The product obtained from animals, was not proposed for human consumption as it should not spread diseases to animals and humans. The animal processing waste can be used as substrate for bioenergy and value added products. In older methods, keratin treatments were done by alkaline and acidic hydrolysis, high pressure and high temperature to avoid contamination.

This requisite recombinant strain, B.megaterium might completely degrade the keratin-rich feather in prior to biogas production, which resulted in the highest yield (80%) of methane. In disagreement, the native keratinase producing B.licheniformis could yield about 66% of methane. From this, it has been clearly emphasized that the recombinant B.megaterium was more efficient in methane yield than the non-recombinant B.licheniformis. This is owing to the existence of xylose inducible promoter which controls the production of keratinase in the recombinant strain. As a result of this, the efficient keratin degrading enzyme was produced without exhibiting any lag phase during the entire process (Forgács et al., 2011). The high protein content of poultry feather waste is an excellent raw material of bio gas production. Mezes et al., (2019) reported the production of hydrogen sulphide which reached the maximum value. The anaerobic digestion process was achieved by the high bio gas yields as well.

Keratin – a plant promoting growth hormone

The literature states that the Paenibacillus strain has an ability to degrade feather and fabricates extracellular enzymes like nitrogenase, keratinase, xylanases and cellulase. Based on the phylogenetic analysis, it reveals that the Paenibacillus were available in various regions such as forest soil, wastewater and desert soil. The strain Paenibacillus woosongensis TKB2 was isolated from the soil. It is an effective chicken feather degrading bacterium used for the plant growth-promoting agent. Clain et al., (2019) suggested that protein hdyrolysates having bio stimulating properties are beneficial to plant growth. The result showed that Trichoderma isolates were screened for high enzyme activity. The fungal isolates were used as medium with keratin wastes. The output showed improved crop health. Peng and his team (2019) concluded that Stenotrophomonas maltophilia had effective feather degraders and to efficiently recycle the chicken feather waste they used S. maltophilia BBE11-1 which showed strongest feather degrading activity

Further, it has been shown that Bacillus licheniformis and arbuscular mycorrhizal fungi play an indispensable role in the field of agriculture. Where, B. licheniformis isolated from the chicken feather has the capability to degrade the feather and it also fabricates the indole acetic acid, ammonia and solubilize tricalcium phosphates. Moreover, the findings from pot experiments have revealed that faba bean seeds (Vicia faba L.) had potential plant growth in both soil inoculated with or without the combination of arbuscular mycorrhizal fungi (AMF) and bacterial feather hydrolysate (BFH) than the non-inoculated plants. It clearly emphasized, the advantage of using AMF and BFH as a biofertilizer in the agricultural fields, (Nafady, Hassan, Abd-Alla, & Bagy, 2018).

Keratin: potential in wound healing

Conventional wisdom holds on the application of keratinase enzyme in wound healing, the enzyme extracts obtained from the chicken feathers were widely utilized for the treatment of wound healing (Wang et al., 2017). These extracted keratins were used in invivo biocompatibility tests to treat the wound, where it provides a moist environment for the wound due to its high water content. It also has an ability to swell in order to absorb tissue exudates and existence of porous structure which supports cell adherence, cell proliferation and allow permeating the oxygen. In contrast to human keratin, feather keratin is easier to utilize owing to its dyeing and perming of human hair. Therefore, the hydrogels of feather keratin were developed by means of cross-linking reaction exists in the thiol groups with hydrogen peroxide. The keratin developed from the chicken feather exhibits a similar invivo biocompatibility, wound healing effects and biodegradation rates compared to the human hair keratin. As a result, the hydrogels of feather keratin could be employed for biomedical applications and wound healing (Wang et al., 2017).

The keratin-rich feather hydrolysate was merged with three various microbial exopolysaccharides such as agar, alginate and gellan to fabricate a therapeutic dermal patch. The dermal patches consist of different wound healing properties such as cell debridement to ensure the topical surface, antioxidant, antibacterial, antifungal as well as tensile strength, water swelling, biodegradability and porosity were also examined to provide the optimum condition for faster wound healing practice. The green synthesized silver nanoparticles were coated on the developed amalgamation patches to prevent the invasion of microbes in the wound. During the development of dermal patches, papain were used to form the enzymatic cell debridement and the activity was calculated by measuring the reduction rate of benzoyl-L-arginine ethyl ester as well as glucose oxidase was added into the patches to control the level of glycemic for topical applications. To improve the progress of wound healing, trolox was loaded in the production of dermal patches and fibroblast growth factor was used to regenerate the skin layer during the wound healing process. From the above, it has been stated that exopolysaccharides based keratins patches are well fitted as a dressing material for wound healing due to its several benefits (Nayak & Gupta, 2017).

Yet it has also been reported that the chicken feather keratin hydrolysate was utilized to synthesis non-woven wound dressings through chicken feather keratin and polysaccharides. The keratin hydrolysates were blended with the polysaccharides such as sodium alginate and chitosan to develop a non-woven wound dressing material such as keratin chitosan (CFK-CS-NW) and keratin sodium alginate (CFK-SA-NW). The fabricated dressing materials might be used for the application of wound healing owing to its physical characteristics like thickness, areal density and air permeability. It also exhibits a potential antibacterial activity in opposition to the Gram-negative bacteria such as Klebsiella pneumoniae, Escherichia coli and Gram-positive bacteria such as Staphylococcus aureus with an effective zone of inhibition. Through biocompatibility test in both invitro and in vivo it concluded that the developed non-woven dressing materials were non-toxic, able to heal the excision wound quickly it also has an ability to support the cell growth. In contrast, the treated chicken feather keratin with chitosan and sodium alginate shows good result than the untreated CFK control group. Hence, the developed feather keratin could be an excellent alternative in the realm of biomedical (Shanmugasundaram et al., 2018).

Keratinase enzyme- an effective environmental pollutant removal

Opportunely, the isolated Alcaligenes were employed in various applications such as the production of keratinase enzyme as well as degradation of chicken feathers and heavy metals. The keratinase enzyme was fabricated up to 10 fold 88.4 U/ml where the highly toxic heavy metals were completely degraded within 36hrs due to the enhanced keratinase activity. Therefore, the heavy metal resistant bacterium such as Alcaligenes has been proved to play an efficient role in the degradation of highly toxic heavy metals and chicken feather wastes for the first time in the field of research. It also been reported that the chicken feather wastes were used in the removal of various heavy metals from the industrial effluents as well as the chicken feather also used as a substrate in the production of keratinase enzyme (Yusuf et al., 2016).

Chicken feathers have attractive physiological properties like low density, low thickness 0and warmth retention, high compressibility all of which make it a remarkable fiber than any other natural or engineered filaments. Added advantage of such remarkable fiber reduces the toxicity of arsenite and sulfate. The powdered form of chicken feathers was used as an organic nutrient source for sulfate-reducing bacteria (SRB) as well as arsenic (III) immobilization. When the powdered chicken feathers were alone act as a carbon source for the sulfate-reducing bacteria, the efficacy in the removal of arsenic (III) and sulfate were decreased. On the other hand, the removal of sulphate and arsenic (III) were enhanced from 30% to 80% in the existence of sodium lactate and powdered chicken feathers. Thus, it has been proved that the powdered chicken feathers incorporated with other electron donors can be utilized as an organic nutrient source for sulfate-reducing bacteria (SRB). The arsenic (III) as well as sulfate was removed from the medium, along with the growth of SRB. The removal of arsenic was interconnected with the reduction of sulfate in the absence of powdered chicken feathers (PCF), however in the existence of PCF; the removal of arsenic (III) is not directly linked with the reduction of sulfate (Costaet al., 2014).

The chicken feather waste consists of rich keratinase enzymes were employed in the degradation of crude oil hydrocarbon. The study reveals that the presence of keratinous waste, the removal of crude oil hydrocarbons were increased (57,400 mg l-1) when compared to the absence of keratinous waste (35,600 mg l-1). From the results of chromatographic techniques, it depicts that the incorporation of keratinous wastes were not only removed the aliphatic carbons, however it also changes the pattern of removal of the crude oil hydrocarbons (Cruz-Cumarillo & Avelizapa,

2009).The bioadsorbents are keratin based was developed to treat the hazardous dye effluents. The three dimensional bioadsorbent were fabricated by impregnating with cellulose nanocrystal (CNC) as well as augmented with sponge matrix of keratin to remove the dyes. It was used in waste water treatment due to the existence of various physical characteristics such as large specific surface area, high porosity and abundant adsorption sites in the developed adsorbent. In addition, the keratin augmented adsorbent can be reused for several times owing to its regenerability and reusability. The bio adsorbent shows good result in the fixed bed column by the removal of 80% dyes such as direct red 80 and reactive black 5. Therefore, the chicken feather keratin based bio adsorbent has proven to be a promising technique and exhibits excellent performance in waste water management, hence, it can be of aid to protect the environment (Song, et al 2017).

Keratin in textile industry and leather industry

The keratins extracted from the chicken feather were utilized in textile industries as sizing warp agents in the garment industry. Basically, polyvinyl alcohol has been used earlier as sizing agent in the textile industries. It was non toxic and biodegradable. However, it degrades gradually. To overcome this issue, keratin from chicken feather were used as a sizing agent instead of polyvinyl alcohol. It provides the same strength improvements and cohesion like PVA but it differs by exhibiting the low scratch resistance on garments such as polyester/cotton and polyester. In addition, the keratin exhibits a significant role in the reduction of chemical oxygen demand while comparing to polyvinyl alcohol. Therefore, chicken feather keratin could be an excellent replacement to polyvinyl alcohol as a size warping agent on account of biodegradable, inexpensive and mainly act as an adequate sizing agent (Reddy et al., 2014).The poultry waste of chicken feather acts as substrate and assist to fabricate the keratinase enzyme production from the keratinolytic bacterium such as Bacillus paralicheniformis MKU3. The synthesized keratinase enzyme was helped out to degrade the feather waste. It can degrade upto 90% of chicken feather wastes. The study also stated that the fabricated keratinase enzyme from the bacterium Bacillus paralicheniformis MUK3 plays an indispensable role in the leather industry owing to it ability in the removal of hair from the sheep skin. It exhibits 100% of results in the dehairing process as well as it aids to avoid the usage of chemicals in the dehairing process (Santha Kalaikumari et al., 2019).

Keratin-a bioactive potential exhibit free radical scavenging as well as anticancer activities

The hydrolysates of chicken feather were acquired by submerged cultivation accompanied by Chryseobacterium sp. Kr6. The antioxidant activity of the supernatant culture was estimated through ABTS radical scavenging method and partially purified using gel-filtration chromatography. Therefore, the bioconversion of chicken feathers with Chryseobacterium sp. Kr6was resulted in protein hydrolysates and consists of potent bioactive peptides with antioxidant properties (Fontoura et al., 2018). Sharma and his team (2017) reported the feather keratin was hydrolyzed by the method of chemical treatment in the alkaline condition. The Keratin based microparticles were examined for the in vitro anticancer activities through sulforhodamine B (SRB) assay in opposition to cell lines such as SK-OV-3, A549 and HeLa. In addition, the cytotoxicity assay was examined towards the cell line by Malin Darby canine kidney (MDCK) and the antioxidant assay was also investigated by the method of DPPH and ABTS. Therefore, the biosynthesized microparticles exhibit a potential anticancer property towards the cell line of SK-OV-3, HeLa and the potent free radical scavenging activity against the ABTS and DPPH method.

CONCLUSION

This review has emphasized about the nature of fibrous keratin with various solicitations which are all eco-friendly methods. As a consequence, there is wide spread interest in utilizing these methods to effectively use the keratinase enzyme. In a way, the magnificent amount of progress has been made in this direction, which actively engaged in method development not only economical but also for better managing of keratinous wastes. Over a last few decades, various pretreatment were performed to enhance the degradability of the keratin containing substances in order to prevent the environmental issues. In contrast, the high-value keratin is one of the important fibrous proteins that have essential value in bio-resource and fertilizer domain. The chicken feather waste can be useful by product of various industries. The hdyrolyzate can also be a nitrogenous fertilizer, bio gas production, animal feed, etc., The hydrolyzate contain rich amino acids for poultry feed development. Hence in future the keratin degraded product can become support a industry level production.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the management of Sathyabama Institute of Science and Technology, Chennai and the Professor K. R. Venakatesan, Principal, Sri Sankara Arts and Science College, Kanchipuram for their help and cooperation.

REFERENCES

Calin, M., Raut, I., Liliana., M., Capra L.,Gurban, M., Doni, M., & Jecu Luiza., (2019) Applications of fungal strains with keratin-degrading and plant growth promoting characteristics. Agronomy, 9, 543.

Cervantes-González, E., Rojas-Avelizapa, L. I., Cruz-Camarillo, R., & Rojas-Avelizapa, N. G. (2009). Effect of keratinous waste addition on improvement of crude oil hydrocarbon removal by a hydrocarbon-degrading and keratinolytic mixed culture. International Biodeterioration and Biodegradation, 63(8), 1018-1022.

Chen, P., Liu, X., Jin, R., Nie, W., & Zhou, Y. (2017). Dye adsorption and photo-induced recycling of hydroxypropyl cellulose/molybdenum disulfide composite hydrogels. Carbohydrate Polymers, 167, 36–43. https://doi.org/10.1016/j.carbpol.2017.02.094;

Costa, P. F., Matos, L. P., Leão, V. A., & Teixeira, M. C. (2014). Bioremoval of arsenite and sulfate by a mixed culture with sulfate-reducing capacity growing on powdered chicken feathers. Journal of Environmental Chemical Engineering, 2(1), 70–75. https://doi.org/10.1016/j.jece.2013.11.022;

Fontoura, A. R., Daroit, D. J., F, A. P., Moresco, K. S., Walter, O., Iii, J. R. Y., & Brandelli, A. (2018). SC. New Biotechnology. https://doi.org/10.1016/j.nbt.2018.09.003;

Forgács, G., Alinezhad, S., Mirabdollah, A., Feuk-Lagerstedt, E., & Horváth, I. S. (2011). Biological treatment of chicken feather waste for improved biogas production. Journal of Environmental Sciences, 23(10), 1747–1753. https://doi.org/10.1016/S1001-0742(10)60648-1;

Jeong, J. H., Lee, O. M., Jeon, Y. D., Kim, J. Do, Lee, N. R., Lee, C. Y., & Son, H. J. (2010). Production of keratinolytic enzyme by a newly isolated feather-degrading Stenotrophomonas maltophilia that produces plant growth-promoting activity. Process Biochemistry, 45(10), 1738–1745. https://doi.org/10.1016/j.procbio.2010.07.020;

Mezes, L., Tamas J, Juhasz, C., & Matyas, B. (2014) Feather waste recycle for biogas production. 2nd International conference on sustainable management: at Athen.

Nafady, N. A., Hassan, E. A., Abd-Alla, M. H., & Bagy, M. M. K. (2018). Effectiveness of eco-friendly arbuscular mycorrhizal fungi biofertilizer and bacterial feather hydrolysate in promoting growth of Vicia faba in sandy soil. Biocatalysis and Agricultural Biotechnology, 16, 140–147. https://doi.org/10.1016/j.bcab.2018.07.024;

Nayak, K. K., & Gupta, P. (2017). Study of the keratin-based therapeutic dermal patches for the delivery of bioactive molecules for wound treatment. Materials Science and Engineering C, 77, 1088–1097. https://doi.org/10.1016/j.msec.2017.04.042.

Onifade, A.A., Al-Sane, N.A., Al-Musallam, A.A., & Al-Zarban, S. (1998). A review : potentials for biotechnological applications of keratin degrading microorganisms and their enzymes for n nutritional improvement of feathers and keratinase as livestock. Bioresource Technology, 66, 1–11.

Paul, T., Halder, S. K., Das, A., Bera, S., Maity, C., Mandal, A., & Mondal, K. C. (2013). Exploitation of chicken feather waste as a plant growth promoting agent using keratinase producing novel isolate Paenibacillus woosongensis TKB2. Biocatalysis and Agricultural Biotechnology, 2(1), 50–57. https://doi.org/10.1016/j.bcab.2012.10.001

Peng, Z., Map, Xzhang, J., Du, G., & Chen J., (2019). Effective biodegradation of chicken feather waste by co-cultivation of keratinase producing strains. Microbial Cell Factory. 18,84.

Reddy, N., Chen, L., Zhang, Y., & Yang, Y. (2014). Reducing environmental pollution of the textile industry using keratin as alternative sizing agent to poly(vinyl alcohol). Journal of Cleaner Production, 65, 561–567. https://doi.org/10.1016/j.jclepro.2013.09.046

Santha Kalaikumari, S., Vennila, T., Monika, V., Chandraraj, K., Gunasekaran, P., & Rajendhran, J. (2019). Bioutilization of poultry feather for keratinase production and its application in leather industry. Journal of Cleaner Production, 208, 44–53. https://doi.org/10.1016/j.jclepro.2018.10.076

Shanmugasundaram, O. L., Syed Zameer Ahmed, K., Sujatha, K., Ponnmurugan, P., Srivastava, A., Ramesh, R., Elanithi, K. (2018). Fabrication and characterization of chicken feather keratin/polysaccharides blended polymer coated nonwoven dressing materials for wound healing applications. Materials Science and Engineering C, 92, 26–33. https://doi.org/10.1016/j.msec.2018.06.020

Sharma, S., Gupta, A., Chik, S. M. S. T., Kee, C. G., Mistry, B. M., Kim, D. H., & Sharma, G. (2017). Characterization of keratin microparticles from feather biomass with potent antioxidant and anticancer activities. International Journal of Biological Macromolecules, 104, 189–196. https://doi.org/10.1016/j.ijbiomac.2017.06.015

Song, K., Xu, H., Xu, L., Xie, K., & Yang, Y. (2017). Cellulose nanocrystal-reinforced keratin bioadsorbent for effective removal of dyes from aqueous solution. Bioresource Technology, 232, 254–262. https://doi.org/10.1016/j.biortech.2017.01.070

Vidmar, B., & Vodovnik M. (2018). Microbial keratinases: enzymes with promising biotechnological applications. Food Technology and Biotechnology, 56 (3). doi: 10.17113/ftb.56.03.18.5658

Wang, J., Hao, S., Luo, T., Cheng, Z., Li, W., Gao, F. Wang, B. (2017). Feather keratin hydrogel for wound repair: Preparation, healing effect and biocompatibility evaluation. Colloids and Surfaces B: Biointerfaces, 149, 341–350. https://doi.org/10.1016/j.colsurfb.2016.10.038

Xia, Y., Massé, D.I., McAllister, T.,A., Beaulieu, C., & Ungerfeld, E. (2012). Anaerobic digestion of chicken feather with swine manure or slaughterhouse sludge for biogas production.WasteManagement,32(3),404–409. ttps://doi.org/10.1016/j.wasman.2011.10.024

Yang, G., Yao, Y., & Wang, X. (2018). Comparative study of kerateine and keratose based composite nanofibers for biomedical applications. Materials Science and Engineering C, 83, 1–8. https://doi.org/10.1016/j.msec.2017.07.057

Yusuf, I., Ahmad, S. A., Phang, L. Y., Syed, M. A., Shamaan, N. A., Abdul Khalil, K., Shukor, M. Y. (2016). Keratinase production and biodegradation of polluted secondary chicken feather wastes by a newly isolated multi heavy metal tolerant bacterium-Alcaligenes sp. AQ05-001. Journal of Environmental Management, 183, 182–195. https://doi.org/10.1016/j.jenvman.2016.08.059.