Research Laboratory-III, Department of Chemical Engineering, Sant

Longowal Institute of Engineering and Technology, Punjab, India.

Corresponding author email: akash_pce1801@sliet.ac.in

Article Publishing History

Received: 21/06/2021

Accepted After Revision: 25/09/2021

In the past two decades, global warming has increased abruptly due to human-induced activities. The contribution of CO2 implies 74.4% and adheres to the most significant impact on observed global warming. In contrast, 66% of total CO2 emission is from fossil-fuel combustion. Carbon Capture and Sequestration (CCS) is an innovative solution to curb the rising level of CO2 from point emitting sources. The current work proposes a novel search criterion for patent extraction on CCS-based technologies, as well as an assessment of the leading patent technologies related with CCS. The patent retrieval was carried out using the commercial database ‘Relecura’ of Relecura Technologies Pvt. Ltd. in order to measure global technological growth via patent life, claims, forward citations, patent strength, top assignees, and ultimate parent.

During the implication of search filter and manual screening, 3376 patents were found globally. China and the United States (U.S.) contribute to 2099 patents, with a share of 62% globally. In context to technology, most research and innovation focus on post-combustion capture. A low number of patents publications were observed on oxy-fuel, algal, and Cryogenic Carbon Capture (CCC) technology. The study also revealed that General Electric Company ranks highest in filing patents compared with other industries. Amine-based post-combustion capture was found to be the most mature and globally available technology. However, ILs (Ionic Liquids), MOF’s (metal-organic framework), membrane and CCC tends to be emerging technology. The current article provides readers an insight about the recent developments, technological drift, major patent filing organizations, and the status of CCS globally.

Carbon Dioxide Capture, CPC Codes, Greenhouse Gas, IPC Codes, Patent Assessment.

Sood A, Thakur A, Ahuja S. M. A Novel Patent Assessment Criterion for Carbon Dioxide Capture Technologies. Biosc.Biotech.Res.Comm. 2021;14(3).

Sood A, Thakur A, Ahuja S. M. A Novel Patent Assessment Criterion for Carbon Dioxide Capture Technologies. Biosc.Biotech.Res.Comm. 2021;14(3). Available from: <a href=”https://bit.ly/3CTiLgf“>https://bit.ly/3CTiLgf</a>

Copyright © Sood et al., This is an open access article distributed under the terms of the Creative Commons Attribution License (CC-BY) https://creativecommns.org/licenses/by/4.0/, which permits unrestricted use distribution and reproduction in any medium, provide the original author and source are credited.

INTRODUCTION

In recent years, the consumption of fossil fuels has raised the level of CO2 at an extreme level of 419.13 ppm, whereas the risen level of CO2 is way above the permissible level of 350 ppm (Lab 2021). Until the year 2100, it is estimated to reach around 750 ppm if no such steps for abatement in CO2 emission were considered. In the current scenario of 2019, China tops the Greenhouse gases (GHG) emissions followed by U.S., India, and Russia; these top emitters produce approx. 55% of global CO2 emissions However, CCS technologies are promising and significantly affect emission reduction targets. A brief history was studied to find the initiation of CCS technology. The beginning of capturing CO2 starts in the late ’70s where this technology was considered emerging in abatement of GHG emissions (Kurihara and Shirayama 2004; Petroleum 2020).

Furthermore, in the chemical and natural gas sectors, CO2 separation was done using chemical and natural gas, in which CO2 was regarded as an impurity. In 1991, the Norwegian government was the first to introduce the carbon tax, which became a milestone in policy planning (Kaarstad 2002). The IPCC conducted a workshop on Carbon Capture and Storage with WMO and UNEP at Regina, Canada in 2002, intending to produce scoping paper on possible ways to assess CCS (Davidson and Metz 2002). The first decision to apply underground storage of CO2 captured from natural gas as a climate change mitigation effort – was taken by Statoil and partners in the Sleipner North Sea license in 1990 (Kaarstad 2002; Sood and Vyas 2017; Sharma et al. 2020).

The IPCC produced a Special Report on CCS in (2005), which elaborates the role of CCS to climate policy expert community (Kheshgi et al. 2012)In 2006 Carbon Capture & Storage Association (CCSA) was formed to promote CCS business; after COP/MOP-11, the rapid growth in CCS was noted (Qiu and Yang 2018). In recent years only a few patent assessment articles on CCS were published (Li et al. 2013; Qiu and Yang 2018; Míguez et al. 2020). Nonetheless, not one of them offers a detailed explanation of the patent search criteria.

This article sets out to design a search query that extracts relevant patents and ranks them depending on how much the parent organization influences its related entities. The article is divided into five sections, beginning from section 1 as the introduction, which briefs the requirement and past developments. However, section 2 explains the methodology and patent retrieval task. Then, the analysis of patent information was done in section 3 whereas, section 4 states the policy implications and future perspectives of the current article, and section 5 refers to the conclusion.

METHODOLOGY

A large majority of patents pertain to little value and only a few pertain high impact value in terms of finance, innovation and research implementation on the ground. Further, the significant impact in value was observed by only the top 10% of patents of the total sample value. The technological capabilities and strategies of an assignee could be effectively determined by analyzing the quality of its patent based on indicators that have been used to assess the value and quality of the patent, like the number of patents cited, citation of the particular patent, patent family size, technological strength, renewal trend and others. However, the extraction of such data in bulk is not available on the open platform. Therefore, an artificial intelligence-based platform named “Relecura” was used (Og et al. 2020).

However, during the patent search, it was observed that the majority of patents found through keywords were misleading and generate garbage value. Therefore, accurate indicators related to the concerned field were used to remove irrelevant data from the search result. Furthermore, during the literature survey, it was observed that the patent classification system follows a hierarchy, and the common classification systems around the world are: (a) International Patent Classification (IPC) and (b) Cooperative Patent Classification (CPC).

Thus, we considered both CPC and IPC codes to incorporate all at once in the current article. The patent retrieval work has been divided into four phases: Phase-I (a) Determination of initial keywords, (b) Determination of CPC and IPC sections and subsections of relevancy. Phase-II: Determination of relevant keywords and finalizing query. Phase-III: Query-based search with filters. Phase-IV: Extraction of data (Shalaby and Zadrozny 2019; Og et al. 2020).

In phase-I, the patents on CCS were studied and keywords were extracted. Later, the CPC and IPC libraries, including their sub-sections, were deeply studied and the relevant codes were extracted. The finalised IPC codes are “B01D19/00, B01D47/00, B01D53/00, B01D53/02, B01D53/04, B01D53/06, B01D53/14, B01D53/18, B01D53/22, B01D53/26, B01D53/32, B01D53/34, B01D53/40, B01D53/46, B01D53/47, B01D53/48, B01D53/50, B01D53/52, B01D53/56, B01D53/60, B01D53/62, B01D53/72, B01D53/73, B01D53/74, B01D53/75, B01D53/77, B01D53/78, B01D53/81, B01D53/83, B01D53/84, B01D53/86, B01D53/92, B01D53/96, B01D61/00, B01D63/02, B01D67/00, B01D69/00, B01D69/02, B01D69/08, B01D69/10, B01D69/12, B01D69/14, B01D71/02, B01D71/06, B01D71/64, B01D71/70, B01J19/00, B01J20/02, B01J20/04, B01J20/06, B01J20/08, B01J20/10, B01J20/18, B01J20/20, B01J20/22, B01J20/26, B01J20/28, B01J20/30, B01J20/32, B01J20/34, C01B13/02, C01B17/16, C01B21/04, C01B23/00, C01B3/02, C01B3/34, C01B3/38, C01B3/48, C01B3/50, C01B3/52, C01B3/56, C01B31/20, C01B32/40, C01B32/50, C01B32/60, C01F11/18, C07C7/00, C07C7/11, C07C7/12, C07C9/04, C09K3/00, C10K1/00, C10K1/12, C10K1/14, C10K1/16, C10L3/10, C12M1/00, F01N3/08, F17C11/00, F23J15/00, F23J15/02, F23J15/04, F25J1/00, F25J1/02, F25J3/00, F25J3/02, F25J3/04, F25J3/06, F25J3/08, H01M8/06 OR Y02C-010/02+ OR Y02C-010/04+ OR Y02C-010/06+ OR Y02C-010/08+ OR Y02C-010/10+ OR Y02C-010/12+ OR Y02C-010/14+)”

To decrease the possibility of overlapping, finalized codes were also co-related with their appropriate CPC. Later, a literature review was conducted in second phase to choose acceptable keywords for further minimising junk data. As indicated in Table 1(a), the completed keywords containing approximately all technologies linked to CCS were included in the search query, which comprised technological terms and their probable synonyms (Abbas et al. 2014; Moullec et al. 2014; Liu et al. 2018; Norhasyima and Mahlia 2018; Qiu and Yang 2018).

Table 1 (a). Technology-based keywords inclusive of the final query

| S. No. | Technology Based Keywords | Synonyms | Search domain | Refined Keyword | Final Query |

| 1 | CO2 | Carbon, Carbon dioxide, Carbonic Acid Gas, Carbonic Acid, CO2 | Title, Abstract and Claims | CO2, Carbon*, Carbon dioxide | (CO2 OR Carbon* OR (Carbon NEAR2 dioxide)) |

| 2 | Capture | Capture, Capturer, Captured, Capturing, Seize, Seizure | Title, Abstract and Claims | Capture*, Seiz* | (Capture* OR Seiz*) |

| 3 | Storage | Storage, Storing | Full text | Storag* | (Storag*) |

| 4 | Absorption | Absorb, Absorbing, Absorption, Absorbent | Full text | Absor* | (Absor*) |

| 5 | Transport | Transport, Transporting, Transportation | Full text | Transport* | (Transport*) |

| 6 | Sorbent | Sorbent | Full text | Sorbent | (Sorbent) |

| 7 | Delivery | Deliver, Delivering, Delivery, Delivered | Full text | Deliver* | (Deliver*) |

| 8 | Adsorption | Adsorb, Adsorbing, Adsorption, Adsorbent | Full text | Adsor* | (Adsor*) |

| 9 | Separation | Separate, Separation, Separating | Full text | Separat* | (Separat*) |

| 10 | Sequestering | Sequester, Sequestering | Full text | Sequest* | (Sequest*) |

| 11 | Acid Gas | Acid Gas, Acidic Gas, Acidic Gases, Acid Gases | Full text | Acid*, Gas* | (Acid* NEAR2 Gas*) |

While study it was discovered that merely technological synonyms were incapable of extracting the entire CCS technological domain patents. As a result, as stated in Table 1(b), the general keywords of CCS technologies were also incorporated in the current syntax. A search for “OR”, “AND”, and “NEAR” operators, together with “all” in-field operator, was conducted. At first, the search string was limited to keywords from which 22,676 families were discovered out of 47,111 documents. The categorization search was done with a 100 IPC and CPC filter, and the result was a list of 3,680 families of 9,542 patent documents. Phase IV entails reviewing data gathered from patents to ensure their relevance.

Table 1 (b). General keywords inclusive of the final query

| S. No. | General Keywords | Synonyms | Search domain | Refined Keyword | Final Query |

| 1 | Pre-Combustion Capture | Pre-Combustion Capture, PCC, Pre-Combustion | Full text | Pre, Combustion, PCC | (Pre NEAR2 Combustion) |

| 2 | Post-Combustion Capture | Post-Combustion Capture, PCC, Post-Combustion | Full text | Post, Combustion, PCC | (Post NEAR2 Combustion) |

| 3 | Oxy-Fuel Combustion | Oxy-Fuel Combustion, Oxy/Fuel | Full text | Oxy, Fuel | (Oxy NEAR2 Fuel) |

| 4 | Membrane Separation | Membrane Separation | Full text | Membrane, Separation | (Membrane NEAR2 Separation) |

| 5 | Cryogenic Carbon Capture | Cryogenic Carbon Capture, CCC, Cryogenic Capture | Full text | Cryogenic, Capture, CCC | (Cryogenic NEAR2 Capture) |

Validation of patent search: A comparative analysis of patent review has been carried out to verify the search string as described in Table 2. The data of patents published in the U.S. and China till 2015 was compared with current search filters and keywords. The results show a slightly higher value than previously published data due to the low selectivity of keywords. Later, while the deep study of patent documents it was observed that no keyword search is perfect as the total relevant patents found were 3376, which concludes to the accuracy of keywords to 91.76% (Qiu and Yang 2018).

Table 2. Comparative analysis

| S. No. | Search domain | Year | Patents | Search engine | Ref. |

| 1 | Global | 2015 | 2325 | Innography | (Qiu and Yang 2018) |

| 2 | Global | 2015 | 2546 | Relecura | Current paper (priority date) |

| 3 | Global | 2020 | 3376 | Relecura | Current paper (priority country code) |

| 4 | U.S. and China | 2015 | 1171 | Innography | (Qiu and Yang 2018) |

| 5 | U.S. and China | 2015 | 1295 | Relecura | Current paper (priority date) |

| 6 | US and China | 2020 | 2099 | Relecura | Current paper (priority country code) |

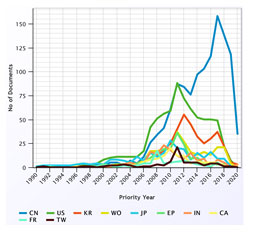

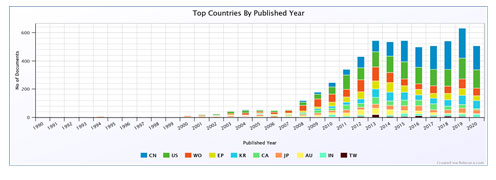

Statistical Summary: In most nations, patents can be awarded for a term of 20 years; however, in Australia and Japan, the time can be extended. Each nation charges a unique fee to keep the patent valid. Table 3 shows the annual fees for the various patent offices. The annual distribution of patents and their applications elucidates the evolution of R&D in CCS across its numerous technological fields. Figure 1 depicts the granted patents in CCS from the top ten nations in order to visualise the efforts and maturity in CCS-based technologies. It was also discovered that the U.S. and China accounted for 62% of all patents published worldwide (Wang and Song 2020).

Table 3. Annual fee and structure of renewal of major patent offices

Note:- The abbreviations used for patent office’s in above are EPO (European Patent Office), USPTO (United States Patent and Trademark Office), IPO (Intellectual Property Office), IP Australia, CNIPA (China National Intellectual Property Administration), JPO (Japanese Patent Office), INPI (France’s Institut National de la Propriété Industrielle | National Industrial Property Institute), Deutsches Patent- und Markenamt (DPMA) – the German Patent and Trade Mark Office, CIPO (Canadian Intellectual Property Office), KIPO (Korean Intellectual Property Office), CGPDTM – The Office of the Controller General of Patents, Designs and Trade Marks | Indian Patent Office.

Figure 1: Top 10 countries V/s Priority year of patents

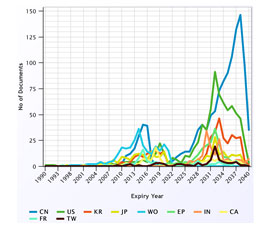

Figure 2: Top 10 countries V/s expiry year of patents

China’s ability to leverage CCS will accelerate in the coming years due to present trends in patents. However, Figure 2 illustrates the expiration year in which both the U.S. and China imprint significant peaks of patents in large.

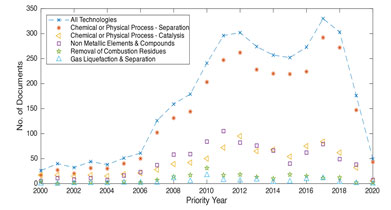

Figure 3: Technological trend per year

During critical analysis, it was observed that some of the patents were in a unique field. Still, most patents do not belong to a single domain of technology comprising two or more IPC technological fields of expertise. The top five technologies according to IPC classification shown in Figure 3. The chemical or physical (inclusive of separation and catalysis) process-based patents were on the top and comprised around 84% share.

Figure 4: Technological trend per year

A global patent publishing analysis was also done to analyze the patent filing per year to evaluate the growth in technology worldwide. A plot was generated, as illustrated in Figure 4. The data revealed that a rise in levels was observed from 2008. However, the maximum numbers of publications were noted in 2019.

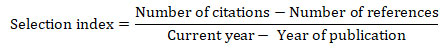

Technological assessment: Most review articles only review research publications; however, the patented technologies were left untold. Therefore, to emphasize the significant development scenario of the patent status of CCS, the article is sub structured into eight subsections where recent and key technological benchmarks has been reviewed. Two approaches were implemented for the selection of patents. First, based on the back citation, the patents with the least referring documents and the maximum number of citations were assumed impactful.

However, it was also observed that the latest patents might not achieve many citations. Therefore, another method was also used considering technological breakthroughs in industrial applications, and patents with the maximum number of families were treated to be the best among all while keeping the constraint of low citing documents in the particular patent (Wang and Song 2020).

Pre-Combustion capture: Pre-combustion capture involves the reaction of a fuel with oxygen or an air stream to produce a synthesis gas (syngas) which is composed of CO and H2. Whereas, produced CO is made to react with steam to give CO2 and additional H2. The CO2 is then separated using physical or chemical absorption. Pre-combustion capture provides high purity rates and a high-efficiency potential. However, the major drawback of pre-combustion is the high capital investment, which leads to a low number of IGCC plants globally. Generally, three commercial pre-combustion technologies were used: (a) Rectisol-based, (b) MDEA-based, and (c) Selexol-based. Pre-combustion envisaged to capture CO2 before combustion or, in other words, can be described as the process of treatment of synthetic gas principally composed of CO2 and hydrogen. In recent years, pre-combustion technology has risen and is commonly employed in IGCC or NGCC plants (Wang and Song 2020).

Di-substituted siloxane solvents with 2 to 4 Si atoms were introduced in US10589228B2, which was covalently modified with polyethylene glycol; however, the solvent inherits the capability to replace glycol-based solvents due to their high-temperature workability and low foaming characteristics (Hopkinson et al. 2020).

Post Combustion capture: The post-combustion carbon capture technique is usually used in coal plants. The carbon is captured after the fuel combustion in conjunction with the purification of the flue gases. After combustion, the methods for carbon separation include absorption in a solvent, adsorption, membrane filtration, and cryogenic separation (Chiang and Pan 2017; Rackley 2017; Subramanian et al. 2017). The most significant advantage of post-combustion is getting the maximum degree of purity (≥ 99.99%). When integrating post-combustion with power plant processes, no significant adjustments were necessary for the power plant processes. However, high investment costs and reduced operational flexibility of power plants equipped with post-combustion units are downsides of the post-combustion process (Rackley 2017; Hopkinson et al. 2020).

Water washing was employed in the early days to remove CO2 from the gas stream. Later, after the advent of amines as a substitute for ammonia, technical drift was observed US1783901A (Bottoms 1930). However, unlike other solvents, amines have a low energy regeneration capacity and great selectivity; this patent started the CO2 capture trend as a foundation for CCS in post-combustion capture systems. The technology was surpassed by US1897725A, which described the first extraction of CO2 using a succession of scrubbing towers using aqueous ammonia (Wilhelm and Walter 1933; Jovanovic and Krishnamurthy 2020).

In US20200147544A1, a method for producing a CO2-containing flue gas was devised by combusting a carbonaceous fuel in a high pressure steam generating unit with combustion air and capturing the CO2 in the flue gas, which was at least partially captured and compressed into CO2 (Clerveaux and Lefebvre 2019). In CN108295802A potassium based CO2 absorbents granules posing low temperature decarburization properties along with good mechanical and fluidization characteristics was synthesized however, the developed absorbent includes active component as potassium carbonate with activated alumina, aluminous cement, kaolin or aluminium hydroxide as carrier (Yafei et al. 2018; Jovanovic and Krishnamurthy 2020).

Oxy-fuel combustion capture: In oxy-fuel combustion, pure oxygen or oxygen-enriched air is used for combustion purposes. However, combustion products are CO2, water vapour and oxygen. The plant process must include an air separation process, flue gas processing unit and a CO2 processing unit. Whereas, lack in the commercial application was for two major reasons, (a) requirement of a specialized oxy-fuel boiler and (b) NOx production (Yoro and Sekoai 2016; Jovanovic and Krishnamurthy 2020).

However, the initial development of recirculation power production technology was started with the burning of fuel and high-concentration oxygen. EP1592867B1 was subsequently introduced and oxygen fuel technology was demonstrated for improved efficiency and cost-effective CO2 collection from enhanced flue gas (Lynghjem et al. 2016). CN108729965A invented a novel extraction process to help combustion in the power plant using oxygen-enriched flue gas, resulting in increased boiler outlet concentration to 30%-60% and posing CO2 capture efficiency ≥ 95% (Xiaoqian et al. 2018). KR102048844B1 was designed by combining a liquified air re-gasification system with a coal fired plant and a CCS unit, which considerably enhances CO2 separation and removal efficiency as well as overall power generation (Nam et al. 2019).

Membrane: In application to CCS the separation of CO2 focuses on flue gas stream before the subsequent transportation and storage/utilization of captured CO2. The prime focus towards membrane separation was its applicability in a continuous system, preferred by industrial and power generation sectors. Membrane separation is one of the few technologies that demonstrates its applicability in all three capture technologies. For post-combustion capture: CO2/N2 separation from flue gas, pre-combustion capture: CO2/H2 separation for IGCC processes, natural gas refining: CO2/CH4, and similarly in oxy-fuel combustion capture: O2/N2 separation for air separation (Lee et al. 2020).

In KR20200015664A, an apparatus was constructed to collect high-concentration CO2 using a low-temperature membrane separation technique, which dramatically minimizes cooling energy demand. CN111111464A developed composite membrane technology involving electrospun polyacrylonitrile fibre film layer and cyclodextrin MOF layer posing enhanced gas selectivity. A CO2 capture system and pre-treatment technique has been developed by CN110813047A utilizing sodium-based weak alkaline absorbent as a pre-treatment (Xiaofu et al. 2019a; Lee et al. 2020). CN211358301 invented a utility model to pre-treat the exhaust of a coal-fired plant.

The proposed embodiment includes the usage of a membrane electrolyzer to regenerate the pre-washing liquid, which significantly reduces the amount of absorbent required for the regeneration (Xiaofu et al. 2019b). Three-step membrane technology for capturing CO2 is described in CN109731437A, providing exceptional gas separation performance for CO2/N2 when used with MOF-ZIF-716-8 (Qianqian et al. 2019). A composite membrane composed of a polyether-based copolymer by dissolving in one or more alcohol and water solutions was developed US20190366277A1 to remove CO2 from the fluid composition (Akhtar et al. 2019; Lee et al. 2020).

Algae-based carbon capture technology: In recent years, the algal route of capturing CO2 gained more interest for commercializing, whereas algae belong to large and diverse groups of simple aquatic organisms. They may be unicellular or multicellular forms and mainly cultivate on the photosynthesis mechanism, like the plants. Algae play an essential role in the global ecosystem as these are spread globally as they pertain capability to utilize CO2 as a carbon source. They are likely to possess higher efficiency against CO2 fixation capability and in optimal culture conditions (Beal et al. 2018; Anguselvi et al. 2019). These can give higher growth rates than conventional crop plants. The biomass produced can be utilized as a feedstock for other value-added products such as biofuel and chemicals (Pires 2017; Beal et al. 2018; Norhasyima and Mahlia 2018; Yang et al. 2020).

A microalgae carbon fixation based energy utilization system for supercritical water treatment was developed in which the waste gas and water generated from supercritical wastewater treatment were used to cultivate microalgae resulting in low-cost energy production with CCS (Yang et al. 2020). CN111151119A developed a biomass production method that is inexpensive and convenient which utilizes a culture media that is more efficient for removing CO2 from the dilute source stream (Chi and Zhu 2020). In order to lower the energy use while concurrently increasing carbon fixation and bio-oil product yield, especially for coal-fired power plant containing CO2 component in flue gas.

A novel approach by using food grade Pseudochlorococcum microalgae for the treatment of flue gas containing CO2 was developed CN111266000A. CN109621699A CO2 capture using three-step chemical absorption and biological transformation coupled with waste water culture was developed (Na et al. 2019). An alternative of conventional CCS system was developed in CN109126361A, the system aimed to facilitate the low power consumption and reduced capital cost using a flue gas separation system and microalgae cultivation resulting in increased recovery rate of waste gas (Yongliang and Liang 2019; Shujun et al. 2020).

Ionic liquids: ILs belong to a category of compounds with ions entirely and pertain to be liquid at or below the process temperature. In most cases, even low-temperature ILs are in the liquid phase, concluding they do not crystallize at low temperatures or below 0°C. Moreover, they show low corrosivity and are non-volatile in prominent working conditions. ILs also pertains low desorption temperature and enthalpies (Brennecke and Gurkan 2010; Shujun et al. 2020).

Therefore, ILs can also be used in pre, post and oxy-fuel combustion. Moreover, ILs are less hazardous in the environment and are less prone to energy losses, which are vital reasons to attract more attention. CN111715031A disclosed method and medium for efficient absorption of CO2 using 1-aminopropyl-3-methylimidazolium bromide. However, despite these benefits, the created IL is stable, possesses a high CO2 absorption speed, and has a high capture rate. Moreover, applications of IL in these various areas attract interest across a wide variety of science and engineering domains, including chemistry, chemical engineering, energy, resources and environment (Pingquan et al. 2020).

The Taiyuan University of Technology disclosed a simple preparation method to modify MOF using IL, resulting in excellent CO2/O2 selectivity, high stability, and recyclability. CN110743326A invented a high-efficiency energy-saving non-water-absorbent for capturing CO2 in which low-viscosity functional treatment on the molecular design level was performed to reduce the rise in viscosity during absorption providing the effect of controlling the viscosity with improved flow and mass transfer capacity with significant improvement in lowering the energy consumption and capture efficacy (Jiejie et al. 2020; Lili et al. 2020).

To reduce energy consumption and lower the solvent cost, CN109200760A developed a kind of eutectic solvent wherein the hydrogen bond acceptor can be ammonium chloride or hydrochloric acid-ammonium chloride and the hydrogen bond donor can be composed of an organic amine and a polyol. However, the organic amine may be MEA, DEA, TEA, DETA and N,N-dimethyl or any of the ethylenediamines; and the polyol may be any one of pentaerythritol, ethylene glycol, glycerine and butylene glycol (Yingying et al. 2019; Jiejie et al. 2020).

Major assignees in CCS: Analysis of patent application and granted patents in the field of CCS elaborates that majority of patents published on absorption followed by adsorption, MOF, ILs, algal and CCC technology. Top assignees in filing patents were General Electric, Air Liquide, Exxon Mobil, CO2 Solutions Inc., Alstom, IFP Energies Nouvelles and Mitsubishi Heavy Industries.

CONCLUSION

The findings of the present study reveals that most patents in recent years originated from research institutes and universities globally. It was also noticed that the United States was leading the way with new patents initially. However, Chinese research and innovation rapidly moved on leaving behind the U.S. after 2015. In recent years, many technologies has been developed for separating, transportation, and utilization against CCS. A systematic keyword search query incorporating relevant CPC & IPC codes, and operators to conduct a comprehensive patent search using paid database Relecura.

ACKNOWLEDGEMENTS

This study was financially supported by All India Council for Technical Education (AICTE) under the project grant of National Doctoral Fellowship with reference file no. 8-39/RIFD/RPS-NDF/Policy-1/2018-19 dated 13-03-2019.

Conflict of Interests: Author(s) declare no conflicts of interests to disclose.

REFERENCES

Abbas, A, Zhang L and Khan S U (2014) A literature review on the state-of-the-art in patent analysis World Patent Information Vol 37 No 6 Pages 3-13.

Akhtar, F H, Karunakaran M, Mahendra K, et al. (2019) CO2-philic thin film composite membranes USPTO Patent No US20190366277A1 Pages 1-28.

Beal, C M, Ian A, Huntley M E, et al. (2018) Integrating Algae with Bioenergy Carbon Capture and Storage (ABECCS) Increases Sustainability Earth’s Future Vol 6 No 3 Pages 524-542.

Bottoms, R R (1930) Process for separating acidic gases USPTO Patent No US1783901A Pages 1-6.

Brennecke, J F and E G Bruce (2010) Ionic Liquids for CO2 Capture and Emission Reduction The Journal of Physical Chemistry Letters Vol 1 No 24 Pages 3459-3464.

Chi, Z and C Zhu (2020) Method for efficiently capturing and utilizing CO2 from air based on microalgae biotechnology CINPA Patent No CN111151119A Pages 1-16.

Chiang, P C and S Y Pan (2017) Carbon dioxide mineralization and utilization Carbon Dioxide Mineralization and Utilization Vol 1 Springer Nature Singapore Pages 1-452.

Clerveaux, F and S Lefebvre (2019) Post-combustion CO2 capture with heat recovery and integration WIPO Patent No WO2019232626A1 Pages 1-48.

Davidson, O and B Metz (2002) Workshop on Carbon Capture and Storage IPCC|WMO|UNEP Vol 1 (Edited by IPCC) Energieonderzoek Centrum Nederland Pages 1-179.

Hopkinson, D P, Nicolas S, Thompson R L, et al. (2020) Di-substituted siloxane solvents for gas capture USPTO Patent No US10589228B2 Pages 1-20.

Jiejie, L, Anhua L and Xiaobing L (2020) Efficient and energy-saving non-water absorbent for capturing carbon dioxide and application CINPA Patent No CN110743326A Pages 1-8.

Kaarstad, O (2002) Geological storage including costs and risks in saline aquifers Proceedings of Workshop on Carbon Dioxide Capture and Storage Pages 53-60.

Kheshgi, H, Coninck H and Kessels J (2012) Carbon dioxide capture and storage: Seven years after the IPCC special report Mitigation and Adaptation Strategies for Global Change Vol 17 No 6 Pages 563-567.

Kurihara, H and Y Shirayama (2004) Effects of increased atmospheric CO2 on sea urchin early development Marine Ecology Progress Series Vol 274 Pages 1-9.

Lab, M L (2021) Global Monitoring Laboratory – Carbon Cycle Greenhouse Gases US Department of Commerce NOAA Global Monitoring Laboratory.

Lee, D, Lee J H, Pyo L Y, et al. (2020) Apparatus and method for low-temperature membrane separation process and CO2 capturing system KIPRIS Patent No KR20200015664A Pages 1-14.

Li, B, Duan Y, Luebke D et al. (2013) Advances in CO2 capture technology: A patent review Applied Energy Vol 102 No 10 Pages 1439-1447.

Liu, Y, Gongping L, Chen Z, et al. (2018) Enhanced CO2/CH4 Separation Performance of a Mixed Matrix Membrane Based on Tailored MOF-Polymer Formulations Advanced Science Vol 5 No 9 Pages 1800982-1800986.

Lynghjem, A, Jakobsen J, Kobro H et al. (2016) Efficient combined cycle power plant with CO2 capture and a combustor arrangement with separate flows EPO Patent No EP1592867B1 Pages 1-17.

Míguez, J L, Porteiro J, Orozco R P, et al. (2020) Biological systems for CCS: Patent review as a criterion for technological development Applied Energy Vol 257 No 10 Pages 114032-114039.

Moullec, Y L, Neveux T, Azki A A, et al. (2014) Process modifications for solvent-based post-combustion CO2 capture International Journal of Greenhouse Gas Control Vol 31 Pages 96-112.

Na, J, Qingling L, Yun Q, et al. (2019) CO2 capture method based on coupling of chemical absorption and biological transformation enhanced by waste water culture CINPA Patent No CN109621699A Pages 1-12.

Nam, J S, Sik L C, Po P J, et al. (2019) System and Method for Liquid Air Evaporation using Carbon Capture System KIPRIS Patent No KR102048844B1 Pages 1-23.

Norhasyima, R S and Mahlia T M I (2018) Advances in CO2 utilization technology: A patent landscape review Journal of CO2 Utilization Vol 26 No 3 Pages 323-335.

Og, J Y, Pawelec K, Kim B K, et al. (2020) Measuring patent value indicators with patent renewal information Journal of Open Innovation: Technology, Market and Complexity Vol 6 No 1 Pages 1-16.

Petroleum, B (2020) Statistical Review of World Energy 2020|, Looney, Bernard (69).

Pingquan, C, Wenhong C, Li L, et al. (2020) Carbon dioxide absorption medium and optimization process thereof CINPA Patent No CN111715031A Pages 1-11.

Pires, J C M (2017) COP21: The algae opportunity? Renewable and Sustainable Energy Reviews Vol 79 No 5 Pages 867-877.

Qianqian, H, Haihui W, Wei Y et al. (2019) Application of capturing of carbon dioxide in flue gas by membrane method CINPA Patent No CN109731437A Pages 1-9.

Qiu, H H and Yang J (2018) An assessment of technological innovation capabilities of carbon capture and storage technology based on patent analysis: A comparative study between China and the United States Sustainability Vol 10 No 3 Pages 1-20.

Rackley, S A (2017) Carbon capture from power generation Carbon Capture and Storage Butterworth-Heinemann United Kingdom (2) Pages 75-101.

Shalaby, W and Zadrozny W (2019) Patent retrieval: a literature review Knowledge and Information Systems Vol 61 Pages 631-660.

Sharma, T, Sharma S, Kamyab H et al. (2020) Energizing the CO2 utilization by chemo-enzymatic approaches and potentiality of carbonic anhydrases: A review Journal of Cleaner Production Vol 247 Pages 119138-119151.

Sood, A and Vyas S (2017) Carbon Capture and Sequestration- A Review IOP Conference Series: Earth and Environmental Science Pages Vol 83 Pages 1-10.

Subramanian, A S R, Jordal K, Rahul A, et al. (2017) A Comparison of Post-combustion Capture Technologies for the NGCC Energy Procedia Vol 114 Pages 2631-2641.

Wang, X and Song C (2020) Carbon Capture From Flue Gas and the Atmosphere: A Perspective Frontiers in Energy Research Vol 8 Pages 265.

Wilhelm, G and Walter S (1933) Process for extracting carbon dioxide from gaseous mixtures and forming alkaline carbonates USPTO Patent No US1897725A Pages 1-3.

Xiaofu, H, Junhua S, Luchang S, et al. (2019a) Carbon dioxide capture pretreatment system and method CINPA Patent No CN110813047A Pages 1-10.

Xiaofu, H, Junhua S, Luchang S, et al. (2019b) Carbon dioxide capture pretreatment system CINPA Patent No CN211358301U Pages 1-9.

Xiaoqian, M, Yuting T, Zeng X et al. (2018) Power generation system with partial oxygen-enriched combustion combined with calcium-based chain and CO2 capturing method CINPA Patent No CN108729965A Pages 1-9.

Yafei, G, Weiling L, Ping L, et al. (2018) Potassium-based CO2 absorbent particles and preparation method and application thereof CINPA Patent No CN108295802A Pages 1-8.

Yang, G, Yanhui L, Song W, et al. (2020) Microalgae carbon sequestration and energy utilization system and method for supercritical water treatment CINPA Patent No CN111235022A Pages 1-10.

Yingying, B, Zhengtian H, Jian X et al. (2019) Stable, low energy consumption and regenerative deep-eutectic solvent with carbon dioxide removal CINPA Patent No CN109200760A Pages 1-5.

Yongliang, L and Liang X (2019) Flue gas separation system and microalgae cultivation device CINPA Patent No CN109126361A Pages 1-8.

Yoro, K and Sekoai P (2016) The Potential of CO2 Capture and Storage Technology in South Africa’s Coal-Fired Thermal Power Plants Environments Vol 3 No 3 Pages 1-20.