1Member of Safety Promotion and Injury Prevention Research Center, Shahid Beheshti University of Medical Sciences, Tehran, Iran

2Department of Environmental Health Engineering, School of Public Health, Shahid Beheshti University of Medical Science, Tehran, Iran

3Environmental engineering (Trends water and wastewater), Kurdistan rural water & wastewater CO (Kamyaran).

4Students Research Commitee, Department of Environmental Health, Faculty of Health, Shahid Beheshti University of Medical Sciences, Tehran, Iran

Article Publishing History

Received: 18/09/2016

Accepted After Revision: 05/11/2016

In this study, the degradation of humic acid was studied using advanced photochemical oxidation by exposing humic acid aqueous solution with low-pressure mercury vapor lamp as a UV light source after the addition of hydrogen peroxide. The effect of different parameters such as H2O2 dosage, pH, and initial concentration of humic acid on the removal efficiency of UV/H2O2 was evaluated and investigated in detail. Increase of initial H2O2 dosage (up to optimum dosage) and also increase of humic acid concentration resulted in the decrease of humic acid degradation. The residual concentrations of humic acid were measured for assessing the process performance and understanding the process reaction behavior. The results showed that humic acid was degradable in the presence of hydrogen peroxide under UV irradiation. In the absence of H2O2, the degradation efficiency was very negligible. The results show 91% humic acid removal in 60 min of reaction time when 30 mmol L-1 of H2O2 aqueous solution was added to the solution compared with only 20% of removal in similar conditions and in the absence of H2O2. Investigation of the kinetics of the UV/H2O2 process demonstrated that the semi-log plot of the humic acid concentration versus time was linear, which suggested a first order reaction.

Humic Acid, Water Solutions, Uv, Peroxide Hydrogen

Massoudinejad M, Golmohammadi S, Ghaderpoori M. Use of Ultraviolet and Ultraviolet /Peroxide Hydrogen Processes for Degradation of Humic Substances from Aqueous Solutions. Biosc.Biotech.Res.Comm. 2016;9(4).

Massoudinejad M, Golmohammadi S, Ghaderpoori M. Use of Ultraviolet and Ultraviolet /Peroxide Hydrogen Processes for Degradation of Humic Substances from Aqueous Solutions. Biosc.Biotech.Res.Comm. 2016;9(4). Available from: https://bit.ly/2O19z1T

INTRODUCTION

Humic acid (HA) is one of the major components of humic substances which arise from the microbial degradation of biomolecules. Natural organic matters (NOMs) such as HA enters water from natural and artificial sources. These materials are caused a variety of problems in treatment operations and distribution systems due to having unpleasant smell and taste, yellow to brown color, reaction with chlorine, and formation of disinfection by-products (DBPs). NOMs could also stimulate the growth of the micro-organisms in water distribution pipelines as well as production of biologically unstable water and other unwanted water quality issues such as metal complexes (Vilhunen et al. 2010; Alkan et al. 2007 Wang et al. 2014).

THMs exhibit mutagenic properties during the chlorination step water treatment. The guideline for THMs in drinking water announced by World Health Organization (WHO) states that DBPs should not exceed 100 μgL-1 (Zhang and Minear, 2006). Consequently, the removal of HA from surface waters or wastewaters is important because of health and environmental concerns (Jacangelo et al. 1995).

HA may account for up to 90% of NOM. Actually, it is not possible to completely remove NOM by conventional methods in water treatment plants. Different treatment technologies have been used in practice to improve NOM removal such as ion exchange, sorption, and membrane processes. But, many of these are not acceptable in terms of economy and efficiency. Advanced oxidation processes (AOPs) are frequently applied for the oxidation of organic and toxic materials. These processes are based on the production of hydroxyl radicals which demonstrate great efficacy in breaking down organic materials (Katsumata et al. 1987; Magdaleno & Coichev 2005; Panyapinyopol et al. 2007; Golmohammadi et al. 2016).

AOPs are defined as the processes that involve highly reactive species, specifically hydroxyl radicals (oxidation potential = 2.8 V) in sufficient quantities to oxidize the majority of complex organic chemicals in water and wastewater. Hydroxyl radicals have a significant role in the treatment of organic materials due to their high reactivity and lack of selectivity toward organic compounds.UV photolysis and UV/H2O2 have been successfully used in removing NOMs from water solutions. However, if the UV absorbance of water is considerably high, the efficient treatment might require great reaction time of UV. In such cases, removing the majority of organic materials by other methods prior to oxidation treatment leads to decreased UV absorbance and improved NOM mineralization (Zepp et al. 2007; Vilhunen et al. 2010; Hui et al, 2011; Bazri et al. 2012; Hiroshi et al. 2013 and Yazdanbakhsh et al. 2014).

The advantage of UV/H2O2 including high reactivity, low sludge production, and capability to achieve complete destruction (mineralization) of pollutants to less harmful by-products (Hui et al, 2011; Bazri et al. 2012; Hiroshi et al. 2013). In UV/ H2O2 process, optimum H2O2 dosage has been reported for each target compound, because the characteristics and concentration of the organic compounds can directly influence H2O2 utilization for degrading organic matters (Kruithof et al.2007; Pereira et al. 2007; Kim et al. 2009).

Upon the UV irradiation, H2O2 absorbs UV energy and results in the production of HO•. The excess H2O2 can react with HO• radicals (Sheikhmohammadi et al. 2013) and serve as an HO• inhibiting agent in the UV/H2O2 process (Vilhunen et al. 2010; Lamsal et al. 2011; Jung et al. 2012; Chandran et al. 2014). Many studies have illustrated the effectiveness of the UV/H2O2 process in the oxidation and mineralization of various organic pollutants and this process has been widely studied for the remediation of both ground and drinking waters (Lamsal et al. 2011; Jung et al. 2012). Therefore, the aim of this study was investigate the suitability and efficiency of the UV and UV/H2O2 processes for the removal of HA as an important problem in treatment operations and distribution systems

MATERIAL AND METHODS

The chemical materials were of reagent grade. Commercially, available HA was extracted from peat coal. HA was contained 56.2% of C, 3.91% of H, 36.1% of O, and 1.07% of N. It was dried for 1 h at 110˚C. A stock solution was prepared by dissolving 1.0 g of HA in 1000 ml deionized water. Then, it was filtered through a 0.45 µm glass–fiber–membrane filter and stored in 4˚C conditions. The as-synthetic sample was prepared by adding the measured amount of HA stock solution to the deionized water. 30% hydrogen peroxide (H2O2, DUKSAN) was also employed. HA and H2O2 solutions were accurately prepared daily to the required diluted concentrations. Ultra-pure water was employed for all the dilutions.

All the photochemical experiments were carried out in a batch photo-reactor, which is schematically shown in Fig. (1) R-52 Mineralight® Lamp which was used a grid design and produces a highly uniform 254 nm UV light with high intensity was used as a light source. A J-225 Black Ray intensity meter was employed to measure the UV irradiation intensity (I). Interior surface of the photo-reactor was made of stainless steel (20 cm diameter and 30 cm depth) for the photo-oxidation of HA in aqueous solutions. UV lamps were fixed parallel at the center of the reactor and covered with a quartz sleeve. The UV lamps were turned on 10 min before performing every experiment. The total UV intensity was controlled by turning on different numbers of UV lamps. Air cooling system, with electrical fans, was used to prevent the lamp from overheating and to maintain the temperature at 25oC.

|

Figure 1: A scheme of batch photo-reactor |

The UV/H2O2 experiments were carried out in a photo-reactor batch type made of a Pyrex-based material with 2 L volume capacity and a UV-C lamp from LIGHTTECH (∧max = 254 nm with the light intensity of approximately 0.05 W cm-2) attached to the center of the reactor. An aqueous HA solution was prepared and subjected to the UV/H2O2 process. The selected levels to run the experiments were: H2O2 (10-100) Mmol L-1, pH (3-11), reaction time (5-60 min), and initial HA concentrations (2.5-8 mg L-1), set at the beginning of the reactions. The removal efficiency of HA by the UV/H2O2 process was determined at the optimum values of pH, H2O2 dosage, and reaction time. Reactions were quenched by removing the excess of H2O2 by catalase or NaHSO3 according to the analysis. A Perkin-Elmer (Lambda-II) double beam spectrophotometer was used for the absorption measurements at 254 nm using the 10 mm quartz cell (Rosenfeldt et al. 2006).

RESULTS AND DISCUSSION

Fig. (2) presents the HA residual fraction at three different concentrations with initial HA of 2.5, 5, and 8 mg L-1. At first, H2O2 concentration was set fixed in the reaction mixture as 30 Mmol L-1. pH was adjusted at 7.0. As shown in Fig. (2a), it seems that the removal efficiency was less for all the concentrations within the initial reaction for the 5 min period. With increasing reaction time, it was observed that the low concentrations of HA had higher removal efficiency than high concentrations. Removal efficiency for the concentrations of 2.5 and 8 mg L-1 was 78 and 91% after 60 min, respectively. As in Fig. (2b), the residual fraction of H2O2 was higher for HA 8 mg L-1 than HA 2.5 mg L-1; therefore, the solution with higher HA concentration was content of higher the residual H2O2. Reduction of HA was related to the existence of HO• radicals in the solution; therefore, considering the dual roles of humic substances at UV light photon absorption and HO• scavenging, higher removal of HA at lower concentrations was expected. Also, at high humic concentration, HA competed with H2O2 for UV absorption and resulted in the reduced light absorption by H2O2 to a greater degree. However, the high generation of H2O2 at high concentration of HA might be due to the formation of H2O2 as the by-product of sunlight-induced reactions in natural waters, which would more appear when HA with certain concentration was irradiated by UV light (Matilainen & Sillanpa 2010; Chang et al. 2010; Haji et al. 2011; Jung et al. 2012; Gonzalez et al. 2013).

|

Figure 2: Effect of initial HA concentration on removal efficiency by UV/H2O2 (a); Residual H2O2 to different concentrations at reaction times 5-60 min (b). |

The HA solution with the concentration of 2.5 mg L−1 was exposed to UV radiation in the absence of H2O2. Fig. (3) shows relative residual concentrations for HA versus time. The samples of the treated solution withdrawn at different times and the residual concentrations of HA were measured. As shown in Fig. (3a), only 20% HA removal was observed after 60 min of the solution exposure to UV radiation. However, the result of this research was different from that of some studies by other researchers, which can be related to the dissimilarity in the experimental conditions, mainly the UV radiation intensity (Vilhunen et al. 2010; Lamsal et al. 2011). Because it is deduced that the residual concentration of HA in the presence of UV radiation linearly decreased versus time, the reaction of HA with UV radiation was of first order (Lamsal et al. 2011), indicating that the removal of HA was affected by UV may be because of UV energy absorbed by HA. Another reason for the improvement of HA removal could be explained by •OH radicals generated by UV photolysis of water (water could be dissociated into a hydrogen atom and hydroxyl radical when exposed to UV irradiation with the wavelength of less than 200 nm (Shemer&Linden 2007; Alkan et al. 2007; Comninellis et al. 2008; Hu et al. 2008).

|

Figure 3: Decomposition of HA by UV radiation (a) and UV/H2O2 (b) (experimental conditions: Initial H2O2 concentration: 30 mmol L-1; pH: 7.0; HA concentration: 2.5 mg L-1). |

UV (occurring at 185 nm) is more effective than UV (occurring at 254 nm) in the photolysis of water, because more energy is transferred to the aqueous solution via UV (6.72 eV) vs UV (4.89 eV). Since this research was focused on the degradation of HA by UV, as shown in Fig. (3a), HA degradation by UV was very slow. Accordingly, the presence of a UV sensitive agent (an oxidizing reagent, for example H2O2) was necessary to enhance the HA degradation rate. Therefore, during the UV treatment, the effect of H2O2 addition on HA degradation was investigated. The presence of H2O2 is necessary to accelerate the HA decomposition process by UV. The solution temperature was maintained at 25˚C and pH of the solution was adjusted to 7.0 (Kruithof et al. 2007; Li et al. 2008). In accordance with Fig. (3b), the highest removal efficiency of HA was 91% in the presence of H2O2 and 60 min of exposure to UV radiation which could be compared with the percentage of HA removal by UV radiation in the absence of H2O2 due to provoking the generation of •OH by UV with ∧max=254 nm in the presence of H2O2. Fig. (3b) shows that relative residual concentrations of HA decreased linearly over time. Therefore, it can be concluded that adding H2O2 to the solution subjected to UV radiation could result in the generation of •OH radicals by the photolysis of H2O2 molecules (Sheikhmohammadi et al. 2013; Yazdanbakhsh et al. 2014); consequently, these radicals oxidized HA molecules.

The cost of H2O2 accounts for most of the cost of AOP processes, so the determination of optimum H2O2 amount is quite important in AOP processes. The effect of initial H2O2 concentration on the residual fractions of HA and H2O2 is presented in Fig. (4). To determine optimum H2O2 concentration, the experiments were conducted by varying the amount of H2O2 from 10 to 100 Mmol L-1 (pH was fixed at 7 and HA concentration was 2.5 mg L-1). Fig. (4) shows that the efficiency of HA removal was maximum at 40 Mmol L-1 of H2O2. It was observed that HA removal efficiency increased from 47% to 70% as H2O2 concentration went up from 10 to 40 Mmol L-1. An increase in the concentration of H2O2 up to 40 Mmol L-1 did not significantly affect the removal of HA and there was no significant difference between the dosages of 40 and 50 Mmol L-1 (Chan et al. 2010). It is interesting to find that, with increasing H2O2 concentration up to 50 Mmol L-1, the degradation rate of HA was decreased, since with increasing H2O2 from 50 to 100 Mmol L-1, removal efficiency decreased from 70% to 56% at 30 min, which might be due to three reasons: 1- At excessive amounts of H2O2, it acts as a scavenger of •OH to produce perhydroxyl radical (HO2•) (Yazdanbakhsh et al. 2014), which might be due to three reasons: 1- At excessive amounts of H2O2, it acts as a scavenger of •OH to produce perhydroxyl radical (HO2•) (Yazdanbakhsh et al. 2014). According to reaction 4 (HO2• has much lower oxidization capacities than •OH).

|

Figure 4: Effect of initial H2O2 on removal efficiency of HA by UV/H2O2 (experimental conditions: pH: 7.0 and HA concentration: 2.5 mg L-1). |

2- The second reason might be due to the reaction pathways of HA degradation, mineralizing HA through UV photolysis alone, and •OH radical oxidation as follows:

3- As shown in Fig. (3), the residual fraction of H2O2 increases with the increasing initial concentration of H2O2 that is due to decrease of decomposition H2O2. Reduction of H2O2 concentration from 40 to 10 Mmol L-1 resulted in a decrease in HA removal efficiency from 70% to 47%, which might be because of partial oxidation at H2O2 concentrations of lower than optimum values. At the optimum concentration of H2O2, the generation of hydroxyl radicals increased (Sheikhmohammadi et al. 2013; Yazdanbakhsh et al. 2014).

Therefore, an H2O2 dosage of 40 Mm L-1 with the HA removal efficiency of 70% was chosen as the optimum dosage. Reactions were quenched by removing the excess of H2O2 by catalase or NaHSO3. Masschelein study group used a diluted enzyme catalyst solution made from Micrococcus lysodeikticus was used to destroy unreacted H2O2 and the amount of residual H2O2 was determined via the molybdate-catalyzed iodometric spectrophotometry method (Rosenfeldt & Linden 2007; Elmolla & Chaudhuri. 2010; Nie et al. 2010; Ghaderpoori & Dehghani 2015).

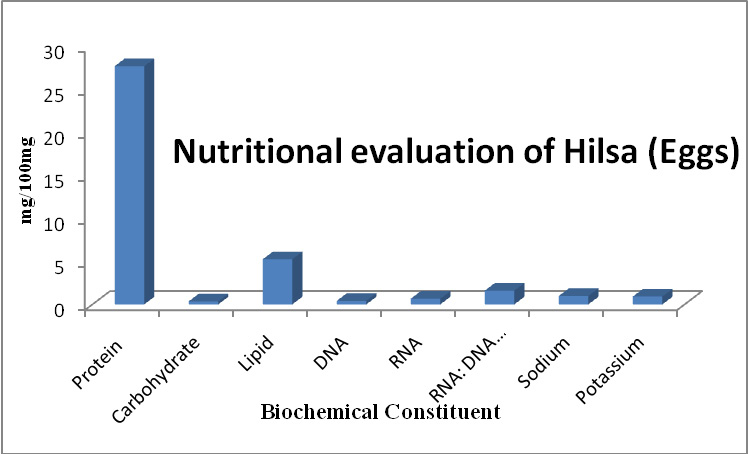

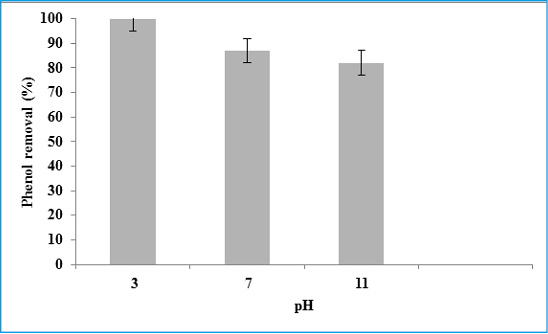

To determine the optimum pH for the UV/H2O2 process, pH was varied from 3 to 11. Fig. (5) shows that HA removal by the UV/H2O2 process was affected by pH. As presented in Fig. (5), maximum HA removal was achieved at pH 7-11, 30 Mmol L-1 H2O2, and 60 min reaction time. Higher HA removal at pH 7-11 can be compared with pH <9. After the 30 min reaction, 70% of HA was degraded at the pH of 7.0 as compared with less than 45% at the pH of 3.0. At pH < 7.0, a substantial decrease in the efficiency of HA removal was observed (Yuan et al. 2009; Nie et al. 2010).

|

Figure 5: Effect of pH on removal efficiency of HA by UV/H2O2 (experimental conditions: Initial H2O2 concentration: 30 mmol L-1; Reaction time: 60 min; HA concentration: 2.5 mg L-1). |

These phenomena could be explained by: 1- UV reacts more slowly with H2O2; therefore, the degradation of H2O2 is slow 2- Scavenging effect of •OH by H+ becomes significant in very low pH ranges (the ions of H+ may have inhibited the generation of hydroxyl radicals necessary to achieve the UV/ H2O2 oxidation (Li et al. 2008; Yuan et al. 2009; Nie et al. 2010).

At higher pH values (alkaline), a rapid increase in HA removal was observed, because in this pH At higher pH values (alkaline), a rapid increase in HA removal was observed, because in this pH range (alkaline solutions), the UV/H2O2 process was most effective and HA removal increased significantly. Increased removal efficiency at optimum pH might be because of two possible reasons: H2O2 stability is less disturbed, which provides further support to earlier work that HA can be totally removed in the pH range of 7–11 in 30 min by UV/H2O2 system, resulting in an increase in the oxidation potential of •OH. Also, it might produce intermediate products that cause an increase in OH radicals (Li et al. 2008; Yuan et al. 2009; Nie et al. 2010).

CONCLUSION

In this study, the UV and UV/H2O2 oxidation processes were employed for the degradation of HA in water solutions. The residual concentration of humic acid was measured for assessing the process performance and understanding the process reaction behavior. The results showed that HA was degradable in the presence of hydrogen peroxide under UV irradiation. In the absence of H2O2, the degradation efficiency was very negligible. It was achieved 91% degradation of HA in 60 min when 40 Mmol L-1 of H2O2 was added to the solution compared with only 20% degradation achieved in 60 min in the absence of H2O2. The effects of H2O2, pH, and initial concentration of HA were investigated in this research. It was concluded that HA degradation was decreased with excess H2O2 amounts and higher HA concentrations. On the other hand, not necessarily guarantee the improvement of the HA degradation in excess H2O2 values because of scavenging effect of the •OH to produce the per-hydroxyl radical and mineralizing of HA through UV photolysis alone (the UV oxidation of humic acids might dominate the removal of HA in the UV/H2O2 process) and •OH radical oxidation. Hence, the degradation of HA was retarded when the H2O2 concentration increased and when the humic degradation was dominated by UV oxidation. Also, the solution with higher humic concentration is content of the high residual H2O2. Reduced HA at high concentration was due to the presence of •OH in the solution and UV light photon absorption; therefore, considering the dual roles of humic substances at UV light photon absorption and •OH scavenging, higher removal of HA was expected at lower concentrations. At higher humic concentrations, HA competed with H2O2 for UV absorption and resulted in reduced light absorption by H2O2 to a greater degree.

ACKNOWLEDGEMENT

This research was supported by Students Research committee of Shahid Beheshti University of Medical Science of Iran (Grant No. 7874).

REFERENCES

Alkan U, Teksoy A, Ateply A, Bapkaya HS (2007). Efficiency of the UV/H2O2 process for the disinfection of humic surface waters, J. Environ. Sci. Health, 16: 21-28.

Arslan-Alaton I, Olmez-Hanci T, Kartal Z (2010). H2O2/UV-C Treatment of the Economically Important Naphthalene Sulfonate J-Acid:Process Optimization, Kinetic Evaluation and Activated Sludge Inhibition, Journal of Advanced Oxidation Technologies,13: 27-35.

Bazri MM, Barbeau B, Mohseni M (2012). Impact of UV/H2O2 advanced oxidation treatment on molecular weight distribution of NOM and biostability of water, Water research, 46:5297-04

Chandran P, Netha N, Sudheer Khan S (2014). Effect of humic acid on photocatalytic activity of ZnO nanoparticles, Journal of Photochemistry and Photobiology B: Biology, 138: 155–159

Chang MW, Chung CC, Chern JM & Chen TS, Tia Shang C. (2010). Dye decomposition kinetics by UV/H2O2: initial rate analysis by effective kinetic modelling methodology, Chem. Eng. Sci, 65: 135-40.

Comninellis C, Kapalka A, Malato S, Parsons SA, Poulios I, Mantzavinos D (2008). Advanced oxidation processes for water treatment: advances and trends for R & D, J. Chem. Technol. Biotechnol, 83:769-776.

Elmolla ES, Chaudhuri M (2010). Photocatalytic degradation of amoxicillin, ampicillin and cloxacillin antibiotics in aqueous solution using UV/TiO2 and UV/H2O2/TiO2 photocatalysis, Desalination, 252: 46-52.

Magdaleno GB, Coichev N (2005). Chemiluminescent determination of humic substances based on the oxidation by peroxymonosulfate, Analytica Chimica Acta, 552: 141-6.

Ghaderpoori M, Dehghani MH (2016). Investigating the removal of linear alkyl benzene sulfonate from aqueous solution by ultraviolet irradiation and hydrogen peroxide process, Desalination and Water Treatment, 57: 15208-15212.

Golmohammadi S, Ahmadpour M, Mohammadi A, Alinejad A, Mirzaei N, Ghaderpoori M, Ghaderpoori A (2016). Removal of blue cat 41 dye from aqueous solutions with ZnO nanoparticles in combination with US and US-H2O2 advanced oxidation processes. Environmental Health Engineering and Management Journal, 3: 107-113

Gonzalez O, Justo A, Bacardit J, Ferrero E, Malfeito JJ, Sans C (2013). Characterization and fate of effluent organic matter treated with UV/H2O2 and ozonation, Chemical Engineering Journal, 226: 402-8.

Haji S, Benstaali B, Al-Bastaki N (2011). Degradation of methyl orange by UV/H2O2 advanced oxidation process, Chemical Engineering Journal, 168: 134-9.

Hu Q, Zhang C, Wang Z, Chen Y, Mao K, Zhang X, Xiong Y, Zhu M (2008). Photodegradation of methyl tert-butyl ether (MTBE) by UV/H2O2 and UV/TiO2, I. Hazard. Mater, 154: 795-803

Kim I, Tanaka HT (2009). Photodegradationcharacteristics of PPCPs in water with UV treatment, Environment international, 35: 793-802.

Kruithof J, Kamp PC, Martijn BJ (2007). UV/H2O2 treatment: a practical solution for organic contaminant control and primary disinfection, Ozone Sci. Eng, 29: 273-80.

Jung YJ, Kim WG, Yoon Y, Kang J.W, Hong YM, Kim HW (2012). Removal of amoxicillin by UV and UV/H2O2 processes, Science of the Total Environment, 420: 160-7.

Kang SF, Yen HY, Liao CH, Yao YC (2010). Decolorization and Mineralization of Textile Effluent by H2O2/Ultraviolet Processes, Environmental Engineering Science, 27: 357-63.

Lamsal R, Walsh ME, Gagnon GA (2011). Comparison of advanced oxidation processes for the removal of natural organic matter, Water Research, 45: 3263-69.

Li K, Hokanson D, Crittenden J, Trussell R, Minakata D (2008). Evaluating UV/H2O2 processes for methyl tert-butyl ether and tertiary butyl alcohol removal: effect of pretreatment options and light sources, Water Res, 42: 5045-53.

Lin HC, Wang GS (2011). Effects of UV/H2O2 on NOM fractionation and corresponding DBPs formation, Desalination, 270: 221 –226.

Matilainen A, Sillanpa M (2010). Removal of natural organic matter from drinking water byadvanced oxidation processes, Chemosphere, 80: 351-65.

Nie Y, Hu C, Zhou L, Qu J, Wei Q, Wang D (2010). Degradation characteristics of humic acid over iron oxides/Fe0 core–shell nanoparticles with UVA/H2O2, J. Hazard. Mate, 173: 474-9.

Pereira VJ, Weinberg HS, Linden KG, Singer PC (2007). UV degradation kinetics and modeling of pharmaceutical compounds in laboratory grade and surface water via direct and indirect photolysis at 254 nm, Environmental science & technology, 41,1682-8.

Rosenfeldt EJ, Linden KG, Canonica S, Gunten U (2006). Comparison of the efficiency of *OH radical formation during ozonation andthe advanced oxidation processes O3/H2O2 and UV/H2O2, Water research, 40: 3695-704.

Rosenfeldt E, Linden K (2007). The ROH, UV concept to characterize and the model UV/H2O2 process in natural waters, Environ. Sci. Technol, 41: 2548- 53.

Sakai H, Autin O, Parsons S (2013). Change in haloacetic acid formation potential during UV and UV/H2O2 treatment of model organic compounds, Chemosphere, 92: 647–651.

Sheikh Mohammadi A, Sardar M, Almasian M (2013). Fenton’s oxidation of para-chlorophenol with zero-valent iron, Desalination and Water Treatment, 12: 1-7

Shemer HS, Linden KG (2007). Aqueousphotodegradation and toxicity of the polycyclic aromatic hydrocarbons fluorene, dibenzofuran and dibenzothiophene, Water research, 41: 853-61

Wang W, Wang W, Fan Q, Wang Y, Qiao Z, Wang XC (2014). Effects of UV radiation on humic acid coagulation characteristics in drinking water treatment processes, Chemical Engineering Journal, 256: 137-43.

Vilhunen Sari, Vilve Miia, Vepsäläinen Mikko, Sillanpää Mika (2010). Removal of organic matter from a variety of water matrices by UV photolysis and UV/H2O2 method, Journal of Hazardous Materials, 179: 776–782.

Yazdanbakhsh AR, Amir SM, Mahdieh S, Godini H, Almasian M (2014). COD removal from synthetic wastewater containing azithromycin using combined coagulation and a fenton-like process, 13: 2929-2936

Yeon J, Gi KW, Yeojoon Y, Kang JW, Min HY, Wook KH (2012). Removal of amoxicillin by UV and UV/H2O2 processes, Science of the Total Environment, 420: 160–167.

Yuan F, Hu C, Hu X, Qu J & Yang, M. (2009). Degradation of selected pharmaceuticals in aqueous solution with UV and UV/H2O2, Water Res, 43: 1766-74.

Zhang X, Minear RA (2006). Formation, adsorption and separation of high molecular weight disinfection byproducts resulting from chlorination of aquatic humic substances, Water Res, 40: 221– 230.

Zepp RG, Braun AM, Hoigne J, Leenheer JA (1987). Photo-production of hydrated electrons from natural organic solutes in aquatic environments, Environ. Sci. Technol, 21:

485-90.