1School of Food Science and Engineering, South China University of Technology, China

2Department of Food Science and Technology, University of Nigeria Nsukka, Nigeria

Corresponding author email:: graciousrinwi@gmail.com

Article Publishing History

Received: 09/03/2021

Accepted After Revision: 03/06/2021

Three process optimality options (optima-options) identified for the hydrolytic digestion of cassava peel into liquefied-digest-sludge or pulp were carried-over from paper-1 of the series and applied on the whole-unpeeled roots. The purpose was to validate the technical efficacy of each of the options for the complete removal of peel from cassava roots with zero or near-zero loss of the starchy-flesh-tissue followed by hand or mechanical scrub-brushing. A factorially designed experimental plan employing a cassava-peeling-efficiency-index (CPEI) factor linked generically with and analogous to the ICPSC (index of cassava peel structural collapse) value also generated from paper-1, was applied for the purpose. Our finding was that two of the process optima-options (a and b) were equally effective for complete peel-removal from cassava roots, viz:(a).

30% lye concentration at 32 oC and 50-minutes time-interval of immersion; and (b). 35% lye concentration at 50 oC and 7.5-minutes time-interval of immersion. The actual effectiveness of an option would depend on the technological circumstances of its application. While option (a) was the low-technology choice (no heating and no temperature control gadgetry), option (b) requires heating and temperature control with precision automatic handling devices attached to minimize the negative effects of heat-penetration into the peeled roots. Option (c) 25% lye-concentration at 103 oC (boiling point) and 4.5-minutes residence time-interval of immersion was dropped entirely as technically unfeasible.

Lye Peeling Efficiency Index (LPEI), Lye-Treatment, Process Optima-Options, Hydrocyanic Acid (HCN), Starchy-Flesh-Tissue Of Peeled Cassava Roots, Hand Brush-Scrubbing, Mechanical Brush-Scrubbing.

Tsekwi G. R, Ngoddy P.O. LYE-Peeling of Cassava Roots II. Brush-Removal of LYE-Digested Peel from Cassava Roots. Biosc.Biotech.Res.Comm. 2021;14(2).

Tsekwi G. R, Ngoddy P.O. LYE-Peeling of Cassava Roots II. Brush-Removal of LYE-Digested Peel from Cassava Roots. Biosc.Biotech.Res.Comm. 2021;14(2). Available from: <a href=”https://bit.ly/3aROFx4“>https://bit.ly/3aROFx4</a>

Copyright © Tsekwi and Ngoddy This is an open access article distributed under the terms of the Creative Commons Attribution License (CC-BY) https://creativecommns.org/licenses/by/4.0/, which permits unrestricted use distribution and reproduction in any medium, provide the original author and source are credited.

INTRODUCTION

This is a follow-up article in a series of two papers on mechanized lye-peeling of cassava roots using a 2-stage investigative approach. Paper-1 of the series by Tsekwi and Ngoddy (2018), defined three optimality-options for the hydrolytic digestion or disintegrative breakdown of cassava peel-specimens following their careful detachment by hand from the roots (otherwise known as hand-peeling), into liquified digest-sludge or pulp that conduced to easy disposal by wet brush-scrubbing by hand or mechanically in a machine. The optima-options defined in the paper for peel-breakdown in lye resulted from an optimization protocol used to investigate the combined effects of three process variables involved in the lye-treatment process, namely: lye concentration, temperature and residence time-interval of immersion.

In the hierarchy of their potential effectiveness for successful peel hydrolysis, the optima-options fall into the following rank-order:(a) lye-concentration (30%), temperature (32 oC) and 50-minutes residence time-interval;(b) lye-concentration (35%), temperature (50 oC) and 7.5-minutes residence time-interval; and (c) lye-concentration (25%), temperature (103 oC) and 4.5-minutes residence time-interval of immersion, (Tsewki 2018, and Tsewki and Ngoddy 2018).

The purpose of the present paper was to test, verify and validate the key findings of paper-1 in relation to the actualization of successful peel-removal from fresh whole-unpeeled cassava roots following withdrawal from lye-treatment, guided by the expeditious application of the pre-established process optima-options aforementioned. The approach employed to accomplish this task was to systematically test the 3 process options, one-by-one on a comparative basis, by applying each of them on sized whole-unpeeled roots in triplicate samples. On withdrawal from the lye-treatment bath, emergent cassava root samples were divided into two batches. One batch was subjected to wet manual (hand) scrub-brushing, while the second batch was channeled into wet mechanical scrub-brushing in a machine (Figure-1) developed for the purpose.

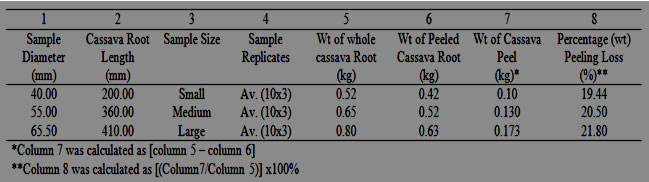

To determine the extent or degree of effectiveness of peel-removal achieved from each experimental cycle of lye-treatment followed by withdrawal and wet-brushing, an efficiency coefficient designated as lye-peeling efficiency index (LPEI) was defined quantitatively and applied using careful hand-peeling as the operating technical quality standard (control) for performance evaluation of competing mechanized cassava peeling techniques. In defining the LPEI-factor, earlier proposals by Wurdemann et al. (1976), Adetan et al. (2003) and Olukunle (2007) were taken into consideration in creating an efficiency index that facilitated the achievement of two complementary objectives, namely: (a) ensure total or complete peel-removal, while simultaneously, (b) engendering the minimization, if not outright elimination, of loss of the starchy-flesh-tissue of peeled cassava roots.

As defined, the generic-numerical character of the LPEI coefficient, as a quality performance criterion, straddled the figure 1.0 in such a manner that when:(a) LPEI = 1.0: peel-removal from root was complete and as good as hand-peeling;(b) LPEI < 1.0: peel-removal from root was incomplete compared to hand-peeling; and(c) LPEI > 1.0: peel-removal from root was excessive compared to hand-peeling, leading to proportional loss of starchy-flesh-tissue. Besides the necessity of satisfying the aforementioned criteria, two other factors loom-large within the cosmology of mechanized lye-peeling of cassava roots (Wurdemann et al., 1976; Igbeka, 1985; Deguchi et al., 2006) and the determination of cyanide content in three sweet cassava cultivars, (Ubwa et al 2015).

The following considerations are:(a) the necessity to avoid or minimize heat-penetration into the starchy-flesh-tissue of the peeled-root leading to its discolouration due to starch gelatinization; the occurrence of a gelatinized starch ring on the peeled-root imposes the need for additional costly abrasion-scrubbing to eliminate the ring, which is wasteful of otherwise useful starch; and (b) the need to ensure that lye-peeled roots satisfy food safety quality specifications of WHO/FAO relating to residual NaOH and residual HCN (hydrocyanic acid) levels.

MATERIAL AND METHODS

Materials used in the study were fresh cassava roots of TME-419 variety, harvested 12-months after planting at the University of Uyo farm, Nigeria. The chemicals used were sodium hydroxide pellets (NaOH), hydrochloric acid (HCl), phenolphthalein, sodium carbonate, and alkaline picrate; all of which were purchased from chemical supply stores in Uyo town, Akwa-Ibom State, Nigeria.Laboratory equipment used include standard items and wares such as wooden spatulas, plastic beakers, pipettes, conical flasks, measuring cylinders, fibre-brushes; thermometers (mercury in glass type), weighing balance, electronic calipers, spectrophotometer (UV/Vis:DO-83070-73); made in China), large metal cooking pots used as lye-baths seated on gas, kerosene or electric heating stoves; protective plastic hand-gloves, boots, coats and eye-goggles, stainless steel peeling knives; and a mechanical brushing machine as elaborated here-under as Figure-1.

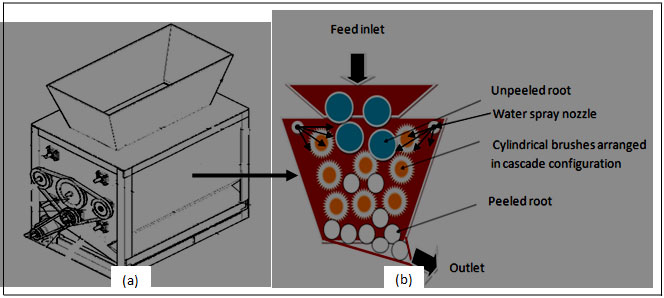

Figure 1: Wet mechanical scrub-brushing machine (a) and vertical cross-section (b) showing the internal structure of its action-chamber

Figure-1 shows an exploded vertical cross-section of a wet mechanical brushing machine developed for the scrub-brushing of lye-treated cassava roots after withdrawal from the lye-bath. The equipment was fabricated in mild steel. Lye-treated roots were fed through the hopper on top. In the action-chamber, the roots cascade under a continuous spray of pressurized water, through three sequential tiers of triple counter-rotating differential-speed hollow-shafted cylindrical fibre-brushes. The scrubbed roots finally exit from a discharge chute at the bottom into lye neutralizing dilute solution of HCl in a receiving bowl.

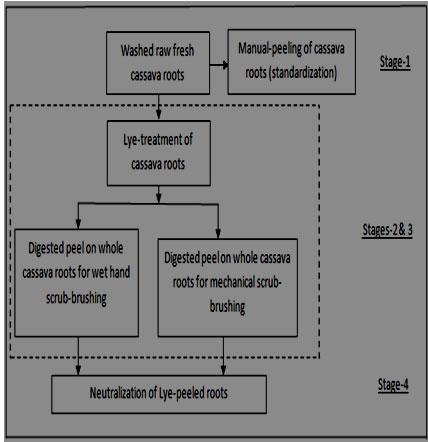

Methodology: Figure-2 is a diagrammatic representation of the experimental protocol employed to execute the four stages of activities involved in the tests.

Figure 2: Flow diagramme of experimental protocol in 4-stages

Stage-1: involved the manual-peeling of representative samples of cassava roots to establish a basis of standardization (or control) against which to compare the outcome of lye-peeling either scrub-brushed by hand or mechanically, following withdrawal from lye-treatment. 90 roots were selected for this purpose; 30 in each of the three size-categories of small, medium and large roots, as specified in the following tabulation.

Table 1

| Size category | Average diameter (mm) | Average length (mm) | Average weight (kg) |

| Small | 40.0 | 200.0 | 0.52 |

| Medium | 55.0 | 360.0 | 0.65 |

| Large | 65.0 | 410.0 | 0.80 |

The percentage of cassava root loss (by weight) due to manual or hand-peeling was computed using the straight forward formula of Wurdemann et al. (1976) as expressed in equation-1:

Percentage root loss from hand-peeling [prlhp]=[mplhp/mrcr] x 100%

Where: mplhp= mass of peel loss from hand-peeling [kg];mrcr= mass of raw cassava root [kg]; and

prlhp= percentage (%) root loss (by weight) from hand-peeling.

Stages-2 & 3: involved the hydrolytic digestion (disintegration or degradation by liquifaction) of cassava peel (in situ) while on the roots into a wet scrub-brushable digest-sludge (or pulp) to determine the comparative effectiveness of lye digestion following immersion, withdrawal from lye and wet scrub-brushing either by hand or mechanically in the machine.180-roots were selected for this purpose; 90-roots per batch (x2-batches), grouped into 3 size- categories per batch of small, medium and large roots as earlier specified, with triplicate samples of 10-roots per size-category. Batch-1 roots were subjected to lye-treatment in accordance with process optima-option (a) (30% lye-concentration at 32 oC for residence time-interval of 50-minutes). Batch-2 roots were similarly subjected to lye-treatment by process optima-option (b) (35% lye-concentration at 50 oC temperature for residence time-interval of 7.5-minutes).

Process optima-option (c) (25% lye-concentration at 103 oC boiling point temperature of lye and 4.5-minutes residence time-interval of immersion), which could have constituted batch-3 of the experimental protocol was dropped for two reasons. First, 103 oC far exceeds the gelatinization temperature of cassava of 60 oC which, as paper-1 suggested, should be avoided because of contingent problems of heat-ring formation associated with heat-penetration. Secondly, boiling point temperature will induce such rapid heat transfer rates that would demand the use of high levels of automation and control devices for effective handling of the process to avoid heat-ring formation. For stages-2 & 3 tests, an index designated as the lye-peeling efficiency index (LPEI) was defined in accordance with earlier proposals by Wurdemann et al. (1976), Adetan et al. (2003) and Olukunle (2007) in the form of equation-2:

Percentage root loss from hand-peeling [prlhp]=[mplhp/mrcr] x 100% (2) Combining equation-2 with equation-1 resulted in equation-3

=[mphp/mrcr]/[mrcr/mpllp]=[mplhp/mpllp];

So that LPEI= [mplhp/mpllp]; dimensionless (3)

Where: mpllp= mass of peel loss from lye-peeling [kg];

As earlier explained in section-2 of this paper, the character of LPEI-factor was such that when:

(a) LPEI = 1.0: peel-removal from root was complete and as good as hand-peeling;

(b) LPEI < 1.0: peel-removal from root was incomplete and less than the loss from hand-peeling; and

(c) LPEI >1.0: peel-removal from root was excessive, leading to proportional loss of starchy-flesh-tissue.

LPEI-values calculated in this manner were applied to rank the comparative efficacy of the two optima-options, furnishing a rational basis of choice, if any.

Stage-4: involved the neutralization of lye-peeled roots following scrub-brushing in stages 2 and 3. Emanent lye-peeled roots were immersed in dilute HCl solution (of 0.1%) concentration to neutralize the residual lye in the roots to bring it down below the specifications of WHO/FAO safety quality standards for GRAS food products. Prior to and after neutralization, lye-treated and scrub-brushed roots were tested to determine the residual NaOH in the roots. This was carried out by taking representative samples of the roots for titration against 0.01% HCl solution using phenolphthalein as indicator. Similarly, residual levels of HCN (hydrocyanic acid) in both the lye-treated and scrub-brushed roots and their correspondent digest-sludges were determined in accordance with the method of Wang and Field (1978).

RESULTS AND DISCUSSION

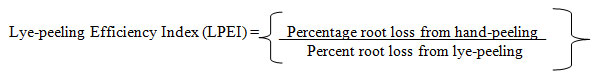

Table-1 presents the averaged summary of recorded values of the percentage of root loss (by weight) resulting from hand or manual-peeling of cassava roots. Hand-peeling was carried out carefully to provide a reliable standard for assessing or comparing competing root-peeling methods. In order to assist analysis, the table has combined in it, the body of available data on the physical characteristics of the cassava roots used in the study.

Table 1. Effect of cassava root size (Wt.) on percentage peeling loss (%)

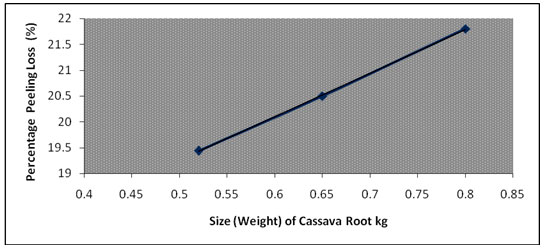

The average root loss by weight (%) recorded in column 8 were 19.44, 20.50 and 21.80%, respectively for small, medium and large-size root-categories. Statistical analysis by ANOVA showed significant differences (p<0.023) among the size-categories investigated with respect to root loss (%) by weight when hand-peeling was conducted carefully by the incision of a sharp knife-edge followed by systematic unfolding of the root cortex and then by careful hand trimming of the proximal (head) and distal (tail) ends. Figure-3 is a photograph of raw cassava roots juxtaposed with hand-peeled roots. Figure-4 presents plots showing percentage root loss from hand peeling as a function of root size by weight.

Figure 3: Raw whole-unpeeled cassava roots of mixed-sizes (left) side-by-side with hand-peeled roots (right)

Figure 4: Percentage loss (% by weight) from hand-peeling of cassava roots as a function of root size (by weight)

When plotted (Figure-4) as a function of root size by weight, the percentage weight loss resulted in a positively sloped straight line which was regressed to equation-4 with the high coefficient of correlation of 0.9997 (Tsekwi, 2018);αh=8.4346β + 15.041 (4) Where:αh=Percentage peeling loss (by weight) from hand-peeling [%]; and β =Size (weight) of cassava root [kg].

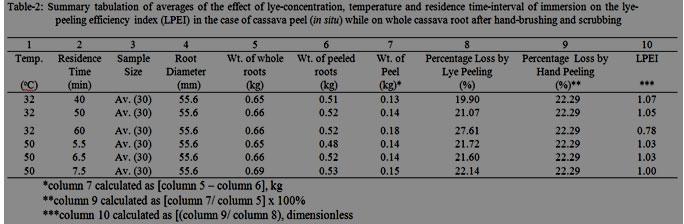

Table-2 presents the averaged summary of recorded values of measurements and calculations relating to the effect of applying, one at a time, the two optima-options of process variables carried-over from paper-1, on whole-unpeeled roots to determine the comparative efficacy of peel-removal from the roots that resulted following the sequence of lye-treatment, root withdrawal from lye and wet brush-scrubbing by hand of the roots. The lye-peeling efficiency index (LPEI) values computed from this set of tests designated as Batch-1 are recorded as column-10 on Table-2.

Table 2

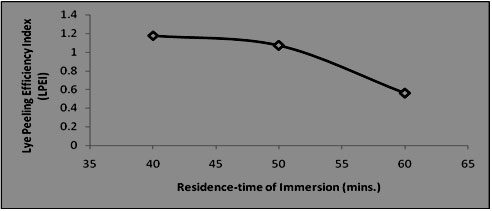

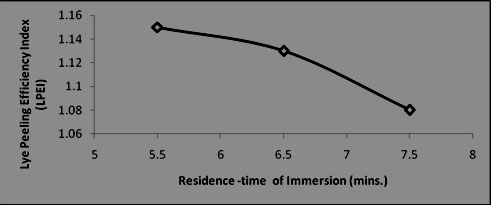

When LPEI-values were plotted as a function of time, Figures-5 and 6 resulted and were respectively regressed statistically to equation-5 at 30% lye-concentration for 32OC temperature [process optima-option (a)]; and equation-6 at 35% lye-concentration for 50OC [process optima-option (b)] with respective coefficients of correlation of 1.00 and 0.916;

Figure 5: Effect of residence-time of immersion on lye-peeling efficiency index (LPEI) for cassava root-peeling (in situ) while on the whole root at 30% lye-concentration

Figure 6: Effect of residence-time of immersion on lye peeling-efficiency index (LPEI) for cassava root-peeling (in situ) while on the whole root at 35% lye-concentration

Ih32 = -0.002θ2 +0.1700θ -2.425 Ih50 = 1.6247θ-0.2 (6)Where:

Ih32 = LPEI- value for 30% lye-concentration at 32 oC after wet brush-scrubbing by hand;

Ih50 = LPEI- value for 35% lye-concentration at 50 oC after wet brush-scrubbing by hand; and

θ = residence time-interval of immersion (mins.).

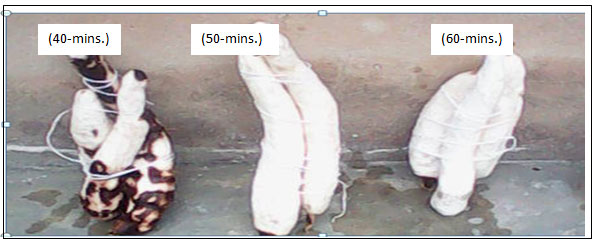

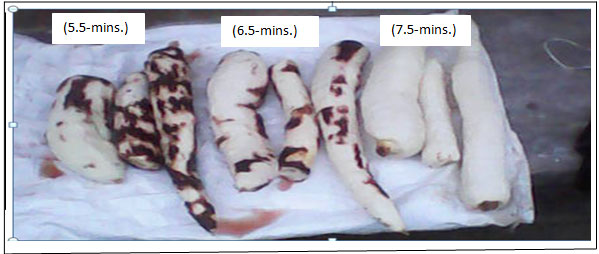

Figures 7: and 8 are photographs of whole-unpeeled cassava roots taken following lye-treatment and wet brush-scrubbing by hand, respectively for 30% lye-concentration at 32 oC, and 35% lye-concentration at 50 oC.

Figure 7: Effect of 30% lye-concentration on whole cassava roots after hand brush-scrubbing of digested peel at 32 oC

Figure 8: Effect of 35% lye-concentration on whole cassava root after hand brush-scrubbing of digested peel at 50 oC

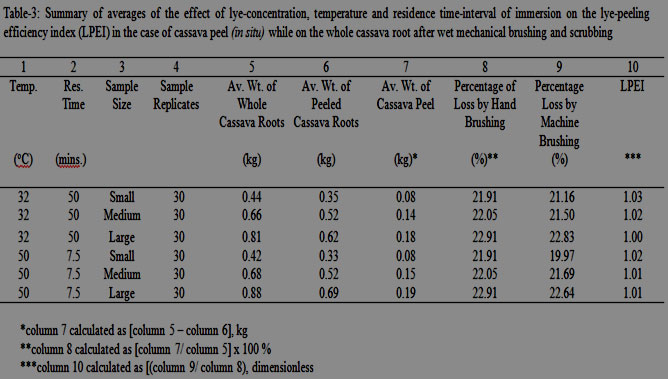

Table-3 presents the averaged summary of recorded values of measurements and calculations relating to the effect of the application, one-by-one, of the two process optima-options of parametric variables carried-over from paper-1, on whole-unpeeled cassava roots (in situ) to determine the comparative efficacy of peel-removal from the roots that resulted after wet mechanical brush-scrubbing of lye-treated roots. Lye-peeling efficiency index (LPEI) values computed from test data (Batch-2) appear in column-10 of the table and suggest a clear pattern of LPEI-value dependency on root-size by weight, irrespective of the lye-concentration and temperature, with LPEI-values decreasing in all cases with increase in root-size by weight.

Table 3

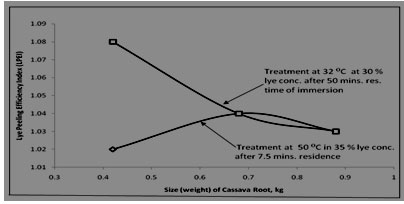

In Figure-9, LPEI-values were plotted as a function of cassava root-size by weight and regressed statistically to equation-7 for 30% lye-concentration at 32 oC and 50-minutes residence time-interval of immersion; and equation-8 for 35% lye-concentration at 50 oC and 7.5-minutes residence time-interval of immersion with a coefficient of correlation of 1.00 for both plots leading respectively, to:

Figure 9: Lye-peeling efficiency index as a function of size (weight) of cassava roots following wet mechanical brushing and scrubbing of peel (in situ) while on whole cassava roots.Im32 = 0.225β2 –

0.4022β + 1.209 (7)

Im50 = 0.275β2 – 0.38040β + 0.908 Where;

Im32 = LPEI for 30% lye-concentration at 32 oC after 50-minutes residence time-interval of immersion;

Im50 = LPEI for 35% lye-concentration at 50 oC after 7.5-minutes residence time-interval of immersion; and β = size (by weight) of whole-unpeeled cassava root [kg].

Figures-10 and 11 are photographs of peeled cassava roots taken following lye-treatment and wet mechanical brush-scrubbing, respectively for 30% lye-concentration at 32 oC after 50-minutes; and 35% lye-concentration at 50 oC after 7.5-minutes residence time-interval of immersion.

Figure 10: Effect of wet mechanical brushing and scrubbing of peel (in situ) while on whole cassava roots lye-treated in 30% lye-concentration at 32 oC for 50 minutes residence time-interval of immersion

Figure 11: Effect of wet mechanical brushing and scrubbing of peel (in situ) while on the whole cassava root lye-treated in 35% lye-concentration at 50 oC) for 7.5 minutes residence time-interval of immersion

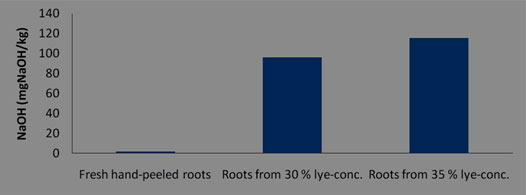

Residual NaOH in cassava roots recorded in the study after withdrawal from lye-treatment are as shown in the bar-chart (Figure-12) which compared these values with residual NaOH-values of raw fresh hand-peeled cassava roots and lye-peeled cassava roots following wet mechanical scrub-brushing from process optima-options [(a) 30% lye-concentration at 32 oC for 50-minutes and (b) 35% lye-concentration at 50 oC for 7.5-minutes]. The residual NaOH-values recorded were, respectively 2.00ppm (fresh hand-peeled roots), 96.90ppm (lye-peeled roots in 30% lye-concentration at 32 oC for 50-minutes time-interval of immersion); and 115.50 ppm (lye-peeled roots in 35% lye-concentration at 50 oC for 7.5-minutes time-interval of immersion). Therefore, the values of NaOH residue clearly increased at higher lye-concentration and temperature.

Figure 12: Sodium hydroxide (NaOH) residues in lye-peeled cassava roots compared with the raw fresh hand-peeled roots

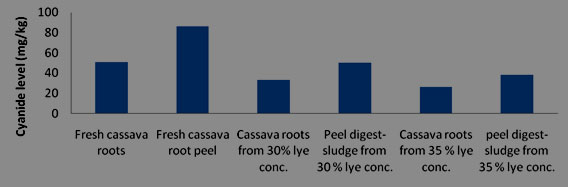

Values of the contents of HCN (hydrocyanic acid) in cassava roots recorded in the study before and following lye-peeling using process optima-options (a) and (b), respectively are as shown in the bar-chart (Figure-13) which compared the residual HCN-contents of fresh hand-peeled cassava roots and their detached peel; along with the residual HCN-contents of lye-peeled and mechanically scrub-brushed roots; and contrasted these values with their associated digest-sludges

Figure 13: Hydrogen cyanide (HCN) content of lye-peeled cassava roots and the resultant sludges compared with raw fresh hand-peeled roots and peel.

The recorded HCN contents from the study were as follows: for fresh hand-peeled roots (50.34 ppm) and for the detached peel of cassava roots (86.17 ppm). For lye-peeled roots after mechanical scrub-brushing, the HCN contents were, respectively: (32.78 ppm) for the peeled roots and (49.80 ppm) for the digest-sludge (in 30% lye-concentration at 32 oC for 50-minutes), (26.00 ppm) for lye-peeled roots and (38.25 ppm) for the digest-sludge (in 35% lye-concentration at 50 oC for 7.5-minutes).

The recorded values of percentage loss of cassava root used as the basis of standardization of assessment in this study were significantly lower than 27.8% reported by FAO (2012) for a pattern of hand-peeling in which the root cortex was removed by deep trimming which lumped-off excessive amounts of useful starchy-flesh-tissue adjacent to the cortex. They were, however, comparable to 20.0% reported by Salami et al. (2000) using a careful peeling technique such as applied in this study.

Our conclusion was that weight loss from hand-peeling was affected significantly not only by the root-size but also importantly by the technique of peel-removal by hand applied. The significance of technique in manual-peeling is brought into sharper focus by two considerations, namely: (a) the direct relationship between the manner (technique) and speed (residence time-interval) of hand-peeling which dictated the rate of output; and (b) wide variations in reported literature values of root peeling loss which, undoubtedly would depend on the disposition of the particular peeler, gender (women are reputed as better and more patient in peeling than children and men), age and, of course, the physical environment in which peeling is conducted. Figure-3 is a photograph taken of raw cassava roots juxtaposed with the hand-peeled roots.

The effect of lye-treatment using pre-established process optima-options followed by wet brush-scrubbing by hand on whole-unpeeled cassava roots to determine the efficacy of peel-removal from the roots suggested a clear pattern of LPEI-value dependency on residence time-interval of immersion in lye, irrespective of both the lye-concentration and temperature of lye-treatment, within the scope of the parametric variables involved in the tests. In all the cases, LPEI-values decreased as the time of lye-treatment increased.

Close inspective scrutiny of Figure-7 showed a time progression pattern of incomplete (inadequate) peel-removal at 40-minutes, complete (adequate) peel-removal at 50-minutes and excessive peel-removal at 60-minutes and suggested 50-minutes as the best time-interval of immersion for 30% lye-concentration at 32 oC lye-treatment. Figure-8 showed a pattern of inadequate (incomplete) peel-removal at 5.5 and 6.5-minutes and adequate (complete) peel-removal at 7.5-minutes, which although it portrayed that peel-removal was complete to the naked eye, may actually be excessive. The implication of these observations was that combining LPEI-values (Table-2) with photo-inspection (Figures-7 and 8) could provide a more reliable immersion-time prescription for lye-treatment.

For 30% lye-concentration at 32 oC, LPEI-values recorded were 40-minutes (1.07), 50-minutes (1.05) and 60-minutes (0.78). These figures confirmed, in conjunction with photo-inspection, that 50-minutes time-interval of immersion was optimal. For 35% lye-concentration at 50 oC, the LPEI-values recorded were at 5.5-minutes (1.03), 6.5-minutes (1.02) and 7.5-minutes (1.00). These figures suggest, in conjunction with photo-inspection, that a time period between 7.0 and 7.5-minutes would be the optimal time-interval of lye-immersion for the roots.

In the case of lye-treatment using pre-established process optima-options followed by wet mechanical brush-scrubbing on whole-unpeeled roots to determine the efficacy of peel-removal from the roots, LPEI-values recorded for 30% lye-concentration at 32 oC for 50-minutes residence time-interval of immersion were, respectively: small-size roots (1.08), medium-size roots (1.04) and large-size roots (1.03). Counterpart LPEI-values recorded for 35% lye-concentration at 50 oC for 7.5-minutes residence time-interval of immersion were, respectively: small-size roots (1.02), medium-size roots (1.01) and large-size root (1.01). These values clearly replicated and validated patterns observed for process optimality conditions defined for wet brush-scrubbing by hand as earlier discussed.

The percentage root loss by weight (%) recorded in this study from wet mechanical brush-scrubbing, averaged 22.0%. This value was comparable to 21.8% obtained for hand-peeling, but differed with values ranging from 25 to 42% and 12 to 41%, respectively reported in the literature by Ugwu and Ukpabi (2000) and Olukunle (2007) for mechanized abrasion-peeling of cassava roots. The LPEI-values recorded in this study were much higher than counterpart values of 0.11 and 0.15 reported by Bakare et al. (2011) for lye-peeled cassava roots. Generally, the literature values relate to circumstances of methodology, cassava root varieties and properties that often times were not properly defined by the investigators reporting them which, hither-to, had been a bane of reported data in the literature relating to cassava root-peeling (Odigbo, 1976a, 1976b; Adetan et al., 2003).

The recorded residual values of NaOH when compared with WHO/FAO guideline for GRAS food products (of 75-100 ppm of NaOH permissible in food products) appeared to be just within the acceptable levels for 30% lye-peeled roots at 32 oC for 50-minutes and not so for 35% lye-peeled roots at 50 oC for 7.5-minutes. The important conclusion from these observations is to underscore the necessity for adequate residual NaOH neutralization as an additional process step in the mechanized lye-peeling of cassava roots, thereby adding one more critical unit operation to the process.

The HCN-contents recorded in the study for the relevant entities of interest, showed that appreciable reduction of the poisonous chemical (HCN) occurred in lye-peeled roots and their associated sludges. At high lye-concentration and temperature of treatment, root samples and their sludges recorded considerably lower HCN contents than those of fresh hand-peeled cassava roots and the associated peel. Values reported for hand-peeled cassava roots and their associated peel by Ugwu and Ukpabi (2000) and Ubwa et al. (2015) vary respectively, from 41.60 to 54.34 ppm for peeled-roots and 63.41 to 108.90 ppm for the detached peel of cassava roots. Exactly, why such significant reductions occurred, although of great interest, was not investigated explicitly but should be the subject of future studies on the lye-peeling of cassava roots.

CONCLUSION

The peel of cassava roots can be efficaciously and profitably removed by lye-treatment with zero or near-zero loss of the starchy-flesh-tissue of the peeled roots and without heat-ring using two optimality-options of process variable-combinations identified in paper-1 of this series of two papers and validated empirically in this follow-up study that constitutes paper-2.The residual level of NaOH in lye-peeled roots was successfully neutralized using HCl solution to satisfy WHO/FAO food safety quality specifications for GRAS food products. A neutralization component is therefore a necessary unit operation for any lye-peeling hardware to be configured for the mechanized lye-peeling of cassava roots.

The contents of HCN (hydrocyanic acid) in lye-peeled cassava roots as well as in the digest-sludge from lye-peeling were found to be about half of the levels in the raw root and peel, suggesting significant reduction-effects of lye-treatment, which needs to be further investigated to establish the exact destination of HCN, because the mere dilution-effect of hydrolytically produced water in the treatment-solution cannot, ipso facto, explain the level of reduction observed. Because only one cassava variety (TME-419, at age 12-months only) was investigated in the study, further work is therefore necessary to test the findings on other promising varieties and ages-at-harvest of new cassava root lines that are mushrooming from biotech-assisted breeding efforts, which are on-going.

ACKNOWLEDGEMENTS

The authors are grateful to the Department of Agricultural and Food Engineering, University of Uyo, Uyo-Nigeria for the laboratories and facilities used for the study. Professor C. N. Okeke is respectfully acknowledged for the generous grant to finance the publication-charges for the article.

REFERENCES

Adetan, D. A., Adekoya, L. O and Aluko, O. L. (2003). Characterization of some properties of cassava root. Journal of Food Engineering.59: 349-353.

Bakare, H.A., Adegunwa, M.O. Osundahunsi. O.F. and Olusanya, O. (2011). Optimization of lye-peeling of cassava (manihot esculenta crantz) using response surface methodology. Journal of Engineering and Natural Science, 10: 111-118.

Deguchi, S., Tsujii, K. and Horikoshi, K. (2006). Cooking cellulose in hot compressed water. Chemical communications (31): 3293.

F.A.O. (2012). Agricultural statistics. Available at http/faostat.fao,org. Accessed on 20/09/2017.

Igbeka, J. C. (1985). Mechanization of tuber (cassava) peeling. Proceedings of the International Symposium of Mechanization of Harvesting and Subsequent Processing of Agricultural Products in tropical Africa and the Manufacturing of Relevant Agricultural Implements, Yaounde, Cameroon; pp. 410-422.

Odigboh, E.U. (1976a). A cassava peeling machine: development, design and testing of a cassava peeling machine.Root Crops and Poverty Alleviation. Conference of the 6thTriennial Symposium of the ISTRC-AB. (Akoroda, M.O. & Ekanayake, I.J. Eds). Lilongwe, Malawi. Pp. 22-28.

Odigboh, E.U. (1976b). A cassava peeling machine: development, design and construction. Journal of Agricultural Engineering Research. Vol.21: 361-369.

Olukunle, O.J. (2007). Development of a cassava peeling machine for cottage industries. Conference on International Agricultural Research for Development. University of Kassel-Witzenhausen and University of Gottingen, October 9-11.

Salami, R. I., Ogunmola, A. L. and. Akindoye, O. (2000): Cassava peel processed by different methods as substitute for maize in cockerel starter diets. Proc. 28th Ann. Conference of Nigeria Society of Animal Production, 16 – 20 March. Ibadan. pp. 177-179, 2003.

Tsekwi,G.R. (2018). Cassava root peeling with lye-treatment followed by wet-mechanical brushing and neutralization. An unpublished M. Eng. Thesis, University of Uyo, 135 pages.

Tsewki, G. R. and Ngoddy P.O. (2018): A 2-stage investigative approach to the successful mechanization of the lye-peeling of cassava roots: a chemo-physico-mechanical (CPM-model) system and protocol for monitoring the hydrolytic digestion of strips of cassava peel-lignocellulose-complex during lye-treatment. Journal of Food Engineering, Nov. 2018

Ubwa, S.T., Otache, M.A., Igbum, G.O. and Shambe, T. (2015): Determination of cyanide content in three sweet cassava cultivars in three Local Government Areas of Benue State, Nigeria. Food and Nutrition Sciences, 6, 1078-1085.

Ugwu, B.O., Ukpabi, U. J. (2000): Potential of soy-cassava flour processing to sustain increasing production in Nigeria.Outlook on Agriculture 31(2) 121-133.

Wang, Y. and Field, M. (1978): Total cyanide determination of plants and food using the picrate and acid method. Food chemistry 77(1) 107-114.

Wurdemann, W. P., Ngoddy, P.O. and Onochie, B.E. (1976). Lye peeling of fresh cassava. A Paper presented by P.O. Ngoddy in the proceedings of the First International Congress on Engineering and Food, Boston (Department of Agricultural and Food Engineering, University of Massachusetts), U.S.A,. August 9-13, pp. 56-73.