1Associate Professor, Department of Biotechnology, Koneru Lakshmaiah Education Foundation, Vaddeswaram, Guntur, AP, India–522502

2,3,4,5Department of Biotechnology, Koneru Lakshmaiah Education Foundation, Vaddeswaram, Guntur, AP, India–522502

Corresponding author Email: kkchandrika@kluniversity.in

Article Publishing History

Received: 19/10/2018

Accepted After Revision: 21/11/2018

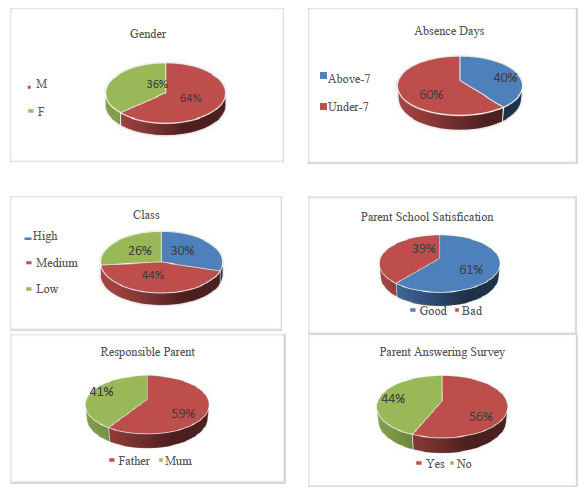

The capability of an algal species to remove NO2 and NO in the simulated flue gas was established using Dunaliella salina in Photobioreactors under two variants of NOx sources. The concentrations studies were in the range between 25ppm to 150ppm. The diffusion of NOx and subsequent reaction with water resulted in NO3- and NO2- in the growth medium. Algal growth by absorption of NO3- and NO2- created a nitrate gradient in the bulk medium resulting in NOx uptake rates from the gas phase of up to 96%, leaving the unconsumed nitrogen of up to 7 mg-N/L in the growth medium. Algal species having an initial cell density of 2.8×105 cells/mL grew to the cell density of 1.73×107 cells/mL and dry weight of 262 mg/L. The Nitrogen content of cells varied from 3-6%. The treatment of NOx in Photobioreactors was investigated with reference to the gas removal efficiency, cell growth and total nitrogen content in the biomass

Dunaliella Salina, Photobioreactors, Algal Growth

Chandrika K, Choragudi S. F, Kakarla K. K, Sumanth K, Devika C. Studies on Nox Removal Using Dunaliella Salina Algae in Photobioreactors. Biosc.Biotech.Res.Comm. 2018;11(4).

Chandrika K, Choragudi S. F, Kakarla K. K, Sumanth K, Devika C. Studies on Nox Removal Using Dunaliella Salina Algae in Photobioreactors. Biosc.Biotech.Res.Comm. 2018;11(4). Available from: https://bit.ly/2knzeGa

Introduction

Disproportionate usage of fossil fuels has been considered as the source for manmade toxic emissions comprising carbon dioxide, sulfur dioxide, nitrogen oxides, volatile organic compounds and heavy metals (Mulholland, 2008; Attilo et al., 2009). The by-products of fossil fuels have been identified as one of the major anthro- pogenic sources of this gas, contributing to global warming by the greenhouse effect. Therefore, it has become obligatory to reduce these toxic emissions before they are disposed into the environment. Nitric oxide (NO) and Nitrogen dioxide (NO2) are the two main components that make up NOx. These components are toxic and have various environmental hazards as per Environmental Protection Agency (Ronda, 2014). The nitrogen removal is 94.9 % in the ammonium form nitrogen group using biofilm (Yuxuan Zhu 2018).

There are several methods for treatment of NOx. Selective catalytic reduction (SCR) is used, however it is more expensive when applied for large-scale power plants (Miller et al., 2010). Another way to treat NOx from stationary sources is to use scrubbers to transfer the risk into an aqueous solution, which still must be treated or disposed of (Raja et al., 2007). Hence, to develop an economical and practical process to handle NOx exists. Cultivation of an algae to take up dissolved NOx from a scrubber as a nitrogen source, and oxygen only released as a by-product. This concept has been worked to estimate that, algal strains and conditions, algae can take up nitrogen from dissolved NOx (Nagase et al., 1997). Toxic compounds present in the flue gas inhibit the growth rate. NO2 has high solubility in water and therefore, reacts with water to form aqueous nitrates (NO3) and nitrites (NO2), some of the unaccounted-for nitrogen was lost due to volatization of gaseous nitrogen species, (Kaitlyan 2018).

Aqueous nitrate and nitrites are used by the algae as a source of nitrogen for cell synthesis, (Mulholland & Lomas, 2008). The dissolved NO2 and NO react to form dissolved nitrogen compounds which are available to ingest, biological conditions for the uptake of nitrate or nitrite by the algae, (Lee & Schwartz 1981). The nitrate or nitrite uptake by the algae reduce the soluble NO2, thus increases the concentration gradient of NO2 between liquid and the air. Thus, apparent solubility of NO2 is proportional to the NO2 gradient in the bulk medium, (Skalska, et al 2010). Nitrogen mono-oxide and sulfur dioxide can be removed by simultaneous absorption into aqueous mixed solutions of sulfite and [Fe II (edta)]H2O)]2−, ferrous ion coordinated to an anion of ethylene-diaminetetraacetic acid, (Tomasz et al 2016). A sequential process for the recovery and purification of multiple products was used on a mixture of algal biomass comprised of Spirulina platensis and Dunaliella salina (Kethineni 2017).

Dunaliella salina is a green algae known to with stand high salinity and accumulate carotenes. The nitrate requirement for algae is more for accumulation of biomass than for accumulation of carotene. Nitrates in the range of 1- 10mM is suitable for algal growth (Tafreshi et al., 2009). Harter et al, (2012) performed a mass balance for nitrogen from NOx for Dunaliella cultures in a column reactor. In a lab scale trail under simulated flue gas the results indicate that with an inflow of 150 µg N/L day NOX along with CO2 the alga could able to maintain a net influx of 0.52.73 µg N L-1 d-1 which amounts to 35% NOx removal. Nagase et al, (1997) studied the removal rate of nitric oxide by Dunaliella tertiolacta supplied in the range between 25-500ppm. At an inlet concentration of 500ppm NO in addition to CO2, it was shown to remove 110 µmoles per hour at a flow rate of 150mL/min. Also, it was shown that within a range of 100 to 400mL/min gas flow rate, a maximum of 60% of the NO was removed. These results suggest that D. salina is a potential algal species for NOx removal. the ability of the green algae, Chlorella to acclimate to high level of NOx and the potential usage of Chlorella strains in biological NOx removal (DeNOx) from industrial flue gases, (Tianpei and Gang Xu 2016). To understand the NOX removal process and to increase its range of applicability. The use of microalgae for simultaneous removal of CO2, SOx and NOx from flue gas is an environmentally benign process, (Hong‐Wei Yen et al, 2016), 75% decrease of the nitrogen concentration in the medium, with respect to the optimal values for growth, increased the lipid fractions of algal species, (Attilio Converti et al 2009).

It is very important to undertake biological NOX fixation. Therefore, in this work, two individual experiments were conducted to productively remove the NOx from simulated flue gas with varying NOx loading rates by estimating the optimal growth parameters. Different NOx concentrations were supplied to each photobioreactor inoculated with Dunaliella salina. NOx removal efficiency and algal growth were determined in each experiment.

Material and Methods

Dunaliella Culture

All three reactors were inoculated with 600 mL of pure Dunaliella salina (SAG:42.88) grown in Dunaliella medium (=Dun) at 250C and a pH of 7.0. The inoculum was grown to a 1 x107 cells/mL, with an initial cell density of 2.8×105 cells/mL

Growth Medium

The modified Dunaliella growth medium was used for inoculum and algae growth experimentation. All the nitrogen uptake by the algal cells was provided through inlet simulated gas. Dunaliella salina was grown in modified Dunaliella medium. A nitrogen free stock solution was prepared with K2HPO4, 0.1 g/ 100 mL. 20 mL of this nutrient was mixed with 30 mL of the soil extract and 930 mL artificial seawater to make a liter solution. The growth medium was given in Table 1.

Operating conditions of the reactor

Case1: pure NO2 feed source:

NO2 gas diluted with ambient air was used as the simulated flue gas for the first run. As the boiling point of NO2 is approximately 20oC at atmospheric pressure; NO2 was initially released as a liquid in the tubing. NO2 was blended with 3Lpm of air to get NOx concentrations of 100ppm, 200ppm,350 ppm in photobioreactors 1a, 1b, and 1c respectively. Experimental conditions were given in Table 2.

The simulated gas entered each photobioreactor through a sparger, pH was maintained in the range of 7.0 to 8.0 using CO2. The carbon dioxide feed was monitored by separate valves to each reactor which was controlled based on the pH in the reactor. NOx removal rates were monitored for four days. The reactors were illuminated with three 1 m long fluorescent white lights emitting, a total of 2700 Klux.

| Table 1: Modified Dunaliella growth medium | ||

| Component | Stock sol. (g/100mL) | Nutrient concentrate ion (mL) |

| KOH | 0.1 | 20 |

| Soil extract | 30 | – |

| Artificial seawater | 930 | – |

Case 2: Gas feed source calibration:

For the case 2, the reactors were inoculated before to the start of NOx loading and left for two days during which, only ambient air was supplied to the system. NOx was given from NO2 calibration gas cylinders comprising 5000 ppm and 9000 ppm NO2 concentration. Thus, in this case, the need for the liquid NO2 trap was ignored as the gas mixture was already in a vapor state. Thus, pumping calibration gas achieved steady inlet concentrations. Experimental conditions were given in table3. The calibrated NO2 is blended using air for the required NOX concentrations. The calibrated gases were supplied to the reactor at 3 Lpm, having NO2 concentrations of 25 ppm, 50 ppm, 120 ppm respectively. The concentration range was chosen to resemble real-time power plant NOx concentrations. Two aquarium stones of 12cm were used to diffuse the gas into the reactor. CO2 was supplied in the system, at a concentration of 400ppm until the pH remains 7 However when the pH is below 7, the pH 7 was maintained using 1.0 g/L solution of sodium bicarbonate (NaHCO3). The system was run for six days after loading of NOx. Influent and effluent concentrations of NO and NO2 in gas samples were measured using an analyser, (Testo 350-S/-XL, USA).

| Table 2: Experimental conditions for case 1 | |||

| Setting | Reactor 1a | Reactor 1b | Reactor 1c |

| Inlet NOx (ppm) | 100 | 200 | 350 |

| Inlet Gas Flow Rate (Lpm) | 3 | 3 | 3 |

| pH | 7-8 | 7-8 | 7-8 |

| Temperature (0C) | 20 | 20 | 20 |

Results and Discussion

Nox Removal Efficiency

Case 1: pure NO2 feed source

In this case, the reactors were fed with pure NO2 which is delivered as a liquid at room temperature and then the collected vapors were diluted with air. Using pure NO2 gas, actual average inlet concentrations for reactors 1a, 1b, and 1c were 108 ppm, 35ppm, 70 ppm respectively (Table 4). Fig. 1 shows the Dunaliella growth curve in reactors 1a, 1b, and 1c during 90-hour run.

| Table 3: Experimental conditions for case 2 | |||

| Setting | Reactor 2a | Reactor 2b | Reactor 2c |

| Inlet NOx (ppm) | 25 | 50 | 120 |

| Inlet Gas Flow Rate (Lpm) | 3 | 3 | 3 |

| Influent CO2(g) (ppm) | 400 | 400 | 400 |

| pH | 7-8 | 7-8 | 7-8 |

| Temperature (0C) | 20 | 20 | 20 |

All three reactors began with 2.8×105 cells/ml. As shown in Fig. 1, the culture in reactor 1a began exhaustive during the first 24 hours, therefore, the cells never attained a density greater than the initial. The maximum cell densities, for 1b, 1c were 1.46×106 cells/mL and 1.48×106 cells/mL respectively. Table 3 presents the NOx removal data for the reactors under case 1. Inlet and outlet NOx in Table 3 is the summation of measured NO and NO2 concentrations in the inlet and outlet streams. The efficiency of NOx removal by the algal system is based on total nitrogen through the reactor system and not on any particular NOx component. Therefore, removal percent of total NOx is only considered in the analysis. Reactor 1a obtained an average NOx removal of 49%, Reactor 1b achieved an average 51% NOx removal, and Reactor 1c has removed an average of 81% of inlet NOx. The average NOx removal efficiency for the first 60 h was 39%, but the average removal for the last 25 hours was 52%. As the algal culture was declining, removal of NOx could be associated with the dissolution of NO2 into the medium.

| Table 4. Influent and effluent NOx concentrations in reactors | ||||

| Reactor | Ratio (NO:NO2) | Inlet NOx (g) Conc (ppm) | Outlet NOx (g) Conc (ppm) | Average removal Conc (%) |

| 1a | 0.47 | 108±55 | 47±33 | 49 |

| 1b | 0.15 | 35±16 | 15±12 | 51 |

| 1c | 0.35 | 70±32 | 8±7 | 81 |

| 2a | 0.038 | 27±6 | 11±4 | 59 |

| 2b | 0.035 | 57±9 | 2±8 | 96 |

| 2c | 0.043 | 126±12 | 7±11 | 95 |

|

Figure 1: Growth curves in Photobioreactors for case 1 |

Reactors 1b and 1c presented moderate growth following an extended lag phase, as shown in the figure1. Algae in reactors 1b, 1c has not truly experienced log phase, and the run was ended after 90 hours.

Case 2: Calibration gas as a feed source

As shown in Fig. 2 all three reactors began with a cell concentration of 2.8×105 cells/mL for three reactors 2a, 2b, and 2c .Maximum cell densities were 1.24×107 cells/mL, 1.46×107 cells/mL and 1.72×107 cells/mL respectively. To overcome some of the problems that appeared from using pure NO2 gas in case 1, NO2 calibration gases of 5000ppm and 10000 ppm NO2 were used to supply NOx for case 2. This allowed for accurate NOx loading concentrations. Actual NOx Loading rates for case 2 were 27 ppm, 57 ppm and 126 ppm for reactors 2a, 2b, and 2c respectively.

| Table 5: Total suspended solids of Photobioreactors in Case 2 | ||

| Photo-bioreactor | TSS Initial (mg/L) | TSS Final (mg/L) |

| 2a | 6.0 | 210 |

| 2b | 5.7 | 243 |

| 2c | 6.3 | 222 |

The data in Table 4 presents the removal of NOx for the reactors (case 2). Inlet and outlet NOx in Table 4 is the summation of measured NO and NO2 concentrations in the inlet and outlet streams. Reactor 2a got an average NOx removal of 59% reactor 2b got an average 96%, and reactor 2c was able to remove an average of 95% of inlet NOx. The lag phase was reduced to less than 24 hours due to delay in NOx loading, and log phase was attained between 24 and 48 hours. NOx loading started at 48 hours, and three reactors showed continued growth, but with a significant decline in growth rate (Fig. 2).

| Table 6: Nitrogen mass balance data | |||

| Reactor 2a | Reactor 2b | Reactor 2c | |

| NOx Input | 890 | 1740 | 3450 |

| NOx Output | 450 | 60 | 90 |

| N Consumed from NOx gas phase | 440 | 1680 | 3360 |

| Initial N in growth medium | 23 | 22 | 23 |

| Final NO3– | 27 | 14 | 48 |

| Final NO2– | 74 | 13 | 163 |

| Net Accumulation of NO3– +NO2– | 78 | 5 | 188 |

| Initial Organic N | 0 | 0 | 0 |

| Final Organic N | 310 | 750 | 1140 |

| N Accumulated in Algal Cells | 310 | 750 | 1140 |

| Total N Accumulated | 388 | 755 | 1228 |

| Mass Balance (% NOx uptake accounted for) | 88% | 45% | 36% |

|

Figure 2: Growth curves in Photobioreactors for case 2 |

Total suspended solids (TSS) for initial and final samples were taken to quantify algal growth and to estimate the nitrogen content of the cells. The results were summarized in the Table 5. Total suspended solid results show that 37 fold average mass growth was accomplished over the 190-hour run. For nitrate and nitrite concentrations, liquid samples from case 2 were analyzed, and the results were shown in Fig.3. Nitrate was completely drained in all three reactors before NOx was loaded into the system at 49 hours. Nitrogen source available for algal growth only after that point was from dissolved NO2. Initial and final total organic nitrogen content of the algal cultures was used to estimate the uptake of nitrogen by algae and to determine the nitrogen content of the cells. These analyses summarized in the table: the cells in reactors 2a, 2b, and 2c were found to contain 6.2%, 4.1%, and 7.9% nitrogen respectively. A mass balance of nitrogen was conducted to assess the effect of NOx through the system. In reactor 2a, the mass balance alleged for 88% of the observed NOx removal, as slightly more nitrogen was found in the cells and growth medium than entering the system.

|

Figure 3: I) & II) Concentrations of NO3 & NO2 in Reactors 2a, b, c |

For reactors 2b and 2c, only 45% and 36% respectively of the nitrogen that entered the system was found in the cells and growth medium. NOx feed stream: Loading NOx at a particular concentration tested to be very difficult for the first case, as can see by more standard deviations in the table 6:. In the first case, NOx was given from a pure NO2 cylinder, and vapors from this liquid were pumped using peristaltic pumps into the reactors. To overcome large deviations in concentration, case 2 was operated using calibration gases. Data analysis considered only in case 2 because of the NOx feed was not consistent during case1.Nitrogen mass balance data summarized in Table 6. The only difference in the three reactors in case 2 was the loading rates of NOx.

NOx removal: In case 2, NOx removal rates are 59%, 95%, 96% for reactors 2a, 2b, and 2c respectively. Only 59% NOx removal was achieved in reactor 2a, which had the lowest NOx loading rate. NOx loading rates were different in three reactors. Aqueous nitrate and nitrite concentrations in the reactors are shown in Figure3.

Cell growth: The average specific growth rate for the first 2 days in reactors 2a, 2b, and 2c was 0.03, 0.06, 0.12 respectively, the average specific growth rates for the same period in reactors 1a, 1b were both negative, the growth curves of case 2 presented in Fig. 3, after loading NOx, growth rates started to decline in all three reactors and never achieved the value as before NOx loading, and this declining growth is proportional to the NOx concentration entering the system. Approximately 48 hours of NOx loading, the inlet concentrations of NOx do not affect algal growth. Algae took nearly 48 hours to adopt new nitrogen source.

Nitrate /Nitrite: The algae was able to take nitrate in solution before the loading of into the reactors. After 48 hours Nitrogen source is available only from NOx. The steady fall in NO3- concentrations and NO2- accumulation in reactor 2c suggests that algae preferred NO3- as its nitrogen source over NO2-.

Conclusion

The primary purpose of this study was to test the hypothesis that Dunaliella can grow on nitrogen from dissolved NO2 as its only nitrogen source for cell synthesis. Dunaliella grew used only nitrate /nitrite generated by the NOx dissolution for cell synthesis, reaching a maximum cell density of 1.75x107cell/ml. A reactor with lower NO2 loading concentrations resulted in lower NOx removal rates, for this reactor, nitrate was not accumulated as efficiently as a similar with grated NOx loading. In case 2: cell growth of mass between 1850mg/L to 198mg/L. Nitrogen was removed from gaseous NOx at a rate of 0.06-0.45 mg N/mg cell growth. Assuming a 700 MW natural gas fired power plant can produce up to 1,70,000m3/h of flue gas with approx. 50ppm NOx concentrations, growth of a minimun110 kg algal cell/h would be required to treat this stream.

References

Attilo Converti et al (2009) Effect of temperature and nitrogen concentration on the growth and lipid content of Nanochloropsi lata and Chlorella vulgaris for biodiesel production Chemical Engineering and Processing Vol.48 1146-1151

Harter H J (2013) Carbon and nitrogen mass balance during flue gas treatment with Dunaliella salina cultures, Journal of Applied Phycology, Volume 2 : 359-368

Hong‐Wei Yen (2015) CO2, NOx and SOx removal from flue gas via microalgae cultivation, Biotechnology Journal Vol. 10: 890-899.

Kaitlyan D (2018) The fate of nitrogen through algal treatment of landfill leachate, Algal Research, Volume 30: 50-58

Kethineni, C. (2017) Development of Sequential Processes for Multiple Product Recovery from Microalgae, Industrial Biotechnology Vol 14 No 2:94-99

Lee, Y. N., & Schwartz, S. E. (1981) Reaction kinetics of nitrogen dioxide with liquid water at low partial pressure. The Journal of Physical Chemistry.Vol 85 No7: 840-848

Miller, J. S., & Ledakowicz, S. (2010) Trends in NOx abatement: A review. Science of the Total Environment, Vol 408 No 19:3976-3989.

Mulholland, M. R., & Lomas, M. W. (2008) Nitrogen Uptake and Assimilation. In D. G. Capone, D. A. Brown, M. R. Mulholland, & E. J. Carpenter (Eds.), Nitrogen in the marine environment Amsterdam: Elsevier Academic Press. (2nd Ed.: 303-384).

Nagase, H. (1997) Characteristics of biological NOx removal from flue gas in a Dunaliella tertiolecta culture system. Journal of Fermentation and Bioengineering,Vol. 83 No 5: 461-465

Raja R S. Hemaiswarya, R. Rengasamy (2007) Exploitation of Dunaliella for â-carotene production. Applied Microbiology & Biotechnology.Vol 74 No 3: 517–523

Ronda JI (2014) A growth inhibitory model with SOx influenced effective growth rate for estimation of algal biomass concentration under flue gas atmosphere, Bioresource Technology, Volume 152: 283-291

Skalsa K (2010), Trends in NOx abatement. Implementation of stringent regulations of NOx emission requires the development of new technologies for NOx removal from exhaust gases.Science of The Total Environment Vol. 408: 3976-3989

Tianpei Li and Gang Xu (2016). The acclimation of Chlorella to high-level nitrite for potential application in biological NOx removal from industrial flue gases. Journal of Plant Physiology Vol. 195: 73-79.

Tomasz T & Hidehiro Kumazawa (2016) Reactivity of nano-size zinc powder in the aqueous solution of (FeIII(Edta) (H2O) Science of The Total Environment Vol. 628–629: 870-881

Yuxuan Zhu (2018), Biological activities and nitrogen and phosphorus removal during the Anabaena flos-aquae biofilm growth using different nutrient form, Bioresource Technology, Volume 251: 7-12