1College of Dentistry, Riyadh Elm University, Riyadh; Derma Dental Clinics Riyadh. Saudi Arabia

2College of Dentistry, Riyadh Elm University, Riyadh; Prince Sultan Military Medical City. Riyadh. Saudi Arabia.

3Prosthodontic Speciality Clinics. King Saud University Medical City, Riyadh. Saudi Arabia.

4Department Of Community Dentistry, Dow International Dental College, Karachi , Pakistan

5Public Security Medical Services, Security Patrols Medical Center, AlRiyadh Saudi Arabia.

6Prince mohammed bin Naif Medical Center, King Fahad Security College, Alriyadh, Saudi Arabia.

7Department Of Prosthetic Dental Science, College Of Dentistry, King Saud University, Riyadh, Saudi Arabia

Corresponding author email: fahimvohra@yahoo.com

Article Publishing History

Received: 17/01/2020

Accepted After Revision: 18/03/2020

The aim was to investigate the surface roughness of de-bonded ceramic surfaces with residual resin when treated with different resin removal treatment protocols. Sixty disc specimens of 5mm diameter and 3mm height of Lithium disilicate ceramic (IPS Emax Press) were fabricated. All specimens were treated with Hydrofluoric (HF) acid (9.5%) for 30 secs. Except 10 specimens as controls, all received silane treatment and a resin cement build-up (3mm x 2mm). All build-ups were sheared with universal testing machine and residual resin was removed using 5 protocols. Group 1: No treatment; Group 2: Bur treatment; Group 3: Heat treatment at 650° C (1min); Group 4: Heat treatment at 750° C (7 min); Group 5: Sandblasting (Al2O3) (2 min). The surface roughness (Ra) of all specimens was assessed using a non-contact laser surface profilometer. Data was assessed using ANOVA and multiple comparisons test. The highest roughness value was observed in the ceramic specimens exposed to sandblasting (Gp 5), which was 9.027 (1.362) μm. However the lowest Ra was observed for Gp 1 specimens [5.092 (0847) μm]. Overall, the difference among the study groups for surface roughness values was statistically significant (p<0.05). Presence of residual resin on de-bonded ceramic surfaces, compromises the surface roughness. Removal of residual resin with heat treatment at 650° C (1min) and sandblasting significantly improved and restored the surface roughness of de-bonded ceramics in comparison to Hydrofluoric acid etched ceramic surface.

Ceramic, De-bonding, Resin removal, HF Acid, Heat treatment, Sandblasting.

Alhamzah N. B, Alsahil N. H, Afzal I, Naseem M, Alqahtani I. M, Aleuhaymi A. A, Vohra F. Influence of Hydrofluoric Acid Etching, Resin Bonding and Resin Removal Treatments on the Surface Roughness of Ceramics. Biosc.Biotech.Res.Comm. 2020;13(1).

Alhamzah N. B, Alsahil N. H, Afzal I, Naseem M, Alqahtani I. M, Aleuhaymi A. A, Vohra F. Influence of Hydrofluoric Acid Etching, Resin Bonding and Resin Removal Treatments on the Surface Roughness of Ceramics. Biosc.Biotech.Res.Comm. 2020;13(1). Available from: https://bit.ly/31S25Uh

Copyright © Alhamzah et al., This is an Open Access Article distributed under the Terms of the Creative Commons Attribution License (CC-BY) https://creativecommons.org/licenses/by/4.0/, which permits unrestricted use distribution and reproduction in any medium, provide the original author and source are credited.

INTRODUCTION

Adhesive dentistry is the mainstay for esthetic restorations in oral rehabilitations. Resin and ceramic based materials are frequently employed for replacement of lost or damaged tooth structure and esthetic rejuvenations (Patil & Shetty, 2009). Esthetic ceramics are used in the form of veneers or crowns, however require surface conditioning of both the tooth and ceramic for predictable adhesive bonding (Farias et al., 2019). Mechanisms used to secure ceramics to tooth structure include, mechanical retention with ceramic surface treatments for improved surface energy and micro-rough surface (Saker et al., 2019).

In addition, application of a chemical silane bifunctional molecule, connecting silica to hydroxyl ions in resin, increasing surface energy of ceramic allowing for penetration of luting agents (Murillo-Gómez et al., 2019). Ceramic surface etching with Hydrofluoric acid (HF acid) with varying concentration and duration is standard treatment for developing mechanically retentive surface. It is suggested that increasing the duration of HF acid application improves the surface pores, roughness and wettability (Zogheib et al., 2011).

Resin cemented ceramic veneers are employed to improve tooth shade, shape, size and form. However debonding of intact veneers followed by re-bonding is a frequent phenomenon due to inadequacies in clinical procedure (Granell Ruíz et al., 2014). Re-bonding is a challenging procedure, as it requires complete removal of luting resin from the ceramic surface without damage (Blatz et al., 2003). It is considered critical to expose the ceramic after removing the luting resin from the surface pores to re-create the desired surface topography of ceramics as displayed after acid etching (Magne et al., 2006; Martins et al., 2012). It is reported that contamination of etched ceramic surface results in compromised ceramic resin bond (Magne et al., 2006; Martins et al., 2012). Contaminants of the etched ceramic surface reduce surface pore size and numbers, potentially altering the surface topography. Therefore a compromised surface microstructure of the ceramic will jeopardize micromechanical retentive properties of ceramic, reducing the potential for ceramic bonding to tooth.

Surface roughness of ceramics is critical in producing an effective micromechanical bond. Increased surface roughness improves micro and nano-scale pores increasing surface area of the bondable ceramic (Ho & Matinlinna, 2011). In addition, increased roughness of ceramic surface further improves the wettability by reducing the contact angle facilitating the penetration of resin for ceramic bonding (Xiaoping et al., 2014; Colares et al, 2013). In the study by Román-Rodríguez et al., HF acid etched ceramics covered with resin were treated for removal of resin (Román-Rodríguez et al., 2015).They concluded that placement of ceramic in furnace at 650 °C for 1 minute pyrolized the resin and left a clean and retentive surface for re-bonding (Román-Rodríguez et al., 2015). However they did not assess the surface roughness of the heated ceramic surface. In addition, the influence of other treatments employed for the removal of resin from debonded ceramic surfaces including diamond bur, sandblasting and ceramic glaze treatment still need to be investigated. It is hypothesized that use of different methods, including diamond bur, heat treatments in furnace (650 °C and glaze treatment) and sandblasting will significantly influence the surface roughness of de-bonded ceramic surface. Therefore the aim of the study was to investigate the surface roughness of de-bonded ceramic surfaces with residual resin when treated with different resin removal treatment protocols.

MATERIAL AND METHODS

Sixty disc specimens of 5mm diameter and 3mm height of Lithium disilicate ceramic (IPS Emax Press, Ivoclar Vivadent, NY, USA), were fabricated using the Hot-Press technique. Discs were initially prepared using inlay wax (Inlay casting wax- Kerr-CA, USA) and a putty mold was produced using it. The wax discs were invested using investment material (IPS PressVest, Ivoclar Vivadent, NY, USA). Ceramic ingots (IPS Emax Press, Ivoclar Vivadent, NY, USA) of light translucency (LT) were hot pressed in a Press furnace (Programat EP 5010) at 5 bar and 925 °C. The divested ceramic discs were sandblasted with glass beads to remove the reaction layer and ultrasonic cleaned in distilled water for 5 minutes. Ceramic discs were polished with 600 grit silicon carbide paper on a slow speed wheel with continuous water.

All ceramic specimens were treated with Hydrofluoric (HF) acid (Porcelain Etchant, 9.5%, Bisco-IL.USA) for 30 secs, followed by washing with water (20 sec) and ultrasonic cleaning in distilled water for 5 min. 10 specimens were kept as controls with no further treatment (positive control) (Gp C). The remaining fifty specimens were treated with silane (1 min) (Monobond Plus- Ivoclar Vivadent. NY, USA). It was followed by a build-up of dual cure resin cement (Nexus 3rd Gen- Kerr CA, USA) (2mm diameter and 3mm height) on the ceramic surface using a putty mold and a glass slide. Excess cement was removed and resin cement was light cured (Bluephase, Ivoclar, Vivadent) for 40 sec from top and 40 sec after removal of mold.

All cement build-ups were sheared from the ceramic discs using a chisel placed parallel to the interface between the cement and ceramic. A controlled force was applied using a universal testing machine (Instron-5965) until fracture. The fifty specimens were further divided into 5 subgroups (n=10) based on the surface treatment for removal of residual resin on the ceramic surface.

Gp 1: No removal of resin (negative control)

Gp 2: Diamond bur on slow speed handpiece to remove the resin cement.

Gp3: Place ceramic in furnace for 1 min at 650 ° C.

Gp 4: Place ceramic in furnace and use glazing heat treatment procedure to pylorize (6+1 min at 750 ° C)

Gp 5: Removal of resin ceramic with sandblasting for 2 minutes (Aluminum oxide).

After ceramic surface treatments, surface profilometry was performed to assess the surface roughness (Ra) using a 3D non-contact optical surface profiler (Contour Gt-K1 optical profiler, Bruker Tucson, AZ, USA). The surface profilometer produced scale independent outcomes and produced sub-nanometer vertical resolutions. The profiler used a strong Vision 64 interface for image production and scanning. The specimens did not need any preparation and prior to each measurement the profilometer was calibrated. An average of upto nine measurements were performed in parallel, oblique and perpendicular planes. The value of Ra in μm, presents an average of the surface traced by the profiler. The data obtained was assessed for normality and compared for roughness among the study groups using ANOVA and Tukey Multiple comparisons test.

RESULTS AND DISCUSSION

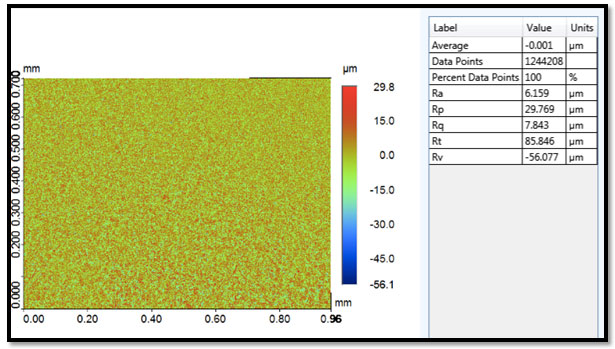

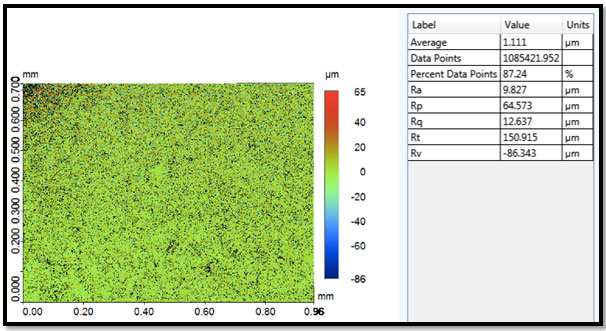

All data obtained from profilometer assessments was normally distributed. The surface roughness after HF acid etching- control group (Gp C) was 7.683 (0.609) μm. With resin coating of the etched ceramic surface (Gp 1) the surface roughness reduced to 5.092 (0847) μm. Four resin removal treatments were assessed in the present study. The surface of ceramic specimens placed in the furnaces i.e. group 3 and group 4, showed roughness (Ra) values of 8.274 (0.652) μm and 7.381 (0.721) μm respectively. The observed roughness values among ceramic specimens treated with diamond bur (Gp 2) were 8.187 (1.539) μm. The highest roughness value was observed in the ceramic specimens exposed to sandblasting (Gp 5), which was 9.027 (1.362) μm (Table 1).

Table 1: Mean and standard deviations of surface roughness (Ra) among study groups.

| Resin Cement Treated | ||||||

| Study Group | Group C

HF Acid (+ve control) |

Group 1

No Treatment (-ve control) |

Group 2

Bur Treatment |

Group 3

650 °C (1 min) |

Group 4

750° C (7 min) |

Group 5

SB (1 min) |

| Surface Roughness (Ra) | 7.683

(0.609) |

5.092 (0.847) | 8.187

(1.539) |

8.274

(0.652) |

7.381

(0.729) |

9.027

(1.362) |

Overall, the difference among the study groups for surface roughness values was statistically significant (p<0.05) using ANOVA. Using multiple comparisons test, study groups were statistically compared (Table 2). The groups with HF acid treatment (Gp C-positive control) [7.683 (0.609) μm] showed significantly higher Ra compared to resin treated group [5.092 (0847) μm] (Gp 1- negative control) specimens (p<0.05) and significantly lower Ra to sandblasted group specimens (Gp 5) [9.027 (1.362) μm] (p<0.05). Specimens with resin treated ceramics without removal treatment (Group 1) showed significantly lower surface roughness [5.092 (0847) μm] compared to all groups (p<0.05). Ra among groups 2 [8.187 (1.539) μm] , 3 [8.274 (0.652) μm] and 4 [7.381 (0.721) μm] specimens were statistically comparable (p>0.05). Group 5 ceramic specimens (sandblasted) [9.027 (1.362) μm] exhibited significantly higher Ra values compared to Group C [7.683 (0.609) μm] and Group 1 specimens [5.092 (0847) μm] (p<0.05) (Figure 1). In addition, surface roughness of sandblasted specimens [9.027 (1.362) μm] was also significantly higher than group 4 specimens [7.381 (0.721) μm] (p<0.05) (Figure 2).

Table 2: p values among the study using Tukey HSD Post-hoc Test

| HF Acid | Group 1

No Treatment |

Group 2

Bur Treatment |

Group 3

650 °C |

Group 4

750° C |

Group 5

SB |

|

| HF Acid | 0 | 0.001* | 0.6268 | 0.4518 | 0.9368 | 0.001* |

| Group 1

No Treatment |

0 | 0.001* | 0.001* | 0.001* | 0.001* | |

| Group 2

Bur Treatment |

0 | 0.999 | 0.134 | 0.105 | ||

| Group 3

650 °C |

0 | 0.0711 | 0.1909 | |||

| Group 4

750° C |

0 | 0.001* | ||||

| Group 5

SB |

0 |

* Indicate statistical significant difference among study groups

Figure 1: Profilometry Micrograph For surface roughness (Ra) of a group 1 specimen

Figure 2: Profilometry Micrograph For surface roughness (Ra) of a group 5 specimen.

The present study was based on the hypothesis that use of different methods, including diamond bur, heat treatments in furnace (650 °C and glaze treatment) and sandblasting will significantly influence the surface roughness of de-bonded ceramic surface. In the present study, specimens treated for resin removal using heat treatment, sandblasting and burs, all showed a significant change in ceramic surface roughness in comparison to untreated specimens. Therefore the proposed hypothesis was accepted. A myriad of explanations could support the outcomes in the present study, including chemical properties of resin, high speed impact of sandblasting and and physical properties of resin and ceramics.Surface roughness of Lithium disilicate (LD) ceramics was assessed as they are widely used in dentistry for oral rehabilitations. They are comprised of a silica glass matrix and lithium oxide crystals, which act as flux. LD ceramics show higher flexural and fracture resistance to conventional glass ceramics, due to the randomly arranged needle like crystals acting as crack stoppers (Awad et al., 2019).

When ceramic veneers are debonded, to improve surface finish, glaze procedure is often repeated; therefore heat treatment of resin-covered ceramics was investigated in the present study. In addition, diamond or carbide burs on a slow speed handpiece are the most common methods of resin removal for clinicians, chairside. Moreover, sandblasting with aluminum oxide particles is commonly employed in laboratories to remove material remnants and improve surface roughness of metals and ceramics (Barutcigil et al, 2019). “Ra” as a parameter of surface profile is widely used in material and ceramic research reports (Blunt et al, 2008). It is recommended that Ra is measured over “a number of consecutive sampling lengths”, and average values to be reported, as observed in the present study (Leach , 2010).

In the present study, HF acid etched surface was considered the standard (control), which showed higher Ra compared to resin treated specimens. The resin cement tends to occupy the surface pores produced by etching, covering the etched surface resulting in low roughness outcomes. Re-bonding of such surfaces does not allow penetration of bonding agent into the micro-porosities, hence resin covered surfaces were treated for resin removal. The use of diamond bur (group 2) in the present study resulted in a significantly higher Ra then group1 specimens (no resin removal). It has been revealed in previous studies that diamond bur and disc treatments improve adhesive resistance of ceramics (Guler et al., 2005). Interestingly, the standard deviations of the bur treatment were wide (1.539), reflecting the operator dependency and error prone nature of this treatment modality.

We assessed the influence of heat treatments at 650° C and 750° C in an attempt to remove resin and expose the etched ceramic surface. It was shown that both heat treatments exhibited significant removal of resin and the Ra improved significantly from group 1. A possible explanation for this finding lies in the boiling point of resins, which is lower than the temperatures applied by the furnace in glaze cycles. In a study by Román-Rodríguez et al., (Román-Rodríguez et al., 2015) it was concluded that placement of ceramic veneer in the furnace at 650° C for 1 minute would burn out the resin on ceramic surface. It is now revealed that the ceramic surface roughness will be re-acquired as a result of heat treatment procedure. In addition the Ra for ceramics heated to 750° C (7 min) was lower (7.381) compared to the Ra for ceramics heated at 650° C (1 min) (8.274). This may be attributed to the melting effect of high temperature heating for silica matrix within the lithium disilicate ceramics (Shenoy and Shenoy, 2010). This results in loss of depth width and size of micro-porosities produced by acid etch (Shenoy and Shenoy, 2010).

It was observed in the present study that resin covered ceramic surface when sandblasted, resulted in the highest surface roughness among all groups. The application of aluminum oxide particles at high speed creates impacts resulting in removal of resin on ceramic surface. However the increased surface roughness does not only represent the resin removal but merely shows the topographical effects of the high-speed particle impacts on the ceramic surface. In addition, the sandblasted specimens also showed a wide standard deviation for Ra (1.362), indicating a resin removal method with less reliability and possible untoward effects on ceramics (Zhang et al., 2004). Therefore although the surface roughness was significantly improved by sandblasting a standard protocol for its use in resin removal should be devised.

The outcomes indicate that the removal of resin from ceramic surface using heat treatment at 650° C (1 min) or sandblasting can result in a rough ceramic surface similar to an etched ceramic surface. However a possible limitation of the study is the lack of adhesive bond strength assessment which would determine the effect of the resin removal on the re-bond of ceramic to resin cements. In addition, it is critical to identify the remaining resin on the ceramic surface after resin removal treatments. Therefore further studies assessing the amount of residual resin and its influence on bond strength after resin removal from de-bonded ceramic surfaces are recommended.

CONCLUSION

Presence of residual resin on de-bonded ceramic surfaces, compromises the surface roughness. Removal of residual resin with heat treatment at 650° C (1min) and sandblasting significantly improved and restored the surface roughness of de-bonded ceramics in comparison to Hydrofluoric acid etched ceramic surface.

Conflict of Interest.

The author declare no conflict of interest

REFERENCES

Awad, M.M., Al Jeaidi, Z.A., Almutairi, N., Vohra, F., Özcan, M. and Alrahlah, A., 2019. Effect of self-etching ceramic primer on bond strength of zirconia-reinforced lithium silicate ceramics. Journal of Adhesion Science and Technology, pp.1-11.

Barutcigil, K., Barutcigil, Ç., Kul, E., Özarslan, M.M. and Buyukkaplan, U.S., 2019. Effect of different surface treatments on bond strength of resin cement to a CAD/CAM restorative material. Journal of Prosthodontics, 28(1), pp.71-78.

Blatz, M.B., Sadan, A. and Kern, M., 2003. Resin-ceramic bonding: a review of the literature. The Journal of prosthetic dentistry, 89(3), pp.268-274.

Blunt, L., Jiang, X., Leach, R., Harris, P. and Scott, P., 2008. The development of user-friendly software measurement standards for surface topography software assessment. Wear,264(5-6), pp.389-393.

Colares, R.C.R., Neri, J.R., Souza, A.M.B.D., Pontes, K.M.D.F., Mendonca, J.S. and Santiago, S.L., 2013. Effect of surface pretreatments on the microtensile bond strength of lithium-disilicate ceramic repaired with composite resin.Brazilian dental journal, 24(4), pp.349-352.

Farias, D.C.S., Gonçalves, L.M., Walter, R., Chung, Y. and Blatz, M.B., 2019. Bond strengths of various resin cements to different ceramics. Brazilian oral research, 33.

Granell-Ruíz, M., Agustín-Panadero, R., Fons-Font, A., Román-Rodríguez, J.L. and Solá-Ruíz, M.F., 2014. Influence of bruxism on survival of porcelain laminate veneers. Medicina oral, patologia oral y cirugia bucal, 19(5), p.e426.

Guler, A.U., Yilmaz, F., Ural, C. and Guler, E., 2005. Evaluation of 24-hour shear bond strength of resin composite to porcelain according to surface treatment. The Journal of Prosthetic Dentistry, 94(6), p.538.

Ho, G.W. and Matinlinna, J.P., 2011. Insights on ceramics as dental materials. Part II: chemical surface treatments. Silicon,3(3), p.117.

Leach, R.K, 2010. Fundamental principles of engineering nanometrology. Elsevier. Micro & nano technologies series. Elsevier, William Andrew, Amsterdam, 1. ed edition,. OCLC: 837259110

Magne, P. and Cascione, D., 2006. Influence of post-etching cleaning and connecting porcelain on the microtensile bond strength of composite resin to feldspathic porcelain. The Journal of prosthetic dentistry, 96(5), pp.354-361.

Martins, M.E., Leite, F.P., Queiroz, J.R., Vanderlei, A.D., Reskalla, H.N. and Ozcan, M., 2012. Does the ultrasonic cleaning medium affect the adhesion of resin cement to feldspathic ceramic. J Adhes Dent, 14(6), pp.507-509.

Murillo-Gómez, F., Wanderley, R.B. and De Goes, M.F., 2019. Impact of Silane-containing Universal Adhesive on the Biaxial Flexural Strength of a Resin Cement/Glass-ceramic System.Operative dentistry, 44(2), pp.200-209.

Patil, R. and Shetty, O., 2019. Full mouth rehabilitation performed using customized Broadrick’s flag to restore mandibular posterior teeth-A Case Report. Clinical Dentistry (0974-3979), 13(2).

Román-Rodríguez, J.L., Alonso-Pérez-Barquero, J., Bruguera-Álvarez, A., Agustín-Panadero, R. and Fons-Font, A., 2015. Cleaning and retreatment protocol for a debonded ceramic restoration. Journal of clinical and experimental dentistry, 7(1), p.e60.

Saker, S., Özcan, M. And Al-zordk, W., 2019. The impact of etching time and material on bond strength of self-adhesive resin cement to eroded enamel. Dental materials journal, pp.2018-126.

Shenoy, A. and Shenoy, N., 2010. Dental ceramics: An update. Journal of conservative dentistry: JCD, 13(4), p.195.

Xiaoping, L., Dongfeng, R. and Silikas, N., 2014. Effect of etching time and resin bond on the flexural strength of IPS e. max Press glass ceramic. Dental Materials, 30(12), pp.e330-e336.

Zhang, Y., Lawn, B.R., Rekow, E.D. and Thompson, V.P., 2004. Effect of sandblasting on the long‐term performance of dental ceramics. Journal of Biomedical Materials Research Part B: Applied Biomaterials:, 71(2), pp.381-386.

Zogheib, L.V., Bona, A.D., Kimpara, E.T. and Mccabe, J.F., 2011. Effect of hydrofluoric acid etching duration on the roughness and flexural strength of a lithium disilicate-based glass ceramic. Brazilian dental journal, 22(1), pp.45-50.