Department of Agriculture, Damghan Branch, Islamic Azad University, Damghan, Iran

Article Publishing History

Received: 02/05/2016

Accepted After Revision: 10/06/2016

The aim of this study was to formulation stable water in oil emulsions contain Neroli essential oil. Gum Arabic, maltodextrin and sucrose were used as coating materials for this essential oil in the emulsions. Emulsions were prepared by combining essential oils at three levels of 1.5%, 3% and 6% (w/w) and different concentrations of coating materials. In order to evaluate physical stability of the emulsions, the produced emulsions were kept at 4, 25 and 40˚C for a month period. According to the results, an increase in essential oil concentration results in a decrease in creaming index that is an indicator of the physical instability of oil-in-water emulsions. As storing temperature rises, although creaming index fell, but instead samples suffered from flocculation destabilization. By increasing gum Arabic concentration in the formulation of emulsions, creaming index decreased significantly (P<0.05). In addition, an adaptive neuro-fuzzy inference system (ANFIS) was used to model and identify the properties of the produced emulsions with temperature and ratios. Comparing the results of experiments and ANFIS modeling determined that ANFIS can make a very satisfactory prediction, so it could be reduced the cost of design experiments by using it.

Microencapsulation, Creaming Index, Arabic Gum, Maltodextrin, Modeling, Anfis

Esmaeelian M. Formulation and Fuzzy Modelling of Emulsion Stability of Neroli Essential Oil, Gum Arabic and Maltodextrin. Biosc.Biotech.Res.Comm. 2016;9(2).

Esmaeelian M. Formulation and Fuzzy Modelling of Emulsion Stability of Neroli Essential Oil, Gum Arabic and Maltodextrin. Biosc.Biotech.Res.Comm. 2016;9(2). Available from: https://bit.ly/35CACHN

Introduction

Microencapsulation is defined as a technology of packaging solids, liquids, or gaseous materials in mini, sealed capsules that can release their contents at controlled rates and conditions. This technology has been used by the food industry for more than 60 years (Desai & Park, 2005).

Typical shell materials for flavours include gum Arabic, maltodextrins, hydrophobically modified starch, and mixtures thereof (Bang & Reineccius, 1998; Boutboul et al., 2003; Levi & Karel, 1995; Reineccius et al., 2002). An encapsulation matrix should has a good solubility in water, has good drying and emulsifying properties and in high concentrations of solids makes a low viscosity (Reineccius, 1998; Kim et al., 1996).

Emulsion technology is generally applied for the encapsulation of bioactive ingredients in aqueous solutions, which can either be used directly in the liquid state or can be dried to form powders after emulsification. Therefore, it is actually a part of encapsulation process. Basically, an emulsion consists of at least two immiscible liquids, usually as oil and water, with one of the liquids being dispersed as small spherical droplets in the other (Friberg, Larsson, & Sjoblom, 2004; McClements, 2005). To obtain a kinetically stable solution, stabilizers such as emulsifiers or texture modifiers, are commonly added in the emulsion systems. Another way of keeping stable emulsions is acquiring small-diameter particles by using devices such as homogenizer and ultrasounds (McClements et al., 2009; Flanagan & Singh, 2006; Augustin & Hemaar, 2009 and Soleimanpour et al., 2013).

The aim of this study was evaluation of the effects of different concentrations of gum Arabic, maltodextrin, Neroli oil and storage temperature on creaming index of the produced emulsions and creating an ANFIS model to predict the final properties of emulsions.

Material And Methods

Commercial Neroli oil was obtained from Argeville Co., Ltd (France). Sucrose (99.96%) was purchased from Naghshe-jahan Co., Ltd (Iran). Gum Arabic (GA), maltodextrin (DE=16.5-19.5) and Lecithin were purchased from Sigma-Aldrich (Germany).

Mixtures of gum Arabic and maltodextrin with an initial amount of 30% (w/w) by ratios (0:1, 1:1, 1:2, 1:3, 2:1, 3:1) was used in order to produce emulsions. Lecithin was added to the mixtures in the amount of 1% of the total ratios of gum Arabic and maltodextrin as an emulsifier. Sucrose was added as the same amount of lecithin too. Neroli essential oil was added at the end by the ratios of (1:20, 1:10 and 1:5) (w/w) of the total ratios of gum Arabic and maltodextri Distilled water was used as continuous phase of emulsion in 30 ˚C. Emulsions were exposed to ultrasonic for 4 min in 59 Hz and 100% power (FALC, MOD.LBS2, 4.5L, Italy) in order to decrease emulsion droplets.

Produced emulsions were kept in 25 ml test tubes in three different temperatures of 4, 25 and 40 ˚C for a month. For each sample there was considered three replicates. During the storage time some emulsions suffer from creaming or flocculation destabilization. Creaming of emulsion samples was monitored at three different temperatures by visual observation of the height of the serum layer formed at the bottom of glass tubes (HS), expressed as a percentage of the total height of the emulsions in the tubes (HE): Creaming Index=100× (HS/HE) (Klinkesorn et al., 2004).

Statistical Analysis Of The Results Of Physical Stability Of Emulsions

Statistical analyses were performed using SPSS Statistics v19 (SPSS Inc, Chicago, IL). Analysis of variance (ANOVA) and means separations were calculated by the general linear model procedure (Proc GLM). Comparisons among treatments were analysed using fisher least significant difference (LSD). Treatment means were considered significant at P < 0.05 (Ghoush et al., 2008).

Fuzzy Modeling

In this study MATLAB software (MATLAB .1.0.0.1 the Math Works Ins) was used. Creaming index of emulsions during a month of storing on the basis of different parameters such as storing temperature and concentrations of gum Arabic, maltodextrin and essential oil was modeled. There were 162 experimental data for network validating and network training. About 80% of experimental data (i.e. 130 data) were used for network training and 20% (i.e. 32 data) were used for network validating.

After loading data, grid partitioning of network is done and the type and number of membership functions is determined. By changing the type and number of membership functions we could access to the least possible error. The best result in this study was obtained from (gaussmf: 3 3 3 3). The hybrid optimization method was used for ANFIS training and error tolerance that is used to create a training stopping criterion was set to 0.

Results And Discussion

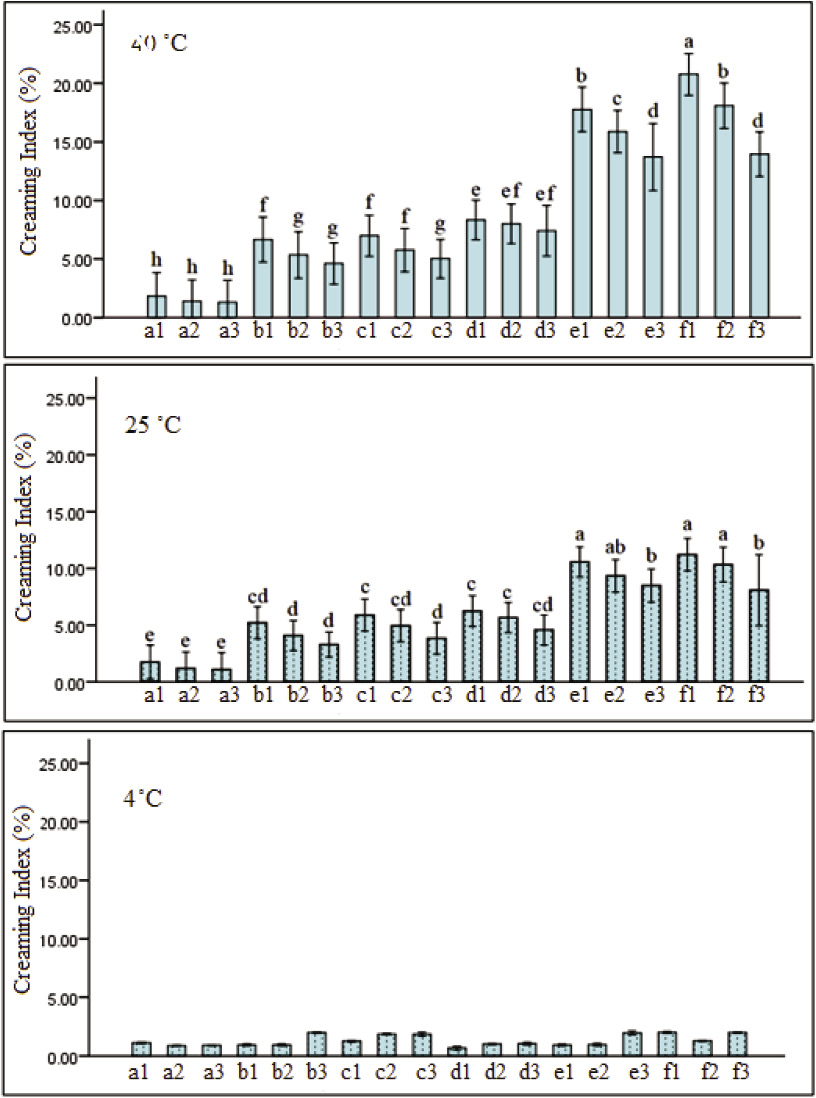

Physical stability of the emulsions was evaluated by measuring creaming index after one month storage at different temperature conditions. Creaming can be appears due to gravity separation. Upward movement of droplets on the fact that their density is less than the density of their environment is called creaming. Flocculation is result of the aggregating of two or more droplet at conditions that each droplet has maintained its entirety. If droplets, bubbles or particles merge during contact to form a single droplet, bubble or particle, this destabilization is called coalescence (Mcclements, 1999). Obtained results of the study have shown in figure 1.

|

Figure 1 |

As shown in figure 1, the stability depends on the gum Arabic concentration: the higher the concentration the more stable the emulsion. Wang et al., (2011) in an investigation of the effects of gum Arabic on the stability of oil-in-water emulsions stabilized by the flaxseed and soybean protein, understood that higher concentrations of gum Arabic make more stable emulsions due to increasing density.

In this study, increasing in maltodextrin concentration led to increasing in creaming index of emulsions. Klinkesorn et al., (2003) evaluated the stability of oil in water, corn emulsions contain 0-30% maltodextrin. They noted rapid creaming occurred when a critical maltodextrin concentration was exceeded, which was attributed to depletion flocculation of the droplets by the non-adsorbed maltodextrin molecules in the aqueous phase of the emulsions.

In the evaluated treatments of this study, increasing in essential oil concentration led to decrease in creaming index. As it mentioned before, this is due to increase in amount of non-adsorbed polysaccharide molecules in low concentrations of oil phase (Klinkesorn et al., 2003; Dokic-Baucal et al., 2004). In the study conducted by Zorba (2006) increasing oil concentration from 25% to 70% led to increasing stability of emulsions, but more increasing did not significant effect on emulsion stability (P<0.01).As storing temperature rises from 4˚C to 25˚C, creaming index fell, but instead samples suffered from flocculation destabilization. By more increasing in storage temperature from 25˚C to 40˚C, the creaming index regardless of the difference in concentration declined and flocculation amount raised. Soleimanpour et al., (2013) in the investigation of effect of Lepidium perfoliatum seed gum addition of whey protein concentrate stabilized emulsions stored at cold and ambient temperature found more stability of the cold temperature of 4˚C.

In another study conducted by Fitzpatrick et al., (2004) on the effect of temperature on the flocculation of different coagulants, it was determined that temperature can increase intensity of flocculation regardless of coagulant type. Li (2011) in a study on treatment of oily wastewater using composite flocculants found that flocculation efficiency improved significantly with the increase of temperature and temperature played a very important role in flocculation performance. With the increase of temperature, the required dosage of flocculants to achieve the best performance decreased. Because temperature controls collision among particles, high temperature could accelerate the flocculation and improve the performance, while low temperature is bad for the full contact between flocculants and oil, and therefore, is not good for flocculation performance (Li, 2011 and Soleimanpour et al., (2013).

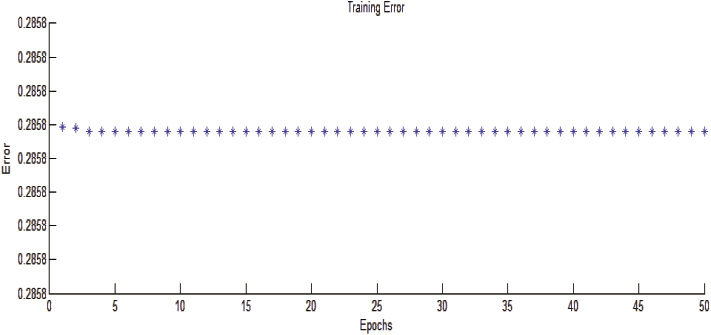

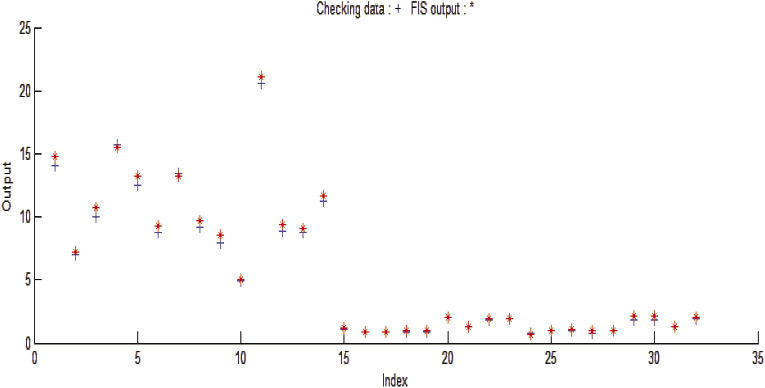

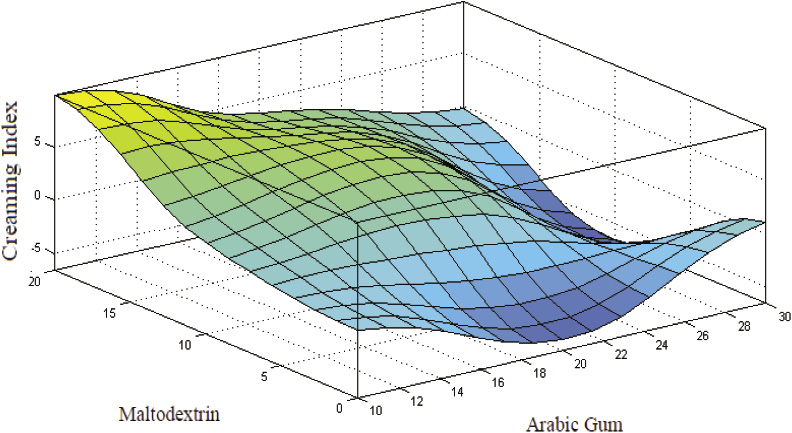

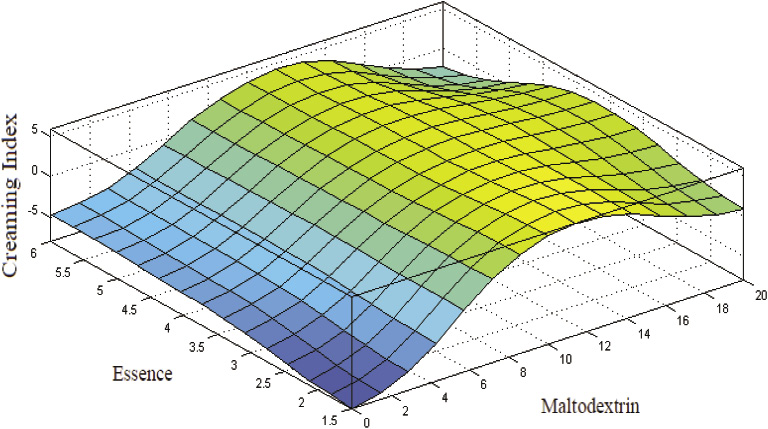

Figure 2 illustrates the ANFIS training curve for creaming index by root mean square error of 0.2857. Comparison between actual values and predicted values in the figure 3 shows that the system is well-trained to model the creaming index. The surface plots (fuzzy model) of creaming index as a function of gum Arabic concentration and maltodextrin and as a function of essential oil concentration and maltodextrin have been shown in figure 4 and 5 respectively. ANFIS model with root mean square error equal to 0.2857 has proven that can be used for prediction of emulsion properties. The efficacy of ANFIS in predicting the emulsification characteristics has been proven in earlier studies too. Abu Ghoush etal.,., (2008) in the formulation and fuzzy modeling of mayonnaise system, introduced ANFIS model with prediction error of 4%. They stated that ANFIS is a technique that can be used efficiently to predict the food properties. Also Sargolzaei etal.,., (2011) introduced modeling by ANFIS as a rapid and helpful method for modeling and simulation of high power ultrasonic process in preparation of stable oil-in-water emulsions.

|

Figure 2: ANFIS training curve for the creaming index model. |

|

Figure 3 |

|

Figure 4: A surface plot (fuzzy model) of creaming index versus gum Arabic and maltodextrin concentrations. |

|

Figure 5: A surface plot (fuzzy model) of creaming index versus maltodextrin and essential oil concentrations. |

|

Figure 6 |

|

Figure 7 |

Conclusion

It can be concluded from the present study that:The higher the concentration of gum Arabic, the more stable the emulsion and the less creaming index.The higher the concentration of maltodextrin leads to increasing in the creaming index of the emulsions.Increasing in essential oil concentration led to decrease in creaming index and this is due to increase amount of non-adsorbed polysaccharide molecules in low concentrations of the oil phase.As storing temperature rises from 4˚C to 25˚C, creaming index fell, but instead samples suffered from flocculation destabilization. By more increasing in storage temperature from 25˚C to 40˚C, the creaming index regardless of the difference in concentration declined and flocculation amount raised. ANFIS model with root mean square error equal to 0.2857 has proven that can be used very well for prediction of emulsion properties. By ANFIS modeling in could be compared each of affecting the stability of the emulsion individually or mutually and this method is rapid, low-cost and high precision that prevents of running repeated tests.

References

Abu Ghoush, M. Samhouri, M. Al-Holy, M. Herald, T. (2008) Formulation and fuzzy modeling of emulsion stability and viscosity of a gum–protein emulsifier in a model mayonnaise system, Journal of Food Engineering 84, 348–357.

Augustin, M. A., & Hemar, Y. (2009) Nano- and micro-structured assemblies for encapsulation of food ingredients. Chemical Society Reviews, 38, 902e912.

Bangs. W. E, Reineccius. G. A, Corn starch derivatives, (1988) In: S. J.Risch & G. A. Reineccius (Eds.), Flavour encapsulation. ACS symposium series 370 (pp. 12–28). Washington, DC: American Chemical Society.

Boutboul. A, Giampaoli. P, Feigenbaum. A, Ducruet.V, (2002) Influence of the nature and treatment of starch on aroma retention, Carbohydrate Polymers, 47, 73–82.

Desai. K. G. H, Park. H. J. (2005) Recent developments in microencapsulation of food ingredients, Drying Technology, 23,136-1394.

Dokic-Baucal.L, Dokic.P, Jakovljevic.J, (2004) Influence of different maltodextrins on properties of O/W emulsions, Food Hydrocolloids 18 ,233–239.

Fitzpatrick. CS, Fradin. E, Gregory, (2006) Temperature effects on flocculation, using different coagulants, J, Water Sci Technol: 50,(12),171-5.

Flanagan, J., & Singh, H. (2006) Microemulsions: a potential delivery system for bioactives in food. Critical Reviews in Food Science and Nutrition, 46, 221e237.

Friberg, S., Larsson, K., & Sjoblom, J, (2004) Food emulsions, (4th ed.). New York: Marcel Dekker.

Ghoush.M, Samhouri. M, Al-Holy. M, Herald. T, (2008) Formulation and fuzzy modeling of emulsion stability and viscosity of a gum–protein emulsifier in a model mayonnaise system, Journal of Food Engineering 84 ,348–357.

Kim. Y. D, Morr. C. V, Schhenz. T. W, (1996) Micro-encapsulation properties of gum Arabic and several food proteins: Liquid orange oil emulsion particles, Journal of Agriculture and Food Chemistry, 44,1308–1313.

Klinkesorn, U, Sophanodora, P, Chinachoti, P, McClements. D. J, (2004) Stability and rheology of corn oil in water emulsions containing maltodextrin, Food Research International, 37, 851–859.

Klinkesorn. U, Sophanodora. P, Chinachoti. P, McClements. D.J, Dickinson. E, (2003) Hydrocolloids at interfaces and the influence on the properties of dispersed systems. Food Hydrocolloids, 17, 25–39.

Levi. G, Karel. M, The effect of phase transitions on release of n-propanol entrapped in carbohydrate glasses, 1995. Journal of Food Engineering, 24, 1–13.

Li. S, (2011) Treatment of Oily Wastewater Using Composite Flocculant of Polysilicate Ferro-Aluminum Sulfate – Rectorite, April 1, Journal of Water Resource and Protection.

McClements, D. J. (2005) Food emulsions: Principles, practice, andtechniques, (2nd ed.). Boca Raton: CRC Press.

McClements, D. J., Decker, E. A., Park, Y., &Weiss, J, (2009) Structural design principles for delivery of bioactive components in nutraceuticals and functional foods. Critical Reviews in Food Science and Nutrition, 49, 577e606.

Mcclements. D.M, (1999). Food Emulsions,principles,practice and techniques, CRC Press, LLC.

Reineccius. G. A, (1988) Spray drying of food flavours. In: S. J. Risch & G. A. Reineccius (Eds.), Flavour encapsulation, ACS symposium series 370 (pp. 55–66). Washington, DC: American Chemical Society.

Reineccius. T. A, Reineccius. G. A, Peppard. T. L, (2002) Encapsulation of flavours using cyclodextrins: Comparison of Arabic retention on alpha, beta, and gamma types, Journal of Food Science,67(9), 3271–3279.

Sargolzaei. J, Hamed Mosavian. M, Hassani, A. (2011) Modeling and Simulation of High Power Ultrasonic Process in Preparation of Stable Oil-in-Water Emulsion, Journal of Software Engineering and Applications,4,259-267.

Soleimanpour. M, Koocheki. A, Kadkhodaee. R, (2013), Effect of Lepidium perfoliatum seed gum addition on whey protein concentrate stabilized emulsions stored at cold and ambient temperature, Food Hydrocolloids, Volume 30, Issue 1, Pages 292-301

Wang. B, Wang. D, Adhikari. B, Shi. J, (2011) Effect of gum Arabic on stability of oil-in-water emulsions stabilized by flaxseed and soybean protein, 1 August Carbohydrate Polymers, Volume 86, Issue 1, Pages 343-351.23-

Zorba. O, (2006) The effects of the amount of emulsified oil on the emulsion stability and viscosity of myofibrillar proteins, July Food Hydrocolloids, Volume 20, Issue 5, Pages 698-702.