1Associate Professor, Dental Sciences Research Center, Department of Prosthodontics, School of Dentistry, Guilan University of Medical Sciences, Rasht, Iran

2DDS Dentist, School of Dentistry, Guilan University of Medical Sciences, Rasht, IRAN

3Dental student, School of Dentistry, University of Debrecen, HUNGARY

Corresponding author Email: Marzieh.neshandar@hotmail.com

Article Publishing History

Received: 01/04/2017

Accepted After Revision: 29/06/2017

The invention of Poly methyl methacrylate lead to new evolution in dental prosthesis science and is an ideal material to produce acrylic denture base resins but unfortunately, fracture is a common problem, so for reinforcement we have to consider some methods for improving them in special conditions. In this study 30 heat cure acrylic (Meliodent) in dimentions (70mm × 15mm × 3mm) were used. In first group heat cure acrylic without any reinforcement, Second group heat cure acrylic was reinforced with 1mm sand blast metal wire and third group, samples were reinforced with 1mm sandblast metal wire that impregnated with 4meta bonding agent. All of the samples tested with universal testing machine by 5 mm speed/min, then the result analyzed by ANOVA and TUKEY HSD. The transverse strength of first group was 87.47 N/mm2. Also, transverse strength in the second and third groups was 98.42 N/mm2 and 111.43 N/mm2, respectively. Based on the results, significant difference detected between 3 groups (P<0.05). The maximum transverse strength was seen in third group. The use of1mm sandblast metal wire that impregnated with 4meta bonding agent had positive effect on strengthening and reinforcement of resin acrylic denture and dimensions which can 27.39% improve the transverse strength.

Transverse Strength, 4-Meta Resins, Dental Prosthesis, Dental Bonding, Acrylic Resins

Asli H. N, Moradian S, Asli M. N. Comparison of Transverse Strength of Three Different Types of Heat Cured Resin Acrylics. Biosc.Biotech.Res.Comm. 2017;10(2).

Asli H. N, Moradian S, Asli M. N. Comparison of Transverse Strength of Three Different Types of Heat Cured Resin Acrylics. Biosc.Biotech.Res.Comm. 2017;10(2). Available from: https://bit.ly/30ybcYp

Introduction

Poly methyl methacrylate (PMMA) material as denture base material which is more preferred material than the other denture base materials (Rickman et al. 2012). PMMA is routinely produced by suspension or emulsion polymerization. PMMA is formed by addition polymerization of multiple methyl methacrylate monomers in the presence of an initiator, typically benzyl peroxide (Alla et al. 2011). The PMMA is usually used for the construction of removable partial or complete dentures (Raj and D’Souza 2011). In heat-cured materials, the polymerization process is initiated by the release of free radicals from benzyl peroxide on supply of heat energy (Ginjupalli et al. 2012). These free radicals react with the monomer molecules and continue till the monomer is available (Bhatia et al. 2013). These materials are supplied in the form of powder while liquid form of them contains finely divided pre-polymerized PMMA beads and liquid contains methyl methacrylate (Gosavi et al. 2013).

The transverse or flexural strength test, one of mechanical strength tests, is especially useful in comparing denture base materials in which a stress of this applied to the denture during mastication. The transverse or flexural strength is a combination of compressive strength, tensile, and shear strength, all of which directly reflect the stiffness and resistance of a material to fracture (Ersu et al. 2009). The transverse strength of acrylic resins depends on numerous factors including polymer molecular weight and bead size, residual monomer level, plasticizer composition, cross–linking agent, internal porosity of the polymer matrix, denture base thickness, patient factory and action of chemical agents (Gurbuz et al. 2010). Physical properties of the denture base are important for longevity of dental prosthesis (Tugut et al. 2012). Transverse strength of acrylic resins is reliable method to estimated resin behavior under different experimental conditions (Tugut et al. 2012).

Essential requirement for denture base polymers are adequate mechanical properties, sufficient aesthetics, hygiene, easy handling of resins and minimal release of residual compounds such as residual monomer (Raj and D’Souza, 2011). To solve this perplexing problem, it is reported to altering the PMMA surface before applying a resilient material (Tugut et al. 2012). In this regard, sand blasting procedure has been introduced which involves spraying a stream of aluminum oxide particles against the material surface intended for bonding under high pressure (Chung et al. 2008). Limit information exist on conflicting on use of sandblasting to increase bond strength of acrylic resin denture base and soft lining material (Ersu et al. 2009).

To decrease the denture fracture incidence, various aspects can be considered such as optimizing chemical structure and processing techniques; improving adhesion; altering composition either chemically (using high impact polymer) and making physical alterations (incorporate materials such as fibers, metal into PMMA) (Gharechahi et al. 2014; Nejatian et al. 2015).

Because of the risk of fracture should a patient drop their denture, high impact strength is a desirable property. Given the function of a denture base in a removable prosthesis, high flexural strength, flexural modulus, and a large yield point distance would help resist torsional forces in function leading to a longer clinical service life for the prosthesis (Meng et al. 2005). So, in the current study we tried to comparison of transverse strength of three different types including heat cure acrylic without any reinforcement, heat cure acrylic reinforced with 1mm sand blast metal wire and heat cure acrylic reinforced with 1mm sandblast metal wire that impregnated with 4meta bonding agent (U Bar).

Material and Methods

In this study 30 heat cure acrylic (Meliodent, HERAEUS KULZER, Germany) in dimensions (70mm × 15mm × 3mm) were used. In first group heat cure acrylic samples without any reinforcement, second group samples were reinforced with 1mm sand blast metal wire and third group, heat cure acrylic was reinforced with 1mm sandblast metal wire that stained impregnated with 4meta (4-methacryloxyethyl trimellitate anhydride) bonding agent UBAR Metal Bonding Cold Cure – Bonding Liner (Pro Tech, USA). For group 1, the acrylic where mixed as 24.3 g powder in 10CC liquid, proceed in the generator at 75°C for 8 h, then samples deflasked and polished.

In the second group the 1mm sand blast metal wire (DENTAURUM GmbH & Co. KG, Germany) was applied using aluminum oxide using Topstar (Bego, Germany). To insert wire into the acrylic, after press and remove the generator and remove the paper, a groove 2×70 mm was done on the generator and the sand blast metal wire longitudinally inserted in the acryl and then the groove filled using heat cure acrylic. In the third group sand blast metal wire was coated with 4meta bonding agent (UBar) to improve the connectivity of the metal wire and acrylic resin. Then the transverse strength of all samples was tested with universal testing machine ( Instron, Shakopee, 79USA) by speed of 5 mm/min using (N/mm2).

Statistical Analysis

Obtained data from the transverse strength processed in excel and analyzed by ANOVA using SPSS (ver. 16). The mean between groups was compared using Tukey HSD test. P<0.05 between the groups was considered as significant differences. Results

According to the data, the transverse strength of heat cure acrylic without any reinforcement was 87.48±0.67. Also, the transverse strength of heat cure acrylic with 1mm sand blast metal wire that impregnated with 4meta bonding agent and heat cure acrylic reinforced with 1mm sandblast metal wire were 98.42±1 and 111.43±0.83, respectively (table 1).

| Table 2: The comparison of the transverse strength among 3 heat cure acrylics | ||||

| Mean Sd | S.E | P value | ||

| Group 1 | Group 2 | 10.95 | 0.37 | 0.0001 |

| Group 3 | 23.96 | 0.37 | 0.0001 | |

| Group 1 | 10.95 | 0.37 | 0.0001 | |

| Group 2 | Group 3 | 13.01 | 0.37 | 0.0001 |

| Group 1 | 23.96 | 0.37 | 0.0001 | |

| Group 3 | Group 2 | 13.01 | 0.37 | 0.0001 |

| Group 1: heat cure acrylic without any reinforcement, 2: heat cure acrylic reinforced with 1mm sandblast metal wire, 3: heat cure acrylic with 1mm sand blast metal wire that impregnated with 4meta bonding agent | ||||

The comparison of the transverse strength among 3 heat cure acrylics is presented in table 2. According to the data, significant difference detected on transverse strength among 3 heat cure acrylics (table 2).

| Table 1: Transverse strength of 3 heat cure acrylics | |||

| Groups | Mean ± Sd | Maximum | Minimum |

| 1 | 87.48±0.67 | 88.4 | 86 |

| 2 | 98.42±1 | 100 | 97 |

| 3 | 111.43±0.83 | 112.9 | 110 |

| P value | 0.001 | ||

| Group 1: heat cure acrylic without any reinforcement, 2: heat cure acrylic reinforced with 1mm sandblast metal wire, 3: heat cure acrylic with 1mm sand blast metal wire that impregnated with 4meta bonding agent |

|||

Discussion

There are three ways to improve the mechanical properties of PMMA including (I) replacing PMMA with an alternative material; (II) chemically modifying and (III) reinforcing the PMMA with other materials. However, the processes of etching, preparing, positioning and impregnation of fibers may be impractical for dental offices (Kim and Watls, 2004). In the current study we tried to comparison of transverse strength of three different types including heat cure acrylic without any reinforcement, heat cure acrylic reinforced with 1mm sand blast metal wire and heat cure acrylic reinforced with 1mm sandblast metal wire that impregnated with 4meta bonding agent (U Bar). As observed, the transverse strength of first group was 87.47 N/mm2. Also, transverse strength in the second and third groups was 98.42 N/mm2 and 111.43 N/mm2, respectively. Based on the results, the maximum transverse strength was seen in heat cure acrylic with 1mm sand blast metal wire that impregnated with 4meta bonding agent.

|

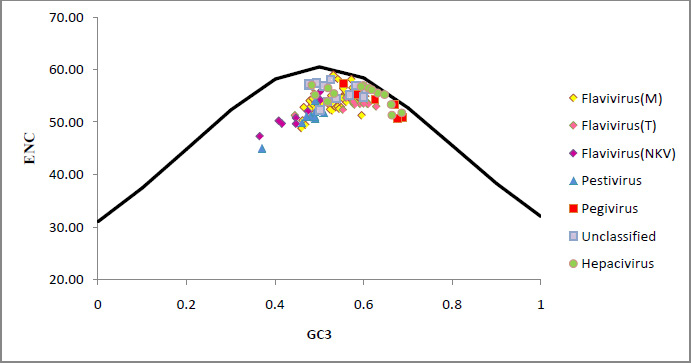

Figure 1: The transverse strength of the samples using universal testing machine |

Reinforcing agents using of cobalt-chromium wires, metallic wires was previously applied. It is reported the transverse strength increased in heat- cured acrylic resin reinforced with metal wires (Vojdani and Khaledi, 2006). Also, increase in strength of PMMA reported by adding silver, copper and aluminium wires (Sehajpal and Sood, 1989). Recently Vojdani et al. (2012) reported reinforcement of the conventional heat-cured acrylic resin with Al2O3 powder (2.5 wt %) increased its flexural strength and hardness with no adverse effects on the surface roughness.

It is reported 1.5mm round wire reinforced strength of denture resins (Polyzois et al. 1996) and our results was in line with their report. It is interesting to mention the effect of placing a metal wire in the anterior part of a maxillary denture on the fracture process. Several authors have reported that the anterior palatal area is the region of maximum tensile stress in a maxillary denture and that midline fracture starts from the weak points, namely, the incisal notch, the area behind central incisors, and then propagates along the palate to the posterior border of the denture (Darbar and Huggett, 1994). It is reported the sandblasted wires did not have a better strengthening effect on the specimens than the glossy wires. This finding is difficult to interpret if it is assumed that the mechanical retention between wire and resin should increase the resistance (Vallittu and Lassila, 1992).

The adhesive resin consisted of a powder MMA and a bonding liner (MMA-, 4-META) introduced to improve and reinforcement of resin acrylic denture. The bonding liner contained the metal adhesive monomer 4-metacryloxyethyl trimellitate anhydride (4- META) is the most important component of the kit (Polyzois et al. 1996). The combination of Meta Fast adhesive resin and metal increased the fracture load and deflection of specimens (Polyzois et al. 1996) and our findings was in agreement with this report. It appeared that incorporation of metal wires played a dominant role in the overall mechanical behavior of the repaired strips and had an overriding effect on the repair strength over the mechanical and adhesive properties of repair and denture resin (Polyzois et al. 1996). In conclusion the use of1mm sandblast metal wire that impregnated with 4meta bonding agent had positive effect on strengthening and reinforcement of resin acrylic denture and dimensions which can 27.39% improve the transverse strength.

References

- Alla RK, Ginjupalli K, Upadhya N, Shammas M, RS Kotha, RK Ravi. 2011 Surface Roughness of Implants: A Review, Trends Biomater. Artif. Organs 25(3):112-118.

- Bhatia V, Bhatia G, Jain N, Jadon AK. 2013 An innovative metal base denture design for a 55-year-old menopausal woman, J Nat Sci, Biol Med. 4(2):4668-472.

- Chung KH, Chung CY, Chung CY, Chan DC.2008 Effect of pre-processing surface treatments of acrylic teeth on bonding to the denture base. J Oral Rehabil 35:268-275.

- Darbar UR, Huggett R, Harrison A. 1994 Denture fracture: a survey. Br Dent J 176:342-5.

- Darbar UR, Huggett R, Harrison A.1994 Stress analysis techniques in complete dentures. J Dent 22:259-64.

- Ersu B, Yuzugullu B, Ruya Yazici A, Canay S.2009 Surface roughness and bond strengths of glass-infiltrated aluminaceramics prepared using various surface treatments. J Dent;37(11):848-856.

- Gharechahi J, Asadzadeh Na, Shahabian F, Gharechahi M. 2014 Flexural strength of acrylic resin denture bases processed by two different methods. Journal of Dental Research, Dental Clinics, Dental Prospects. 8(3): 148-125.

- Ginjupalli K, Upadhya N, Alla RK, Nandish BT. 2012 Evaluation of cohesive and adhesive strength of dental materials, Manipal Odontoscope 4:47-52.

- Gosavi SS, Gosavi SY, RK Alla. 2013 Titanium: A Miracle metal in Dentistry, Trends Biomater Artif Organs 27(1):42-46.

- Gurbuz O, Unalan F, Dikbas I. 2010 Comparison of the transverse strength of six acrylic denture resins. OHDMBSC 9(1):21-24.

- Kim SH, Dc Watls. 2004 The effect of reinforcement with woven Eglass fibers on the impact strength of complete dentures fabricated with high-impact acrylic resin. J Prosthet Dent 91:274e80.

- Meng TR, Latta MA.2005 Physical Properties of Four Acrylic Denture Base Resins. J Contemp Dent Pract November;(6)4:093-100.

- Nejatian T, Sefat F, Johnson T.2015 Impact of packing and processing technique on mechanical properties of acrylic denture base materials. Materials 8, 2093-2109.

- Polyzois GL, Andreopoulos AG, Lagouvardos PE. 1996 Acrylic resin denture repair with adhesive resin and metal wires: effects on strength parameters. J Prosthet Dent. Apr;75(4):381-7.

- Raj N, D’Souza M. 2011. Comparison of transverse strength of denture base resin on immersion for varying time period in water and denture cleansers – an in vitro study. Asian Journal of Oral Health & Allied Sciences – 1(2): 97-100.

- Rickman LJ, Padipatvuthikul P, Satterthwaite JD. 2012 Contemporary denture base Resins: Part 1, Dent Update 39(1):25-30.

- Sehajpal SB, Sood VK. 1989 Effect of metal fillers on some physical properties of acrylic resin. J Prosthet Dent. 61(6):746-51.

- Tugut F, Akin H, Mutaf B, Akin G, Ozdemir AK 2012 Strength of the bond between a silicone lining material and denture resin after Er:YAG laser treatments with different pulse durations and levels of energy. Lasers Med Sci Lasers Med Sci 27:281-285.

- Vallittu PK, Lassila VP. 1992 Reinforcement of acrylic resin denture base material with metal or fibre strengtheners. J Oral Rehabil. May;19(3):225-30.

- Vojdani M, Bagheri R, Khaledi AAR.2012 Effects of aluminum oxide addition on the flexural strength, surface hardness, and roughness of heat-polymerized acrylic resin. Journal of Dental Sciences 7, 238e244.

- Vojdani M, Khaledi AAR.2006 Transverse strength of reinforced denture base resin with metal wire and E-Glass fibers. Journal of Dentistry of Tehran University of Medical Sciences. 3(4):159-166.