Department of Foods and Nutrition, Post Graduate and Research Centre, Smt. VHD Central Institute of Home Science, Sesadri Road, Bangalore 560001

Article Publishing History

Received: 23/03/2019

Accepted After Revision: 25/05/2019

Four differently processed peanut oils viz. refined, filtered, cold pressed and organic were selected for the study. The total antioxidant capacity was estimated by DPPH method, Ferric Reducing Antioxidant Power and in vitro digestibility of antioxidants was determined. The oxidative stability of the samples was tested by biodiesel Rancimat analysis. Organoleptic evaluation was done using a 5 point hedonic scale. When analyzed by DPPH method, and FRAP method, filtered peanut oil showed highest antioxidant capacity followed by refined oil. The percent digestibility of antioxidants was highest in case of organic peanut oil (92.3%). The oxidative stability results showed that cold pressed oil was most stable at all temperatures followed by filtered oil. Although, the oil samples showed difference in the sensory scores, the potato chips deep fried in these peanut oils did not show statistically significant difference(P<0.05). Filtered peanut oil had highest antioxidant capacity but the digestibility of antioxidants was higher in case of organic peanut oil. The results need to be validated by in vivo studies. Cold pressed oil was most stable at all temperatures so it is more suitable for deep frying.

Antioxidant capacity, Cold pressed oil, Filtered oil, Organic oil, Refined oil

Kanabur V. Antioxidant Capacity, Oxidative Stability and Sensory Evaluation of Peanut Oils Produced Using Different Processing Techniques. Biosc.Biotech.Res.Comm. 2019;12(2).

Kanabur V. Antioxidant Capacity, Oxidative Stability and Sensory Evaluation of Peanut Oils Produced Using Different Processing Techniques. Biosc.Biotech.Res.Comm. 2019;12(2). Available from: https://bit.ly/2Z9OXar

Copyright © Kanabur, This is an open access article distributed under the terms of the Creative Commons Attribution License (CC-BY) https://creativecommns.org/licenses/by/4.0/, which permits unrestricted use distribution and reproduction in any medium, provide the original author and source are credited.

Introduction

Peanut or groundnut (Arachis hypogaea) is eulogized as king of oil seeds in India as it is an important source of edible oil. It contributes 25 per cent to the total share of vegetable oil production in India (National Food Security Mission). Oils and fats are an important source of energy providing 900 K Cal/100g. Peanut oil has very good lipid profile. It has saturated, monounsaturated and polyunsaturated (Saturated Fatty Acid: Mono Unsaturated Fatty Acid: Poly Unsaturated Fatty Acid = 20: 54: 26) fatty acids in healthy proportions. They are an excellent source of fat soluble vitamins such as Vitamin A, D, E and K. Nutrients such as vitamin E, vitamin C, Vitamin A, selenium have antioxidant abilities. Oils are a good source of natural antioxidants, ( Longvah et. al. 2017 Durmaz and Gökmen 2019 ).

Antioxidants are the chemical substances which neutralize free radicals. They can prevent damage to the body cells or repair damage that has already been done by free radicals. Free radicals are generated by the body during the course of normal metabolism. Some conditions such as diabetes, obesity, exercise, high fat and high sugar diet, stress, infections, air pollution, UV rays, smoke etc increase free radical generation. The balance between antioxidants and oxidants decides the health and of a person (Lien Ai Pham-Hay et. al. 2008).The combined ability of all antioxidants in a given food to neutralize the free radicals is referred to as total antioxidant capacity of a food. A number of factors such as soil type, chemistry, plant nutrients, climatic conditions, pest pressure, post harvest treatments influence the total antioxidant capacity of a food (Brandt et al.,2002).Oils do not occur free in nature. They occur in seeds from which they are isolated, refined, and processed for specific use. Processing of oil brings about changes in the composition, properties of oil (Akhtar et al 2014 and Durmaz and Gökmen 2019 ).

There are different techniques employed to extract oil and based on this, different types of oils such as filtered oil, refined oil, cold pressed oil, organic oil are available in the market. Filtered peanut oil is made by pressing peanuts through Expeller or extracted using solvents such as hexane. In case of refined peanut oil, after filtration, the constituents such as free fatty acids, unsaponifiable matter, gums, waxes, mucilaginous matter, a variety of colouring matter, metallic contaminants, undesirable odoriferous constituents etc are removed by bleaching, neutralization, deodorization using chemicals. Most highly refined peanut oils remove the peanut allergens and have been shown to be safe for “the vast majority of peanut-allergic individuals,” ( Marvin et al 1998).Cold pressed peanut oils are produced by pressing the peanuts using heavy granite millstones or modern stainless steel presses. Although pressing and grinding produces heat through friction, the temperature must not rise above 120°F (49°C) for any oil to be considered cold pressed. The extraction of oil at lower temperature is believed to retain their flavor, aroma, and nutritional value, (Wang 2016).

Organic peanut oils are the oils produced using peanuts which are grown using organic substances during production, storage or processing. No synthetic chemicals are used in extraction and processing and extraction takes place at a lower temperature. Organic oils in general are 25% more expensive and consumers have a strong perception that they are tastier, nutritious and healthy compared to the conventional foods. But there are very few scientific studies on oils to prove or disprove this claim.

In this study an attempt was made to know if these differences in extraction methods and processing of oil influence the antioxidant capacity, oxidative stability and organoleptic properties of peanut oil. This study was carried out with the following objectives: To estimate total antioxidant capacity of the selected peanut oils, to determine the differential oxidative stability of selected peanut oils and to carry out organoleptic evaluation of some selected recipes using selected peanut oils. Limitations of the study: All brands of peanut oils available in the market have not been tested. Sensory evaluation was done on a small scale.

Materials and Methods

The methodology of the study is presented under the following headings. The research was carried out in 4 phases: Selection and procurement peanut oils samples, Estimation of antioxidant capacity of the selected samples, determination of oxidative stability of the peanut oil samples and sensory evaluation of deep fried food using 4 peanut oil samples.

- Selection of and Procurement of Peanut Oil Samples: Four differently processed peanut oil samples viz. Refined, filtered, cold pressed, and organic peanut oil samples were selected for the study. One popular brand (safola) of refined and filtered ground nut oil, cold pressed oil (24 Mantra cold pressed) were obtained from a hypermarket. Organic sample was procured from organic outlet certified by the horticultural department. All the chemicals used for analysis were of the analytical grade. Triple distilled water was used for the study.

- Estimation Of Antioxidant Capacity Of The Selected Samples: About twenty different methods of antioxidant assay are currently being used. But no single method is sufficient to quantify the total antioxidant capacity. Scientists have opined that 2-3 methods rather than a single method can give better indication of total antioxidant capacity of a food. In the present study the following methods have been used for estimation of total antioxidant capacity of the samples.

- Free radical scavenging activity using 2, 2-Diphenyl-1-picrylhydrazyl (DPPH method): The ability of antioxidants to reduce DPPH was determined according to the procedure described by Moreno et al (1998) with some modifications. 10 ml of oil sample was dissolved in 20 ml of n-hexane. The solutions were prepared in n-hexane because the methonolic solution of DPPH causes turbidity in the reaction mixture and hence interferes with the results. The solution was kept in magnetic stirrer for one hour and filtered through Whatman # 1. The filtrate was used for analysis. To the above sample extract, 40 µM of DPPH solution was added. The reaction mixture was incubated with varying concentrations of sample in different dilutions. The reaction mixture was incubated for 20 minutes at room temperature in dark and the absorbance of the resulting solution was read at 517 nm against a blank using a spectrophotometer (Double beam UV VIS Spectrophotometer (AU2701 Systronics). Trolox was used as a standard. All the analyses were carried out in triplicate. Free radical scavenging ability of the sample was calculated according to the following equation.

DPPH radical scavenging activity (%) = {(Abs Control-Abs Sample)/Abs of Control} X 100

- Ferric Reducing Antioxidant Power (FRAP): Ferric-reducing antioxidant power was measured following the procedure originally described by Benzie and Strain (1996), in which Fe3+ is reduced to Fe 2+ ion reduction, at low pH, causes the formation of a coloured ferrous-TPTZ complex (2,4,6 tripyridyl-s-triazine) resulting in an increase in absorbance at 593 nm.

Sample extraction: Sample was extracted according to procedure used by Sreeramulu and Raghunath (2011). 5 ml of the oil sample was mixed with 20 ml of 70% methanol containing 0.1% HCl by shaking vigorously for four hours at room temperature. The solution was centrifuged at 10,000 g for 15 min at 10⁰C. The supernatant was collected and filtered through Whatman # 1 filter paper and the filtrate was stored at –20 ⁰C. Samples in the range of 30 to 70 µl were added to 4500 µl of FRAP reagent. FRAP reagent consists of the following. 1) 0.3 M acetate buffer, pH 3.6,2)10 mM TPTZ in 40mM hydrochloric acid and 3)20 mM ferric chloride in 40 m M hydrochloric acid.All the above were mixed in the ratio of 10:1:1(v/v/v) to obtain FRAP reagent. The reagent was preheated to 38°C and the initial absorbance was measured using acetate buffer blank. The reaction mixture was shaken vigorously for 15 sec and incubated at 27°C for 90 min. The absorbance was measured at 593 nm at the end of 90 min. Control experiments without the sample or TPTZ were carried out to exclude the effect of the added test compounds. Higher absorbance indicates higher ferric reducing power. The results are expressed as Trolox equivalent reducing power.

In vitro digestibility of antioxidants

In vitro digestibility of the samples was determined according to a method described by Luten et al. (1996).

Determination Of Oxidative Stability Of The Peanut Oil Samples: The oxidative stability of the four samples was tested by biodiesel rancimat analysis. This was out sourced from CSIR- Central Salt & Marine Chemicals Research Institute, Bhavnagar, Gujarat.

Sensory Evaluation Of Deep Fried Food Using 4 Peanut Oil Samples: The preparation and sensory evaluation was done in Food and Nutrition Laboratory of the College a) Development of the score card: A score card was prepared keeping in mind the quality characteristics of the test drink. A 5- point hedonic rating scale was used for rating attributes such as colour, taste, odour and overall acceptability. Highest score (5) was assigned to the most preferred characteristic and 1 to the most undesired characteristic. Mean score for each attribute was calculated.b) Preparation of one deep fried product: Potato finger chips of uniform size and thickness were deep fried separately in each of the peanut oil samples and were presented for sensory evaluation.c) Sensory evaluation of the product: Acceptability of the product was tested by a selected panel of judges. A panel of 40 judges from the staff and post graduate students of Department of Food and Nutrition were selected for the evaluation of the product.Statistical analysis of data was done using suitable methods.

Results and Discussion

The results are presented under the following headings. Antioxidant Capacity of the samples: The DPPH free radical scavenging activities of peanut oil samples at different sample concentrations are shown in Table 1.

Table 1: Antioxidant capacity of different peanut oils by DPPH Method

| Sl. No | Concentration of sample (µM/g) | Standard

(%) |

Refined Peanut oil (%) | Filtered Peanut oil

(%) |

Cold Pressed peanut Oil (%) | Organic

Peanut oil (%) |

| 1 | 25 | 82 | 21 | 24 | 19 | 20 |

| 2 | 50 | 84 | 23 | 41 | 20 | 21 |

| 3 | 75 | 90 | 43 | 63 | 31 | 37 |

| 4 | 100 | 93 | 51 | 61 | 47 | 50 |

The free radical scavenging ability expressed as inhibition percentage was maximum in case of standard (trolox). Of the four samples tested, filtered peanut oil showed highest inhibition followed by refined oil. Cold pressed oil and organic peanut oil showed the low antioxidant activity. There was statistically significant difference between standard and peanut oil samples (P<0.05).

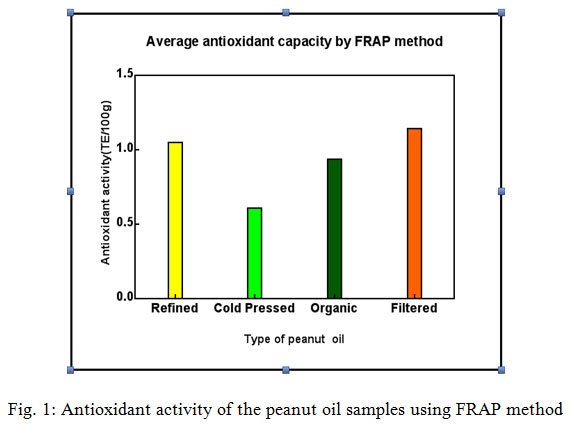

Antioxidant activity by Ferric Reducing Antioxidant Power (FRAP): The mean antioxidant activity value as assessed by ferric reducing power is given in Fig 1. One way ANOVA shows that there was a significant difference (P<0.05) between the absorbance values of the four oils tested. It was highest in case of filtered oil, followed by refined oil, organic oil and cold pressed oil.

|

Figure 1: Antioxidant activity of the peanut oil samples using FRAP method |

Gökhan Durmaz , VuralGökmen (2019) found that the process of refining of oils in case of hazelnut oil brought about a decrease in bioactive compounds. Lutein and zeaxanthin were lost completely whereas phenolic compounds and tocopherols were partly lost during bleaching step of the refining. This resulted in significant reduction of antioxidant capacity.

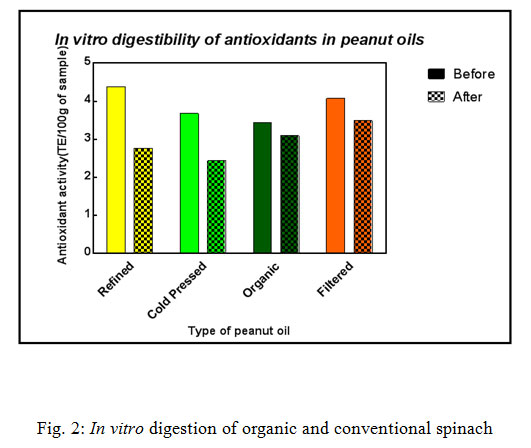

In vitro Digestibility/Bioavailability of peanut oil samples: The antioxidant capacity in terms of trolox equivalents before and after in vitro digestion in case of peanut oil samples is shown in Fig.2.

|

Figure 2: In vitro digestion of organic and conventional spinach |

There was statistically significant difference between the samples with respect to digestibility of antioxidants. It is interesting to note that the percent digestibility of antioxidants was highest in case of organic peanut oil (92.3%), closely followed by filtered oil (85.7%) and was quite low in case of refined oil (63.24%) and cold pressed oil (66.30%). There are hardly any studies on digestibility of antioxidants and so the result could not be compared with other studies.

Oxidative stability of oils: Freshness and oxidative stability of fats are often determined on the basis of the induction period, meaning the period in which peroxide creation is untraceable or very small, until the point of its sudden increase in the volume of the analysed sample. The results of oxidative stability as assessed by biodiesel rancimat method are given in table 2.

Table 2: Oxidative stability in terms of induction time for peanut oil samples at different temperatures.

| Type of peanut oil | Induction time at 30⁰ C (hours) | Induction time at 110⁰ C (hours) | Induction time at

120⁰ C( hours) |

| Refined Oil | 3,649 | 7.08 | 3.3 |

| Filtered Oil | 5,160 | 8.47 | 3.8 |

| Cold pressed Oil | 7,741 | 9.5 | 4.11 |

| Organic Oil | 3,178 | 6.37 | 2.88 |

The induction period –the time taken to the onset of oxidation – is the indicator of oxidative stability in this method. One way ANOVA shows that there is significant difference between induction time of peanut oils at different temperatures. At room temperature the oxidative stability of cold pressed oil was highest followed by filtered oil and refined oil. Cold pressed oil was found to be most stable at all temperatures followed by filtered oil. Organic oil showed least stability at higher temperature. Arranz et. al. (2008) studied the relation between DPPH free radical scavenging capacity and oxidative stability (Rancimat method) in different hazelnut, peanut, pistachio, walnut and almond oils. They found that highest free radical scavenging capacity was in case of pistachio and least was in case of peanut oil. They also found a significant correlation between DPPH and Rancimat methods assays. In case of hazelnut oil the neutralization process increased oxidative stability whereas deodorization slightly decreased oxidative stability as there was a partial removal of tocopherols during deodorization, (Durmaz and Gökmen 2019).

Organoleptic Properties of peanut oils: Peanut oil is one of the cooking oils with a high smoke point; 450 °F. Therefore it is preferred oil for deep frying. List (2016) opines that the flavour, crispness and mouth feel of foods deep fried in peanut oil are excellent because of high levels of oleic acid and absence of linolenic acid and optimum amount of linoleic acid. Table 3. gives the mean sensory scores for the potato chips deep fried in different peanut oil samples as tested by the panellists.

Table 3: Mean sensory scores for potato chips deep fried in peanut oil samples

| Type of peanut oil | Colour | Taste | odour | Overall acceptability |

| Refined oil | 4.8 | 3.8 | 4.0 | 4.1 |

| Filtered oil | 4.7 | 3.7 | 3.9 | 4.2 |

| Cold pressed oil | 4.68 | 4.3 | 4.5 | 4.3 |

| Organic oil | 4.8 | 4.5 | 4.5 | 4.3 |

Although, the cold pressed peanut oil and organic peanut oil had a deep yellow colour with pleasant nutty aroma and sweet taste and refined oil had light yellow with the neutral taste, the sensory scores of the potato chips deep fried in these oils did not show statistically significant difference (P<0.05). People with peanut allergy should be cautious in consuming cold pressed and organic peanut oils as the processing may not remove the allergens. Studies have shown that the process of refining alters the organoleptic properties. Peanut oil which is, pale yellow in colour with distinctive nutty taste and odour obtained from the processing of its kernel becomes odourless after refining (Sanders, 2002). DuPlessis et al. (1981) compared the performance of peanut oil and cottonseed oil and concluded that potato chips deep fried in peanut oil had significantly higher flavour scores. The study has not compared the effect of refining of peanut oil on organoleptic properties of foods deep fried in peanut oil.

Conclusion

Processing of oil influences the properties of the peanut oil. Cold pressed oil was found to be most stable at all temperatures followed by filtered oil. Organic oil showed least stability at higher temperature. Although there was a significant difference in the sensory attributes of peanut oil samples, there was no significant difference in the deep fried food among the four samples when used as a medium for deep frying.

References

Benzie H and Strain K (1996). The ferric reducing ability of plasma as a measure of antioxidant power the FRAP Assay. Analytical .Biochemistry. 239: 70-76.

Brandt, K., Ejlerson, A., Norbaek, R. and Peterson, H. L. (2002).Effects of cultivation conditions for apples on growth rates of fruit fly larvae and contents of phenolics. Organic E-Prints. Accessed from http://orgprints.org/1588/ on 22nd Jan 2015.

Du Plessis L. M., P. Van Twisk, van Niekerk P. J. ,Steyn M (1981) Evaluation of peanut and cottonseed oils for deep frying Journal of American Oil Chemist’s Society 58 (5) : 575-578.

Gary R. List, (2016) Processing and Food Uses of Peanut Oil and Protein In Peanuts, Genetics, Processing, and Utilization H. Edited by Thomas Stalker and Richard F. Wilson Elsevier Inc. Publications Page No 405-428

Gökhan Durmaz and Vural Gökmen (2019) Effect of refining on bioactive composition and oxidative stability of hazelnut oil, Food Research International 116:586-591.

Lien Ai Pham-Hay, Hua He and Chuong (2008) Free Radicals, Antioxidants in Disease and Health. International Journal of Biomedical Science 4(2): 89–96.

Longvah T, Ananthan R, Bhaskaracharya K and Venkaiah K. 2017, Indian Food Composition Table National Institute of Nutrition

Luten, J., Crews, H., Flynn, A., Dael, P. V., Kastenmayer, P., Hurrell, R., Deelstra, H., Shen, Li-Hua. Tait, F. S., Hickson, K., Farre, R., Schlemmer, U. and Frohlich, W., (1996). Interlaboratory trial on the determination of the in vitro iron dialyzability from food. J. Sci. Food Agric.,72: 415–424.

Marvin W. Formo, A. Richard Baldwin, R. Paul Singh (1998) Fat and Oil processing Chemistry Encyclopaedia Britannica Inc. Publications accessed on 24th May 2019 from https://www.britannica.com/science/fat-processing

Moreno, S. C, Lanauri J A and Saura-Calixo F. A. (1998). Procedure to measure the anti radical efficiency of polyphenols. Journal of Science, Food and Agriculture. 76:270-276.

National Food Security Mission, Govt of India , Present Status of Oilseed crops and vegetable oils in India, Accessed from https://www.nfsm.gov.in/StatusPaper/NMOOP2018.pdf on 23rd May 2019

Sanders, T. H. (2002) Groundnut (peanut) oil In: Vegetable Oils in Food Technology Composition, Properties, and Uses, pp. 231–243. Gunstone, F. D. (Ed.), Blackwell Publishing Ltd, Oxford, UK

Sara Arranz Rosa Cert JaraPérez-Jiménez Arturo Cert FulgencioSaura-Calixto (2008) Comparison between free radical scavenging capacity and oxidative stability of nut oils. Food Chemistry, 110(4): 985-990.

Shamim Akhtar, Nauman Khalid, Iftikhar Ahmed, Armghan Shahzad, And Hafiz Ansar Rasul Suleria (2014) Physicochemical Characteristics, Functional Properties, and Nutritional Benefits of Peanut Oil: A Review. Critical Reviews in Food Science and Nutrition, 54:1562–1575.

Sreeramulu, D and Raghunath M. (2011) Antioxidant and Phenolic content of nuts, oil seeds, milk and milk products commonly consumed in India. Food and Nutrition Sciences,2: 422-427.

Wang Q, Liu H.HuR. MzimbiriY.YangY.Chen 2016 Peanut Oil Processing Technology In Peanuts: Processing Technology and Product Development : 63-81 Academic Press Elsevier Inc Publications