Department of Post-Harvest Process and Food Engineering, Jawaharlal Nehru Krishi Vishawa Vidhyalaya, Jabalpur (M.P.) India

Corresponding author Email: iitkgp84@gmail.com

Article Publishing History

Received: 22/01/2019

Accepted After Revision: 24/03/2019

Geometric and gravimetric properties of grain are necessary for designing the equipment for processing, sorting, sizing and other post-harvest operations. The aim of this study is to determine the geometric and gravimetric properties of polished rice, (Pusa Sugandha-1).The geometric properties i.e. length, breadth, thickness, sphericity, size, L/B ratio and the gravimetric properties i.e. bulk density, true density, porosity and test weight were measured. The experiments were conducted at fourteen percent moisture content (wb). The average kernel length, breadth and thickness were observed as 8.17, 1.60 and 1.54 mm respectively. The size and volume were recorded as 2.77 mm and 10.53 mm3 respectively. The sphericity was found 33.90. Bulk density, true density and porosity were observed as 798 kg/m3, 1412.56 kg/m3 and 43.4 percent respectively. Test weight of polished rice was recorded as 16.82 grams. The L/B ratio was found 5.10. This rice will be characterized as extra-long (>7 mm), slender shape (L/B> 3) in an international market.

Polished Rice, Geometric, Gravimetric, and Dehusking

Tiwari V. K, Ansari N. P, Asati A, Madhusudhan. Studies of Geo-gravimetric Properties of Polished Rice, Oryza Sativus, (Pusa Sugandha-1). Biosc.Biotech.Res.Comm. 2019;12 (1).

Tiwari V. K, Ansari N. P, Asati A, Madhusudhan. Studies of Geo-gravimetric Properties of Polished Rice, Oryza Sativus, (Pusa Sugandha-1). Biosc.Biotech.Res.Comm. 2019;12(1). Available from: https://bit.ly/2KlUztZ

Copyright © Tiwari et al., This is an open access article distributed under the terms of the Creative Commons Attribution License (CC-BY) https://creativecommns.org/licenses/by/4.0/, which permits unrestricted use distribution and reproduction in any medium, provide the original author and source are credited.

Introduction

Rice (Oryzasativa L.) is the most important and extensively grown food crop in the world (Agriculture Statistics 2016). As a cereal grains, it is the most widely consumed staple food for a large part of the world’s human population, especially in Asia. India is the second largest rice producer, exporter and consumer after China. Rice is the main food approximately for sixty per cent of the Indian population. Milling consists of the removal of husk and bran to obtain the edible portion (endosperm) to a level that is acceptable and _t for human consumption (Singh et al., 2015). Determining geo-gravimetric properties of rice can facilitate design of machinery for planting, harvesting, storing and processing operations such as threshing, handling, cleaning and drying (Ash-tiani et al., 2010; Ghasemlou et al., 2010). Milling consists of the removal of husk and bran to obtain the edible portion (endosperm) to a level that is acceptable and _t for human consumption (Singh et al., 2015). Rice not only supplies the energy (calorie) need but also fulfil much of the requirement of proteins, vitamins and other nutrients. Total nutrient contents of rice are carbohydrate (77.8 g), protein (6.8 g), fiber (1.4 g), fat (0.6 g) and energy 344 Kcal (Verma and Shukla, 2011, Rather et. al. 2016, Tiwari et al., 2017 Sahu et al 2018).

Paddy consists of 18-24 % husk, 8-12 % bran depending on the milling degree and 68-72 % white rice depending on the variety (IRRI Rice Knowledge Bank, 2017). Rice is also available in the form of brown rice, white rice, sweet rice, jasmine bhutanese red rice and forbidden rice. Rice is obtained after dehusking the paddy and is termed as brown rice. When outer layer bran is removed, the rice is termed as polished rice. The process is known as whitening or polishing.

Material and Methods

All the experiments were carried out in the rice milling laboratory of Post-Harvest Process and Food Engineering Department, College of Agricultural Engineering, JNKVV, Jabalpur.

Determination of moisture content:According to the standard procedure of AOAC (1980), weighed samples of kernel is kept in a Petri dish and dried in a hot air oven at 105 0C for 24 hours. The moisture content was determined by following formula.

Cleaning and grading

The Pusa sugandha-1 variety of rice was cleaned and graded by laboratory model air screen cleaner (Model – Delux, S.No: T.S.G. 135). The clean paddy was shelled by rubber roll sheller (Indosaw Industrial Products Pvt. Ltd.) and polished by friction polisher (Osaw Industrial Products Pvt Ltd).

|

Plate 1: Polisher |

|

Plate 2: Rubber roll Sheller |

Geometric properties

Hundred kernels were randomly selected for measurement of length, breadth and thickness. These parameters were determined by using a digital dial gauge (least count 0.01 mm). Length was taken as the largest intercept of the kernel at resting position, breadth was taken as the largest intercept perpendicular to the length and thickness was measured as the largest intercept perpendicular to the length and breadth.

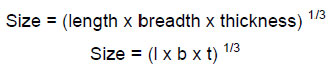

Size: Size and shape are important physical properties and are used to describe the object. Size measurement analysedbehavior of grain during handling, processing, storage and designing the machinery using following expression.

L/B ratio

In India, most of the rice varieties are long (more than 7 mm) and slender in shape (L/B >2.5 and < 3). The shape of the grain infl uenced volume and weight. Slender varieties of paddy or rice occupy more volume than round varieties. Therefore, one ton of a slender variety of paddy will need more storage space than the same weight of round variety of paddy. Size and shape of rice affects many other properties, namely, sieving, dehusking, polishing, storage as well as cooking (Rather et. al. 2016).

Sphericity: Sphericity is defined as the ratio of the diameter of a sphere of same volume as that of the sphere particle and the largest diameter of the sphere. This parameter shows the shape character of the particle relative to the sphere having the same volume. The sphericity (ϕ) of the kernels was calculated as (Curray et al. 1951).

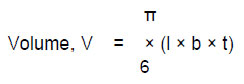

Volume:The unit volume of the rice kernels was calculated by the following relationship (Varnamkhasti et al., 2007).

Where,

V = unit volume (mm3). l, b and t = length, breadth and thickness of grain (mm)

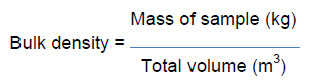

Gravimetric properties: Bulk Density: The density of the grains is used in the design of storage bins and silos, separation of desirable materials from impurities, cleaning and grading, evaluation of the grain maturity etc. The bulk density of the rice kernels is the density of whole grains (including the voids). It was determined by filling a 100 ml cylindrical vessel with rice kernels, tapping it twice to cover the extra space between the kernels and then weighing the contents of the vessel using a weighing balance. The volume of the vessel taken as the volume of the rice kernels. Bulk density is the ratio

of the mass of the sample to its total volume.

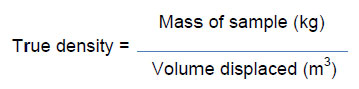

True Density: The true density of the rice kernels is the density of grains excluding the voids. This was determined by the toluene (C6H5CH3) displacement method. In this method, toluene was filled in a 100 ml measuring cylinder and then same mass of sample that was taken for bulk density was put into the vessel containing toluene. The displacement of toluene level in the vessel on putting rice kernels was noted down. The ratio of the mass of rice kernels to the volume of displaced toluene gave the true density.

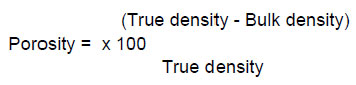

Porosity: The porosity of rice grains refers to the fraction of the pore spaces in the bulk grain that is not occupied by the grain. It is calculated from the values of true density and bulk density by the following relationship.

Test weight: Thousand grain weights of different rice samples was determined by counting one hundred rice kernels, weighing them on a weighing balance and then multiplying it with the factor of 10 (Varnamkhasti et al., 2008).

Results and Discussion

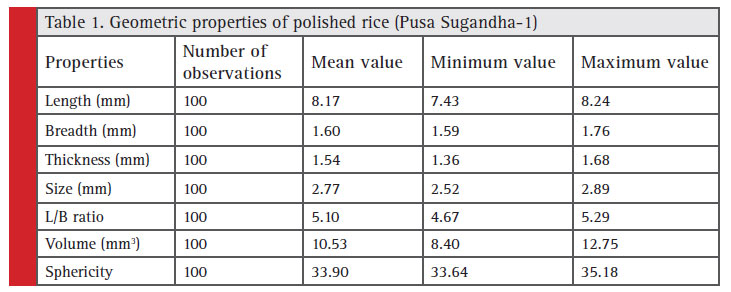

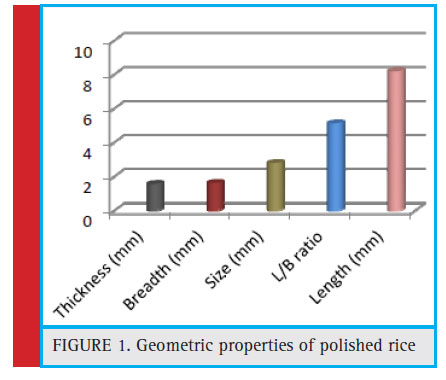

The length, breadth and thickness are very important geometric characteristics for deciding the size of opening of air screen cleaners. A summary of the results of the geogravimetric properties of polished rice (Pusa Sugandha-1) is shown in Table 1 and 2. The average length, breadth and thickness were 8.17, 1.60 and 1.64 mm respectively. The ratio of length and breadth was obtained as 5.10. Tiwari et al. (2017) conducted a study to evaluate of physical properties of brown rice (MTU 1010) and reported average values of length, breadth and thickness as 6.39, 2.14 and 1.9 mm. Similar results were observed by Sahu et. al (2018) while studying some physical properties of Madhuraj, Hanthipanjra and Mahamayavarieties.The shape and L/B ratio are very important for designing the indents of disc and cylindrical separator. Shape is very important for design of helices of spiral separator also. Extra-long (> 7 mm) rice gets high price in national and international market. Rice is also grouped in three grades i.e. super fi ne (L/B >3), fine (L/B > 2.5) and common (L/B<2.5) on the basis of above ratio, (Araullo et al., 1985).

Size of polished rice was observed in the range of 2.52- 2.89 mm. The size of the grain is useful in estimation of the projected area of a particle moving in the turbulent or near- turbulent region of an air steam (Omobuwajo et al., 1999). The sphericity of polished rice was observed as 33.9, which indicates elongated shape of the grains and makes it diffi cult to roll on surface. This was lower than corresponding value of sphericity (35.72) reported by Tiwari et al (2010) for Sugandha-3 variety of rice. While the value of sphericity of paddy (var. Sazandegi) was 39.88% (Varnamkhasti et al., 2007). Paddy grains with lower sphericity will likely be more difficulty to roll freely on a fl at surface, Sanusiet. al (2017). The ability to either roll or slide is necessary in the design of hoppers for milling process. Sphericity values (44.36, 38.82, and 41.47 %) were reported bySahuet.al (2018) for Madhuraj, Hanthipanjra and Mahamaya varieties respectively.

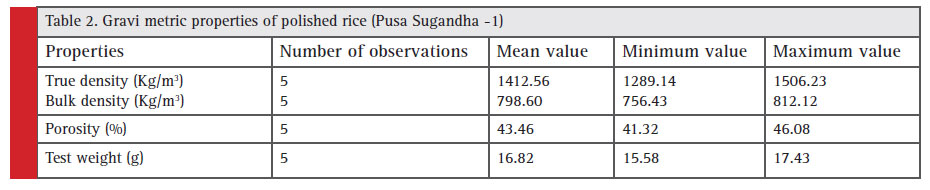

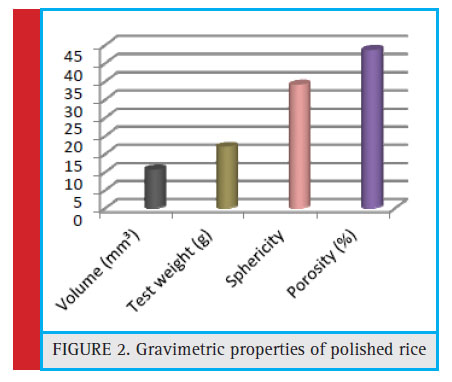

The bulk density, true density, and porosity of polished rice were observed as 798.60 kg/m3, 1412.56 kg/ m3, and 43.4 percent respectively. Varnamkhasti et al. (2007) studied true density, bulk density, and porosity of rough rice (Sazandegi) and reported the values as 798.60 kg/m3,1193.38 kg/m3 and 60.3 percent respectively. The similar results 592.50 kg/m3, 1145.88 kg/m3 and 48.09 percent respectively, were also observed by Tiwari and Sharma (2012) for brown rice (WGL 32100). These properties are used for designing the size of opening of screen.Thousand grain weight is commercially very important as it characterized various grades like extra heavy, heavy and moderately heavy, which decides the export price. Thousand-grain weight of polished rice was recorded as 16.82 grams. Since the weight of polished rice is less than 20 grams it will be characterized in moderately heavy group.

|

Plate 3: Paddy |

|

Plate 4: Polished rice |

|

Table 1: Geometric properties of polished rice (Pusa Sugandha-1) |

|

Table 2: Gravi metric properties of polished rice (Pusa Sugandha -1) |

|

Figure 1: Geometric properties of polished rice |

|

Figure 2: Gravimetric properties of polished rice |

Conclusion

The results of geometric and gravimetric properties of Pusa Sugandha-1 at fourteen percent moisture content (wb) are shown in Table 1 and 2 respectively. The average length, breadth and thickness were observed as 8.17, 1.60 and 1.54 mm respectively. The average size, L/B ratio and volume were determined 2.77 mm, 5.10 and 10.53 mm3. The bulk density true density, and porosity were observed 798.6 kg/m3, 1412.56 kg/m3 and 43.46 percent. The sphericity of rice was 33.90 percent which shows that rice is elongated and will create friction in rolling.

References

Agriculture Statistics at a Glance, http://eands.dacnet.nic.in/ PDF/Glance-2016.pdf, (2016).

AOAC. 1980. Association of Analytical Chemists, Official methods of analysis, 13th Edition, Washington, D.C

Araullo EU, Padua DBD and Graham M. 1985. Rice post-harvest technology. International Development Research Centre.

Ashtiani AH, Sadeghi M, Hemmat A. 2010. Physical properties of two rough rice varieties affected by moisture content. International

Agrophysics 24: 205-207.

BhupendraSahu, D. Khokhar, S. Patel, N. K. Mishra and Girish Chandel (2018). Some Engineering Properties of Selected Paddy Varieties.

Department of the Agricultural Processing and Food Engineering, Faculty of Agricultural Engineering, IGKV, Raipur, Chhattisgarh. Int. J. Pure App. Biosci.6 (2): 1337-1342 (2018).

Curray JR. 1951. Analysis of sphericity drying of food grains. Int Res Journal 22 15-20. Dipti, S. S., Bari, M. N., &Kabir, K. A. (2003). Grain quality characteristics of some beruin rice varieties of Bangladesh. Pakistan Journal Nutrition, 2 (4), 242-245.

Ghasemlou M, Khodaiyan F, Gharibzahedi SMT, Moayedi A, Keshavarz B. 2010. Study on postharvest physico-mechanical and aerodynamic properties of mungbean [Vigna radiate (L.) Wilczek] seeds. International Journal of Food Engineering 6: 122. IRRI Rice Knowledge Bank. 2017. (www.knowledgebank.irri. org/…/postharvest/milling). IRRI, 2013. Trends in global rice consumption: Rice Today. International Rice Research Institute, Manila, Philippines.12:1.

Mayowa S. Sanusia, Rahman Akinosoa, and NahemiahDanbabab (2017). Evaluation of Physical, Milling and Cooking Properties of Four New Rice (Oryzasativa L.) Varieties in Nigeria). International Journal of Food Studies. Department of Food Technology, Faculty of Technology, University of Ibadan, Nigeria. October 2017 Volume 6 page 245-256.

Omobuwajo TO, Akanda EA and Sanni LA. 1999. Selected physical, mechanical and aerodynamic properties of African breadfruit (Treculla Africana) seeds. J. Food Engg 40: 241–4.

Rather, T. A., Malik, M. A., & Dar, A. H. (2016). Physical, milling, cooking, and pasting characteristics of different rice varieties grown in the valley of Kashmir india. Cogent Food & Agriculture, 2 (1), 1178694.

Tiwari VK and Sharma N. 2012. Varietal infl uence on physical characteristics of brown rice. JNKVV Res J 46(1): 90-93.

Tiwari VK, Dayma V, and Sharma HL note on the studies of physical properties of brown rice. International Journal of Scientific Development and Research 2.

Tiwari VK. 2010. Investigations on physical and engineering properties of rice variety Sugandha-3 grain at Jabalpur, Madhya Pradesh. JNKVV Res J 44(2): 213-216.

Varnamkhasti MG, Mobli H, Jafari A, Rafiee S, Heidarysoltanabadi M and KheiralipouR K..2007. Some Engineering Properties of Paddy (var. Sazandegi).International Journal of Agriculture & Biology 5:763–766.

Varnamkhasti MG, Mobli H, Jafari A, Key-hani AR, Soltanabadi MH, Raee S and Kheiralipour, K. 2008. Some physical properties of rough rice (Oryzasativa.) grain. Journal of Cereal Science 47 (3):496.

Verma DK, and Shukla K. 2011. Nutritional value of rice and their importance. Indian Farmers’ Digest.