Faculty of Biotechnology, Ho Chi Minh City Open University, Ho Chi Minh City, Vietnam

Corresponding author email: minh.np@ou.edu.vn

Article Publishing History

Received: 07/07/2020

Accepted After Revision: 15/09/2020

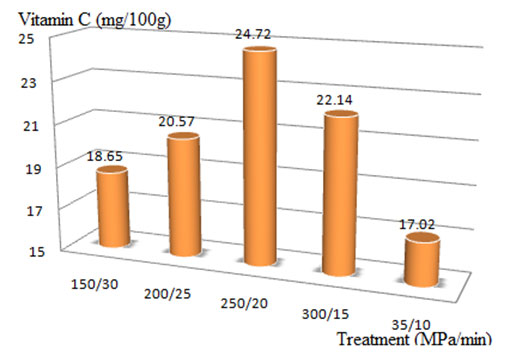

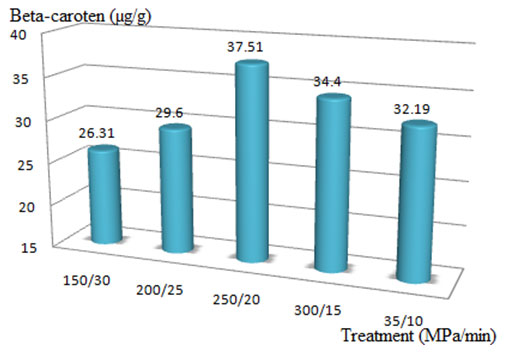

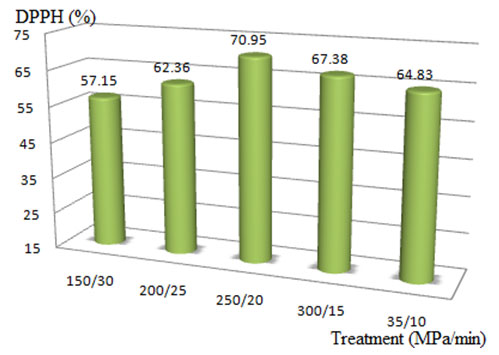

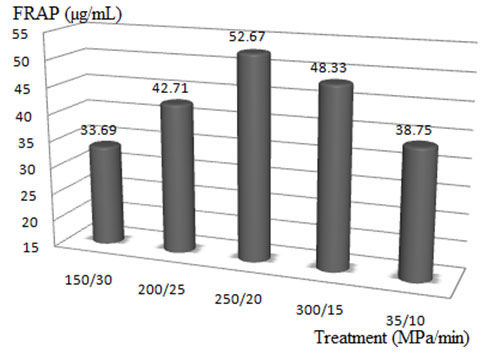

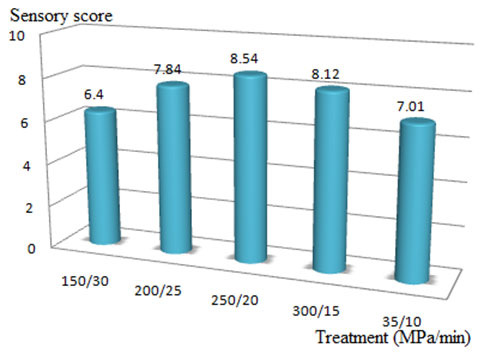

High hydrostatic pressure (HHP) has been considered as one of the most innovative technologies widely applied in food processing by its superior advantages to other conventional processing methods. HHP destroys vegetative cells and inactivates enzymes with an insignificant modification in the organoleptic attributes. Mango (Mangifera indica L.) juice is a healthy food drink highly appreciated by its sweet-sour taste and high nutritional components. It’s commonly treated by thermal treatment to inactivate microbial and enzyme activity to achieve a long stability in storage and distribution. However, heat seriously affected to sensitive phytochemical components as well as organoleptic properties. Mango juice was treated with hydrostatic pressure under different conditions (150/30, 200/25, 250/20, 300/15, 350/10, MPa/min) to evaluate vitamin C (mg/100g), beta-caroten (µg/g) retention; residual polyphenol oxidase and peroxidase activity (%); free radical scavenging activity (% DPPH), ferric reducing antioxidant power (FRAP, µg/mL); overall acceptance of mango juice. Results showed that vitamin C, beta-caroten, free radical scavenging activity (% DPPH), ferric reducing antioxidant power (FRAP, µg/mL) were highly maintained at 250 MPa in 20 minutes while the residual polyphenol oxidase and peroxidase activity (%) were kept in the highest level. Under the hydrostatic pressure treatment, mango juice also had good overall acceptance. Therefore HPP treatment at 250 MPa/20 min would be ideal in making of mango juice.

Beta-Caroten, DPPH, FRAP, Hydrostatic Pressure, Mango Juice, Peroxidase, Polyphenoloxidase

Nguyen M. P. Influence of High Hydrostatic Pressure on Vitamin C, Beta-carotene Retention, Residual Polyphenol Oxidase and Peroxidase Activity, Antioxidant Capacity and Overall Acceptance of Mango (Mangifera indica ) Juice. Biosc.Biotech.Res.Comm. 2020;13(3).

Nguyen M. P. Influence of High Hydrostatic Pressure on Vitamin C, Beta-carotene Retention, Residual Polyphenol Oxidase and Peroxidase Activity, Antioxidant Capacity and Overall Acceptance of Mango (Mangifera indica ) Juice. Biosc.Biotech.Res.Comm. 2020;13(3). Available from: https://bit.ly/30nSgy2

Copyright © Nguyen This is an open access article distributed under the terms of the Creative Commons Attribution License (CC-BY) https://creativecommons.org/licenses/by/4.0/, which permits unrestricted use distribution and reproduction in any medium, provide the original author and source are credited.

INTRODUCTION

Thermal treatment is a conventional method to inactivate microbial organisms and enzymes in fruit juices; however, heating also causes negative impacts on vitamin C, speeds up decomposition of bioactive constituents, and decreases physicochemical attributes as well as sensory, functional and nutritional values, (Suh et al. 2004; Ndiaye et al. 2009; Patras et al. 2010; Zhang et al., 2016). High hydrostatic pressure (HHP) is one of non-thermal innovative emerging methods not only satisfying the Pasteurization but also significantly maintaining phytochemical components inside fruit juice by the lower processing temperature (Allenda et al. 2006; Rawson and Patras 2011). Different literatures in the recent past have mentioned that HHP is effective in inactivating microorganisms as well as retention of physicochemical characteristics of strawberry juice (Ferrar et al. 2011), pomegranate juice (Varela-Santos et al., 2012), blueberry juice (Barba et al. 2012), apricot, peach, and pear (Anthoula et al., 2014), strawberry juice (Xiamin et al., 2014), beetroot (Paciulli et al., 2016), carrot juice (Zhang et al., 2016), jabuticaba juice (Kim et al., 2017), apple juice (Nayak et al., 2017), grape juice (Chang et al., 2017), mulberry juice (Engmann et al., 2020).

Moreover, high hydrostatic pressure also enhanced antioxidant activity, polyphenol content, flavor, taste and overall acceptability of these juices in comparison to non-pressurized or thermally processed samples. HHP could accelerate the extractability of bioactive elements from food matrix by causing microstructural modification in plant tissues, thus favoring the release of these components (Vázquez-Gutiérrez et al., 2011; Vázquez-Gutiérrez et al., 2013; Xi and Luo, 2016). HPP causes physical damage to the structures of food products, it can also be used as a synergistic extraction technology to enhance the extraction efficiency of functional components, thereby reducing extraction time (Hsiao-Wen et al., 2020). HHP technology offers an effective and safe method of modifying protein structure, enzyme inactivation, and formation of chemical constituents (Gezai et al., 2019).

Mango (Mangifera indica L.) has favourable nutrient properties as a source of phenolics, carotenoid, vitamin C, excellent flavour, aroma and colour. It is rich in bioactive molecules protecting human cells from the detrimental effect of free radicals. This fruit is rich in antioxidants potentially reducing the risk of cardiac disease, anti-diabetic, anticancer, anti-inflammatory and antiviral activities (Abbasi et al., 2011; Kalpn et al., 2016; Masud et al., 2016). Because of high perishability, mango fruit becomes rotten quickly and preservation is very essential to make it available for a long stability (Sajeda et al., 2018). Objective of our study focused on the vitamin C (mg/100g), beta-carotene (µg/g) retention; residual polyphenol oxidase and peroxidase activity (%); free radical scavenging activity (% DPPH), ferric reducing antioxidant power (FRAP, µg/mL); overall acceptance of mango juice under high hydrostatic pressure under different conditions (150/30, 200/25, 250/20, 300/15, 350/10, MPa/min).

MATERIAL AND METHODS

Material: Fully ripen raw mango fruits were collected from Soc Trang province, Vietnam. After washing thoroughly with clean water, the fruits were peeled by sharp knife. They were cut into small pieces and then pressed by a screw extractor. The juice was obtained from the filter. The juice was centrifuged at 2000g for 10 min to remove fine solid particles.

Method: Mango juice was filled into polyethylene terephthalate bottles with screw-cup closures. These bottles were placed a hydrostatic pressurization unit. Different conditions (150/30, 200/25, 250/20, 300/15, 350/10, MPa/min) were examined to evaluate vitamin C, beta-carotene retention; residual polyphenol oxidase and peroxidase activity; (%); free radical scavenging activity (% DPPH), ferric reducing antioxidant power (FRAP, µg/mL); overall acceptance of mango juice.

Physicochemical and sensory analysis: Vitamin C (mg/100g) was determined by using 2,6 dichlorophenolindophenol titration as described in the AOAC (2015). Beta-carotene content (µg/g) was analyzed by using high performance liquid chromatography (Nauman et al., 2007). Residual polyphenol oxidase (%) and peroxidase (%) activities were assayed using UV spectrophotometry method proposed by Engmann et al. (2020). DPPH (%) was conducted according to Bakar et al. (2015). FRAP (µg/mL) assay was performed by procedure of Benzie and Strain (1996). Overall acceptance of mango juice was evaluated by a group of panelists using 9 point-Hedonic scale.

Statistical analysis: The experiments were run in triplicate with three different lots of samples. The data were presented as mean ± standard deviation. Statistical analysis was performed by the Statgraphics Centurion version XVI.

RESULTS AND DISCUSSION

HPP application resulted in an instantaneous and uniform transmission of the pressure throughout the product independent of the product size and geometry (Ramirez-Suarez and Morrissey, 2006). As HPP only influenced non-covalent bonds, such as hydrogen bonds, ionic bonds, and hydrophobic bonds, it induced changes in the physicochemical properties and functional activities of biomacromolecules in food products, and even resulted in protein denaturation, enzyme deactivation, and microbe inactivation. In contrast, low molecular weight compounds, such as flavor substances, natural nutrients, and aromatic components, were not affected by HPP (Martinez-Monteagudo and Saldana, 2014).

In our research, bottles of mango juice was treated by HPP under different parameters (150/30, 200/25, 250/20, 300/15, 350/10, MPa/min). Results revealed that vitamin C (mg/100g), beta-carotene (µg/g), free radical scavenging activity (% DPPH), ferric reducing antioxidant power (FRAP, µg/mL) were highly maintained at 250 MPa in 20 minutes while the residual polyphenol oxidase and peroxidase activity (%) were kept in the highest level. Under the hydrostatic pressure treatment, mango juice also had good overall acceptance (figure 1-7). Yen and Lin (1996) reported that 11.32% of ascorbic acid in strawberry coulis decreased after HHP treatment at 400 MPa/20°C/30 min. HHP can improve cell permeability due to its aptitude to deprotonate charged groups and disrupt salt bridges and hydrophobic bonds in cell membranes; therefore, the extraction of polyphenols from pulp particles is more accessible, (Xiamin et al., 2014). Antioxidant activity of strawberry and blackberry purees was reduced by 25% by thermal processing but there was only 5% reduction treated by HPP with better antioxidants and ascorbic acid retention, (Gezai, 2019).

Aaby et al. (2018) proved that HPP did not result in significantly different vitamin C contents in strawberry juice. Andrés et al. (2016) showed that the total carotenoid content of soy-smoothies increased after HPP (650 MPa/3 min). Ali et al. (2019) demonstrated that HPP resulted in a substantial retention of vitamin C content of wheatgrass juice. Some studies reported that HHP could not effectively inactivate polyphenol oxidase, peroxidase in fruits and vegetables (Goodner et al., 1999; Corredig et al., 2002; Baron et al., 2006; Dalmadi et al., 2006). The antioxidant capacity in mango juice after HHP treatment was evaluated using·DPPH and FRAP methods. Phenolic compounds were responsible for antioxidant capacities in fruits, and the fruits with higher phenolic contents generally showed stronger antioxidant capacities. Sánchez-Moreno et al. (2006) indicated that total scavenging activity (DPPH) in aqueous and organic fractions of tomato puree was unaffected by HHP treatment at 400 MPa/15 min/25°C.

Chaikham and Prangthip (2015) found that DPPH radical inhibition (%) and FRAP value (mMFeSO4/g) revealed a higher antioxidant capacity in pressure-treated longan flower-honey. González-Cebrino et al. (2016) proved that HHP influenced the volatile constituents of red plum purée. Hartyáni et al. (2011) and Ferrari et al. (2010) demonstrated that the aroma of HHP-treated citrus and pomegranate juices, could be significantly different from that of the fresh juice. Oey et al. (2008) suggested that HHP resulted in slightly modified organoleptic properties. Engmann et al. (2020) demonstrated that hydrostatic pressure treatment at 200 MPa in 10 min showed a better inactivation of enzyme activity, higher conservation of anthocyanin of the mulberry juice.

Figure 1: Effect of HPP treatment (MPa/min) on vitamin C (mg/100g) of mango juice

Figure 2: Effect of HPP treatment (MPa/min) on beta-carotene (µg/g) of mango juice

Figure 3: Effect of HPP treatment (MPa/min) on DPPH (%)of mango juice

Figure 4: Effect of HPP treatment (MPa/min) on FRAP (µg/mL) of mango juice

Figure 5: Effect of HPP treatment (MPa/min) on residual PPO (%) of mango juice

Figure 6: Effect of HPP treatment (MPa/min) on residual PO (%) of mango juice

Figure 7: Effect of HPP treatment (MPa/min) on sensory score of mango juice

CONCLUSION

High hydrostatic pressure is an innovative processing strategy that includes subjecting fruit juice to high isostatic pressures, causing microbial and enzyme inactivation to ensure improvement of food safety and stability of perishable components, while maintaining nutritional, functional and organoleptic properties. Consumers are demanding minimally processed and fresh food products, the application of non-thermal techniques like HHP is gaining popularity.

ACKNOWLEDGEMENTS

We acknowledge the financial support for the publication provided by Ho Chi Minh City Open University, Vietnam.

Conflict Of Interest: The authors declared that present study was performed in absence of any conflict of interest.

REFERENCES

Aaby K, I. H. Grimsbo, M. B. Hovd, T. M. Rode (2018). Effect of high pressure and thermal processing on shelf life and quality of strawberry purée and juice. Food Chem 260: 115-123.

Abbasi K, N. Anjum, S. Sammi, T. Masud, S. Ali (2011). Effect of coatings and packaging material on the keeping quality of mangoes (Mangifera indica L.) stored at low temperature. Pakistan J. Nutr. 10: 129-138.

Ali N, V. Popović, T. Koutchma, K. Warriner, Y. Zhu (2019). Effect of thermal, high hydrostatic pressure, and ultraviolet-C processing on the microbial inactivation, vitamins, chlorophyll, antioxidants, enzyme activity, and color of wheatgrass juice. J Food Process Eng 2019: 13036.

Allenda A, F. A. Tomás-Barberán, M. I. Gil (2006). Minimal processing for healthy traditional foods. Trends in Food Science and Technology 17: 513–519.

Andrés V, L. Mateo-Vivaracho, E. Guillamón, M. J. Villanueva, M. D. Tenorio (2016). High hydrostatic pressure treatment and storage of soy-smoothies: colour, bioactive compounds and antioxidant capacity. LWT – Food Sci Technol 69: 123-130.

Anthoula A A, C. T. Chrysoula, S. Fotios, M. Constantinos, C. Nikos (2014). Effect of high hydrostatic pressure processing on microbiological shelf-life and quality of fruits pretreated with ascorbic acid or SnCl2. Biomed Res Int. 2014: 819209.

AOAC (2015). Official method of analysis of analytical chemists, 14th edition. Washington DC, USA.

Bakar M F A, F. A. Karim, E. Perisamy (2015). Comparison of phytochemicals and antioxidant properties of different fruit parts of selected Artocarpus species from Sabah, Malaysia. Sains Malaysiana 44: 355-363.

Barba F J, H. Jäger, N. Meneses, M. J. Esteve, A. Frígola, D. Knorr (2012). Evaluation of quality changes of blueberry juice during refrigerated storage after high-pressure and pulsed electric fields processing. Innovative Food Science and Emerging Technologies 14: 18–24.

Baron A, J. Dénes, C. Durier (2006). High-pressure treatment of cloudy apple juice. LWT–Food Science and Technology 39: 1005–1013.

Benzie I F F and J. J. Strain (1996). Ferric reducing ability of plasma (FRAP) as a measure of antioxidant power. The FRAP assay. Anal Biochemistry 239: 70-76.

Chaikham P and P. Prangthip (2015). Alteration of antioxidative properties of longan flower-honey after high pressure, ultra-sonic and thermal processing. Food Biosci 10: 1-7.

Chang Y H, S. J. Wu, B. Y. Chen, H. W. Huang, C. Y. Wang (2017). Effect of high-pressure processing and thermal pasteurization on overall quality parameters of white grape juice. J Sci Food Agric 97: 3166-3172.

Corredig M and L. Wicker (2002). Juice clarification by thermostable fractions of marsh grapefruit pectin methylesterase. Journal of Food Science 67: 1668–1671.

Dalmadi I, G. Rapeanu, V. A. Loey, M. Hendrickx (2006). Characterization and inactivation by thermal and pressure processing of strawberry (Fragaria ananassa) polyphenol oxidase: A kinetic study. Journal of Food Biochemistry 30: 56–76.

Engmann F N, Y. K. Ma, R. Sanful (2020). The impact of high hydrostatic pressure treatment on anthocyanins, colour, microorganisms, and enzyme activity of mulberry (Morus nigra) juice. International Food Research Journal 27: 88 – 95.

Ferrari G, P. Maresca, R. Ciccarone (2011). The effects of high hydrostatic pressure on the polyphenols and anthocyanins in red fruit products. Procedia Food Science 1: 847–853.

Ferrari G, P. Maresca, R. Ciccarone (2010). The application of high hydrostatic pressure for the stabilization of functional foods: pomegranate juice. J Food Eng 100: 245–253.

Gezai A W (2019) Review on high-pressure processing of foods. Cogent Food and Agriculture 5: 1568725.

González-Cebrino F, J. García-Parra, R. Ramírez (2016). Aroma profile of a red plum purée processed by high hydrostatic pressure and analysed by SPME–GC/MS. Innov Food Sci Emerg Technol 33: 108–114.

Goodner J K, R. J. Braddock, M. E. Parish, C. A. Sims (1999). Cloud stabilization of orange juice by high pressure processing. Journal of Food Science 64: 699–700.

Hartyáni P, I. Dalmadi, Z. Cserhalmi, D. B. Kántor, M. Tóth-Markus, A. Sass-Kiss (2011). Physical-chemical and sensory properties of pulsed electric field and high hydrostatic pressure treated citrus juices. Innov Food Sci Emerg Technol 12: 255–260.

Hsiao-Wen H, H. Chiao-Ping, W. Chung-Yi (2020). Healthy expectations of high hydrostatic pressure treatment in food processing industry. Journal of Food and Drug Analysis 28: 1-13.

Kalpna R, K. Mital, C. Sumitra (2016). Physicochemical and phytochemical analysis of different parts of Indian Kesar mango–A unique variety from Saurashtra Region of Gujarat. Pharmacogn. J. 8: 502-506.

Kim O P I, G. T. Alexandre, P. Daniel, M. Mariana (2017). High hydrostatic pressure processing affects the phenolic profile, preserves sensory attributes and ensures microbial quality of jabuticaba (Myrciaria jaboticaba) juice. J Sci Food Agric 6: 1-9.

Martinez-Monteagudo S I and M. D. A. Saldana (2014). Chemical reactions in food systems at high hydrostatic pressure. Food Eng Rev 6: 105-127.

Masud P G M (2016). Pharmacological activities of mango (Mangifera indica): A review. Journal of Pharmacognosy and Phytochemistry 5: 01-07.

Nauman A, M. Saleemullah, U. S. Hamid, A. K. Iqtidar, A. U. R. Saljoqi (2007). Determination of beta carotene content in fresh vegetables using high performance liquid chromatography. Sarhad J. Agric. 23: 767-770.

Nayak P K, K. Rayaguru, K. R. Krishnan (2017). Quality comparison of elephant apple juices after high-pressure processing and thermal treatment. J Sci Food Agric 97: 1404-1411.

Ndiaye C, S. Y. Xu, Z. Wang (2009). Steam blanching effect on polyphenol oxidase, peroxidase and colour of mango (Mangifera indica L.) slices. Food Chemistry 113: 92–95.

Oey I, M. Lille, A. V. Loey, M. Hendrickx (2008). Effect of high pressure processing on colour, texture and flavour of fruit- and vegetable-based food products: a review. Trends Food Sci Technol 19: 320–328.

Paciulli M, I. G. Medina-Meza, E. Chiavaro, G. V. Barbosa-Canovas (2016). Impact of thermal and high pressure processing on quality parameters of beetroot (Beta vulgaris L.). LWT – Food Sci Technol 68: 98-104.

Patras A, N. Brunton, C. O’Donnell, B. K. Tiwari (2010). Effect of thermal processing on anthocyanin stability in foods; mechanisms and kinetics of degradation. Trends in Food Science and Technology 21: 3–11.

Ramirez-Suarez J C and M. T. Morrissey (2006). Effect of high pressure processing (HPP) on shelf life of albacore tuna (Thunnus alalunga) minced muscle. Innovative Food Science and Emerging Technologies 7: 19–27.

Rawson A and B. K. T. Patras (2011). Effect of thermal and non thermal processing technologies on the bioactive content of exotic fruits and their products: review of recent advances. Food Research International 44: 1875–1887.

Sajeda B, C. D. Pabitra, K. Poly (2018). Processing of mixed fruit juice from mango, orange and pineapple. Fundamental and Applied Agriculture 3: 440–445.

Sánchez-Moreno C, L. Plaza, B. De Ancos, M. P. Cano (2006). Impact of high-pressure and traditional thermal processing of tomato purée on carotenoids, vitamin C and antioxidant activity. Journal of the Science of Food and Agriculture 86: 171–179.

Suh H J, J. M. Kim, H. Lee, S. W. Lee, Y. M. Choi (2004). Thermal kinetics on antiradical capacity of mulberry fruit extract. European Food Research and Technology 219: 80–83.

Varela-Santos E, A. Ochoa-Martinez, G. Tabilo-Munizaga, J. E. Reyes, M. Pérez-Won, V. Briones-Labarca (2012). Effect of high hydrostatic pressure (HHP) processing on physicochemical properties, bioactive compounds and shelf-life of pomegranate juice. Innov Food Sci Emerg Technol 13: 13–22.

Vázquez-Gutiérrez J L, A. Quiles, I. Hernando, I. Pérez-Munuera (2011). Changes in the microstructure and location of some bioactive compounds in persimmons treated by high hydrostatic pressure. Postharvest Biol Biotechnol 61:137–144.

Vázquez-Gutiérrez J L, L. Plaza, I. Hernando, C. Sánchez-Moreno, A. Quiles, B. de Ancos (2013). Changes in the structure and antioxidant properties of onions by high pressure treatment. Food Funct 4: 586–591.

Xiamin C, L. Fengxia, W. Jihong, L. Xiaojun, H. Xiaosong (2014). Effects of high hydrostatic pressure combined with blanching on microorganisms and quality attributes of cloudy and clear strawberry juices. International Journal of Food Properties 17: 1900-1920.

Xi J and S. Luo (2016). The mechanism for enhancing extraction of ferulic acid from Radix Angelica sinensis by high hydrostatic pressure. Sep Purif Technol 165: 208–213.

Yen G C and H. T. Lin (1996). Comparison of high pressure treatment and thermal Pasteurization on the quality and shelf life of guava purée. International Journal of Food Science and Technology 31: 205–213.

Zhang Y, X. Liu, Y. Wang, F. Zhao, Z. Sun, X. Liao (2016). Quality comparison of carrot juices processed by high-pressure processing and high-temperature short-time processing. Innov Food Sci Emerg Technol 33:135–144.