Environmental

Communication

Biosci. Biotech. Res. Comm. 9(4): 865-871 (2016)

Removal of cadmium from industrial waste water

by adsorption zeolite clinoptilolite

Leila Dstan

1

and Mohsen Dehghani

2,

*

1

Water and Wastewater Master’s Graduates, Islamic Azad University Bandar Abbas

2

Department of Environmental Engineering, Islamic Azad University Bandar Abbas Branch Hormozgan, Iran

ABSTRACT

Today, with the expansion of industry and industrial development, the risk of heavy metals pollution is more than

before. With due attention to the increasing of environmental pollution by heavy metals, using appropriate methods

is essential for removal of these elements from environment. In this study, the absorption of the Zeolite clinoptilolite

was used to remove Cd

+2

from industrial waste. For this purpose, the effect of pH parameters, contact time, adsorbent

dosageand initialconcentrationof cadmium was studied on the removal of cadmium ef ciency. The results showed

that, the optimal pH, optimal contact time and optimal adsorbent dosage is equal to 4 and 15 minutes and 1 g/L

respectively. The results of Langmuir, Freundlich, Temkin and Dubinin–Radushkevich adsorption isotherms showed

that Freundlich model is the best adapted model to the equilibriumexperimentdata for absorbent. According to the

ef ciency of natural zeolite clinoptilolite for removal of cadmium from industrial waste with an ef ciency of 98%

and also due to low cost, available and less environment effects of this absorbent than many of kinetics absorbent is

proposed that industrial units use this kind of absorbent in waste water treatment.

KEY WORDS: REMOVAL, CADMIUM, CLINOPTILOLITE, INDUSTRIAL WASTEWATER

865

ARTICLE INFORMATION:

*Corresponding Author: Dehghani933@gmail.com

Received 2

nd

Aug, 2016

Accepted after revision 20

th

Dec, 2016

BBRC Print ISSN: 0974-6455

Online ISSN: 2321-4007

Thomson Reuters ISI ESC and Crossref Indexed Journal

NAAS Journal Score 2015: 3.48 Cosmos IF : 4.006

© A Society of Science and Nature Publication, 2016. All rights

reserved.

Online Contents Available at: http//www.bbrc.in/

INTRODUCTION

The risk of environmental pollution, resulting from human

activities has become a global concern (Alvarez-Ayuso,

2003).Heavy metals are also an important group of pol-

lutants in the environment. Today, with the development

of industry and technology the risk of heavy metals pol-

lution has been created in the environment more than

before (Inglezakis et al., 2004). Most of the heavy metals

are very soluble at low concentration and they have thea-

bility to access to vital components of living things. In the

nature, heavy metals are in the group of rate elements and

generally have been formedless than one percent of the

Earth’s crust (Erdem et al., 2004). Removal of heavy metals

from wastewater has become a major concern nowadays

because of its ability to contaminate water bodies.

866 REMOVAL OF CADMIUM FROM INDUSTRIAL WASTE WATER BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Leila Dstan and Mohsen Dehghani

Many processes have been proposed for removal of

heavy metals, including chemical sedimentation, mem-

brane ltration, ion exchange, reverse osmosis and

adsorption by the activated carbon which is the most

common of these methods (Buerge-Weirich et al., 2002).

Researchers for the aim of environment protection are

looking for appropriate solutions, scienti c and eco-

nomical to minimize the harmful effects of ef uent.

In this regard, the using of methods and materials that

have minimal side effects are in top priority. Zeolite with

extraordinary structure, high cation exchange capacity,

keeping structure in high temperature, low cost and abun-

dant distribution of it in the world has been caused to

consider as a remover (Cecille and Toussaint, 1989, Bable

et al., 2003, Rosales et al., 2012 and Kalantry et al 2014).

These minerals are used primarily in the high range

in the industry as an adsorbent for removal of oil and

metals (Inglezakis et al., 2004, Papaioannou et al., 2005).

clinoptilolite is an inorganic and natural compound and

safe, non toxic and harmless that using of that does not

have sideeffects on the environment (Wu, 2008). In this

study, with due regard to the previous studies for remov-

ing heavy metals from waste water and industrial water,

it is tried to present best conditions to remove cadmium

ion from simulated aqueous solution in the waste water

by using of zeolite.

MATERIAL AND METHODS

In this study, zeolite was studied as adsorbent for the

removal of cadmium ions from industries waste water

to evaluate the effect of studied process of pH, con-

tact time, concentration of cadmium, adsorbent mass

and interferences effect. Utilizing Zeolitein this study

was obtained from mines of Semnan in the central of

Iran. pH meter system multi 340 I and shaker system

FG model with regulating capability of round 50 to 600

was used for determining pH and for samples disorder

respectively. The solution of centrifuge system centrion

model was used to separate absorbent. This study was

conducted non continuous in laboratory scale at tem-

perature of 25ºC and.

1) The Preparation of absorbent

Zeolite clinoptilolite samples were obtained from Sem-

nan mines and they were used without any chemical

modi cations. At rst, by using a sieve 1 & 3 mm, Par-

ticles absorbent have been grouped, and in different

experimentation processes were used from these Parti-

cles in the size of 1-3 mm of absorbent.

2) Preparing an aqueous solution ofcadmium ion

At rst, stock standard production was provided

1000 m/g per liter cadmium from sulfate cadmium

(CdSO

4.

8H

2

O) and then standard solutions was made

from it with concentrations1, 2.5, 5, 10.

3) The adsorption experiments stages

Experiments for determining the effects of pH on the

adsorption process:

At this stages, cadmium solution was prepared with a

concentration of 15mg per liter and its pH was regulate

by 1 and 0.1 HCl and NaOH on the values of 4,5,6,7,8,

and 9. Then Zeolite adsorbent was added with mass of

1g. The samples were analyzed for 120minutes on a

shaker with speed of 180rpm and were centrifuged for

20minutes and nally the remaining cadmium concen-

tration was measured by atomic absorption spectrom-

etry. At rst, the concentrations of 1, 2.5, 5, and 10 mg/l

of cadmium was prepared from stock solution and after

regulating pH, about 1 g of adsorbent was added to

the samples. All of the laboratorial pipes settled on the

shaker to shake and then after separating the solution

from adsorbent with centrifuge, the remaining value of

Cadmium was measured in the solution. After determin-

ing the optimal pH and concentration of cadmium, the

effect of adsorption value was carried out for Zeolite

clinopetilolite adsorbent in the masses of 0.1, 0.25, 0.5

and 1g in the solution and then the remaining concen-

tration Cadmium was measured.

For determining the optimal time, 20 ml of Cadmium

solution was prepared separately with concentration of

2.5 ppm at the optimal pH. The value of 1 g of adsor-

bent (optimal adsorbent) was added to the sample. Solu-

ble were separately on the shaker in contact times of

5,10,15,20,30,60 minutes with absorbent with around

180rpm, and after separation of solution, the remaining

concentration of cadmium ion was measured by using

atomic absorption system.In order to evaluate the effect

of other ions on cadmium on the zeolite, according to

the analysis of industrial units `ef uent, an simulation

ef uent was prepared and ions Cu

+2

, Mg

+2

, Zn, Ca

+2

, Pb

+2

,

Cl

-

, NH

4+

, and sulfate was selected and studied as the

experimental matrix.

In this study, Langmuir, Freundlich, Temkin and

Dubinin–Radushkevich isotherms models were used

for modeling process of cadmium adsorption. Lang-

muir isotherm based on a uniform (homogenous) and

monolayer of adsorb material with the same energy is

on all the levels of the adsorbent. Freundlich isotherm

unlike Langmuir is on the adsorbent, based on multi-

layer adsorption and heterogeneous adsorbent material.

Temkin isothermal include one factor that shows clearly

interactions between adsorbent and adsorb particles

and Dubinin–Radushkevich model is more public than

Langmuir, because in this model the monotonousness

of adsorption sites is not needed (Crittenden et al., 2012,

Naghizadeh, et al, 2011).

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS REMOVAL OF CADMIUM FROM INDUSTRIAL WASTE WATER 867

Leila Dstan and Mohsen Dehghani

Freundlich isotherm model:

Equation 1 represents the mathematical model of Frend-

lich isotherm.

(1)

Mass ratio of the solid phase which is the mass of

adsorbent material, ratio to the mass of absorbent mate-

rial.

C

e

=Concentration in equilibrium

Kempirical constant (Freundlich equation coef cients)

Langmuir isotherm model:

The mathematical model of this isotherm, have been

shown in Equation 2:

(2)

B and qm are empirical constants

Ce and q parameters are resemblance to Frendlich iso-

therm.

Temkin Isotherm:

The general from of Temkin isotherm is as follows:

By considering B=RT/B a linear form of Temkin isother-

mal will be as follow:

In this equation A in terms of mg/l is equivalent to

bond constant associated with maximum energy, and

b in terms of mol/J is Temkin isothermal constant,

and b (no unit) constant is proportional to the heat of

adsorption.

Dubinin Rudoshkevich isotherm model

In this equation:

qe is the amount of dissolved material that is on the

adsorbent mass unit and qm is the capacity of absorp-

tion of adsorbent in per unit mass.

K is Dubinin–Radushkevich constant adsorption and

is potential.

RESULTS

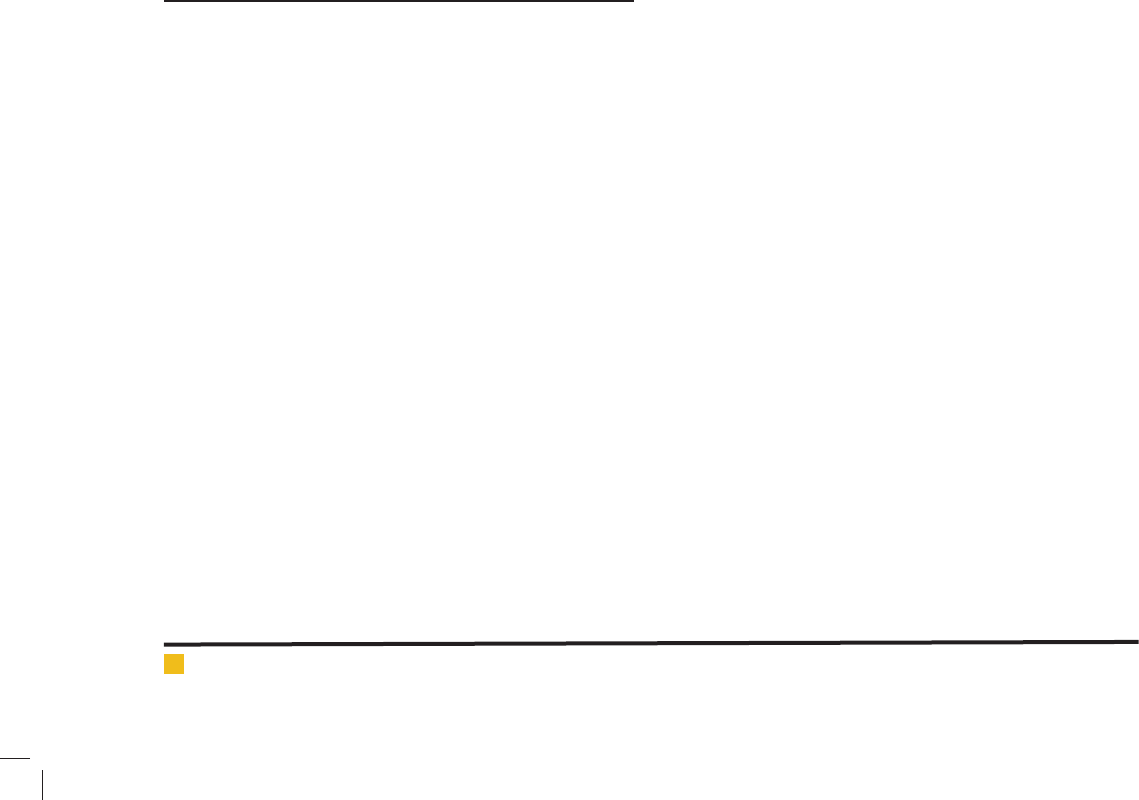

Clinoptilolite mineral analysis and mapping of x-ray

diffraction of this mineral are presented in table1 and

gure 1.

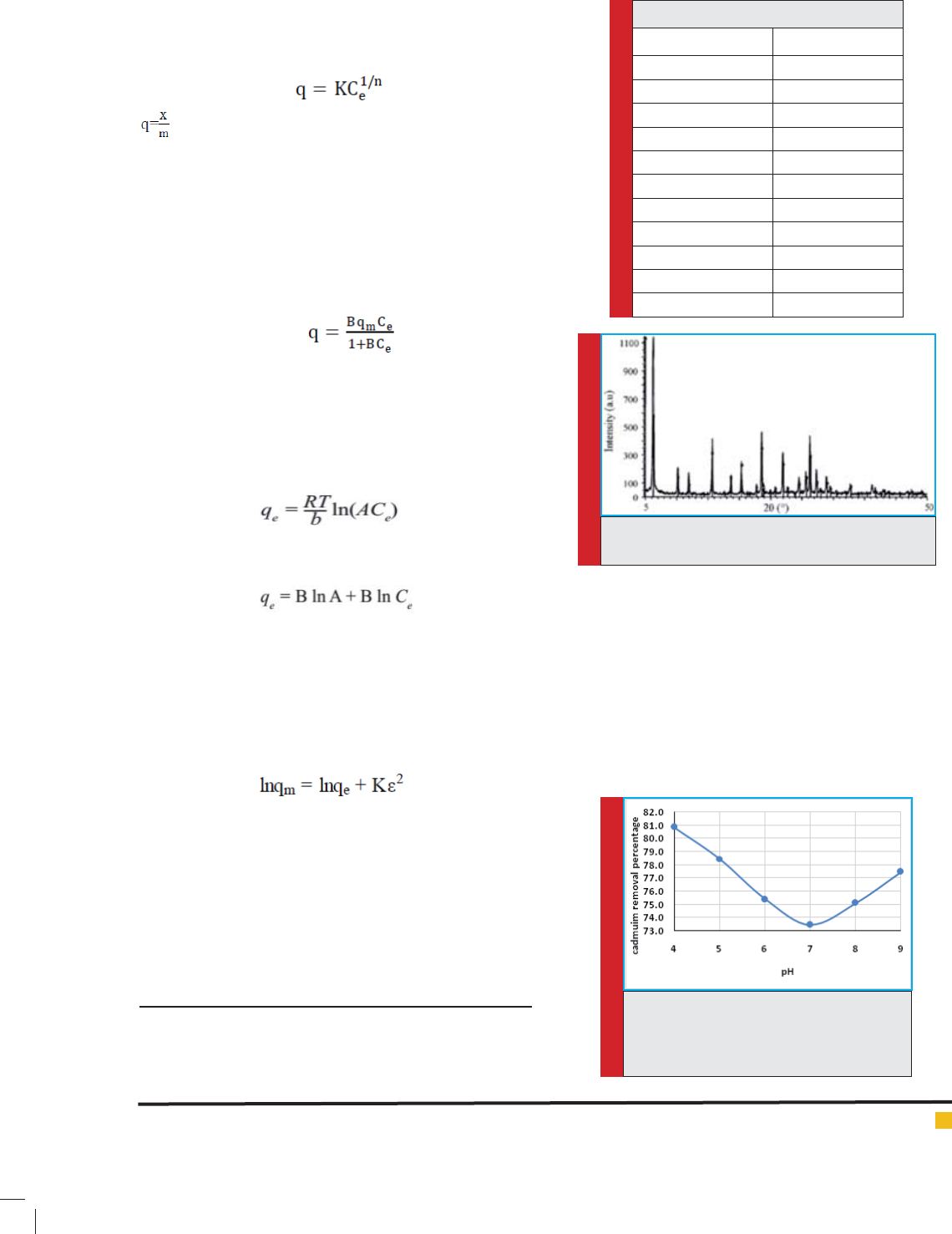

The effect of pH on cadmium adsorption:

The effect of pH solution on the adsorption of cadmium

ions showed that the adsorptions process of the Zeo-

lite have better conditions in acidic pHs and with the

increasing of pH from 4 to 9 the value of removal is

decreased and then by increasing of pH from 7 to 9

adsorption will increased. The presented results in gure

2 shows that the highest adsorption ef ciency of cad-

mium was observed at pH=4.

FIGURE 1. The radiation of X-ray related to the

zeolite powder samples.

FIGURE 2. The effect of pH parameter on

cadmium adsorption ef ciency at tempera-

ture of 25ºC and 15 minutes, the concen-

tration of 1gr/L of adsorbent.

Table 1: Analysis of zeolite clinoptilolite

PercentageComposition

61.91SiO

2

11.02Al

2

O

3

0.99Fe

2

O

3

0.17TiO

2

0.32CaO

0.79MgO

6.75Na

2

O

2.47K

2

O

0.01P

2

O

5

14.34LOIa

98.78Total

868 REMOVAL OF CADMIUM FROM INDUSTRIAL WASTE WATER BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Leila Dstan and Mohsen Dehghani

FIGURE 4. The effect of adsorbent value on

the cadmium removal ef ciency in optimal

pH4, at temperature 25ºC,cadmium optimal

concentration of 2.5 ppm in 15 minutes

and 1 gr/L concentration of adsorbent.

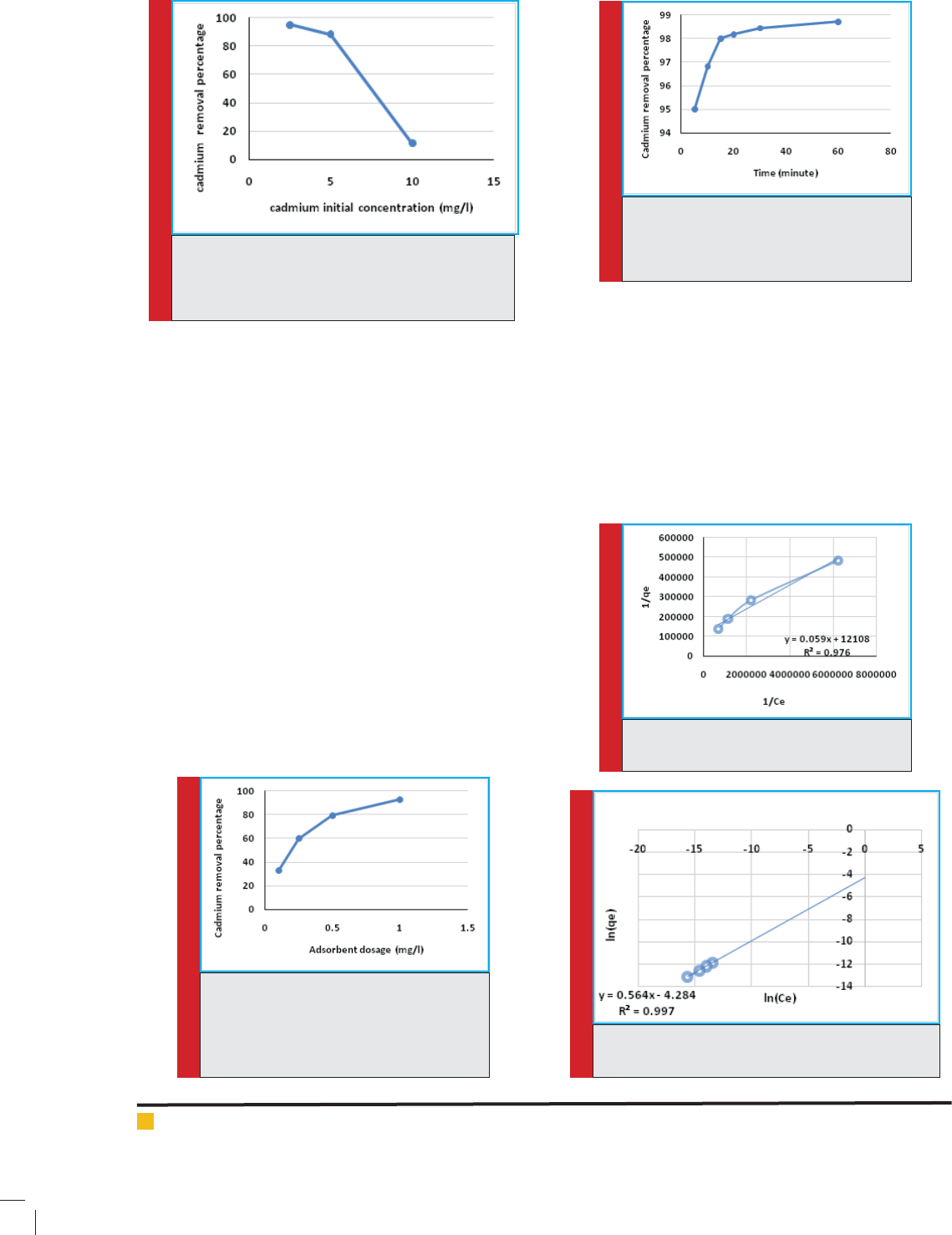

Initial concentration effect on cadmium adsorbent

In gure 3, adsorption data have been shown in differ-

ent initial concentrations of cadmium ion. As you can

see the value of adsorption is at the highest by zeolite in

concentration of 2.5 mg/l.

The effect of zeolite clinoptilolite adsorbent for the

removal of cadmium

The results showed that, by increasing of 0.1 to 1g of

adsorbent, the removal rate has increased from 32.70

to 92.77, which according to obtained result with the

weight of 1g per liter is selected as optimal weight of

adsorbent to absorb cadmium. (Figure 4).

The effect of time on the adsorption process.

Figure 5 shows the effect of time on the absorption pro-

cess. At the initial times the rate of absorption is very

high and by passing time, the removal rate has increased

and after 15 minutes of contact time, the removal rate-

will change with low slope.

Interferences effect on the process of cadmium adsorption

The comparison of removal rate of cadmium in the terms

of without interference ions and at the presence of inter-

fering ions shows that at the presence of interference

ions did not have signi cant impact on the process of

removing cadmium by using zeolite clinoptilolit. The

obtained results in this study correspond with the results

of Motsi et al(2009). So that the removal of cadmium

was 97% at the presence of while this amount for solu-

tions without interfering ions was 98.1%.

FIGURE 3. SThe effect of different concentration on

removal ef ciency inoptimal pH 4 at the tempera-

ture of 25ºC, in 15 minutes and concentration of 1

gr/L adsorbent.

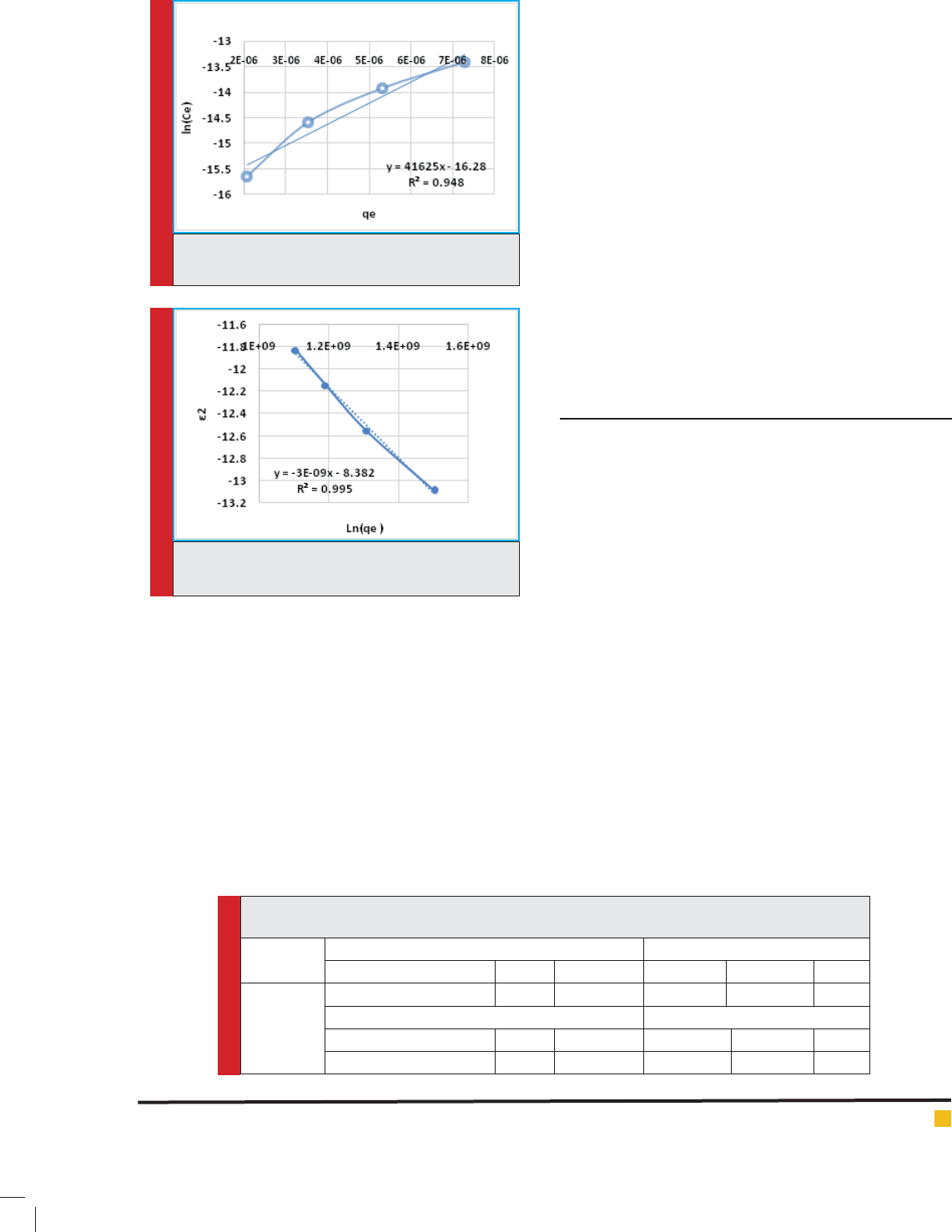

FIGURE 6. Langmuir isotherm curve for

cadmium absorption in optimal condition.

FIGURE 7. Freundlich isotherm curve for adsorption

of cadmium in optimal condition.

FIGURE 5. The effect of contact time

changes on cadmium removal ef ciency

inoptimal pH (4), the concentration of 2.5

ppm cadmium at a temperature of 25ºC.

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS REMOVAL OF CADMIUM FROM INDUSTRIAL WASTE WATER 869

Leila Dstan and Mohsen Dehghani

Table 2: The results of adsorption isotherm coef cients for the removal of cadmium from

aqueous by zeolite clinoptiolite.

LangmuirFreundlich

Adsorbent

R

2

KL (L/mg)q

max

(mg/g)R

2

NK(mg/g)(mg/l)

n

0.9764.9316.730.9981.770.013

Zeolite

TemkinDubinin–Radushkevich

R

2

KBR

2

KE(kJ/mol)

0.9495.142.270.995109×312.91

The results of adsorption isotherms for zeolite

clinoptilolite adsorbent.

The gures of 6, 7, 8, and 9 show the Langmuir, Fre-

undlich, Temkin and Dubinin–Radushkevich isotherms

for studied adsorbent respectively. According to the

obtained results, it is observed that cadmium adsorp-

tion by zeolite clinptilolite from Freundlich model with

a correlation coef cient R

2

=0.998 have better ef ciency

than other isotherm models.

In Langmuir isotherm model, the coef cients of q

max

and K

L

will be calculated respectively through the slope

and intercept of linear graph versus Ce.

In Freundlich isotherm model, we have constants of

(n) and (K

f

) that n is desirability of index in the adsorp-

tion process (densities) and K

f

is the absorption capacity

in terms of mg/g(1/mg)

1/n

. In this model, the values of n

less than 1, indicates poor absorption and the values of

1-2 and 2-10 represent optimal and average adsorption

respectively.

In Temkin isotherm model, the amount of coef cients

of B and K

t

will be determined through slope and inter-

cept linear graph q

e

versus LnC

e

respectively.

E Index is used for Radushkevich isotherm to evalu-

ate the capability of using equation. This parameter pro-

vides information related to adsorption process mecha-

nism (physical, chemical), in such a way that the values

of E between 8 and 16 kJ/mol indicate that adsorption

process has been follow a chemical mechanism and for

values less than 8 kJ/mol, the mechanism had physical

natural adsorption process (RezaeiKalantary et al., 2014).

DISCUSSION

The obtained results of initial pH effect of solution

showed that the removal ef ciency of cadmium by zeo-

lite clinoptilolite, will be affected by the solution pH. In

adsorption process, oH

-

and H

+

are two determiners ions

for surface charge. (Lu et al, 2009). Natural zeolite pref-

erably tends to absorb H

+

ions from solution in compari-

son with heavy metals ions (Inglezakis et al., 2004). So

by increasing of acidic conditions the adsorption of H

+

ions will increase from solution that includes the most

ef ciency for removing of cadmium, which its results

correspond with the results of Moreno et al. (2001). In

Low concentration of cadmium, speci c surface and the

sites ofadsorbent adsorption were more and cadmium

ions are able to react to each other with available absorp-

tion opportunities on adsorbent surface and therefore

the removal rate will increase. The removal ef ciency

of cadmium ions from solution

has reverse relation by

using of zeolite clinoptilolite with concentration more

than 2.5 mg per liter and the results correspond with the

results of Motsi et al (2009).

The study of balance time effect, showed that the

removal of cadmium in contact time of 15 minutes have

FIGURE 8. Temkin isotherm curve for cadmium

adsorptionin optimal conditions.

FIGURE 9. Dubinin–Radushkevich isotherm curve

for cadmium adsorption in optimal condition.

Leila Dstan and Mohsen Dehghani

870 REMOVAL OF CADMIUM FROM INDUSTRIAL WASTE WATER BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

maximum ef ciency by zeolite clinoptilolite. The cause

of high absorption rate in the initial moments of reac-

tion is a large number of absorption active sites (Gho-

rai 2005). These results correspond with the results of

Shawabkeh (2004).The results of adsorbent dosage effect

on the adsorption process showed that, by increas-

ing of adsorbent value, the value of cadmium absorp-

tion will be increased, that is because of increasing the

number of levels at the available of adsorbent because

of its increasing, which leads to an increasing in the

level of contact and increasing in the free bonds on

the level of adsorbent (Wajima et al., 2009; Ramdani

et al., 2010).These obtained results correspond with the

results of Shawabkeh, 2004 and Shamohammadi et al.,

2008).

Rate and value of adsorption is subject to charge

and mass of adsorbent. At all multipartite soluble con-

centrations, the amount of total absorb heavy metals

ions increased in per unit mass of natural zeolite in

comparison with the amount of absorbed article from

partial solutions. This shows that the difference in the

mechanism of surface absorption may include surface

absorption per action. The obtained results correspond

with Motsi et al (2009).In Freundlich model has been

supposed that the adsorbed exit on heterogeneous sur-

faces will be occurred by adsorption on multi layers.

By performed calculation it showsthat the value of R

2

is equal to 0.998 and n is equal to 1.77 and it indicates

that this adsorption is optimal and the reaction follows

from Freundlich equation. Also in this study, based on

Radushkevich model E is equal to 12 kJ/mol (between

8 and 16 kJ/mol). So adsorption process is a chemical

reaction. In a study that carried out by Motsi et al on

the removal of Mn

2

by natural zeolite, also the obtained

results by Wanga and Peng (2010) as well as the results

of Mishra and Patel (2009) on the modi ed zeolite in

aqueous environment, this process follows Freundlich

model that corresponds with the results of the removal

of cadmium zeolite clinoptilolite.

CONCLUSION

The results of this study shows that natural zeolite for

removal of cadmium from industrial waste water under

optimal conditions (times of 15 minutes, pH=4, adsor-

bent dosage of 1 g per liter and concentration of 2.5

ppm cadmium) has very good ef ciency. The bene ts of

this natural, low cost, mineral article, is easy access to

it. Moreover this absorbent is more advantageous than

common absorbents such as activated carbon or opera-

tional procedures such as electro dialysis and exists in

the numerous mines in Iran, including Semnan, Kerman

and Azarbaijan.

REFERENCES

Cecille, L., Toussaint, J. (1989) Future Industrial Prospects of

Membrane Processes. Springer Netherlands.

Alvarez-Ayuso, E., Garcia-Sanchez, A., Querol, X., (2003) Puri-

cation of metal electroplating waste waters using zeolites.

Water Res. 37, 4855–4862.

Babel. S, Kurniawan. T.A, (2003), Low-cost adsorbent for heavy

metals uptakefrom contaminated water: a review, J. Hazard.

Mater. B97. 219–243.

Crittenden, J. Trussell, R. Hand, D. Howe, K, Tchobanoglous,

G. (2012) Water Treatment: Principles and Design. New York:

John Wiley and Sons.

Erdem, E., Karapinar, N., Donat, R. (2004). The removal of

heavy metal cations by natural zeolite. J. Colloid Interface Sci.

280, 309–314.

Ghorai S, Pant KK (2005) Equilibrium, kinetics and break-

through studies for adsorption of uoride on activated alu-

mina. Separation and puri cation technology 42 (3), 265-271

Inglezakis V.J. and Grigoropoulou H.P. (2004) Effects of oper-

ating conditions on the removal of heavy metals by zeolite in

xed bed reactors, J. Hazard. Mater., B112 37–43.

Lu J, Li Y, Yan X, Shi B, Wang D, Tang H (2009) Sorption of

atrazine onto humic acids (HAs) coated nanoparticles. Colloids

Surf A Physicochem Eng Asp 347:90–96.

Moreno N, Querol X., Ayora C., Pereira C.F.(2001) Utiliza-

tion of zeolites synthesized from coal y ash for the puri -

cation of acid mine waters. Environ Sci Technol. 2001 Sep

1;35(17):3526-34.

Motsi, T., Rowson, N.A. and Simmons, M.J.H. (2009) Adsorp-

tion of Heavy Metals from Acid Mine Drainage by Natural

Zeolite. International Journal of Mineral Processing, 92, 42-48.

Naghizadeh, A. Nasseri, S. Nazmara, Sh.(2011) Removal of

Trichloroethylene from Water by adsorption on to Multiwall

Carbon Nanotubes, Iran. J. Environ. Health. Sci. Eng., vol. 8,

No. 4, pp. 317-324.

Papaioannou D., Katsoulos P.D., Panousis N. and Karatzias H.

(2005). The role of natural and synthetic zeolites as feed addi-

tives on the prevention and / or the treatment of certain farm

animal diseases: a review. Micropor. Mesopor. Mat. 84, 161-

170.

Ramdani A, Taleb S, Benghalem A, Ghaffour N.(2010) Removal

of excess uoride ions from Saharan brackish water by adsorp-

tion on natural materials. Desalination 250 (1), 408-413.

Wajima T, Umeta Y, Narita S, Sugawara K.(2009) Adsorption

behaviour of uoride ions using a titanium hydroxide-derived

adsorbent. Desalination; 249:323–30.

Buerge-Weirich D., Hari R., Xue H., Behra P.(2002) Adsorp-

tion of Cu, Cd, and Ni on goethite in the presence of natural

groundwater ligands Environ Sci Technol.1;36(3):328-36.

Shamohammadi, Z., Moazed H., Jaafarzadeh, N., and Haghighat

Jou, P. (2008). Removal of low concentrations of cadmium

from water using improved rice husk. Journal of Water and

Wastewater, Vol. 19 No.3 (67), 27-33.

Leila Dstan and Mohsen Dehghani

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS REMOVAL OF CADMIUM FROM INDUSTRIAL WASTE WATER 871

Shawabkeh. R.A (2004) Synthesis and characteriza-

tion of activated carbo-aluminosilicate material from oil

shale. Microporous and Mesoporous Materials 75(1):107-

114·

Rezaei Kalantary R, JonidiJafari A., Kakavandi B., Nasseri S.,

Ameri A., Azari A (2014) Adsorption and Magnetic Separation

of Lead from Synthetic Wastewater Using Carbon/Iron Oxide

Nanoparticles Composite. J Mazandaran Univ Med Sci 24(113):

172-183.

Rosales, E., Pazos M., Sanromán, M. A., & Tavares, T. (2012).

Application of zeolite-Arthro bacter viscosus system for the

removal of heavy metal and dye: Chromium and Azure B.

Desalination, 284, 150–156.

Mishra P.C., Patel R.K.(2009) Removal of lead and zinc ions

from water by low cost adsorbents, J. Hazard. Mater. 168

(2009) 319–325.

Wanga S., Peng Y. (2010) Natural zeolites as effective adsor-

bents in water and wastewater treatment, Chemical Engineer-

ing Journal. 156 11–24.

Wu D., Sui Y., He S., Wang, Li C., Kong H.(2008) Removal of

trivalent chromium from aqueous solution by zeolite synthe-

sized from coal y ash, J. X. Hazard. Mater. 155 415–423.