Synthesis of 4, 4’-(1, 3 and 1, 4-phenylene) bis

(6-methyl-2-oxo-1,2,3,4-tetrahydropyrimidine-5-

carboxylate) via a one- pot three-component reaction

of Urea with dialdehydes and acetoacetates in the

presence of hydrochloric acid and heteropolyacid

Haniyeh Mahmoudi Esgandani, Mina Roshani, Ehsan Akhondi Ranjbar and

Mohammad Shaker*

Department of Chemistry, Mashhad Branch, Islamic Azad University, Mashhad, PO Box 91735-413, Iran

ABSTRACT

A simple and ef cient synthesis of 4, 4’-(1, 3 and 1, 4-phenylene) bis (6-methyl-2-oxo-1,2,3,4-tetrahydropyrimidine-

5-carboxylate) via a one- pot three-component reaction of Urea with dialdehydes and acetoacetates in the presence

of hydrochloric acid and heteropolyacid is described. All synthesized compounds were characterized on the basis of

their spectral and microanalytical data. In the rst stage we report a convenient synthesis of new 4, 4’-(phenylene)

bis tetrahydropyrimidines 4a-4f by a one-pot three-component reaction of Urea 1, dialdehydes 2a-4b, and acetoac-

etates 3a-3c in re uxing hydrochloric acid. And then, in the second stage, we used heteropolyacids in this reaction.

We report reaction conditions (solvent, temperature, reaction time, catalyst type, and concentration) were studied to

optimize in this procedure. Melting points were recorded on a Stuart SMP3 melting point apparatus. The IR spectra

were obtained using a Bruker Tensor 27 spectrophotometer using KBr discs. The

1

H NMR (300 MHz) was recorded

with Bruker-300 MHz spectrometers. The

13

C-NMR was recorded with Bruker-300 MHz spectrometers at 75 MHz

frequencies. The mass spectra were scanned on an Agilent Technologies instrument at 70 eV. Elemental analysis was

performed on a Thermo Finnigan Flash EA microanalyzer.

KEY WORDS: BIS (1, 2, 3, 4-TETRAHYDROPYRIMIDINE-5-CARBOXYLATE), HETEROPOLYACID, UREA, ACETOACETATES, DIALDEHYDES,

BIGINELLI REACTION

112

ARTICLE INFORMATION:

*Corresponding Author: mshaker985@gmail.com

Received 31

st

Dec, 2016

Accepted after revision 29

th

March, 2017

BBRC Print ISSN: 0974-6455

Online ISSN: 2321-4007

Thomson Reuters ISI ESC and Crossref Indexed Journal

NAAS Journal Score 2017: 4.31 Cosmos IF : 4.006

© A Society of Science and Nature Publication, 2017. All rights

reserved.

Online Contents Available at: http//www.bbrc.in/

Biosci. Biotech. Res. Comm. Special Issue No 1:112-117 (2017)

Haniyeh et al.

INTRODUTION

3,4-Dihydropyrimidin-2-(1H)-ones (DHPMs) and their

derivatives gained considerable interest from the rst

reported in 1891 until today both in academia and

industry because of their important and promising

therapeutic and pharmacological properties (Biginelli

et al. 1891). For instance, they have emerged as integral

backbones of several channel blockers, antihypertensive

agent -1antagonists, neuropeptide Y (NPY) antagonists

and anticancer activities (Singh et al. 2009; Russowsky

et al. 2006; Kumar et al. 2009; Da Silva et al. 2012).

The classical Biginelli reaction involves the strong

acid-catalyzed cyclocondensation reaction of ethyl ace-

toacetate, benzaldehyde and urea in ethanol at re ux

temperature for long reaction time. Furthermore, this

one-pot three-component procedure often provides with

relatively low yields of the dihydropyrimidine deriva-

tives. In order to improve the ef ency and synthetic pro-

cedure of the classical one-pot Biginelli reaction, using

different types of catalysts and conditions have been

reported by different research groups. The most of these

procedures are all similar, using different acid catalyst

such as BF

3

.OEt

2

(Hu et al. 1998), FeCl

3

.6H

2

O (Xu et al.

2004), MgCl

2

.6H

2

O (Zhang et al. 2004), MgBr

2

(Gulten,

2013; Salehi, 2004), BiCl

3

(Ramalinga et al. 2001), InCl

3

(Ranu et al. 2000), ZnO nano particles (Hassanpour et al.

2015), zeolites (Radha et al. 2001), LaCl

3

.7H

2

O (Lu et al.

2000), LiClO

4

(Yadav et al. 2001), Mn(OAc)

3

.2H

2

O (Kumar

et al. 2001), NiCl

2

.6H

2

O (Lu, 2010), and so on, in solvent

such as CH

3

CN, CH

2

Cl

2

, THF, EtOH or H

2

O. In addition

procedures employing ultrasound, microwave (Kappe,

1999), solid and uorous (Studer et al. 1997) phase syn-

theses have reported.

A number of procedures under solvent free conditions

using different acid catalyst have also been reported

(Zhang et al. 2015). However, despite their potential

utility some these procedures use expensive catalysts,

strong acidic conditions, higher temperatures, stoicho-

metric amounts of catalyst, toxic reagents, large amount

of solvents, unsatisfactory yields, inconvenient pruri -

cation techniques, incompatibility with other functional

groups and require longer reaction times are not all

acceptable in the context of green synthesis.

On the other hand, Polyoxometalates (POMs) are a

large class of metal oxide cluster compounds consist-

ing of transi-tion metal atoms bridged by oxygen atoms.

POMs can exist in a variety of different size and struc-

ture, and compounds belonging to this class have been

studied extensively because they possess interesting

electronic and molecular properties, such as wide-rang-

ing reduction potentials, acidities, and polarities. Based

on their attractive properties, POMs have also been used

in a variety of different application, including catalysis,

biomedicine, magnetism, nanotechnology, and materi-

als science (Müller et al. 1998; Pope and Müller, 2001;

Davoodnia et al. 2013; Coronado et al. 1998; Okuhara

et al. 1996). The development of methods using heter-

opolyacids (HPAs) as Catalyst for the synthesis of ne

chemicals, such as avors, pharmaceuticals, and in

food industries, has gained attention in the last decade

(Chwegler et al. 1991).

Catalysts based on heteropolyacids have many advan-

tages over liquid-acid catalysts. They are not corrosive

and are environmentally benign and present fewer dis-

posal problems.

Solid heteropolyacids have attracted much attention

organic synthesis owing to easy work-up procedures,

easy ltration, and reduction of cost and waste genera-

tion through reuse and recycling of the catalysts.

MATERIAL AND METHODS

In spite of much work on the synthesis of substituted

tetrahydropyrimidines, to the best of our knowledge,

the synthesis of 4, 4’-(1, 3 and 1, 4-phenylene) bis

(6-methyl-2-oxo-1, 2, 3, 4-tetrahydropyrimidine-5-car-

boxylate) has not been reported in the literature. In this

paper, in the rst stage we report a convenient synthe-

sis of new 4, 4’-(phenylene) bis tetrahydropyrimidines

4a-4f by a one-pot three-component reaction of Urea 1,

dialdehydes 2a-4b, and acetoacetates 3a-3c in re ux-

ing hydrochloric acid. And then, in the second stage, we

used heteropolyacids in this reaction. We report reaction

conditions (solvent, temperature, reaction time, catalyst

type, and concentration) were studied to optimize in this

procedure (Scheme 1).

RESULTS AND DISCUSSION

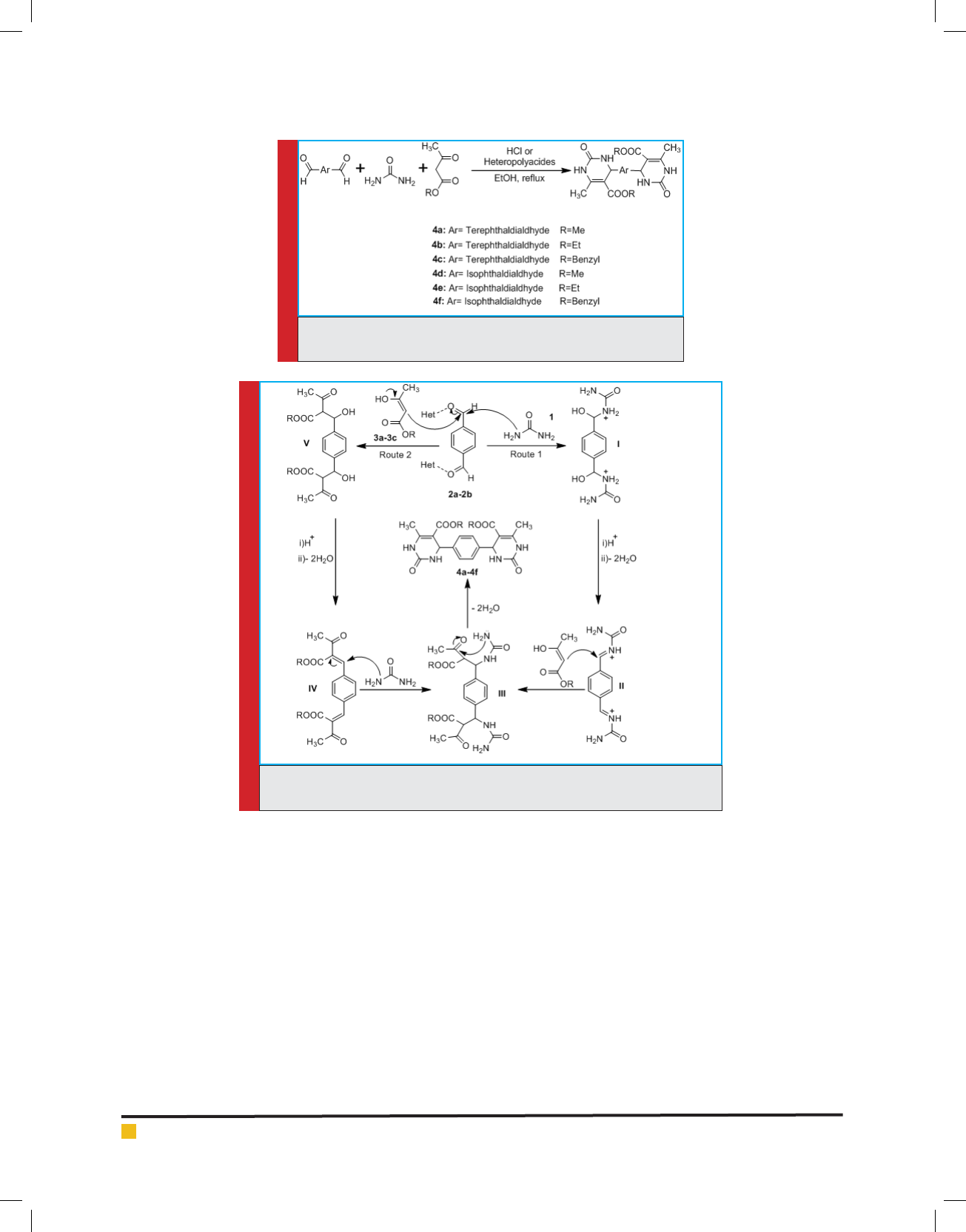

Although we did not investigate the reaction mechanism,

two plausible mechanisms for this three-component

reaction as have been depicted in Scheme 2. For exam-

ple in route 1, it is proposed that the reaction occurs

via initial formation of the intermediate I as a result

of a nucleophilic attack of Urea at the carbonyl group

of dialdehydes. Dehydration of the intermediate I fol-

lows the intermediate II. Reaction of acetoacetates with

this intermediate then gives the intermediate III which

after cyclization followed by dehydration afforded nal

products 4a-4f. As shown in Scheme 2, we propose that

Hydrochloric acid and Heteropolyacid Het activate the

reactants and the intermediates in this reaction.

A one-pot three-component reaction of Urea 1, an

dialdehydes 2a-2b and acetoacetates 3a-3c in the pres-

ence of hydrochloric acid under re ux for 4h leads to

the facile formation of 4, 4’-(1, 3 and 1, 4-phenylene)

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS SYNTHESIS OF 4, 4’-(1, 3 AND 1, 4-PHENYLENE) BIS 113

Haniyeh et al.

bis (6-methyl-2-oxo-1, 2, 3, 4-tetrahydropyrimidine-

5-carboxylate) 4a-4f in 80-90% yields (Table 1).

The structures of the products were deduced from

their spectral and microanalytical data. For example, the

1

H NMR spectrum of compound 4a which this is a sym-

metrical produce, exhibited one sharp signal at 2.250

and 3.541ppm for methyl groups, 5.109ppm for CH

groups, 7.736 and 9.231ppm for NH groups, as well

as the signals in the aromatic region, 7.189 ppm, due

to 4 aromatic protons indicating the formation of the

compound 4a. The IR spectrum of 4a showed strong

absorptions at 3430 cm

-1

for NH absorption, 3028 and

2943 cm

-1

due to the aromatic and aliphatic protons, two

strong absorptions in 1697 and 1661 cm

-1

for stretching

C=O in the pyrimidine ring, two strong absorptions as

doublet in 1433 and 1385 cm

-1

for stretching C=C in

rings and a medium absorption in 1238 cm

-1

for C-N

respectively.

The MS (APCI) of 4a showed a peak at m/z 414.1([M]

+

)

corresponding to the molecular formula C

20

H

22

N

4

O

6

. This

product gave also satisfactory proton decoupled

13

C

NMR data in 18.30, 51.32, 53.99, 99.40, 129.78, 144.25,

149.15, 152.62, 166.28 ppm.

In the second stage, we studied the ef ciency using

two heteropolyacids contain Keggin-type H

3

[PMo

12

O

40

]

and preyssler H

14

[NaP

5

W

30

O

110

]. The results are reported

in Table1 with the order of ef ciency as follows:

H

3

[PMo

12

O

40

]> H

14

[NaP

5

W

30

O

110

].

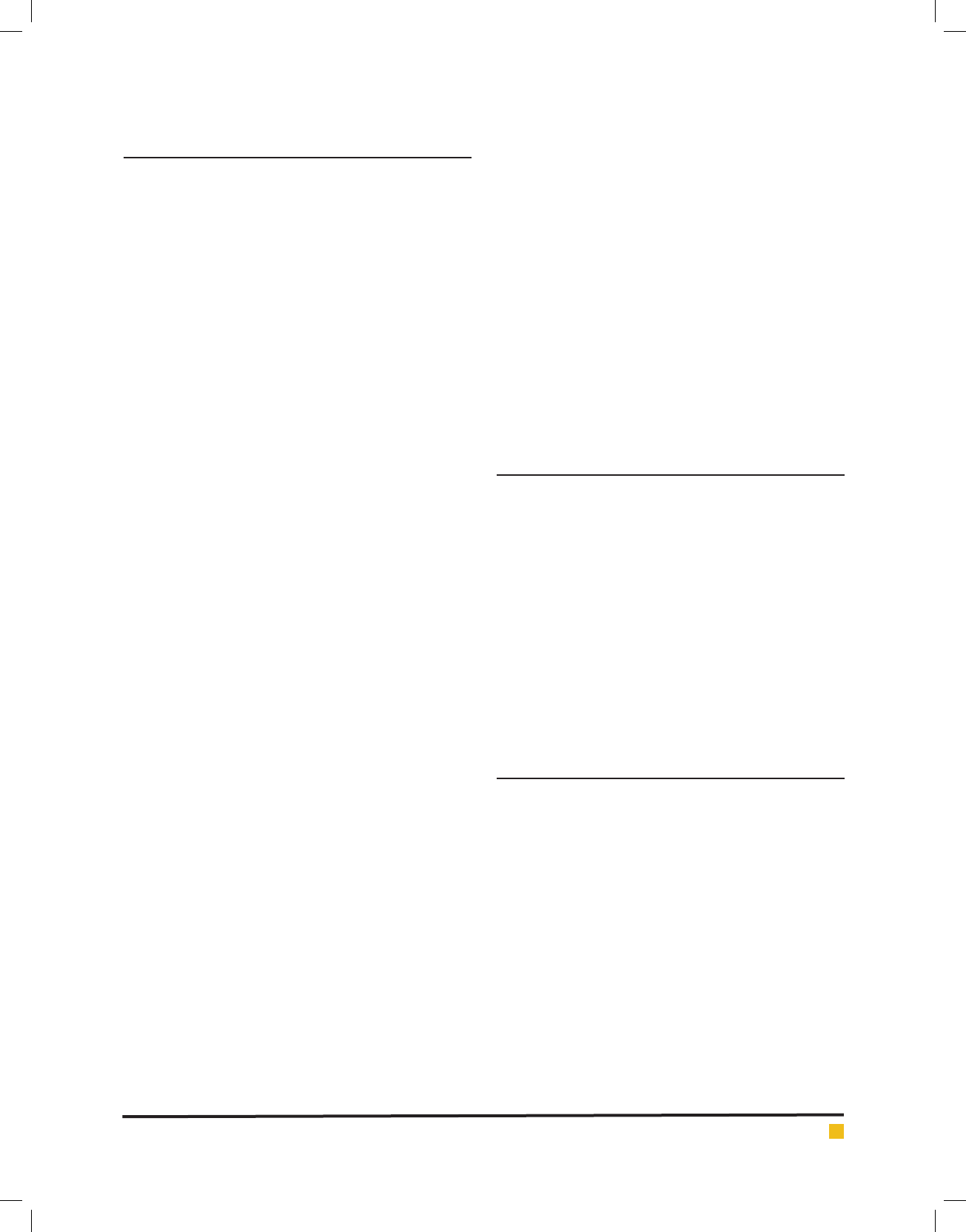

SCHEME 1. Synthesis of some 4,4’-(phenylene)bis tetrahydropyri-

midines in HCI=Het

SCHEME 2. Plausible mechanism for the formation of some 4,4’-(phenylene)bis

tetrahydropyrimidines in HCI=Het

114 SYNTHESIS OF 4, 4’-(1, 3 AND 1, 4-PHENYLENE) BIS BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Haniyeh et al.

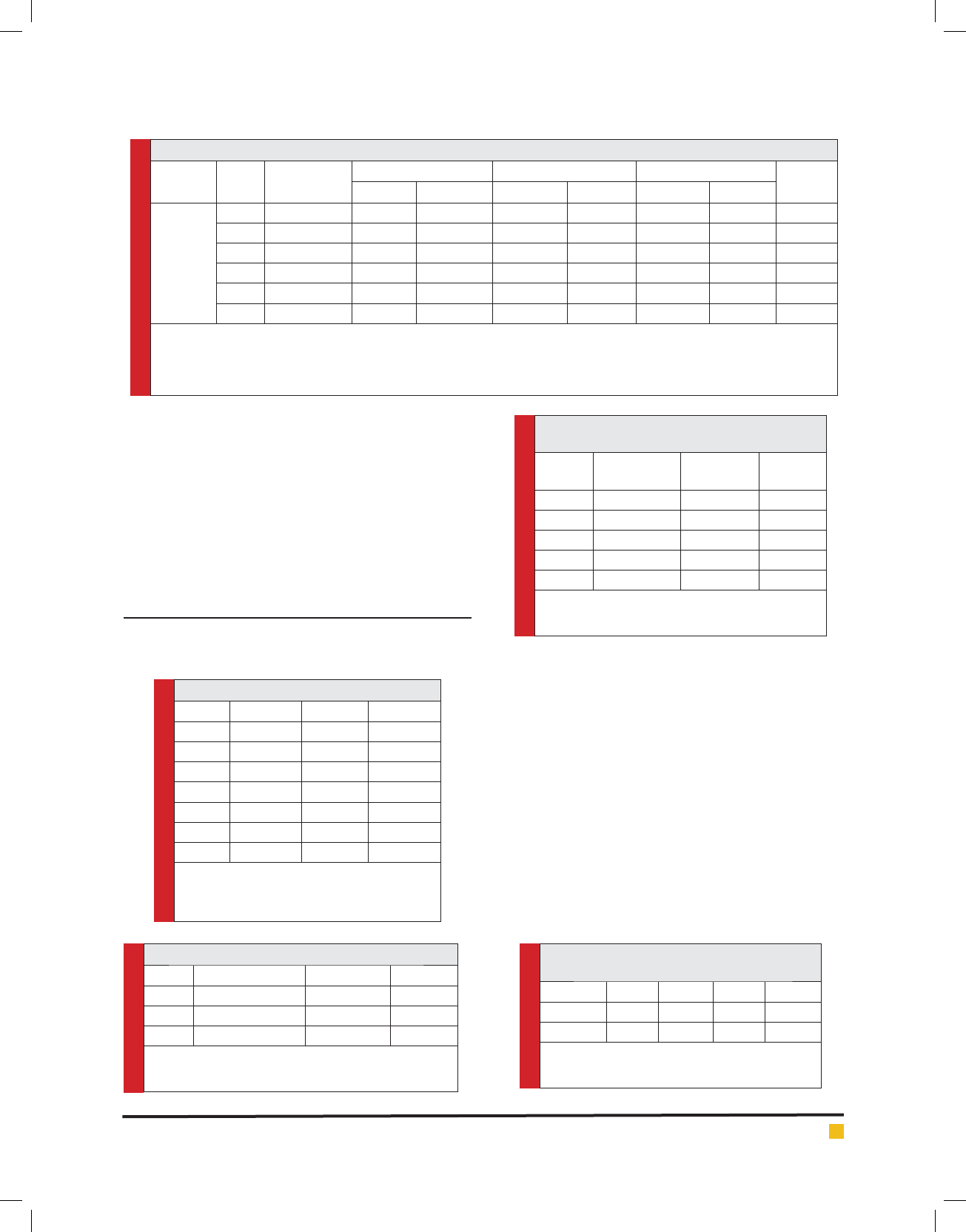

Table1. Synthesis of some new 4, 4’-(phenylene) bis tetrahydropyrimidines 4a-4f

Product

c

RAr

HCl

a

H

3

[PMo

12

O

40

]

b

H

14

[NaP

5

W

30

O

110

]

b

M.P. (ºC)

Time(hr) Yield (%)

d

Time(min) Yield (%) Time(min) Yield (%)

4a Me 1,4-phenylene 4 84 30 86 60 84 315 dec.

4b Et 1,4-phenylene 4 87 30 90 60 86 310 dec.

4c PhCH

2

1,4-phenylene 5 90 30 92 60 88 294-296

4d Me 1,3-phenylene 6 85 30 88 60 80 279-281

4e Et 1,3-phenylene 4 80 30 85 60 84 289-291

4f PhCH

2

1,3-phenylene 5 85 30 85 60 82 300 dec.

a

Reaction conditions : Urea 1 (2 mmol), a dialdhyde 2a-2b (1 mmol), an acetoacetate 3a-3c (2 mmol), Ethanol (6 ml), Hydrochloric acid (4-5 drops), re ux.

b

Reaction conditions : Urea 1 (2 mmol), a dialdhyde 2a-2b (1 mmol), an acetoacetate 3a-3c (2 mmol), Ethanol (6 ml), Hydrochloric acid (4-5 drops),

H

3

[PMo

12

O

40

] or H

14

[NaP

5

W

30

O

110

] (0.1gr), temperature room.

c

All the products were characterized according to their spectral and microanalytical data.

d

Isolated yields.

Table 2. Effect of Solvent on the yields of 4a

a

Entry Solvent Time(hr) Yield (%)

1H

2

O3 38

2 DMSO 3 32

3 DMF 3 35

4C

6

H

5

CH

3

3 Trace

5CH

2

Cl

2

3 Trace

6 CHCl

3

3 Trace

7 EtOH 30(min) 86

a

Reaction conditions : Urea 1 (2 mmol),

Terephthaldialdhyde 2a (1 mmol), methyl acetoacetate

3a (2 mmol), solvent (6 ml), H

3

[PMo

12

O

40

] (0.1gr),

Hydrochloric acid (4-5 drops), temperature room.

Table 3. Effect of temperature on the yields of 4a

a

Entry Temperature (ºC) Product (gr) Yield (%)

1 Room 0.356 86

2 50 0.228 55

3 110 0.141 34

a

Reaction conditions : Urea 1 (2 mmol), Terephthaldialdhyde 2a (1

mmol), methyl acetoacetate 3a (2 mmol), solvent (6 ml), H

3

[PMo

12

O

40

]

(0.1gr), Hydrochloric acid (4-5 drops).

Table 4. Effect of the amounts of Keggin

H

3

[PMo

12

O

40

] on the yields of 4a

a

Entry amounts of

Keggin(gr)

Time (min) Yield (%)

1 0.05 30 28

2 0.07 30 68

3 0.10 30 86

4 0.12 30 63

5 0.15 30 52

a

Reaction conditions : Urea 1 (2 mmol), Terephthaldialdhyde

2a (1 mmol), methyl acetoacetate 3a (2 mmol), solvent (6 ml),

Hydrochloric acid (4-5 drops), temperature room.

Table 5. Synthesis of 4a with recycled Keggin

H

3

[PMo

12

O

40

]

a

.

1

st

run 2

nd

run 3

rd

run 4

th

run

Time (min) 30 30 40 50

Yield (%) 86 78 76 70

a

Reaction conditions : Urea 1 (2 mmol), Terephthaldialdhyde

2a (1 mmol), methylacetoacetate 3a (2 mmol), solvent (6 ml),

H

3

[PMo

12

O

40

] (0.1gr), Hydrochloric acid (4-5 drops).

The effect of varying the reaction duration was stud-

ied for the synthesis of 4a by reaction of Urea 1, Tere-

phaldialdhyde 2a, and methyl acetoacetate 3a.

The effect of solvent on the synthesis of 4a was stud-

ied on solvents including C

6

H

5

CH

3

, DMF, DMSO, H

2

O,

CH

2

Cl

2

, CHCl

3

, and EtOH. Ethanol proved to be the best

in terms of yield (Table 2).

The effects of temperature, and the amounts of heter-

opolyacid, had showed respectively Tables 3 and 4.

CONCLUSION

Melting points were recorded on a Stuart SMP3 melt-

ing point apparatus. The IR spectra were obtained using

a Bruker Tensor 27 spectrophotometer using KBr discs.

The

1

H NMR (300 MHz) was recorded with Bruker-300

MHz spectrometers. The

13

C-NMR was recorded with

Bruker-300 MHz spectrometers at 75 MHz frequencies.

The mass spectra were scanned on an Agilent Technolo-

gies instrument at 70 eV. Elemental analysis was per-

formed on a Thermo Finnigan Flash EA microanalyzer.

Synthesis of bis-1, 2, 3, 4-tetrahydropyrimidines

4a-4f; (general procedure). A mixture of urea 1 (2

mmol), an aldehyde 2a-2b (1 mmol), -ketoester 3a-3c

(2 mmol) and conc. HCl (4-6 drops) in EtOH (6mL) was

heated under re ux for 4-6 hours. After the completion

of the reaction, the solvent was evaporated in vacuo.

The crude product was collected and re-crystallized from

ethanol to give compounds 4a-4f in 80-90% yields.

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS SYNTHESIS OF 4, 4’-(1, 3 AND 1, 4-PHENYLENE) BIS 115

Haniyeh et al.

Synthesis of bis-1, 2, 3, 4-tetrahydropyrimidines

4a-4f in presence of heteropolyacids; (general proce-

dure). To a mixture of urea 1 (2 mmol), a dialdehyde

2a-2b (1 mmol), and -ketoester 3a-3c (2 mmol), a

catalytic amount of heteropolyacid (0.1 gr) was added

and the resulting mixture was stired in solvent (6 mL).

The progress of the reaction was monitored by TLC. On

completion, the catalyst was ltered off, the solvent was

evaporated and the pure product was collected and re-

crystallized from ethanol to give compounds 4a-4f in

85-92 % yields.

Dimethyl 4, 4’-(1, 4-phenylene) bis (6-methyl-2-

oxo-1, 2, 3, 4-tetrahydropyrimidine-5-carboxylate)

(4a). Yield 84-86%, yellow powder, mp 315ºC >decom-

posed, IR spectrum, , cm

-1

: 3430(N-H), 3028 (arom-

CH), 2943 (aliph-CH), 1697(C=O), 1661(C=O), 1433 and

1385 (C=C), 1238(C-N), 1094(C-O).

1

H NMR spectrum

(DMSO-d

6

), , ppm (J, Hz): 2.250(s, 6H, -CH

3

); 3.541(s,

6H, -CH

3

); 5.109(s, 2H, -CH); 7.189(s, 4H, C

6

H

4

); 7.736(s,

2H, N-H exchange with D

2

O), 9.231(s, 2H, N-H exchange

with D

2

O).

13

C NMR (DMSO-d

6

), , ppm: 18.30(CH

3

),

51.32(CH

3

), 53.99(CH), 99.40(C), 126.78(Ar), 144.25(Ar),

149.15(C), 152.62(C=O), 166.28(C=O). Mass spectrum (EI,

70 eV), m/z (I

rel

, %): 414.1[M]

+

(10), 413.1[M-H]

+

(15),

375.1(40), 311.1(20), 260.1(20), 182.9(20), 131.0(25),

97.1(45), 71.0(43), 43.1(100). Elemental Analysis: Found,

%: C 55.43; H 5.21; N 12.89; C

20

H

22

N

4

O

6

. Calculated, %:

C 57.97; H 5.35; N 13.52.

Diethyl 4, 4’-(1, 4-phenylene) bis(6-methyl-2-

oxo-1, 2, 3, 4-tetrahydropyrimidine-5-carboxylate)

(4b). Yield 86-90% , white powder, mp 310ºC decom-

posed, IR spectrum, , cm

-1

: 3308(N-H), 3019 (arom-

CH), 2931 (aliph-CH), 1703(C=O), 1660(C=O), 1453 and

1372 (C=C), 1235(C-N), 1085(C-O).

1

H NMR spectrum

(DMSO-d

6

), , ppm (J, Hz): 1.067-1.128(t, 6H, CH

3

);

2.242(s, 6H, -CH

3

); 3.949-4.018(q, 4H, -CH

2

);5.115(s, 2H,

-CH); 7.190(s, 4H, C

6

H

4

); 7.704(s, 2H,N-H exchange with

D2O), 9.197(s, 2H, N-H exchange with D

2

O).

13

C NMR

(DMSO-d

6

), , ppm: 14.53(CH

3

), 22.88(CH

3

), 54.06(CH),

59.69(CH

2

), 99.69(C), 126.78(Ar), 144.40(Ar), 148.76(C),

152.53(C=O), 165.77(C=O). Mass spectrum (EI, 70 eV),

m/z (I

rel

, %): 442.3[M]

+

(15), 441.2[M-H]

+

(22). Elemen-

tal Analysis: Found, %: C 58.46; H 5.68; N 12.07;

C

22

H

26

N

4

O

6

. Calculated, %: C 59.72; H 5.92; N 12.66.

Dibenzyl 4, 4’-(1, 4-phenylene)bis(6-methyl-2-

oxo-1, 2, 3, 4-tetrahydropyrimidine-5-carboxylate)

(4c). Yield 88- 92%, white powder, mp 294-296 ºC, IR

spectrum, , cm

-1

: 3356(N-H), 3107 (arom-CH), 2958

(aliph-CH), 1693(C=O), 1641(C=O), 1453 and 1380

(C=C), 1223(C-N), 1090(C-O).

1

H NMR spectrum (DMSO-

d

6

), , ppm (J, Hz): 2.281(s, 6H, -CH

3

); 5.028(s, 2H, -CH);

5.148(s, 4H, -CH

2

); 7.127-7.331(m, 14H, C

6

H

4

and C

6

H

5

);

7.754(s, 2H, N-H exchange with D

2

O), 9.301(s, 2H,

N-H exchange with D

2

O).

13

C NMR (DMSO-d

6

), , ppm:

18.36(CH

3

), 54.09(CH), 65.31(CH

2

), 99.21(C), 126.85(Ar),

128.06(Ar), 128.20(Ar), 128.76(Ar), 128.78(Ar), 136.96

(Ar), 144.28(Ar), 149.74(C), 152.53(C=O), 165.52 (C=O).

Mass spectrum (EI, 70 eV), m/z (I

rel

, %): 566.3[M]

+

(5),

259.0(20), 183.0(18), 90.9(100), 44.0(95). Elemental

Analysis: Found, %: C 66.34; H 5.04; N 9.13; C

32

H

30

N

4

O

6

.

Calculated, %: C67.83; H5.34; N 9.89.

Dimethyl 4, 4’-(1,3-phenylene)bis(6-methyl-2-

oxo-1, 2, 3, 4-tetrahydropyrimidine-5-carboxylate)

(4d). Yield 80-88%, white powder, mp 279-281 ºC, IR

spectrum, , cm

-1

: 3408(N-H), 3031 (arom-CH), 2950

(aliph-CH), 1696(C=O), 1646(C=O), 1436 and 1318 (C=C),

1233(C-N), 1092(C-O).

1

H NMR spectrum (DMSO-d

6

),

, ppm (J, Hz): 2.249(s, 6H, -CH

3

); 3.550(s, 6H, -CH3);

5.124(s, 2H, -CH); 7.142-7.169(m, 3H, C

6

H

4

); 7.280-

7.332(m, 1H, C

6

H

4

); 7.769(s, 2H,N-H exchange with

D

2

O), 9.249(s, 2H, N-H exchange with D2O).

13

C NMR

(DMSO-d

6

), , ppm: 18.24(CH

3

), 51.19(CH

3

), 54.29(CH),

99.56(C), 124.43(Ar), 125.63(Ar), 129.04(Ar), 145.51(Ar),

149.01(C), 152.65(C=O), 166.18(C=O). Mass spectrum (EI,

70 eV), m/z (I

rel

, %): 414.2[M]

+

(4), 169.0(100), 137.0(50),

42.1(40). Elemental Analysis: Found, %: C 57.24; H

5.12; N 12.98; C

20

H

22

N

4

O

6

. Calculated, %: C 57.97; H5.35;

N 13.52.

Diethyl 4, 4’-(1, 3-phenylene)bis(6-methyl-2-

oxo-1, 2, 3, 4-tetrahydropyrimidine-5-carboxy-

late) (4e). Yield 80-85%, yellow powder, mp 289-291

ºC, IR spectrum, , cm

-1

: 3360(N-H), 3118 (arom-CH),

2978 (aliph-CH), 1699(C=O), 1649(C=O), 1461 and

1385 (C=C), 1225(C-N), 1093(C-O).

1

H NMR spectrum

(DMSO-d

6

), , ppm (J, Hz): 1.048-1.095(t, 6H, -CH

3

);

2.227(s, 6H, -CH

3

); 3.913-3.998(q, 4H, -CH

2

); 5.101(s,

2H, CH); 7.118-7.138(m, 3H, C

6

H

4

); 7.256-7.309(m, 1H,

C

6

H

4

); 7.761(s, 2H,N-H exchange with D

2

O), 9.182(s,

2H, N-H exchange with D

2

O).

13

C NMR (DMSO-d

6

), ,

ppm: 14.55(CH

3

), 18.18(CH

3

), 54.41(CH), 59.60(CH2),

99.70(C), 124.55(Ar), 125.78(Ar), 128.93(Ar), 145.53(Ar),

148.80(C), 152.52(C=O), 165.69(C=O). Mass spectrum

(EI, 70 eV), m/z (I

rel

, %): 442.1[M]

+

(6), 441.0[M-H]+(20).

Elemental Analysis: Found, %: C 58.91; H 5.38; N 11.96;

C

22

H

26

N

4

O

6

. Calculated, %: C 59.72; H 5.92; N 12.66.

Dibenzyl 4, 4’-(1, 3-phenylene)bis(6-methyl-2-

oxo-1, 2, 3, 4-tetrahydropyrimidine-5-carboxylate)

(4f). Yield 82-85%, white powder, mp 300ºC decom-

posed, IR spectrum, , cm

-1

: 3369(N-H), 3048 (arom-

CH), 2933 (aliph-CH), 1697(C=O), 1644(C=O), 1451 and

1382 (C=C), 1227(C-N), 1084(C-O).

1

H NMR spectrum

(DMSO-d

6

), , ppm (J, Hz): 2.260(s, 6H, -CH

3

); 4.990(s,

2H, CH); 5.179 (s, 4H, -CH

2

); 7.153-7.276(m, 3H, C

6

H

4

);

7.454(m, 1H, C

6

H

4

); 7.835(s, 2H,N-H exchange with

D

2

O), 9.310(s, 2H, N-H exchange with D

2

O).

13

C NMR

(DMSO-d

6

), , ppm: 18.32(CH

3

), 54.26(CH), 65.23(CH

2

),

99.30(C), 124.61(Ar), 125.79(Ar), 128.79(Ar), 129.57(Ar),

137.03(Ar), 145.39(Ar), 148.83(Ar), 149.75(C), 152.55

116 SYNTHESIS OF 4, 4’-(1, 3 AND 1, 4-PHENYLENE) BIS BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Haniyeh et al.

(C=O), 165.49(C=O). Mass spectrum (EI, 70 eV), m/z (I

rel

,

%): 565.9[M]

+

(3), 565.0[M-H]+(20), 220.9(15), 137.0(10),

97.1(65), 91.1(100), 43.6(85) . Elemental Analysis:

Found, %: C 64.82; H 5.11; N 9.06; C

32

H

30

N

4

O

6

. Calcu-

lated, %: C 67.83; H 5.34; N 9.89.

REFERENCES

Biginelli, P. Ber. Dtsch. Chem. Ges. (1891): 24, 1317. Chwegler,

M. A.; Bekkum, H.; Van Munck, N. (1991): Appl Catal, 74, 191.

Coronado, E.; Gomez-Garcia, C. J (1998): Chem Rev, 98, 273.

Da Silva, D.L.; Reis, F.S.; Muniz, D.R.; Ruiz, A.L.T.G.; Carvalho,

J.E.; Sabino, A.A.; Modolo, L.V.; De Fatima, A. (2012): Bioorg

Med Chem, 20, 2645.

Davoodnia, A.; Bakavoli, M.; Barakouhi, G.; Tavakoli-

Gulten, S. J (2013): Heterocyclic Chem, 50, 391.

Harikrishnan, P.S.; Rajesh, S.M.; Perumal, S.; Almanson, A.I.

(2013): Tetrahedron Lett, 54, 1076.

Hu, E.; Sidler, D.R.; Dolling, U.H. J (1998): Org Chem, 63, 3454.

Kappe, C.O. (1999): Synthesis, 10, 1799.

Kumar, B.R.P.; Sankar, G.; Baig, R.B.N.; Chandrashekaram, S.

(2009): Eur J Med Chem, 44, 4192.

Kumar, K.A.; Kasthuraiah, M.; Reddy, C.S.; Reddy, C.D. (2001):

Terahedron Lett, 42, 7873.

Lu, J.; Bai, Y.; Wang, Z.; Yang, B.; Ma, H. (2000): Tetrahedron

Lett, 41, 9075.

Lu, J.; Ma, H.; (2010): Synlett, 1, 63.

Müller, A.; Peters, F.; Pope, M. T.; Gatteschi, D. (1998): Chem

Rev, 98, 239.

Okuhara, T.; Mizuno, N.; Misono, M. (1996): Adv Catal, 41,

221.

Pope, M. T.; Müller, A. (2001): Polyoxometalate Chemistry from

Topology via Self-Assembly to Applications; Kluwer Academic

Publishers: Netherlands.

Radha, Rani; V.; Srinivas, N.; Radha, K.M.; Kulkarni, S.J.;

Raghavan, K.V. (2001): Green Chem, 3, 305.

Ramalinga, K.; Vijayalakshmi, P.; Kaimal, T.N.B. (2001): Syn-

lett, 6, 0863.

Ranu, C. B.; Hajra, A.; Jana, U. J (2000): Org Chem, 65, 6270.

Russowsky, D.; Canto, R.F.S.; Sanches, S.A.A.; D’Oca, M.G.M.;

De Fatima, A.; Pilli R.A.; Kohn, L.K.; Antonio, M.A.; De Car-

vallho, J.E. (2006): Bioorg Chem, 34, 173.

Salehi, H.; Guo, Q.X. (2004): Synth Commun, 34, 171.

Singh, K.; Arora, D.; Falkowski, D.; Liu, Q.; Moreland, R.S. J

Org Chem (2009): 19, 3258.

Studer, A.; Jeger, P.; Wipf, P.; Curran, D.P. J (1997): Org Chem,

62, 2917.

Yadav, J.S.; Subba, R.B.V.; Srinivas, R.; Venugopal, C.; Ramal-

ingam, T. (2001): Synthesis, 9, 1341.

Zhang, Y.; Wang, B.; Zhang, X.; Huang, J.; Liu, C. (2015): Mol-

ecules, 20, 3811.

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS SYNTHESIS OF 4, 4’-(1, 3 AND 1, 4-PHENYLENE) BIS 117