Excavation Methods and Excavation Modelling from

South Wells of Iran by Poro-elastic Method

Nasrollah Majidian

1

, Alireza Jirsaraee

2

, Mohammad Samipoorgiri

3

and Ali Pourazar

4

*

1,2,3

Assistant Professor of Technical and Engineering Faculty of Islamic Azad University, North Tehran Branch

4

Student of Master course in the eld of Chemical Engineering, Process Engineering, Islamic Azad University,

North Tehran Branch

ABSTRACT

Excavation uids are important sections on excavation operations which are being used to control well and propel

excavation barrels to ground surface. Thus, they play important role in the operations without having excavation

operations. Today, some of cases which used in excavation are made as arti cial but all manufacturers insist on

adaptability and the rigid laws pertain to geographical situation and regional limitations.Excavation clay consists of

water and other materials in order to facilitate and continue excavation operation which has been used in Iran and

different materials with physical and chemical properties have been added.In this article, by geo-mechanical model-

ling of tank and well with poro-elastic model which is derived from continuation, compromise, balance, hook and

darcy equations, Poro-elastic equations are located in Matlab environment and solve by limited element in order to

increase tensions and pressure around well during certain duration.

KEY WORDS: EXCAVATION CLAY, EXCAVATION CLAY SYSTEM, PORP-ELASTIC, LIMITED ELEMENT MODEL

102

ARTICLE INFORMATION:

*Corresponding Author: Alipourazar2011@gmail.com

Received 11

th

Jan, 2017

Accepted after revision 2

nd

April, 2017

BBRC Print ISSN: 0974-6455

Online ISSN: 2321-4007

Thomson Reuters ISI ESC and Crossref Indexed Journal

NAAS Journal Score 2017: 4.31 Cosmos IF : 4.006

© A Society of Science and Nature Publication, 2017. All rights

reserved.

Online Contents Available at: http//www.bbrc.in/

INTRODUCTION

Excavation clay has long term history since last past

to now, at rst, the Chinese understood that the clay

softens what is on structure and they believed that exca-

vation clay helps to rise up the barrels from bottom of

well. Regardless some well which excavated by Chinese

in 18th century, some well excavated in row of stones by

hand which the rst well was excavated by two brothers

named David and JospehRafner at 1806 to 1807 for salt

water (Hartman, 1959).

In this regard, in 1829, when excavation was con-

tinued to excavate salt water in one of the states of

America, immediately, 1000 barrels of oil were propelled

from well instead of salt water. In systems which have

been used till 1846 and after that, owing water has

been used. No data about excavation method. In 1890,

Chapman pointed that water and plastics can and this

Biosci. Biotech. Res. Comm. Special Issue No 1:102-104 (2017)

Nasrollah Majidian et al.

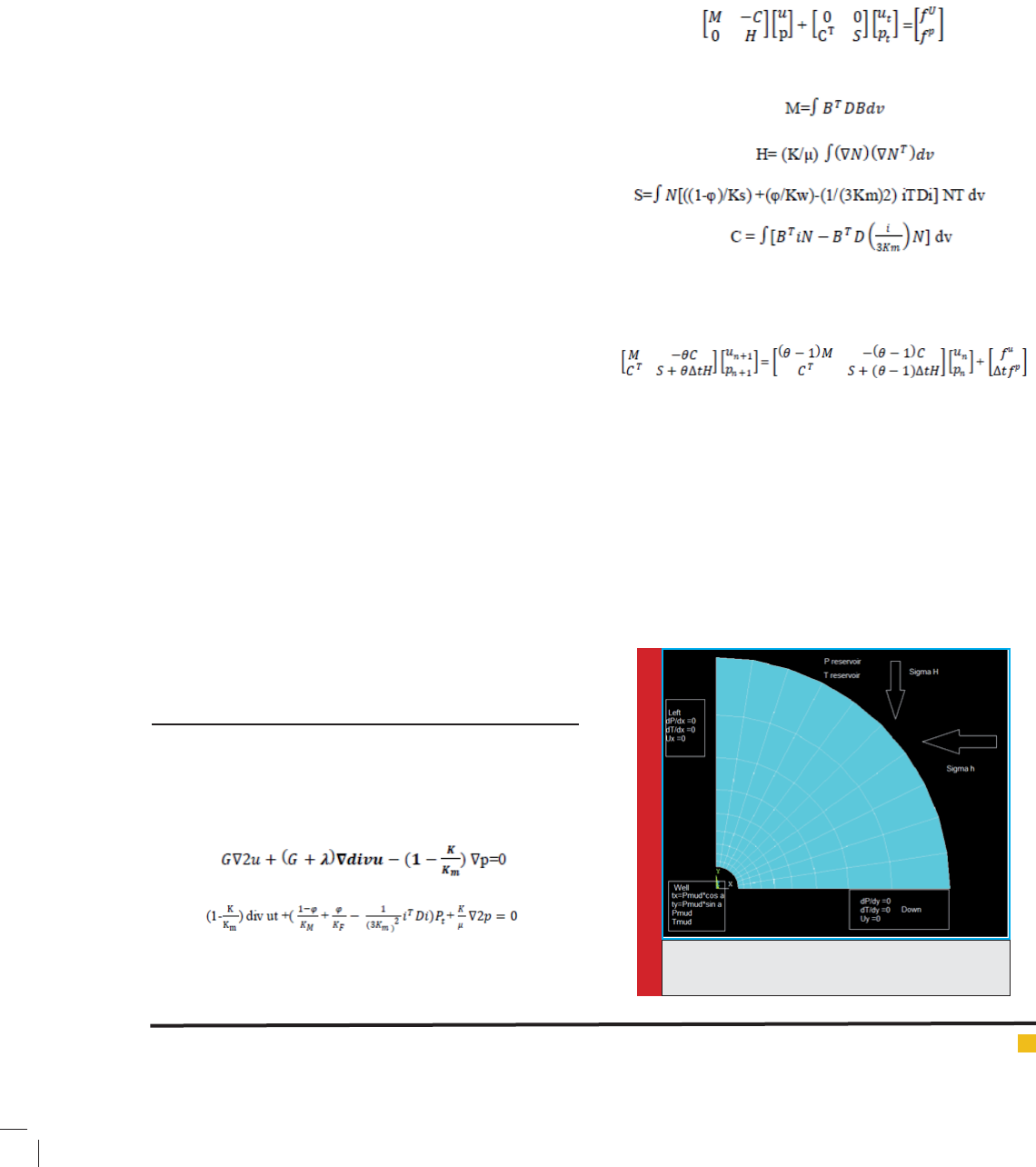

FIGURE 1. Tank and well by borderline situa-

tions

is start of modern engineering in history of excavation

clay. He obtained applications of excavation clay that

means ability to prevent from watering in layers and

concluded that another material has been used to cover

well wall (Rothenburg et al. 1994).

Chapman pointed to application of soil, core of wheat,

grains, cement and similar materials. In 1889, a watery

well employer named Androw from America pointed

that paste soils can be applied to make wall voids. At

same year, person named John Yakingham stated that

fat materials have been used instead of water to apply

soil clays.On October 1990, Krat Mill stated that when

excavation uid was wetted by soil, it helped to make

well signi cantly. Apparently, in that period, excavation

uid could not attract others and physical properties

were not suitable to in uence on it.It can be imagined

that clay was made by well solids is so heavy or high

granular and it has been used to slight it. If total gran-

ule is reduced or adds from tanks into new clay system,

excavation is continued. If total weight is slight, well

evaporates and if the drop is so much, falling of well

wall caused cleavage of pipes(Hutin et al. 2001).

There are not effective additives ingredients for con-

trol physical properties and it was made by claying. 13

years after advent the rst excavation clay for Lucas at

1901, the model was emerged as necessity in excava-

tion industry in order to discuss excavation investiga-

tions. This problem was discovered in 1914 after vast

research was performed by PoulardVehigourg who used

more concentrated clay for excavating well in Okla-

homa State. They stated that use of clay and soil is not

new phenomenon in excavation industry and the rst

well has been excavated in Texas by clay but till 1913,

when the wells were excavated by tower and without

using clay, suitable clay is one which is so concentrated

and can block voids of classes as if the uid cannot

penetrate into well, so that it has able to block sand

voids, prevent from dropping of well and control gas

pressures(Williamson, 1968).

MATERIAL AND METHODS

In order to display tension and penetration pressure of

porosity environment, the uids are obtained by com-

bination, continuation, balance, compromise, hook and

Darcy equations (1).

(1)

(2)

In which y is xed, Lame, G is shearing model, K stabil-

ity, U is viscosity of uid and u and p are replacement

and pressure, t is time and u is porosity, D matrix of

elastic fatigue, K, Km, KfYalk model of building, matrix

and uid (0, 11), i= two dimensions calculations also D is

function of F (Young model) and V (Poison coef cient).

Modelling or solving element is written in Matlab

environment.

Poro-elastic model was obtained as limited element

model (2).

(3)

In this model, parameters (4) are:

(4)

(5)

(6)

(7)

One of the best methods for solving equations is obtained

by Zozanagheh (3).

In which, = 1.2 is considered.

In order to discuss effect of weight increment on ten-

sions of clay and penetration pressure, rstly, a tank

with pressure 500 psi (34e5pa) is considered and clay

pressure is increased to 870 (60e5pa) and its effects are

discussed on tension and pressure.

Borderline situations are displayed for following

gure:

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS EXCAVATION METHODS AND EXCAVATION MODELLING FROM SOUTH WELLS OF IRAN 103

Nasrollah Majidian et al.

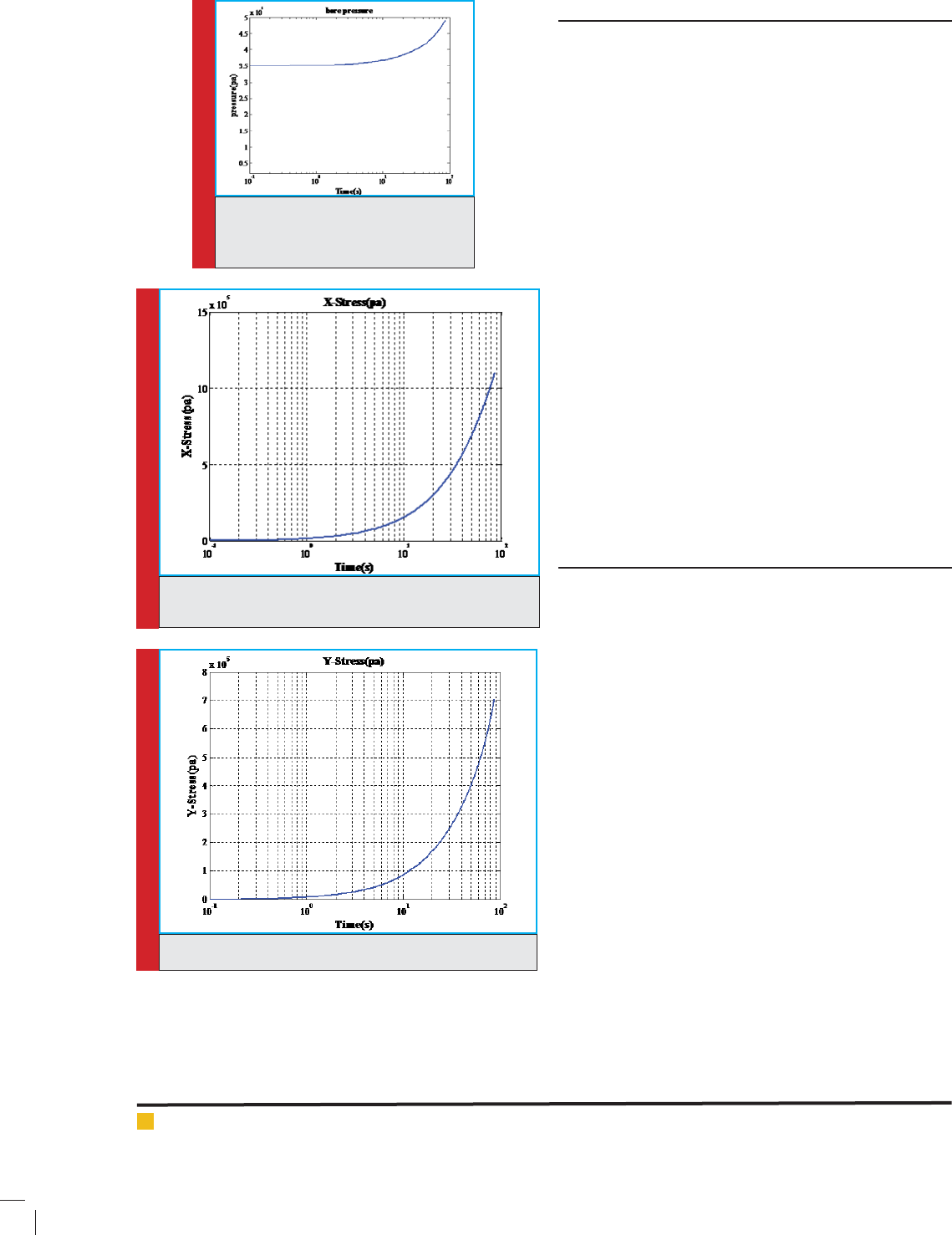

RESULTS AND DISCUSSION

In order to discuss effect of weight increment for ten-

sions and well of wall, rstly, a tank with pressure of

500 is considered and scale of pressure is increased

till 870.

Entrance data are:

E=560e5 Pa,

K=16.e-14 m2

μ=26222 Pa.s

=2624, =2614

T=162,

Kf=1e12 Pa,

Km=22e5 Pa,

fcf=1022242

scs=1520222

s=14e-. ºC-1,

f =322e-. ºC-1,

Sigmah=360e.Pa,

SigmaH=4e. Pa

fu,fp

Which are node load of pressure and replaced node of

pressure equal to zero and all nodes are equal to tank

pressure.

CONCLUSION

With increment weight of excavation clay and pressure

around well is increased and in the lacking calculation

of total weight, in this article, by increment of weight

of clay from 34e5 to 60e5 in Pascal and as for infor-

mation it was increased as 96% from tension around

well.

REFERENCES

Hartman, H.L. (1959): Basic studies of percussion Drilling,

Trans AIME. Vol. 214. PP. 68-75.

Hutin R., Tennent R.W., Kashikar S.V., Schlumberger SPE.

(2001): New Mud Pulse Telemetry Techniques for Deepwater

Applications and improved real- time Data Capabilities.

Rothenburg, L., Bratli,R.k. and Dusseault, M.B. (1994): A

poroelasric solution for transient uid ow into a well. PMRI

Publication, University of Waterloo, Canada.

Williamson T.N. (1968): Rotary Drilling Chapt .6.3 Surface

Mining E.P. P eider. Ed. AIME, NewYork, PP.300 – 324.

FIGURE 2. Increment of penetration

pressure (pascal) on touching with

clay in terms of second

FIGURE 3. Increment of tension in step of x (PASCAL) to

second

FIGURE 4. Increment of tension in Y (pascal) to second

104 EXCAVATION METHODS AND EXCAVATION MODELLING FROM SOUTH WELLS OF IRAN BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS