Medical

Communication

Biosci. Biotech. Res. Comm. 10(4): 797-801 (2017)

The production and evaluation of biologically synthesized

anticancer Chlorambucil - DTPA – Methionine

Elham Poonaki

1

, Leila Pishkar

2

, Mahdyeh Zarandooz

3

, Hadi Hejazinia

3

, Marzyeh Hosseini

4

,

Artin Assadi

3

, Mohammad Zahedi

3

and Shahin Hadadian*

5

1

Department of Biotechnology, I.A.U of Damghan, Damghan, Iran

2

Young Researchers and Elite Club, Islamshahr Branch, Islamic Azad University, Islamshahr, Iran

3

Department of Radiopharmacy, Faculty of Pharmacy, Tehran University of Medical Sciences, Tehran, Iran

4

Department of Cellular and Molecular Biology, Islamic Azad University, Tehran North Branch,Tehran, Iran

5

Nanobiotechnology Department, Pasteur Institute of Iran, Tehran, Iran

ABSTRACT

Chromabucil is a direct acting direct acicular anticancer drug which is still widely used in the treatment of some

cancers as a primary treatment, but its use is often limited due to the unwanted side effects of this drug due to the

lack of speci city in targeting cancer cells. In this project, our effort to increase the speci city of Chlorambucil

using methionine amino acid has led to the production and evaluation of biological antimicrobial Nano conjugate

Chlorambucil-DTPA-Methionine. Research has shown that the consumption and harvesting of cancer cells increases

signi cantly over nitrogen and polyamide compounds, while some amino acids, including methionine amino acids,

are more expressed on the surface of the cancer cells, resulting in tissue Cancer cells increase to methionine amino

acid, so in our study, we have been using methionine amino acid as a carrier and enhancer of the uptake of Chloram-

bucil antimicrobial to produce this conjugate from the connector We used DTPA. After studying this Nano conjugate

and examining its structure, we investigated the therapeutic and biological effects of this nanoagonergic drug as

compared to Chlorambucil on the MCF-7 and HT-29 cell line (breast cancer and colon cancer), including The MTT

assay tests the determination of cell death and cell necrosis and a test for the determination of conjugate toxicity on

mice, which ultimately led to the understanding that the new nano conjugate Chlorambucil-DTPA-Methionine not

only retained its anti-cancer properties against the Chlorambucil drug But has shown less abnormal toxicity.

KEY WORDS: BREAST CANCER / CHLORAMBUCIL / METHIONINE / DTPA / CONJUGATE

797

ARTICLE INFORMATION:

*Corresponding Author: hadadian@yahoo.com

Received 10

th

Oct, 2017

Accepted after revision 16

th

Dec, 2017

BBRC Print ISSN: 0974-6455

Online ISSN: 2321-4007 CODEN: USA BBRCBA

Thomson Reuters ISI ESC and Crossref Indexed Journal

NAAS Journal Score 2017: 4.31 Cosmos IF: 4.006

© A Society of Science and Nature Publication, 2017. All rights

reserved.

Online Contents Available at:

http//www.bbrc.in/

DOI: 10.21786/bbrc/10.4/27

798 THE PRODUCTION AND EVALUATION OF BIOLOGICALLY SYNTHESIZED ANTICANCER BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Elham Poonaki et al.

INTRODUCTION

Since cancer is a fatal illness worldwide, it is the sec-

ond leading cause of death in the world after car-

diovascular disease and, according to annual reports,

causes many deaths from cancer. Today’s treatments

are very costly and have unpleasant side effects in the

patient’s body. Today, efforts are being made to nd

newer and more effective treatments, including these

treatments, for chemical treatments. Nowadays, there

is a lot of research to discover new drugs, appropriate

drug delivery routes, and optimal drug targeting with

less side effects. Recently, therapeutic studies have been

conducted on the transmission of antibody-dependent

drugs, but since the therapeutic method of drug delivery

using antibodies also has inef ciencies and transitional

problems, costs and side effects, in particular, itself, a

newer research for the transfer of anticancer drugs is

taking place. Since then, research has shown that the

consumption and removal of cancer cells increases sig-

ni cantly over nitrogen and polyamide compounds, and

the expression of some amino acids such as methionine

amino acids on the surface of the cancer cells is more

pronounced and therefore cancer tissue cells to increase

the amino acid methionine, (Levine et al., 2000, Palmer

et al. 2009, Roché et al. 2011).

In this study we have used methionine amino acid

as carrier and antimicrobial agent for the treatment of

Chlorambucil. Cancer treatment as an anticancer drug,

like other anticancer drugs, has side effects on the can-

cerous patient’s body, the reason is that by designing

an anticancer drug conjugate using methionine amino

acid (as an enhancement of cellular uptake and DTPA

interface and conducting biologic studies of the effect

of this conjugate on cancer cells through drug delivery

to reduce side effects and Increase the ef cacy of Chlo-

rambucil to as an appropriate drug delivery method, we

tried to do that. So far, hybrids have been made of non-

interfacing Chlorambucil, such as Chlorambucil glucose

and Chlorambucil –tyrosine (Gupta A et al. 2010).

But the proper interface for ef cient drug delivery is

very important. We have been working to produce this

conjugate for the amino acid linkage of methionine We

used the DTPA connector for Chlorambucil amine, which

looks very good interface due to amine groups, because

amine receptors from cancer cells increase and drug

delivery will be more successful. We then performed the

relevant biological tests on the MCF-7 and HT-29 cell

line breast cancer cells.

MATERIAL AND METHODS

Following chemicals were used in the study.Chloram-

bucil (Sigma-Aldrich, USA) USA • Cell line MCF-7 and

HT-29 (Pasteue Institute of Tehran) • Sulfo-NHS (Sigma-

Aldrich, USA) USA) • EDC (Sigma-Aldrich, USA) • PBS

(Merck, Germany) • DMSO (Merck, Germany) • Sepha-

dex G-10 Fine (Sigma-Aldrich) • Chloroform (Merck,

Germany) • FCS (Seromed Biochrom, Germany) ) • FBS

(Merck, Germany) • RPMI medium (Sigma-Aldrich, USA)

• Penicillin powder (Sigma-Aldrich, USA) • Streptomy-

cin powder (Sigma-Aldrich, USA) • The TNF-alpha kit

(The RayBio® Human TNF -alpha ELISA) Kitin Annex-

inV-PI (BD Pharmingen, UK).

Combination or hybridization of an antimicrobial

agent of Chlorambucil and methionine amino acid,

produced by the interface of DTPA herein. 2.320 g of

methionine (if used 3 mg of Chlorambucil) is added in

5-5 milliliters of water Soluble. 2. Add 1 mg DTPA to

the solution and dissolve it by sterilizer. 3. After 1 to 2

minutes, add twice as much amino acid as EDC to the

previous solution. To the product of the rst stage after

1 to 5 minutes of production, 758 mg / kg of Chloram-

bucil is added. 2. To complete the Chlorambucil disso-

lution, dissolve it with sterilization. 3. The product is

ready for the next reaction. Use of DSMO is due to fat-

loving Chlorambucil (CBL) and DMSO helps to dissolve

it and accelerate the reaction. At this stage, puri cation

of the conjugated product is studied. The purity of the

compound produced was investigated by TLC chroma-

tography.

A 10 milliliter TLC solvent was prepared containing

3 milliliters of chloroform (nonpolar solvent to dissolve

lipophilic compounds) and 7 milliliters of methanol

(polar solvent to dissolve hydrophilic compounds) (30%

chloroform and 70% methanol) TLC papers were cut in

rectangles with dimensions, length 8-7 cm and width of

5-4 cm. Then 1 millimeter above the solvent line (the

highest part of the paper that is placed inside the sol-

vent), with the capillary tube, there were delicate spots

spaced apart, which included, respectively, methionine,

DTPA, Sulfur-NHS, conjugate synthesis They were Chlo-

rambucil and EDC. Each paper was placed in a solvent

containing a 45° angle inside the container and due to

the evaporation of chloroform and methanol, as well as

the toxicity of chloroform, it should be closed in a con-

tainer. The required amount of 25-26 C° and the required

time in this method is about 20 minutes. Be Due to the

fact that all materials and stains are colorless, UV light

was used to observe the movement rate of the material,

and stains were observed in the range of 280-220. The

patches created with DTPA, sulfur-NHS, EDC, and CBL

stain were a blurry and sharp spot. By this method, the

result was that the synthesis product, conjugate Chlo-

rambucil-methionine-DTPA, was present in the fourth to

seventh test tubes.

Mass Spectroscopy analysis was carried out to con-

rm methionine - DTPA- Chlorambucil

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS THE PRODUCTION AND EVALUATION OF BIOLOGICALLY SYNTHESIZED ANTICANCER 799

Elham Poonaki et al.

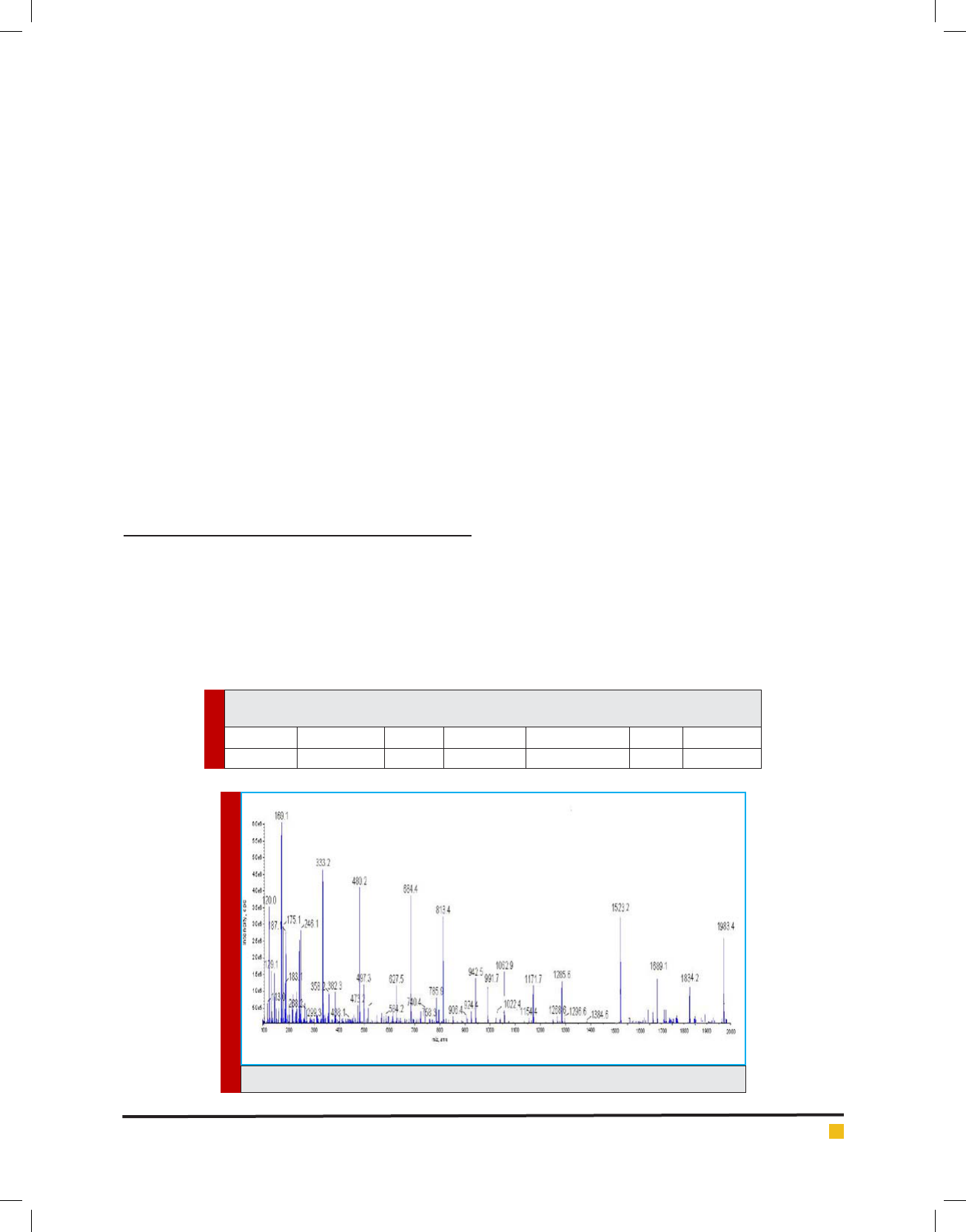

FIGURE 1. Mass Spectrum Display

Table 1. The values of Rf are calculated from the TLC paper from the distance that the

material goes through to the distance that the solvent travels.

E DCCBLCBL-Met DTPASulfo-NHSDTPAMethionineMaterial

88.032.040.049.082.072.0Rf

Conjugation. MTT is a colorimetric assay which is

used to assess cell viability based on metabolic activity.

This assay is based on reduction of yellow tetrazolium

salt (MTT) to form dark colored formazan dye by dehy-

drogenase enzymes in metabolically active cells the cells

(MCF7) and (HT-29) were brooded with different concen-

trations of methionine - DTPA- Chlorambucil (0.1, 0.2,

0.5 mg/ml and Chlorambucil 0.5 mg/ml and untreated

cell (as a negative control) for 48h.. After incubation

(48 h), 50 μl XTT detection solution was added to each

well of 96-well plate and the plate is kept in the incu-

bator for 2 h. The formazan dye is soluble in aqueous

solution and can be measured by evaluating the absorb-

ance at 450 nm using a spectrophotometer. The results

were compared to the untreated control cells. Statistical

data analysis was done using Prism and excels software

(Microsoft Of ce 2013). For quantitative data analysis

paired One Way ANOVA in case of cluster comparison,

were applied. P < 0.05 were considered statistically sig-

ni cant.

RESULTS AND DISCUSSION

In gel ltration chromatography, the solution was

removed from the chromatography column with 1 ml

(20 drops) in 20 separate test tubes. Then, each tube was

subjected to thin layer chromatography (TLC) to verify

the accuracy of the nal product. On the TLC paper, one

millimeter above the solvent line with a capillary tube,

delicate spots were separated from each other, which

consisted of methionine, DTPA, Sulfo-NHS, synthetic

conjugate, Chlorambucil-methionine- DTPA, Chloram-

bucil (CBL), and EDC. The stain was then investigated

by the UV lamp and the presence of the product in the

fourth to seventh tubes was determined, and then the

Rf of each compound was calculated according to the

formula given in Chapter 2, as follows (Table 1)

LC / MC mass spectrometry (LC / MC) spectroscopy

was used to study the molecular structure and iden-

tify the conjugated Chlorambucil -methionine DTPA.

The results are presented Figure 1.The 1983 molecular

weight spectrum shows well that the molecular weight

of 1983 is exactly equal to the conjugate molecular

weight, which is proof of conjugated synthesis. The syn-

tactic conjugate molecule is well visible

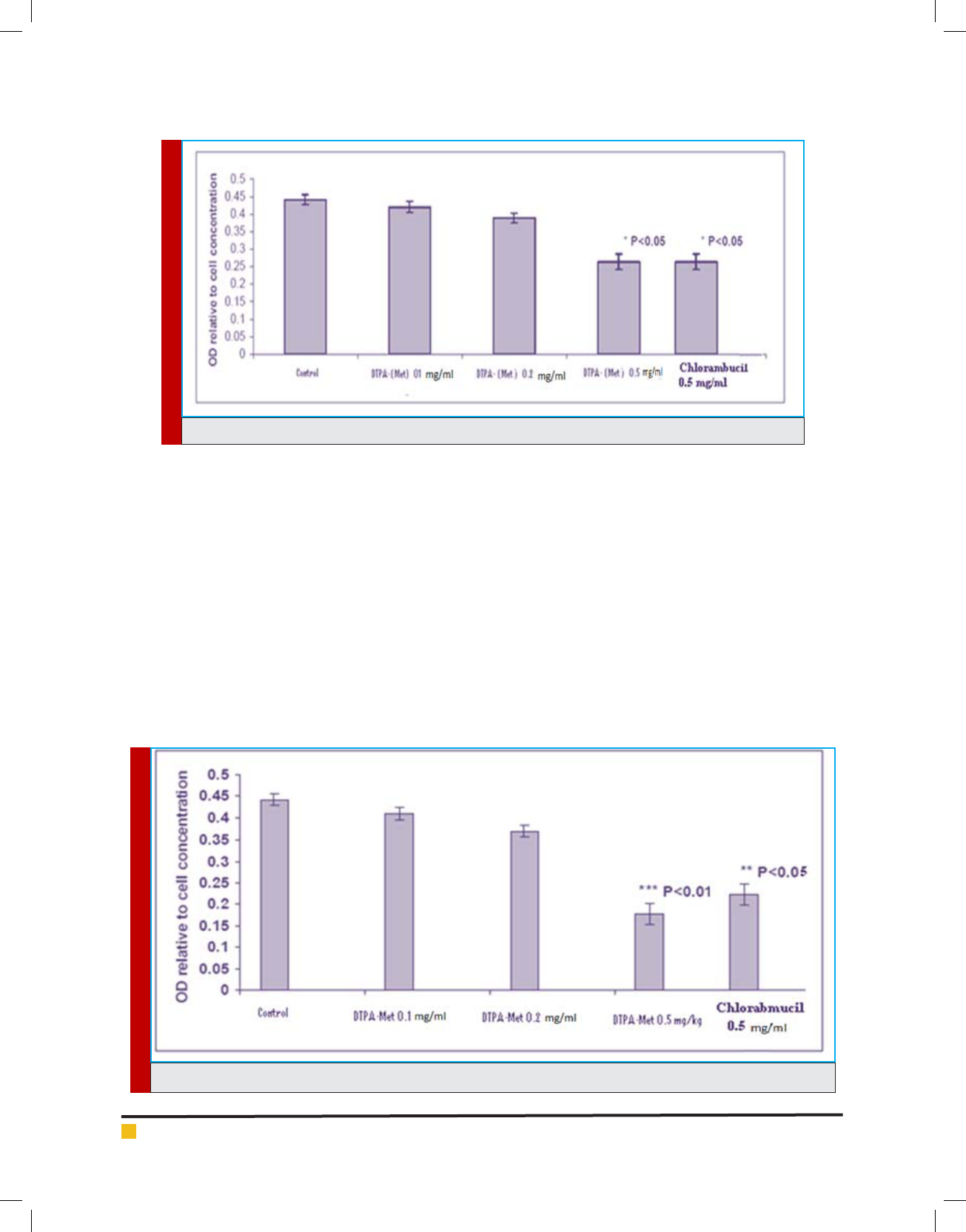

In Figure 2 and 3 the results of the compound toxicity

on the MCF-7 and HT-29 cell line respectively indicate

that our combination at 5 mg / ml dose has a signi -

cant toxicity (p < 0.05), and this toxicity is completely

equal to Chlorambucil. Making targeted drugs is a very

important part of cancer treatment. The use of non-can-

cerous anticancer drugs causes various side effects in the

patient. One of the oldest anti-cancer drugs is Chloram-

bucil, which belongs to the group of alkalizing drugs,

its effects on the cells are non-speci c and mechani-

cally unknown and have many side effects for patients.

The production of a molecular conjugate of Chloram-

bucil -methionine was performed with the goal of hav-

ing anticancer properties and also acting purposefully.

The ability to kill Conjugate Chlorambucil-Methionine-

Elham Poonaki et al.

800 THE PRODUCTION AND EVALUATION OF BIOLOGICALLY SYNTHESIZED ANTICANCER BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

FIGURE 2. Showing the results of the MTT assay test on the MCF-7 cell line

FIGURE 3. Showing the results of the MTT assay test on the HT-29 cell line

DTPA in similar doses compared to Chlorambucil on the

HT-29 and MCF-7 cell line was higher.

According to the results of experiments on conju-

gate and its comparison with Chlorambucil, the results

were that: the binding of methionine amino acid to

Chlorambucil not only does not eliminate the antican-

cer effect of this drug, but also increases its antican-

cer effect and increases the conjugated effect Because

cancer cells tend to receive high amounts of polyam-

ine compounds, the binding of the methionine amino

acid to Chlorambucil will result in a targeted formu-

lation that can absorb cancer cells of this conjugate.

In 2004, according to Bothenichen’s research on polyam-

ine and cancer, it was discovered that the accumulation

of polyamide compounds in cancerous tissues increased,

as well as the concentration of these compounds in

the body uids of patients with cancer, (Buchrach

et al. 2004) and in 2005 researchers it was found that

the transfer of some essential amino acids in cancer

cells increases, because in cells with high metabolism,

the absorption of amino acids also increases. There-

fore, using drugs reduces the synthesis of polyamine or

inhibits the carriers of these amino acids, it can inhibit

cancer, and these drugs can be a good option for can-

cer treatment (Yoon et al. 2005). In 2009, Palmer and

colleagues in their research stated that increasing the

concentration of polyamines plays an important role

in the development of cancer, from the onset to the

maintenance of the phenotype of the transformation,

(Palmer et al. 2009).

Elham Poonaki et al.

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS THE PRODUCTION AND EVALUATION OF BIOLOGICALLY SYNTHESIZED ANTICANCER 801

One of the ways of cancer cells to increase the con-

centration of polyamine compounds is the absorp-

tion of polyamines by the polyamine (PTS) trans-

fer system in these cells. PTS is a rugged system that

transmits a large amount of polyamines. Therefore, it

may be possible to transfer cytotoxic drugs by bind-

ing to polyamine vesicles and using this system to

target cancer cells selectively (Yoon et al. 2005).

In 1997, the dependence of the growth of a num-

ber of solid tumors on high levels of methionine and

the increased need for tumor cells to methionine were

observed in relation to normal cells, which suggests

that methionine can be considered as an appropri-

ate choice for tumor treatment. (Buchrach et al. 2004).

Conjugate Chlorambucil -methionine DTPA-D, due to

its high chemical content, is considered as a polyamide

compound and also has a methionine-like acid compo-

nent in its structure, which is due to two reasons for

its absorption in cancer cells. So far, much research has

been done to transfer targeted drugs through speci c

molecules to tumors. The use of transfusion carriers and

the manufacture of drug conjugates can have a more

effective and speci c effect on drugs. Due to the high

side effects of Chlorambucil anticancer drugs and its

nonspeci c effects on the cells of the body, the purpose

of this drug and its side effects have been many studies

on Chlorambucil conjugation.

In 2010, they used Chlorambucil-estradiol for chemo-

therapy for breast cancer and found that they had bet-

ter and better ef cacy compared to Chlorambucil (Gupta

et al. 2010). In 2011, researchers, given the frequent

expression of receptors Folate (FRS) at the level of the

malignant tumor cells synthesized two new conjugated

folate carrying Chlorambucil, and they were biologically

evaluated on the leukemia cell line. The results of the

antitumor activity showed more conjugates compared

to non-conjugated Chlorambucil (Guaragna et al. 2011).

By reviewing the articles, it was concluded that the

synthesized conjugates of Chlorambucil had a posi-

tive effect and their effectiveness was much better than

that of Chlorambucil, and these considerations made

the conjugated Chlorambucil -DTPA-methionine II as a

novel drug in The treatment of breast cancer has also

been strengthened. Also, according to the aforemen-

tioned articles, the synthesis of conjugate Chlorambucil

and the study of binding methods led to the conclusion

that the binding of Chlorambucil to amino acids was

carried out from its carboxyl side, not from the chlo-

rine region. Because chlorine is a very important factor

for killing cells by alkylating them. The carboxyl side

of the Chlorambucil has a pharmacokinetic aspect (no

dynamic aspect). Through this position, the drug enters

the body, it traverses and excretes a pathway. Therefore,

the manipulation and binding of the amino acid in this

region, with the exception of the effect on absorption

and its shelf-life in the body will not have an effect on

inhibiting the effectiveness of the medicine.

ACKNOWLEDGMENTS

The authors would to thank Tehran University of Medi-

cal Sciences as well as all laboratories and technicians

who provided supported during within the course of the

study.

CONFLICT OF INTEREST

The authors declared no con ict of interest.

REFERENCES

Buchrach U. Polyamines and cancer: Mini review article.

(2004) Amino Acids. 26(4), 307-9

Gupta A, Saha P, Descôteaux C, Leblanc, Asselin É, Bérubé

G. (2010) Design, synthesis and biological evaluation of estra-

diol-chlorambucil hybrids as anticancer agents. Bioorganic &

Medicinal chemistry letters. 20(5), 1614-1618.

Gupta A, Saha P, Descôteaux C, Leblanc V, Asselin E, Bérubé G,

2010 Design, synthesis and biological evaluation of estradiol-

chlorambucil hybrids as anticancer agents. Bioorg Med Chem

Lett. 2010 Mar 1;20(5):1614-8.

Levine RL, Moskovitz J, Stadtman ER. (2000) Oxidation of

methionine in proteins: roles in antioxidant defense and cel-

lular regulation. IUBMB Life. 50, 301-7.

Palmer AJ, Ghani RA, Kaur N, Phanstiel O, Wallace HM. (2009)

A putrescine-anthracene conjugate: a paradigm for selective

drug delivery. Biochem J. 424(3), 431-8.

Roché H, Vahdat LT, (2011) Treatment of metastatic breast can-

cer: second line and beyond. Ann Oncol. 22(5), 1000-10.

Yoon JH, Kim IJ, Kim H, Kim HJ, Jeong MJ, Ahn SG, Kim SA,

Lee CH, Choi BK, Kim JK, Jung KY, Lee S, Kanai Y, Endou H,

Kim DK. (2005) Amino acid transport system L is differently

expressed in human normal oral keratinocytes and human oral

cancer cells. Cancer Lett. 222(2), 237-45.