Utilization of damaged and spoiled wheat grains for

bioethanol production

Nadia Razdan* and G.S. Kocher

Department of Microbiology, Punjab Agricultural University, Ludhiana-141004, India

ABSTRACT

First generation ethanol from starchy crops particularly maize is an established technology that being a renewable

and bio-based resource has advantages over gasoline. The second generation ethanol from lignocellulosics owing to

its economic considerations is still at pilot scale and is yet to see commercialization. This has increased the demand

of starchy feed-stocks for energy. The recently released National Policy on Biofuels in May, 2018 categorically also

emphasizes on the potential of different raw materials for ethanol production by consenting the utilization of dam-

aged food grains like wheat, broken rice etc. that area otherwise un t for human consumption. As far as wheat is

concerned, The Comptroller and Auditor General (CAG), India (2017) reported that Food Corporation of India’s (FCI)

wheat stock worth 700 crores was damaged solely in Punjab from 2011 to 2016 as the grain was kept in open areas

attributed to the lack in storage facility. Development of ef cient technology to pretreat and convert damaged starch

into fermentable sugars and optimization of enzymatic hydrolysis using commercial as well as indigenous enzyme

preparation are the key points for the ef cient bioethanol production from damaged wheat. Further, the synergistic

action of alpha and glucoamylase in the hydrolysis of wheat mash have been tried that has revealed 96.25% con-

version ef ciency with an ethanol yield 5.60 % (v/v). The present review discusses research progress in bioethanol

production from damaged wheat grains containing higher starch content. Thus, utilization of especially damaged

and spoiled wheat grains pave better way for commercialization of bioethanol production from an economical

perspective.

KEY WORDS: BIOTHANOL, INDIGENOUS, LIGNOCELLULOSICS, DAMAGED WHEAT

658

Agricultural

Communication

Biosci. Biotech. Res. Comm. 11(4): 658-673 (2018)

ARTICLE INFORMATION:

Corresponding Authors: nadiarazdan2012@gmail.com

Received 25

th

Oct, 2018

Accepted after revision 24

th

Dec, 2018

BBRC Print ISSN: 0974-6455

Online ISSN: 2321-4007 CODEN: USA BBRCBA

Thomson Reuters ISI ESC / Clarivate Analytics USA

Mono of Clarivate Analytics and Crossref Indexed

Journal Mono of CR

NAAS Journal Score 2018: 4.31 SJIF 2017: 4.196

© A Society of Science and Nature Publication, Bhopal India

2018. All rights reserved.

Online Contents Available at:

http//www.bbrc.in/

DOI: 10.21786/bbrc/11.4/17

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS UTILIZATION OF DAMAGED AND SPOILED WHEAT GRAINS FOR BIOETHANOL PRODUCTION 659

Nadia Razdan and G.S. Kocher

INTRODUCTION

Global demand for energy sources and their utilization

determine the economic status and growth of develop-

ing countries all over the world (Xu and Liu 2009). The

major energy demand is still supplied from conventional

fossil fuels such as oil, coal and natural gas which don’t

regenerate at sustainable manners (Twidell and Weir

2003). Fossil Fuels have played an indispensible role in

development of industry but its indiscriminate use and

the resulting environmental pollution led to advent of

alternate fuels. The Energy Information Administration

(EIA) reported that 70% of oil consumed in the United

States was used for transportation (EIA 2015 a). Accord-

ing to EIA’s 2014 report, 27% of petroleum consumed

in the United State was imported from foreign countries

(EIA 2015b). Hence, use of renewable resources to pro-

duce liquid biofuels offer attractive solutions to reducing

greenhouse gas emissions, decreasing reliance on foreign

oils, addressing energy security concerns, strengthening

rural and agricultural economies and increasing the sus-

tainability of the world transportation system. Today,

Bioethanol has long been regarded as a suitable sub-

stitute to fossil fuels. It has immense properties such as

higher compression ratio, shorter burn time and leaner

burn engine, which lead to theoretical ef ciency advan-

tages over gasoline (Hansen et al 2005). Brazil has the

world’s rst sustainable bioethanol economy with 6.19

billion gallons produced in 2014, which represents over

25% of the world’s ethanol fuel and is ranked second in

the world next to the United States (Biofuels 2016).

According to the Renewable Fuels Association (RFA

2018), the global production of bioethanol stood at 27

billion gallons in the year 2017, with the USA (15,800

million gallons) and Brazil (7,600 million gallons) as

the largest producers in the world. India ranks eighth

in ethanol production next to EU, China, US and Brazil

with a total production of 280 million gallons in 2017

(RFA, 2018).

The rst and second generation bioethanol are

commonly referred as rst generation bioethanol

resources and third type as second generation bioetha-

nol resources. The shift from rst to second generation

bioresources is obligatory due to main reasons; one is

that rst generation bio resources have alternate uses

such as food (sugarcane, corn), animal feed (molas-

ses) etc, secondly that these are still unable to meet

the global demand of bioethanol. On the other hand,

Lignocellulosics need costly steps of pretreatment and

range of enzyme requirement for sacchari cation which

is making bioethanol production from lignocellulosics

a costly affair. In this scenario, there is need for a suit-

able economical substitute as an alternative. Therefore

the National Policy on Biofuels –2018 categorically

emphasis on the potential of different raw materials for

ethanol production by consenting the utilization of sug-

arcane juice, sugar containing materials like sugar beet,

sweet sorghum, starch containing materials like corn,

cassava, damaged food grains like wheat, broken rice,

rotten potatoes, un t for human consumption. India is

an agricultural country where wheat and rice are staple

food for its burgeoning population. In terms of produc-

tion, India stands second after china in wheat and rice

production accounting for about 200MT/year out of this

about 12MT (6%) of grains are damaged by post-harvest

storage due to poor storage facilities and hence damaged

by insects, rodents, birds and microbial spoilage (Sharon

et al 2014). As far as wheat is concerned, Comptroller and

Auditor General (CAG) (2017) reported that Food Corpo-

ration of India’s (FCI) wheat stock worth 700 crore was

damaged solely in Punjab from 2011 to 2016 as the grain

was kept in open areas attributed to the lack in stor-

age facility (Anonymous 2017). All this damaged grains

were disposed off as they were not t for consumption

by human and animals. However, the damaged grains

can be put to application by producing ethanol from its

starch content which constitutes 70-80% in wheat and

rice. Theoretically, 30gal/MT of ethanol from damaged

wheat and rice may be obtained (Gawande and Patil

2015). Wheat starch is comprised of one quarter amylose

and around three quarters amylopectin with little pro-

tein and lipid debasements (0.8% and 0.2% respectively)

(Bowler et al 1985).

The process of grain bioethanol production involves

milling (grinding and pretreatments), mashing (enzy-

matic or acid hydrolysis, steaming, adding supplements

etc) and Fermentation (SHF or SSF) which is followed

by distillation and dehydration to produce anhydrous

ethanol. The conversion of starch to ethanol can be

accomplished by acid hydrolysis, but the generation of

by products such as levulinic and formic acid may cause

hampered yeast growth hence, lower yields of alcohol

(Kerr 1944). The acid hydrolysis has now been largely

switched with amylolytic enzymes (-amylase and glu-

coamylase) which deliver 95% more yield of glucose

(Hua and Yang 2016).

Though using damaged grains will incur lower sub-

strate cost, mashing involves costly commercial sac-

chari cation and enzymes which may also be taken

care of by using indigenous culture of Bacillus subti-

lis, Bacillus circulans, Bacillus cereus etc for -amylase

and Aspergillus such as Aspergillus niger, Aspergillus

oryzae etc for glucoamylase. Fermentation is the nal

stage performed after starch pretreatment (digestion) for

bioethanol production The process cost may be further

be reduced by using Simultaneous Sacchari cation and

Fermentation as it reduces the time as well as energy

by using two different vessels for Sacchari cation and

660 UTILIZATION OF DAMAGED AND SPOILED WHEAT GRAINS FOR BIOETHANOL PRODUCTION BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Nadia Razdan and G.S. Kocher

Fermentation besides lowering the chances of contami-

nation. This review designed to provide an insight into

the process details as well as the update of the damaged

cereals particularly damaged wheat for bioethanol pro-

duction.

FEEDSTOCKS FOR BIOETHANOL PRODUCTION

The raw materials for bioethanol production can broadly

be classi ed as (i) sucrose-containing feedstock (sugar-

cane, sugar beet and sweet sorghum) (ii) starch-con-

taining feedstock (wheat, corn and cassava) and (iii)

cellulosic feedstock (straw, grasses, wood, stovers, agri-

cultural wastes and paper etc) (Table 1) while the bioeth-

anol produced from sucrose-and starch-containing feed-

stock is classi ed as 1st generation bioethanol (ethanol

from corn and sugarcane) that produced utilizing cel-

lulosic feedstock is referred as 2

nd

generation bioethanol.

The source of third generation biofuel is lipolytic com-

pounds obtained predominantly from algae. Most cur-

rent bioethanol production processes utilize more read-

ily degradable biomass feedstock such as cereals (corn

and grain) and molasses. However, the utilization of

edible agricultural crops exclusively for biofuel produc-

tion con ict with food and feed production (Wheals et al

1999). One of the major problems with bioethanol pro-

duction is the variability in available raw materials as

their geographic locations differ from season to season,

place to place and price of substrates which affects and

hence the production cost of bioethanol (Kumar 2006;

Yoosin et al 2007).

UTILIZATION OF DAMAGED CEREAL GRAINS

FOR BIOETHANOL PRODUCTION

Cereal grains are used mostly for food and feed. How-

ever, post heat losses from farm to fork take a signi -

cant portion of damaged/infested cereal grains which

are not t for consumption. But there are rich sources

of sugar (in the form of starch) just like simple sugar

substances such as molasses, sugarcane juice can be fer-

mented. These starch based materials like corn, rice and

wheat have infact proved to be promising raw mate-

rials for their ef cient fermentation into industrial as

well as potable ethanol with the help of appropriate fer-

menting micro-organisms (Awasthi et al 2015). As per

estimates provided by Food Corporation of India (FCI)

huge quantities of cereal grains are getting spoiled every

year due to unfavourable climate conditions and become

un t for human and animal consumption and one mil-

lion tonnes of damaged grains is lying unutilised in FCI

stores (Kumar et al 1999). The damage includes discol-

oration, breakage, cracking, attack by fungi, insect dam-

age, chalky grain, partial softening due to dampness, off

smell etc (Gawande and Patil 2015).

The damaged grains used for ethanol production are

ten times cheaper than ne quality. These damaged or

waste cereal grains can be utilized for the effective pro-

duction of ethanol using fermentation process which

will not only meet (partially) our needs but may pro-

vide some incentive to the farmers who suffers due to

crop damage. The chemical composition of cereal grains

is characterized by the high content of carbohydrates

mainly starch (56–74%) deposited in the endosperm and

bre in the bran (2–13%). The second important group

of constituents is the proteins which fall within an aver-

age range of about 8–11% and high content of B-vita-

mins is, in particular, of nutritional relevance. Hence,

spoiled and damaged starchy grains can also be used for

bioethanol production.

DAMAGED WHEAT: A PROMISING RAW

MATERIAL FOR BIOETHANOL PRODUCTION

Global Scenario of wheat

Wheat is produced in 120 countries and accounts for

about 19 per cent of the world’s calorie supplies. It is

used primarily as our for making bread, pastry, pasta

and noodles etc. It is also used to feed livestock, with the

feed accounting for about 17 per cent of global wheat

consumption. In addition, the by-products from milling

of wheat into our are also used as feed. The annual

global production of dry wheat is about 529 Tg whereby

Asia (43%) and Europe (32%) are the primary producers.

Like rice, China is the largest producer of wheat with

about 18% of global production at an average yield of

3:4 dry mg ha

-1

.The second largest producer is India,

where dry wheat production is 71 Tg (12%), and the

yield is 2:4 dry mg ha

-1

(Seungdo et al 2004).

India produces wheat in appreciable amount that can

be a very good raw material for bioethanol production.

Secondly, a huge quantity of wheat is wasted every year

due to mismanagement; lack of proper storing facilities

in the warehouses and spoiled wheat can also be utilized

for bioethanol production. In the present Indian scenario

as per estimates provided by Food Corporation of India

(FCI) huge quantities of cereal grains are getting spoiled

every year due to unfavorable climatic conditions and

become un t for human and animal consumption. There

are about one million tons of damaged and spoiled

grains lying unutilized in FCI stores (Kumar et al 1999).

As far as wheat is concerned, Comptroller and Audi-

tor General (CAG) (2017) reported that Food Corporation

of India’s (FCI) wheat stock worth 700 crores was dam-

aged solely in Punjab from 2011 to 2016 as the grain

was kept in open areas attributed to the lack in stor-

age facility (Anonymous 2017). All this damaged grains

were disposed off as they were not t for consumption

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS UTILIZATION OF DAMAGED AND SPOILED WHEAT GRAINS FOR BIOETHANOL PRODUCTION 661

Nadia Razdan and G.S. Kocher

by human and animals. Belboom et al (2015) reported

that the consumption of 1 MJ bioethanol produced from

wheat instead of 1 MJ gasoline can reduce greenhouse

gas emissions by 42.5 - 61.2%.

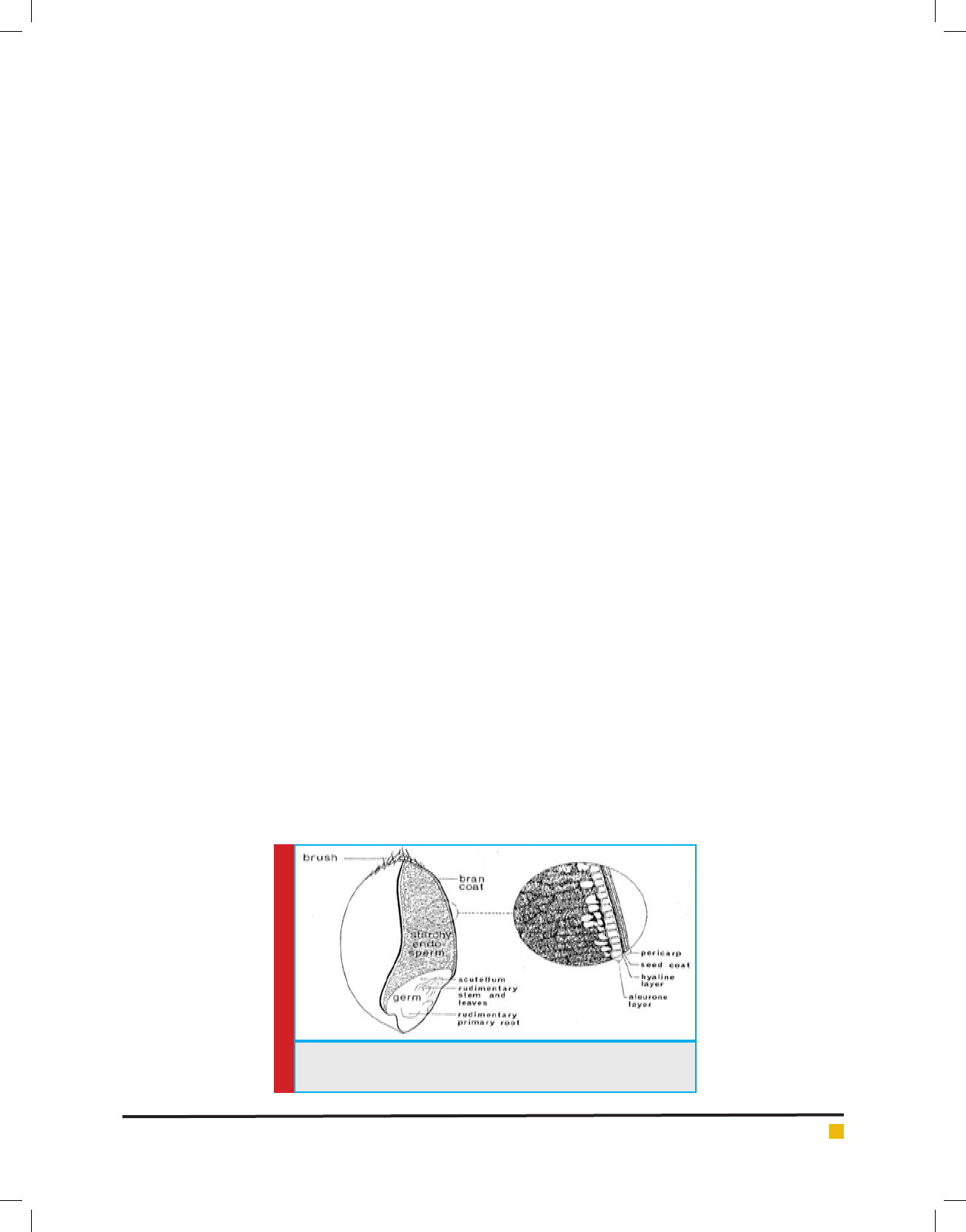

Structure and composition of wheat grain

Wheat, derived from the wild (Triticum aestivum L.) is

today the fth major cereal plant cultivated in the world

(Fig 2.1). Besides growing wheat for food purposes, there

is also an interest in wheat cultivars for non-food and

technical uses starch and bioethanol production (Kust

and Potmesilova 2014). Damaged wheat grains could be

an economical carbon source for ethanol fermentation

in the industry, because of high starch content and low

commercial value. Yan et al (2010) tested eld-sprouted-

sorghum and concluded that the use of these kernels sig-

ni cantly reduced fermentation time and yielded higher

ethanol. Starch or amylum is a polymeric carbohydrate

comprising of a large number of glucose units joined by

glycosidic bonds and contains two main structural com-

ponents, amylose and amylopectin. Amylose is essen-

tially a linear polymer in which the glucose residues are

connected by the -1, 4 linkages. The other main com-

ponent of starch is amylopectin, which is a larger and

branched molecule with both -1, 4 and -1, 6 link-

ages. Most native wheat starch is a mixture of amylose

and amylopectin, in the ratio of 1:3 by weight. The con-

tent of amylose in wheat starch generally ranges from

20–26% (Buresova et al 2010).

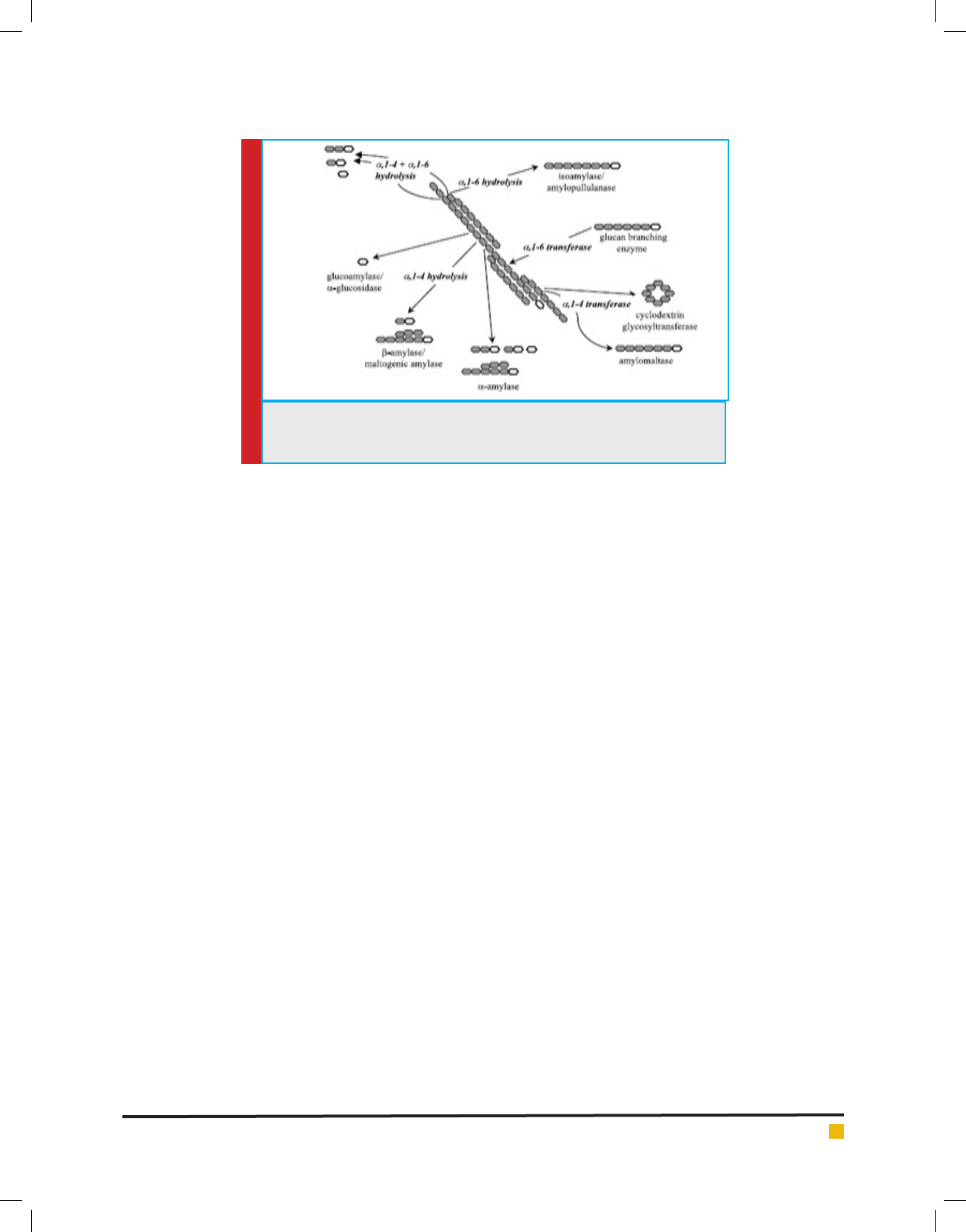

STARCH HYDROLYSIS

In industry, starch is converted into sugars or fermented

to produce ethanol. Starch cannot be metabolized

directly by yeast, but must rst be broken down into

simple six carbon sugars (glucose) prior to fermentation.

The conversion of starch-containing feedstock to obtain

fermentable sugars is mainly comprised of three opera-

tions which are: (i) milling, (ii) liquefaction and (iii) sac-

chari cation using enzymes.

The rst stage of starch hydrolysis is gelatinization

which is to break down the intermolecular bonds of

starch with heat in the presence of water. Starch gran-

ules are quite resistant to penetration by both water and

hydrolytic enzymes due to the formation of hydrogen

bonds within the molecule and other molecules. How-

ever, these intra and inter- hydrogen bonds are weak-

ened during gelatinization. During this stage, the tem-

perature of aqueous suspension of starch is elevated,

the water absorption and expanded granules dissolving

starch granules to form a viscous suspension or slurry.

This allows disruption or burst of the starch granules

and exposes it to enzyme attack. This process is known

as gelatinization and the temperature at which starch

properties are changed is named as gelatinization tem-

peratures (Albani 2008). The susceptibility of starch to

amylase attack depends on the properties of the speci c

starch, such as e.g. degree of gelatinization and the char-

acteristics of the speci c amylase (Bijttebier et al 2008).

Different starches have different gelatinization tempera-

tures, implying different ease of cooking. Cassava starch

has a lower temperature, relatively to cereal starches; the

pasting temperatures for cassava, corn, wheat and rice

are 60-65ºC, 75-80ºC, 80-85ºC and 73-75ºC, respectively

(Swinkels 1998; Thirathumthavorn and Charoenrein

2005). The physicochemical properties of starch impose

limitations in the use of higher starch concentrations

as a result of gelatinization of the starch which causes

undesirable viscosity development.

Liquefaction is a step that starch is degraded by an

endo-acting enzyme namely alpha –amylase (EC 3.2.1.1)

which hydrolyzes only -1, 4 and causes dramatically

drop in viscosity of cooked starch. Typically, liquefying

enzymes can have an activity at a high temperature (>

85°C) so that the enzyme can help reduce paste viscos-

ity of starch during cooking. The dextrins, i.e. products

FIGURE 1. Wheat grain cut lengthwise through crease (Pomeranz

1988)

662 UTILIZATION OF DAMAGED AND SPOILED WHEAT GRAINS FOR BIOETHANOL PRODUCTION BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Nadia Razdan and G.S. Kocher

obtained after liquefaction, is further hydrolyzed ulti-

mately to glucose by glucoamylase enzyme which can

hydrolyze both -1,4 and -1,6 glycosidic linkage in

amylase and amylopectin branches of starch. Glucoam-

ylase (GA), also known as amyloglucosidase (EC 3.2.1.3),

is an inverting type and exo-acting enzyme, capable of

hydrolyzing -1,4 glycosidic linkages in raw or soluble

starches and related oligosaccharides with the inversion

of the anomeric con guration to produce glucose.

The starch-based bioethanol industry has been com-

mercially viable for about 30 years; in that time, tre-

mendous improvements have been made in enzyme

ef ciency, reducing process costs, time, increasing

hydrolysis and bioethanol productivity. Hydrolysis of

starch may be considered as a key step in the process-

ing of starch-based feedstock for the bioethanol produc-

tion. Starch can be hydrolyzed by acid, acid-enzyme and

enzyme-enzyme techniques.

Acid hydrolysis (lintnerization)

Acid hydrolysis is an important chemical modi cation

that can signi cantly change the structural and func-

tional properties of starch without disrupting its granular

morphology. During acid hydrolysis, amorphous regions

are hydrolysed preferentially, enhancing the crystallin-

ity and double helical content of acid hydrolyzed starch

(Wang and Copeland 2013). According to Dziedzic and

Kearsley (2012) acid hydrolysis was discovered at the

beginning of the 19

th

century by boiling wheat starch

with dilute sulphuric acid results in a sweet syrup. Later,

potato starch was used as the starch source and sulphu-

ric acid was replaced by hydrochloric acid and indirect

heating of the reaction vessel was common practice.

Since then, acid has been used to a great extent for the

breakdown of starch into glucose particularly in indus-

try. Bej et al (2008) had investigated on concentrated

acid hydrolysis (H

2

SO

4

) of wheat our in a batch reac-

tor at different temperatures and acid concentrations. A

maximum conversion (42%) of starch to the reducing

sugars was obtained at 95°C and pH 3.

Similarly, Hoseinpour et al (2010) showed that

hydrolysis of starch using dilute sulphuric acid leads to

complete conversion to glucose under optimum condi-

tions of 130°C, 1% acid and 7.5% solids loading for 30

minutes. The mineral acid or acid-base involved in the

hydrolysis can be of diluted or concentrated form and

dilute acid process at 1-5% concentration is conducted

under high temperature, pressure and has fast reaction.

The concentrated acid process on the other hand uses

relatively mild temperatures and reaction times are typi-

cally much longer as compared to dilute acid hydrolysis.

The biggest advantage of dilute acid processes is their

fast reaction rate, which facilitates continuous process-

ing for hydrolysis of both starch and cellulosic materi-

als. Their prime disadvantage however is the low sugar

yield and this has opened up a new challenge to increase

glucose yields higher than 70% (especially in cellulosic

material) in an economically viable industrial process

while maintaining high hydrolysis rate and minimizing

glucose decomposition (Xiang et al 2004; McConnell

2008). The concentrated acid hydrolysis offers high

sugar recovery ef ciency, up to 90% of both hemicellu-

loses and cellulose sugars. However, this technique does

have a number of drawbacks such as relatively low yield

and formation of undesirable by-products (Ramprakash

and Muthukumar 2014).

Enzymatic hydrolysis

In the last decade, the starch industry has transformed

from using acid in the hydrolysis process to enzyme. The

acid was largely replaced by enzyme which gives 95%

more yield of glucose (Hua and Yang 2016). Enzymatic

hydrolysis of starch requires two types of enzymes due

to the fact that starch or amylum comprises of two major

components, namely amylose, a mainly linear polysac-

charide consisting of -1,4-linked -glucopyranose

units and the highly branched amylopectin fraction that

consists of -1,4 and -1,6-linked -glucopyranose

units (Knox et al 2004). These two types of linkages,

-1, 4 and -1,6-linked required an ef cient starch

hydrolysis agent or enzyme that can fraction -1,4 and

promote -1,6 debranching activity which leads to a

reduction in viscosity of gelatinized starch in the lique-

faction process. There are certain type of carbohydrate-

degrading enzymes include a -amylases, b -amylases,

debranching enzymes, cellulases, b -glucanases and glu-

cosidases etc. The process of enzyme hydrolysis involves

hydration of starch by heating the starch in aqueous

suspension to give -amylase an access to hydrolyze

the starch (Fig 2). Exoamylases such as glucoamylase

is added during sacchara cation which hydrolyses 1,4

and 1,6-alpha linkages in lique ed starch(Maarel et al

2002).The important advantages of the sacchari cation

of starch by the amylase mode include higher yield and

purity, easy crystallization, better process control, lower

cost of production, ion exchange capacity, signi cant

reduction in energy requirement, elimination of heavy

depreciations on expensive corrosion resistant equip-

ment, production of new products and formation of

lower by-products (Barfoed 1967; Madsen and Norman

1973; Fullbrook 1984).

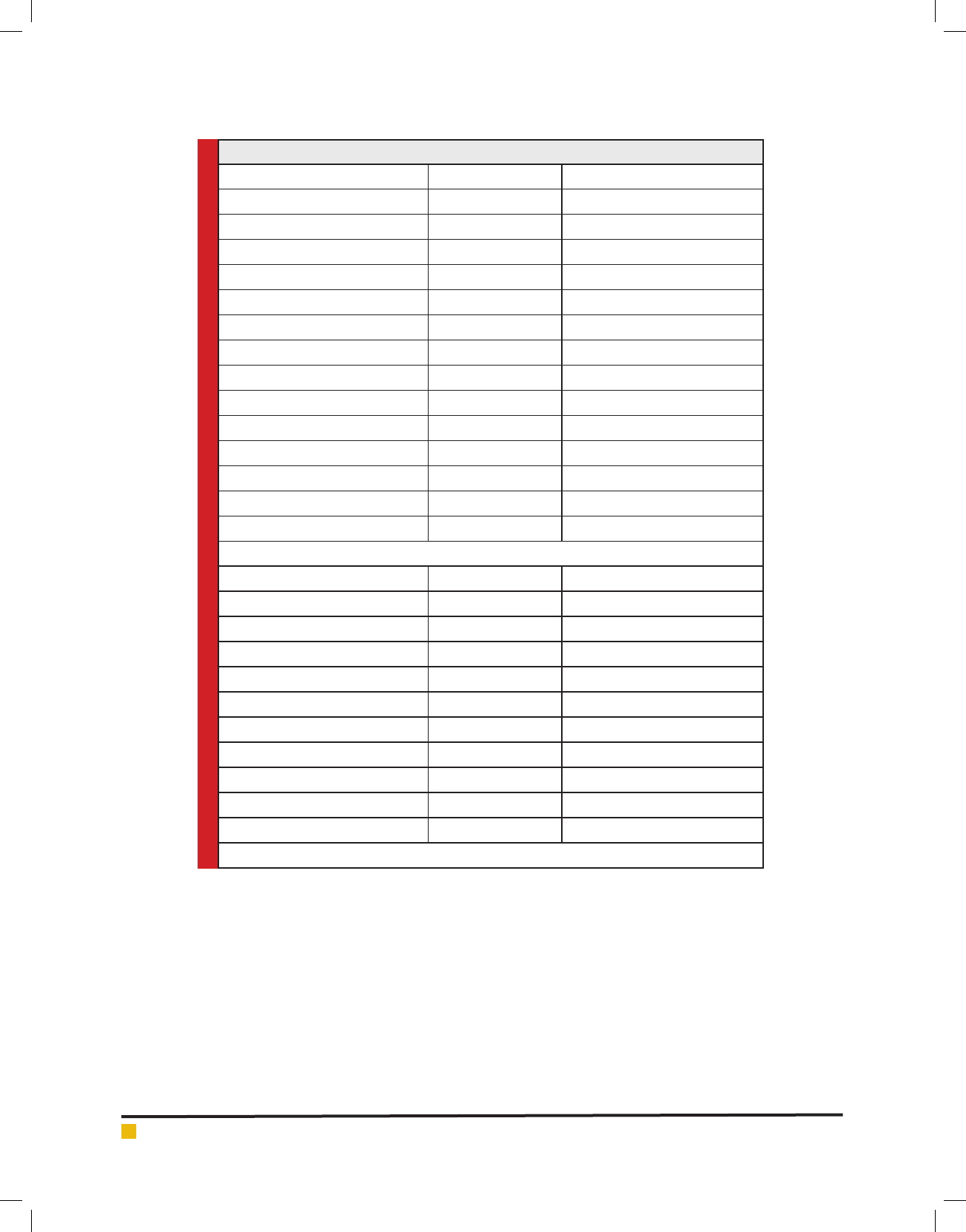

MICROBIAL DIVERSITY INVOLVED IN AMYLASE

PRODUCTION

The amylolytic microorganisms have immense applica-

tions in industries as well as in scienti c research as

they are more stable when compared with plant and ani-

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS UTILIZATION OF DAMAGED AND SPOILED WHEAT GRAINS FOR BIOETHANOL PRODUCTION 663

Nadia Razdan and G.S. Kocher

mal amylase. The major advantage of using microorgan-

isms for the production of amylases is the economical

bulk production capacity and the fact that microbes are

easy to manipulate to obtain enzymes of desired char-

acteristics. Though amylases are produced by several

fungi, yeast, bacteria and actinomycetes, but only a few

selected strains of fungi and bacteria meet the criteria

for commercial amylase production (Table 1).

Microbial production of alpha amylase

Pro ling microorganisms with high potential for amyl-

ase production in submerged fermentation (SmF) using

synthetic media has been widely recognized due to their

myriad applicability in bioethanol production. Raplong

et al (2014) identi ed Bacillus using mannitol egg yolk

polymyxin B (MYP) agar a highly selective media.They

reported that Bacillus cereus strain SB2 had largest zone

of hydrolysis of 12mm on nutrient agar supplemented

with starch. Amylase activity of 2.56U/ml was obtained

at pH (6.5), temperature (35ºC), incubation time (24 hr)

and inoculum concentration (4%) in submerged fermen-

tation. Singh and Kumari (2016) isolated starch degrad-

ing bacteria from soil samples collected from different

environment sources (Banana, Potato and Sugarcane

eld samples). Out of 10 isolated bacterial strains, Bacil-

lus sp. B3 gave positive starch hydrolysis and thus was

suggested for industrial application like starch modi -

cation with better ef ciency with the increase in tem-

perature.

Similarly, Rehman and Saeed (2015) investigated

39 amylase producing Bacillus sp. from soil of which

Bacillus sp. stain AS-2 was reported to have highest

enzyme activity (3179.62 IU/ml/min). Vaseekaran et al

(2015) isolated, identi ed and characterised thermo-

stable amylolytic bacteria from contaminated soil with

decaying materials i.e. kitchen waste and bakery waste

soil etc. Their investigation revealed one strain identi ed

as Bacillus licheniformis with highest -amylase activ-

ity (7.0±0.21 Um/L) at 24 h and enzyme showed neutral

optimum pH and temperature (90

o

C) without additives.

Dash et al (2015) also identi ed and optimized new

B. subtilis strain BI19 that produced appreciable amount

of amylase. Singh et al (2012) produced extracellu-

lar amylase by Bacillus sp. which was optimized in a

submerged fermentation as maximum enzyme activity

was obtained at 35°C and pH 7 and after 10 h inocula-

tion. In submerged fermentation, contents of a synthetic

medium are very expensive and uneconomical, so there

is urgent need of these to be replaced with more eco-

nomically available agricultural, industrial and domestic

by products which are used as substrates for SSF to pro-

duce enzymes in economical way.

SSF holds tremendous potential for the production

of enzymes in view of its economic and engineering

advantages. It can be of particular relevance in those pro-

cesses where a crude fermented product may be used as

an enzyme source (Pandey et al 1999). The major criti-

cal factors affecting microbial synthesis of enzymes in a

SSF system include selection of a suitable substrate and

strains, particle size of the substrate, inoculum concen-

tration, moisture level of the substrate, temperature and

pH. Selection of an appropriate solid substrate plays an

important role in the development of ef cient SSF pro-

cesses (Lonsane et al 1985). Sexena and Singh (2011)

carried out solid state fermentation using various agro-

industrial wastes with best amylase producing strain

isolated from soil. Different physicochemical conditions

were varied for maximum enzyme production. The iso-

FIGURE 2. Different enzymes involved in the degradation of starch. The open

ring structure symbolizes the reducing end of a polyglucose molecule (Maarel

et al 2002).

664 UTILIZATION OF DAMAGED AND SPOILED WHEAT GRAINS FOR BIOETHANOL PRODUCTION BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Nadia Razdan and G.S. Kocher

Table 1. Over view of amylase producing bacterial and fungal strains (Sundarram et al 2014)

Amylolytic Microorganism type Fermentation type Reference

B.amyloliquefaciens SSF Oboh (2005)

Bacillus licheniformis SSF Babu et al (1995)

Bacillus coagulans SSF Prakash et al (2009)

B. polymyxa SSF Prakash et al (2009)

B. mesentericus SSF Prakash et al (2009)

B. vulgarus SSF Prakash et al (2009)

B. megaterium SSF Prakash et al (2009)

Bacillus licheniformis GCB-U8 SmF Sodhi et al (2005)

Bacillus sp. PS-7 SSF Ramesh and Lonsane (1990)

Bacillus licheniformis M27 SSF Amoozegar et al (2003)

Halobacillus sp MA-2 SmF Gomes and Gomes (2003)

Halomonas meridiana SmF Kathiresan and Manivannan (2006)

Rhodothermus marinus SmF Anto et al (2006)

Bacillus cereus MTCC 1305 SSF Sivaramakrishnan et al (2007)

Fungi

Aspergillus oryzae SSF Leveque et al (2000)

Penicillium fellutanum SmF Erdal et al (2010)

Thermomyces lanuginosus SSF Upgade et al (2011)

Aspergillus niger SSF, Smf Yang and Wang (1999)

Penicillium roquefortii SSF Sivaramakrishnan et al (2006)

Streptomyces rimosus SSF, Smf Sudo et al (1994)

Aspergillus kawachii SSF, Smf Balkan and Ertan (2007)

Penicillium chrysogenumm SSF Sindhu et al (2009)

Penicillium janthinellum (NCIM 4960) SSF Prakasham et al (2007)

Aspergillus awamori SmF Siqueira et al (1997)

Pycnoporus sanguineus SSF Saito et al (1975)

*SSF-Solid state Fermentation ; * SmF- Submerged Fermentation

late produced about 5400 units/g of amylase at 1:3 mois-

ture content, 20% inoculum concentration, temperature

(50ºC), pH 6.0 and after 72 h of incubation with Mustard

Oil seed cake as the substrate. Similarly, Maity et al (2015)

utilized Bacillus subtilis (ATCC 6633) for production of

alpha amylase by optimization of the fermentation media.

They also reported that 80% retention of alpha amylase

activity comparable to puri ed porcine pancreatic amyl-

ase in the presence of drastic conditions of temperature

(60°C), pH (6-11), detergents and utilized various indus-

tries like detergent, food and paper industries.

RSM is a statistical and mathematical tool for design-

ing experiments, building models, evaluating the com-

bined effect of many variables to investigate the optimum

conditions for desirable response with reduced number

of required experiments. Tanyildizi et al (2005) com-

bined effects of macronutrients of media on -amylase

production by Bacillus sp. using response surface meth-

odology. The results showed that yeast extract had no

effect on -amylase production. The optimal combina-

tions of media constituents for maximum -amylase

production were determined as 17.58 g/l starch, 12.37%

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS UTILIZATION OF DAMAGED AND SPOILED WHEAT GRAINS FOR BIOETHANOL PRODUCTION 665

Nadia Razdan and G.S. Kocher

(v/v) glycerin and 8.77 g/l peptone. Similarly, Sun et

al (2011) optimized the process parameters through the

statistical approach for the production of alpha amyl-

ase by Bacillus subtilis ZJF-1A5 in submerged fermen-

tation. Among the variables screened, the temperature

and time were most signi cant and also showed a posi-

tive interaction. The optimum levels were: temperature

(35.8ºC), pH (5.03) and time (54hrs). Under these condi-

tions -amylase yield was 191.15 U/ml.

Puri cation is a key step in the enzymes produc-

tion where residual cell proteins and contaminants are

removed. The methods used to purify amylases can vary

considerably, but most puri cation protocols involve a

series of steps (Sun et al 2010). Aassar et al (1992) per-

formed the acetone fractionation of Bacillus lentus cul-

ture ltrate yielded the highest -amylase activity and

66.6% fraction reached 13-fold that of the crude enzyme

preparation. -amylase from Bacillus licheniformis was

puri ed 6-fold with a yield of 38% using by two gel

ltration chromatography steps on Sephadex G-100 and

Superose 12 column (Bozic et al 2011). In addition to

the classical chromatographic techniques, immunoaf n-

ity chromatography has been applied for the preparation

of highly puri ed amylases (Jang et al 1994). Abdu et

al (2011) identi ed a novel Bacillus cereus MS6 strain,

which could produce extra cellular amylase that was

puri ed by DEAE-Cellulose anion exchange and sepha-

rose gel ltration chromatography, resulting in high

yield of enzyme. The native protein showed a molecular

mass of 149 kDa being composed of a homo dimer of 78

kDa polypeptide by SDS–PAGE.

Biochemical characterization of alpha amylase

When de ning the proposed unit of activity for any

enzyme, the International Unit of Biochemistry stated

that reaction conditions should be speci ed as optimal.

This implies that enzyme activities are only valid within

a range of physical properties. Therefore, optimum con-

ditions for producing maximum enzyme activities need

to be determined.

Amenaghawon et al (2016) conducted a study of

enzymatic hydrolysis towards cocoyam starch and

found that the rate of hydrolysis was faster at a higher

temperature. Therefore, there has been a need and con-

tinual search for more thermophilic and thermostable

-amylase (Burhan et al 2003). Aassar et al (1992)

observed that the pure enzyme from Bacillus lentus

was stable at higher temperatures in the presence of its

substrate. It exhibited an optimum reaction temperature

of 70°C and retained about 42°-70°C of its activity at

85°C and even at higher temperatures the enzyme still

showed some activity. Weemaes et al (1996) studied sta-

bility of -amylases produced by B. amyloliquefaciens,

B. licheniformis and B. stearothermophilus under com-

bined high temperature and pressure and the results

indicated that -amylase produced by B. licheniformis

was the most stable enzyme.

The pH of a solution affects the structure and activ-

ity of enzymes. Khanna (2010) explained that pH has an

effect on the state of ionization of acidic or basic amino

acids. If the state of ionization of amino acids in a pro-

tein is altered then the ionic bonds that help to deter-

mine the 3D shape of the protein got changed. Sodhi et

al (2005) reported that -amylase of Bacillus sp. PS-7

strain showed pH optima at pH 6.5 and displayed 87

and 52% of peak activity at pH 6.0 and 5.0, respectively.

Elkhalil and Gaffar (2011) analysed the pH activity pro-

le of Bacillus sterothermophilus which showed an opti-

mum activity at pH 7 compared to the B. acidocaldarius,

with an activity optimum at pH 6. The relative activities

of Bacillus sterothermophilus at pH 9 and 10 were about

1.5 and 4.5 times higher than those of the B. acido-

caldarius. Similary, Qader et al (2006), who stated that

the optimum pH of Bacillus sp. AS-1 was around 7.5.

Most of amylases are known to be metal ion-dependent

enzymes, namely divalent ions like Ca

2+

, Mg

2+

, Mn

2+

,

Zn

2+

and Fe

2+

etc (Pandey et al 2000). Naja and Kemb-

havi (2005) studied the effects of chemical modi ers on

-amylase enzyme activity from marine Vibrio sp. The

results suggested the involvement of amino acids such

as Lys, Trp, Asp/Glu and His in enzyme activity. It also

has been reported that heavy metal ions such as Hg

2+

,

Ag

2+

and Cu

2+

inhibited amylase activity (Dey et al 2002).

Asoodeh et al (2013) studied the effect of metal ions

(K

+

, Na

+

, Zn

2+

, Ba

2+,

Mg

2+

, Ca

2+

, Fe

2+

and Hg

2+

), on the

enzyme activity. Among the testi ed metal ions, Mg

2+

,

Fe

2+

and Ba

2+

increased the amylase activity, while Hg

2+

and Zn

2+

were established to inhibit enzyme activity.

Asoodeh et al (2013) determined the kinetic parameters

by incubating 0.1 ml of enzyme (0.1 mg/ml) in the pres-

ence of 0.9 ml starch at different concentrations (0.1–1.2

% w/v). As estimated from Michaelis–Menten equation

the values of Km and Vmax for starch as substrate were

4.5 ± 0.13 mg/ml and 307 ± 12 lM/min/mg, respectively.

SIGNIFICANCE OF FUNGAL GLUCOAMYLASE

(GA) IN STARCH HYDROLYSIS

Glucoamylase (GA), also known as amyloglucosidase (EC

3.2.1.3), is an inverting and exo-acting enzyme, capa-

ble of hydrolyzing -1,4 glycosidic linkages in soluble

starches and related oligosaccharides with the inversion

of the anomeric con guration to produce glucose. In

addition to acting on -1,4 linkages, the enzyme slowly

hydrolyzes -1,6 glycosidic linkages of starch (Weil

et al 1954; Fierobe et al 1998). The widely accepted

mechanism of hydrolysis involves proton transfer from

the catalyst to the glycosidic oxygen of the scissile bond.

666 UTILIZATION OF DAMAGED AND SPOILED WHEAT GRAINS FOR BIOETHANOL PRODUCTION BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Nadia Razdan and G.S. Kocher

A general acid–base catalyst (McCarter and Withers,

1994; Sinnot, 1990; Tanaka et al 1994) donates hydro-

gen to the glucosidic oxygen and a catalytic base guid-

ing the nucleophilic attack by a water molecule on the

C-1 carbon of the glucose moiety.

Microbial production of glucoamylase

Traditionally, glucoamylase have been produced by

SmF. The development of microbial strains, media com-

position and process control has contributed to the

achievement of high levels of extracellular glucoamyl-

ase. Banakar et al (2012) investigated the amylase pro-

duction from fungal species by submerged fermentation

(SmF). The Production medium was supplemented with

2% (w/v) soluble starch incubated under shake culture at

a temperature of 28±1ºC, pH-7.0 for 7 days. Maximum

amylolytic activity was recorded with crude enzyme at

3rd day of incubation by Penicillium sp. (0.87±0.05 U/

mL) followed by Penicillium chrysogenum (0.69±0.05 U/

mL), Aspergillus candidus (0.67±0.03 U/mL), Aspergillus

fumigatus (0.066±0.06 U/mL) and at 7th day of incuba-

tion was by Penicillium sp. (1.13±0.03 U/mL) followed

by Penicillium chrysogenum (1.12±0.004 U/mL). Wang

et al (2008) investigated food waste (FW) as potential

substrate for the glucoamylase production by Aspergil-

lus niger UV-60 under submerged fermentation. They

reported that optimum concentration of 2.50% (dry

basis), smashed food waste (smashed-FW) produced glu-

coamylase of 126 U/ml after 96 h of incubation, whereas

137 U/ml of glucoamylase could be achieved within the

same time from raw food waste (raw-FW) of 3.75%.

Recently, Okwuenu et al (2017) optimized the produc-

tion of glucoamylase from Aspergillus niger in a sub-

merged fermentation process using amylopectin from

guinea corn starch as the sole carbon source. Speci c

activities for crude enzymes were found to be 729.45 U/

mg and 1046.82 U/mg at ve and twelve days harvested

enzymes, respectively. Benassi et al (2014) investigated

the production of glucoamylase from Aspergillus phoe-

nicis in Machado Benassi (MB) medium using 1% malt-

ose as carbon source. The maximum amylase activity

was recorded with temperature (60–65 °C) and pH (4.5)

after 4 days of incubation in static conditions. However,

the glucoamylase costs are still too high for the estab-

lishment of a cost effective production of energy syrup.

The SSF process has potential to signi cantly reduce

the enzyme production costs because of lower energy

requirements, increased productivity, smaller ef uent

volumes and simpler fermentation equipment (Ellaiah et

al 2002). Cereal bran ours, potato residue and other

starchy waste materials have been utilized as fermen-

tation substrate for glucoamylase production by la-

mentous fungi (Joshi et al 1999; Biesebeke et al 2005).

Glucoamylase production by A. niger was extensively

studied using wheat bran in SmF and SSF by Kaur et al

(2003). Wheat bran, paddy husk, rice processing wastes

or other starch containing wastes have gained impor-

tance as supports for fungal growth during glucoamyl-

ase production (Arasartnam et al 2001).

Sethi and Gupta (2015) isolated amylolytic fungi

from soil and identi ed them as Aspergillus niger, Pen-

cillium chrysogenum, Microsporium sp. and Fusarium

sp on the basis of morphological, biochemical character-

ization and starch hydrolysis assay, of these Pencillium

chrysogenum was most potent alkaline amylase produc-

ing fungi with highest enzyme activity under optimised

conditions i.e pH (8.0), temperature (45°C), wheat bran

(1%) and peptone incubated for 7 days. Indriati et al

(2018) reported that 3, out of 16 thermophile bacteria

produced high amylase activity in media supplemented

with wheat our @ 2% at 40-50ºC.

Zambare (2010) employed response surface method-

ology to optimize SSF medium and various parameters

for production of glucoamylase by Aspergillus oryzae

on the solid surface of rice husk, wheat bran, rice bran,

cotton seed powder, corn steep solids, bagasse powder,

coconut oil cake, and groundnut oil cake as substrates

which resulted in a 24% increase in the glucoamyl-

ase activity. Optimum glucoamylase production (1986

μmoles of glucose/min/g of fermented substrate) was

observed on wheat bran supplemented with 1%, (w/w)

starch, 0.25%, (w/w) urea at pH 6, 100%, (v/w) initial

moisture and 300ºC after incubation of 120 hrs.

Kiran et al (2014) utilized food wastes such as waste

bread, waste cakes, cafeteria waste, fruits, vegetables

and potatoes for glucoamylase production by solid state

fermentation. Response surface methodology was used

to optimize the fermentation conditions for improving

enzyme production and waste cake was the best sub-

strate for glucoamylase production. The highest glucoa-

mylase activity (108.47 U/gds) was achieved at initial pH

(7.9), moisture content (69.6% wt) and inoculum load-

ing 5.2×105 cells/g of substrate and incubation time of

6 days. Kumar and Satyanarayana (2004) improved the

glucoamylase production by a thermophilic mold Ther-

momucor indicae seudaticae in solid-state fermentation

(SSF) by applying response surface methodology (RSM).

The glucoamylase production containing wheat bran as

substrate, under the conditions optimized by RSM, was

455 ± 23 U/g of dry moldy bran (DMB) is higher than

those reported in the literature.

Similarly, Banerjee and Ghosh (2017) applied response

surface methodology, a statistical tool for the optimiza-

tion of glucoamylase production by Aspergillus niger

in solid state fermentation using garden pea peel as a

substrate. The optimized fermentation composition was

incubation time: 5 days; incubation temperature: 30°C;

and substrate amount: 3g, which resulted in GA produc-

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS UTILIZATION OF DAMAGED AND SPOILED WHEAT GRAINS FOR BIOETHANOL PRODUCTION 667

Nadia Razdan and G.S. Kocher

tion of 90.1728 Ugds-1.

In literature also, Alam et al

(2014) examined the effect of process parameters (pH,

inoculum concentration and agitation speed) on glucoa-

mylase production from bitter cassava by Aspergillus

niger using response surface methodology (RSM).Utmost

glucoamylase production of 38.30 U/ml was attained

under optimized conditions of pH, inoculum concentra-

tion and agitation speed of 4.8, 3.7 % (v/v) and 260 rpm,

respectively. Both the experimental and predicted results

were in agreement with each other as values of 38.30

U/ml and 38.07 U/ml were obtained respectively thus,

con rmed the validity of the developed model as well as

attainment of the optimal points.

Glucoamylase from various sources have been puri-

ed extensively by the procedures using several types of

column fractionations including ion-exchange, hydro-

phobic and gel ltration chromatographic steps. Bagheri

et al (2014) investigated a glucoamylase enzyme from

Aspergillus niger and puri ed it using fractionation, fol-

lowed by anion-exchange chromatography. The results

revealed that molecular mass of glucoamylase enzyme

was estimated to be 62,000 Da, using SDS–PAGE and

57151 Da, based on mass spectrometry. Slivinski et al

(2011) produced glucoamylase by Aspergillus niger in

solid-state fermentation. The enzyme was partially

puri ed by ammonium sulphate precipitation and ion

exchange and gel ltration chromatographies. Its molec-

ular mass was estimated as 118.17 kDa by electrophore-

sis. Okwuenu et al (2017) investigated the production

of glucoamylase from Aspergillus niger in a submerged

fermentation process using amylopectin fractionated

from guinea corn starch as the carbon source. The crude

enzyme with speci c activity 729.45 U/mg was puri ed

to the level of gel ltration (using sephadex G-100) via

ammonium sulphate (70%) precipitation and speci c

activities were found to be 65.98 U/mg and 180.52 U/

mg respectively.

Biochemical characterization of glucoamylase

Many glucoamylases derived from fungi were function-

ally active at thermophilic temperatures, usually 50 to

60 °C. The enzymes from Aspergillus niger NRRL 330

and Aspergillus awamori var. kawachi were optimally

active at 50 °C and 60°C, respectively whereas GAs of

Arthrobotrys amerospora were optimally active at 55.8ºC

(Spinelli et al 1996; Norouzian et al 2000). Ali and Hos-

sain (1991) reported that the optimum temperature for

the action of the glucoamylase was 60°C. The enzyme

was stable at temperatures between 40 and 60°C with

essentially no loss of activity in 30 min.

The rate of an enzyme catalysed reaction varies with

pH of the system. Slivinski et al (2011) produced glucoa-

mylase enzymes by Aspergillus niger in SSF and par-

tially puri ed and characterized them biochemically. The

partially puri ed enzyme had an optimum pH (4.5-5.0)

and temperature (60 °C), with an average activity 152.85

U ml

-1

. Jebor et al (2014) puri ed and characterized glu-

coamylase enzyme from Aspergillus niger The puri ed

glucoamylase (A&B) had a maximum activity at pH (8

and6.5) and temperature (40°C and 30°C) respectively.

It was also found that the K

m

and V

max

value of glucoa-

mylase (B) were (2.8 mM and 9.8 mM/min) respectively

using different concentration of starch. Banerjee and

Ghosh (2017) used garden pea peel as a substrate in SSF

by Aspergillus niger for the production of glucoamyl-

ase. The K

m

and V

max

for glucoamylase were 0.387 mg

of soluble starch ml

-1

and 35.03 U

-1

μl

-1

min

-1

respectively.

Okwuenu et al (2017) obtained Lineweaver-Burk plot

of initial velocity at different substrate concentrations

and K

m

and V

max

of the enzyme were found to be 770.75

mg/ml and 2500 μmol/min respectively. Vivian et al

(2014) reported the activation of glucoamylase from

Aspergillus phoenicis by manganese (Mn

2+

) and calcium

(Ca

2+

) ions. The rise in glucoamylase activity caused by

these metal ions (Ca

2+

, Zn

2+

, Co

2+

, Fe

2+

and Mn

2+

ions)

could be attributed to the ability of these metals ions

to serve as an electron donor or Lewis acid as they

participate directly in the catalytic mechanism of the

enzyme.

SYNERGISTIC USE OF ALPHA AMYLASE AND

GLUCOAMYLASE IN STARCH HYDROLYSIS

Kunamneni and Singh (2005) prepared crude amylases

from Bacillus subtilis ATCC 23350 and Thermomyces

lanuginosus ATCC 58160 under SSF. The effect of vari-

ous process variables was studied for maximum conver-

sion ef ciency of maize starch to glucose using crude

amylase preparations. Doses of pre-cooking and post-

cooking amylase, glucoamylase and sacchari cation

temperature were found to produce maximum conver-

sion ef ciency and were optimization of fermentation

process. Maximum conversion ef ciency (96.25%) were

recorded at pre-cooking and post-cooking -amylase

(2.243 and 3.383 U/mg solids) respectively and glucoa-

mylase (0.073 U/mg solids) at sacchari cation temper-

ature (55.1 ºC). Soni et al (2003) isolated Bacillus sp.

AS-1 and Aspergillus sp. AS-2, producing very high

titres of thermostable -amylase and glucoamylase (198

950 and 3426 U/g fermented dry matter, respectively),

during SSF of wheat bran. Both enzymes were active

and stable over a wide range of temperature and pH.

-Amylase exhibited a high liquefying ef ciency (96%)

while glucoamylase revealed high sacchari cation ef -

ciency (87%), in a 15% starch solution, at 50.8ºC. When

used in combination, these enzymes could effectively

hydrolyzed wheat mash revealing a maximum conver-

sion ef ciency (96%).

668 UTILIZATION OF DAMAGED AND SPOILED WHEAT GRAINS FOR BIOETHANOL PRODUCTION BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Nadia Razdan and G.S. Kocher

Sodhi et al (2005) used alpha amylase from Bacil-

lus sp. PS-7 in combination with a standard commer-

cial amyloglucosidase (AMG), BioglucanaseTM in the

hydrolysis of malt starch for alcohol production. It was

found that the laboratory alpha amylase preparation

worked very well in the synergistic use with AMG, with

over all mashing ef ciency (89.0 %), overall ef ciency

(79.5 %) and alcohol yields (25.43 %) and also competed

well with the commercial alpha -amylase preparation,

PromaltTM, commonly used in combination with Bio-

glucanaseTM, a commercial amyloglucosidase, for malt

starch hydrolysis in Indian breweries and distilleries.

ETHANOLIC FERMENTATION OF WHEAT

HYDROLYSATE

Direct fermentation of starch using amylolytic micro-

organism offers a better alternative to the conventional

multistage employing commercial amylases for lique-

faction and sacchari cation followed by yeast fermen-

tation (Verma et al 2000; Knox et al 2004). By using this

amylolytic microorganism in direct fermentation, the

ethanol production cost can be reduced via recycling of

microorganism back to fermenters, thereby maintaining

a high cell density, which facilitates rapid conversion

of substrate into ethanol. However, there are very few

types of amylolytic yeasts that are capable of ef ciently

hydrolyzing starch. Recombinant microbes and mix

of amylolytic microorganism with glucose fermenting

yeast in co-culture fermentation can be used to enhance

starch hydrolysis and fermenting ef ciency.

Review of literature has revealed that ability of yeast

strains to achieve high level of ethanol strongly depends

on the nutritional conditions and protective functions.

The immobilization of fermenting organism for the

bioethanol production has been greatly explored as a

strategy to overcome substrate and product inhibition

and to improve the ethanol tolerance (Ljiljanamojovic et

al 2009 In Separate Hydrolysis and Fermentation (SHF)

con guration, the enzyme production, hydrolysis of

biomass, hexose and pentose fermentation are carried

out in separate reactors and at their optimum fermenting

conditions (Lynd et al 2002).

The disadvantages of SHF led to the development of

Simultaneous Sacchari cation and Fermentation (SSF)

process (Wright et al 1988). It is generally accepted that

integration of the enzymatic sacchari cation and fer-

mentation step which are carried out in one vessel so

called simultaneous sacchari cation and fermentation

(SSF) process could reduce the production cost and pro-

cess time compared to conventional separate hydrolysis

and fermentation (SHF) process (Mojovic et al 2006). The

presence of yeast or bacteria along with enzymes mini-

mizes the sugar accumulation in the vessel because the

fermenting organism immediately consumes the released

sugars. Since sugar produced during starch breakdow n

slows down -amylase action, higher rates, yields and

concentrations of ethanol are possible using SSF rather

than SHF, at lower enzyme loading. Additionally, the

presence of ethanol makes the mixture less vulnerable

to contamination by unwanted microorganisms, which

is a frequent burden in case of industrial processes (Bai

et al 2008).

In literature, Kumar et al (1999) used simultaneous

sacchari cation and fermentation to produce ethanol

from starch of damaged quality wheat and sorghum

grains by employing crude amylase preparation from B.

subtilis VB2 and an amylolytic yeast strain S. cerevisiae

VSJ4. They reported that 25% concentration of damaged

wheat and sorghum starch was found to be optimum for

damaged wheat and sorghum starch yielding 4.40%V/V

and 3.50%V/V ethanol respectively. Whereas 25% raw

starch of ne quality wheat and sorghum grains gave

an yield of 5.60%V/V and 5.00%V/V respectively. Simi-

larly, simultaneous sacchari cation and fermentation

(SSF) of damaged grains of sorghum and rice was con-

ducted using Aspergillus niger (NCIM 1248) and Sac-

charomyces cerevisiae VSJl. More yield of ethanol was

produced from the damaged sorghum (2.90% v/v) than

damaged rice (2.09% v/v) under optimal fermentation

conditions (Kumar et al 1998). Recent research studies

on Simultaneous Sacchari cation and Fermentation

(SSF) of damaged corn grains using symbiotic strains

of starch digesting Aspergillus niger (NCIM 1248 and

sugar fermenting Saccharomyces cerevisiae (MTCC 170)

revealed that SSF of damaged corn grains yielded maxi-

mum ethanol concentration of 4.24 (g/100ml) whereas

ne corn grains yielded (6.3 g/100ml) ethanol (Gawande

and Patil 2018).

Waste potato mash was chosen as a renewable carbon

source for ethanol fermentation because it is relatively

inexpensive compared with other feedstock considered

as food sources. Izmirlioglu et al (2012) optimized the

parameters for ethanol fermentation using response sur-

face methodology to achieve maximum ethanol produc-

tion. The study revealed that pH (5.5) and 3% inoculum

size were optimum for maximum ethanol concentration.

The maximum bio-ethanol production rate was attained

at the optimum conditions of 30.99 g/L ethanol. Hence,

waste potato mash was found as a promising carbon.

Current and future perspectives

This review paper investigated the potential for utiliza-

tion of spoiled wheat grains for bioethanol. The main

source for ethanol production in India is still molas-

ses which single handedly cannot sustain the demand.

Hence, there is need to look for alternate substrates for

meeting the increasing ethanol production. Secondly,

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS UTILIZATION OF DAMAGED AND SPOILED WHEAT GRAINS FOR BIOETHANOL PRODUCTION 669

Nadia Razdan and G.S. Kocher

thermostable alpha amylases are a more recent research

which may reduce energy on cooling the mash prior to

sacchari cation. It is also imperative to standardize the

mash composition by optimizing solid-liquid ratio, addi-

tion of protease etc and mash environment (optimum

temperature and pH). Further, to lower down the cost

of fermentation recombinant glucoamylase-expressing

yeasts were utilized to improve the ef ciency of starch

fermentation. The process cost may be further reduced

by using this process as it reduces the time as well as

energy by using two different vessels for sacchari ca-

tion and fermentation besides lowering the chances of

contamination.

Genetic engineering approaches should be more

focused on developing new improved strains with higher

substrate tolerance and improved production kinetics.

Though using damaged grains will incur lower substrate

cost, mashing involves costly commercial sacchari ca-

tion and enzymes which may also be taken care of by

using indigenous culture of Bacillus subtilis, Bacillus

circulans, Bacillus cereus etc for -amylase and Asper-

gillus sp. such as Aspergillus niger, Aspergillus oryzae

etc for glucoamylase. Thus, utilization of especially

damaged and spoiled wheat grains pave better way for

commercialization of bioethanol production from an

economical perspective.

REFERENCES

Aassar S A E, Omar S H, Gouda M K, Ismail A M, Abdel-Fattah

A F (1992) Puri cation of

-amylase from Bacillus lentus cul-

tures. Appl Microbiol Biotechnol 38: 312-314.

Abu T F A, Enujiugha V N, Sanni D M and Bamidele O S (2014)

Puri cation and characterisation of

-amylase from Bacillus

subtilis isolated from fermented African locust bean (Parkia

biglobosa) seeds. Int J LifeSc Bt Pharm Res 3(4): 1-18.

Alam M Z, Khalaf A, Salleh H M and Salihu A(2014) Process

Optimization of Glucoamylase Production by Aspergillusniger

Using Bitter Cassava (Manihotes culenta). J Environ Biol 8(17):

42-47.

Albani J R (2008) Principles and Applications of Fluorescence

Spectroscopy. Oxford, UK: Blackwell.

Ali S and Hossain H (1991) Characteristics of glucoamylase

from Aspergillus terreus. J Appl Microbiol 71: 144-6.

Amenaghawon N, Osagie E and Ogbeide S (2016) Optimisa-

tion of Combined Acid and Enzymatic Hydrolysis of Cocoyam

Starch to Produce Fermentable Hydrolysate. Pertanika J Sci

Technol 24(1): 123-36.

Amoozegar M A, Malekzadeh F and Malik K A (2003) Produc-

tion of amylase by newly isolated moderate halophile Haloba-

cillus sp. Strain MA-2. J Microbiol 52: 353-59.

Anonymous (2017) FCI wheat worth Rs 700 crores got dam-

aged till Mar 2016 in Punjab: CAG (https://www.tribuneindia.

com/.../punjab/fci-wheat...damaged...punjab.../447086.html)

Anto H, Trivedi U and Patel K (2006)

-Amylase production

by Bacillus cereus MTCC 1305 using solid-state fermentation.

Food Sci Biotechnol 44 (2): 241-45.

Arasaratnam V, Mylvaganam K and Balasubramaniam K (2001)

Improvement of glucoamylase production by Aspergillus niger

in solid-state fermentation with paddy husk as support. J Food

Sci Technol 38: 334-38.

Asoodeh A, Alemi A, Heydari A and Akbari J (2013) Puri-

cation and biochemical characterization of an acidophilic

amylase from a newly isolated Bacillus sp. Extremophiles 17:

339-48.

Awasthi P, Shrivastava S, Kharkwal A C and Verma A (2015)

Biofuel from agricultural waste. Int J Curr Microbiol App Sci

4: 470-77.

Babu K R and Satyanarayana T (1995)

-Amylase production

by thermophilic Bacillus coagulans in solid state fermentation.

Process Biochem 30 (4): 305-09.

Bagheri A, Khodarahmi R,Mostafaie A(2014)Puri cation and

biochemical characterization of glucoamylase from a newly

isolated Aspergillus niger: Relation to starch processing. Food

Chem 161: 270–278.

Bai F W, Anderson W A and Moo-Young M (2008) Biotechnol

Adv 26: 89–105.

Balkan B and Ertan F (2007) Production of a-amylase from

Penicillium chrysogenum under solid-state fermentation by

using some agricultural by-products. Food Technol Biotechnol

45: 439-42.

Ballesteros I, Negro M J, Oliva J M., Cabanas A, Manzanares

P and Ballesteros M (2006) Ethanol production from steam-

explosion pretreated wheat straw. Appl Biochem Biotechnol

130: 496 -508.

Banakar S P, Thippeswamy, Thirumalesh and Naveenkumar K

(2012) Isolation, Production and Partial Puri cation of Fungal

Amylase from Forest Soils of Bhadra Wildlife Sanctuary, West-

ern Ghats. J Pharm Biotech and Microbiol 20(3): 1-8.

Banerjee S and Ghosh U (2017) Production and Characteriza-

tion of Glucoamylase by Aspergillus niger. Appl Food Biotech-

nol 4(1): 19-26.

Banerjee S and Ghosh U (2017) Production and Characteriza-

tion of Glucoamylase by Aspergillus niger. Appl Food Biotech-

nol 4(1): 19-26.

Barfoed H (1967) Die Verwendung von Enzymenbei der Her-

stellung von Dextrose und Starkes irup. Starke 19: 2-8.

Bej B, Basu R K and Ash S N (2008) Kinetic study on acid cata-

lyzed hydrolysis of starch. J Sci Ind Res 67: 295-98.

Belboom S, Bodson B and Leonard A (2015) Does the Produc-

tion of Belgian Bioethanol Fit with European Requirements

on GHG Emissions Case of Wheat. Biomass Bioenergy 74: 58-

65.

Benassi V M, Pasin T M, Facchini1, Joao J A and Lourdes M

D (2014) Novel glucoamylase activated by manganese and

calcium produced in submerged fermentation by Aspergillus

phoenicis. J Basic Microbiol 54: 333-39.

670 UTILIZATION OF DAMAGED AND SPOILED WHEAT GRAINS FOR BIOETHANOL PRODUCTION BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Nadia Razdan and G.S. Kocher

Biesebeke R, Record E, van Biezen N, Heerikhuisen M, Franken

A, Punt P J, and Hondel C A (2005) Branching mutants of

Aspergillus oryzae with improved amylase and protease produc-

tion on solid substrates. Appl Microbiol Biotechnol 69: 44-50.

Bijttebier A, Goesaert H and Delcour J (2008) Amylase action

pattern on starch polymers. Biologia 63: 989-99.

Bowler P, Towersey P J, Waight S G and Galliard T (1985)

Minor Components of Wheat Starch and Their Technological

Signi cance. In: Hill R D and Munck L (ed) New Approaches to

Research on Cereal Carbohydrates. Pp. 71-9 Elsevier Science,

Amsterdam, Holland.

Bozic N, Ruizb J, Lopez-Santinb J and Vujci Z (2011) Produc-

tion and properties of the highly ef cient raw starch digesting

-amylase from a Bacillus licheniformis. Biochem Eng J 53:

203-09.

Buresova I, Sedlackova I, Famera O and Lipavsky J (2010)

Effect of growing conditions on starch and protein content

in triticale grain and amylose content in starch. Plant Soil

Environ 56: 99-104.

Dash B K, Rahman M M and Sarker P K (2015) Molecular iden-

ti cation of a newly isolated Bacillus subtilis BI19 and opti-

mization of production conditions for enhanced production of

extracellular amylase. Biomed Res Int 2015 859: 1-9.

De Almeida Siqueira E M, Mizuta K and Giglio J R (1997) Pyc-

noporus sanguineus: a novel source of -amylase. Mycol Res

101(2): 188-90.

Dey G, Palit S, Banerjee R and Maiti B R J (2002) Puri cation

and characterization of malto oligosaccharide-forming amyl-

ase from Bacillus circulans GRS 313. Ind Microbiol Biotechnol

28: 193-200.

Dziedzic S Z and Kearsley M W (1995) Handbook of Starch

Hydrolysis Products and their Derivatives DOI 10.1007/978-1-

4615-2159-4 ISBN 978-1-4615-2159-4

EIA. 2015a. Annual energy outlook, Energy Information

Administration. Washington, D.C. Available at http: //www.

eia.gov/forecasts/aeo/MT_ liquid fuels. cfm (accessed on 10

August 2015).

EIA. 2015b. Net petroleum imports data- 2014, U.S Energy

Information Administration. Washington, D.C. Available at

http: //www.eia.gov/tools/faqs/faq.cfm?id=32&t=6 (accessed

on 10 August 2015).

Elkhalil L and Gaffar F Y (2011) Biochemical characterization

of thermophilic amylase enzyme isolated from bacillus strains.

Int J Sci Nat 2(3): 616-20.

Ellaiah P, Adinarayana K, Bhavani Y, Padmaja P and Sriniva-

sula B (2002) Optimization of process parameters for glucoa-

mylase production under solid state fermentation by a newly

isolated Aspergillus species. Process Biochem 38: 615-20.

Erdal S and Taskin M (2010) Production of alpha-amylase by

Penicillium expansum MT-1 in solid-state fermentation using

waste Loquat (Eriobotrya japonica Lindley) kernels as sub-

strate. Rom Biotechnol Lett 15(3): 5342-50.

Fierobe H P, Clarke A J, Tull D and Svensson B (1998) Enzy-

matic properties of ceystein sulfonic acid derivative of the cat-

alytic base mutant Glu400YCys of glucoamylase from Asper-

gillus awamori. Biochem 37: 3753-9.

Fullbrook P D (1984) The enzymatic production of glucose syr-

ups. In: Dziedsic S Z and Kearsley M W (Eds.) Glucose Syrups:

Science and Technology, pp. 65-115. Elsevier, London.

G Indriati* ; R R P Megahati, E Rosba Potency of Amylase-

producing Bacteria and Optimization Amylase Activities. IOP

Conf. Series: Materials Science and Engineering 335 (2018)

012023 doi:10.1088/1757-899X/335/1/012023

Gawande S B and Patil I D (2015) A review on causes for dam-

aged sorghum and corn grains. IJSSBT 3: 5-9.

Gawandea S and Patil I D (2018) Experimental investigation

and optimization for production of bioethanol from damaged

corn grains. Materials Today: Proceedings 5: 1509-17.

Gomes I, Gomes J and Steiner W (2003) Highly thermostable

amylase and pullulanase of the extreme thermophilic eubac-

terium Rhodothermus marinus: production and partial charac-

terization. Bioresource Technol 90(2): 207-14.

Gulten Izmirlioglu 1 and Ali Demirci Ethanol Production from

Waste Potato Mash by Using Saccharomyces cerevisiae Appl.

Sci. 2012, 2, 738-753; doi:10.3390/app2040738.

Hansen A C, Zhang Q and Lyne P W L (2005) Ethanol diesel

fuel blends a review. Bioresource Technol 96: 277-85.

Hoseinpour H, Karimi K, Zilouei H and Taherzadeh M J (2010)

Simultaneous pretreatment of lignocellulose and hydrolysis of

starch in mixtures to sugars. Bioresources 5(4): 2457-69.

Hua X and Yang R (2016) Enzymes in starch processing. In:

Chandrasekaran M (Ed.) Enzymes in Food and Beverage Pro-

cessing, pp. 139-70. Boca Raton: CRC Press.

Hua X and Yang R (2016) Enzymes in starch processing. In:

Chandrasekaran M (Ed.) Enzymes in Food and Beverage Pro-

cessing, pp. 139-70. Boca Raton: CRC Press.

Indian biofuels 2016 Gain report number IN608 (https://gain.

fas.usda.gov/.../Biofuels%20Annual_New%20Delhi_India_6-

24-2016).

Jang S, Cheong T, Him W, Kim J and Park K (1994) Puri cation

of Bacillus licheniformis thermostable -amylase by immune

af nity chromatography. Korean Biochem J 27: 38-41.

Jebor M A, Ali Z A and Hassan B (2014) Puri cation and char-

acterization of the glucoamylase from Aspergillus niger. Int J

Curr Microbiol App Sci 3(1): 63-75.

Joshi V K, Pandey A and Sandhu D K (1999) Waste treat-

ments in fermentation technology. In: Joshi V K and Pandey A

(Eds.) Biotechnology: Food Fermentation. Vol. 2, Trivandrum,

India: Educational Publication and Distribution, pp. 1291-

1338.

Kathiresan K and Manivannan S (2006) Amylase production

by Penicillium fellutanum isolated from mangrove rhizosphere

soil. Afr J Biotechnol 5: 1-10.

Kaur P, Grewal H S and Kocher G S (2003). Production of

-

amylase by Aspergillus niger using wheat bran in submerged

and solid state fermentations. Indian Journal of Microbiology.

43. 143-145.

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS UTILIZATION OF DAMAGED AND SPOILED WHEAT GRAINS FOR BIOETHANOL PRODUCTION 671

Nadia Razdan and G.S. Kocher

Kerr R W (1944) Chemistry and industry of starch: starch,

sugar and related compounds. Academic press, New York.

Khanna P (2010) Cell and Molecular Biology. I.K. International

Publishing House, New Delhi.

Kiran E U, Trzcinski A P and Liu Y (2014) Glucoamylase pro-

duction from food waste by solid state fermentation and its

evaluation in the hydrolysis of domestic food waste. Biofuel

Res J 3: 98-105.

Knox A M, Preez J C and Kilian S (2004) Starch fermentation

characteristics of Saccharomyces cerevisiae strains transformed

with amylase genes from Lipomyces kononenkoae and Saccha-

mycopsis buligera. Enzyme Microb Technol 34: 453-60.

Knox A M, Preez J C and Kilian S (2004) Starch fermenta-

tion characteristics of Saccharomyces cerevisiae strains trans-

formed with amylase genes from Lipomyces kononenkoae and

Sacchamycopsis buligera. Enzyme Microb Technol 34: 453-

60.

Kumar N V, Dhavala P, Goswami A and Maithel S (2006). Liq-

uid biofuels in South Asia: resources and technologies. Asian

Biotechnol Develop Rev 8: 31-49.

Kumar S and Satyanarayana T (2004) Statistical optimization

of a thermostable and neutral glucoamylase production by a

thermophilic mold Thermomucorindicae-seudaticae in solid-

state fermentation. World J Microbiol Biotechnol 20: 895-

902.

Kumar S, Kiransree N and Rao L V (1999) Production of etha-

nol by raw starch hydrolysis and fermentation of damaged

grains of wheat and sorghum. Bioprocess Eng 21: 165-68.

Kumar S, Kiransree N and Rao L V (1999) Production of etha-

nol by raw starch hydrolysis and fermentation of damaged

grains of wheat and sorghum. Bioprocess Eng 21: 165-68.

Kunamneni A and Singh S (2005) Response surface optimiza-

tion of enzymatic hydrolysis of maize starch for higher glucose

production. Biochem Eng J 27: 179-90.

Kust F and Potmesilova J (2014) Situation and Outlook Report:

Grain. Prague, Ministry of Agriculture of the Czech Republic.

(In Czech).

Leveque E, Janecek S, Haye B and Belarbi A (2000) Thermo-

philic archaeal amylolytic enzymes. Enzyme Microb Technol

26(1): 3-14.

Ljiljanamojovic, Dusankapejin, Olgicagrujic, Sinisamarkov,

Jelenapejin, Maricarakin, Majavukasinovic, Nikolic S, Dra-

gisasavic (2009) Progress in the Production of Bio-ethanol on

Starch Base Feed stocks. Chem Ind Chem Eng 15: 211-26.

Lonsane B K and Ramesh M V (1990) Production of bacterial

thermostable -amylase by solid-state fermentation: a poten-

tial tool for achieving economy in enzyme production and

starch hydrolysis. Adv Appl Microbiol 35: 1-56.

Lynd L R, Weimer P J, van Zyl W H, Pretorius IS microbial cel-

lulose utilization: Fundamentals and biotechnology. Microbiol

Mol Biol Rev. 2002 66(3):506-77.

Maarel M J E C, vander Veen B, Uitdehaag J C M, Leemhuis H

and Dijkhuizen L (2002) Properties and applications of starch-

converting enzymes of the -amylase family. J Biotechnol 94:

137-55.

Madsen G B, and Norman B E (1973) New speciality glucose

syrups. In: Birch G G and Green L G (Eds.) Molecular Structure

and Function of Food Carbohydrates, pp. 50-64. Appl. Sci.,

London

Maity S, Mallik S, Basuthakur M and Gupta S (2015) Optimiza-

tion of Solid State Fermentation Conditions and Characteri-

zation of Thermostable Alpha Amylase from Bacillus subtilis

(ATCC 6633). J Bioprocess Biotech 5: 1-7.

McCarter J D and Withers S G (1994) Mechanism of enzymatic

glycoside hydrolysis. Curr Opin Struct Bio 4: 885-92.

McConnell, C. (2008). Acid Hydrolysis. Qittle. 1st April 2011,

Available at http: //doyouqittle. com/2008/03/08/acid-hydrol-

ysis/

Mojovic L, Nikolic S, Rakin M. and Vukasinovic M (2006) Pro-

duction of Bioethanol from Corn Meal Hydrolyzates. Fuel 85:

1750-55.

Naja M F and Kembhavi A (2005) One-step puri cation and

characterization of an extracellular a-amylase from marine

Vibrio sp. Enzyme Microb Technol 36: 535-39.

Norouzian D, Rostami K, Nouri I D and Saleh M (2000) Sub-

site mapping of puri ed glucoamylases I, II, III produced by

Arthrobotry samerospora ATCC 34468. World J Microbiol Bio-

technol 16: 155-61.

Oboh G (2005) Isolation and characterization of amylase from

fermented cassava (Manihot esculenta Crantz) wastewater. Afr

J Biotechnol 4: 1-10.

Okwuenu P C, Agbo K U, Ezugwu A L, Eze S O and Chilaka F

C (2017) Effect of Divalent Metal Ions on Glucoamylase Activ-

ity of Glucoamylase isolated from Aspergillus niger. Ferment

Technol 6: 141-45.

Okwuenu P C, Ezugwu A L and Chilaka F C (2017) Produc-

tion and optimization of Aspergillus niger glucoamylase using

amylopectin from guinea corn starch as the sole carbon source.

J Sci Ind Res 52: 263-72.

Okwuenu P C, Ezugwu A L and Chilaka F C (2017) Produc-

tion and optimization of Aspergillus niger glucoamylase using

amylopectin from guinea corn starch as the sole carbon source.

J Sci Ind Res 52: 263-72.

Pandey A, Selvakumar P, Soccol C R and Nigam P (1999) Solid

state fermentation for the production of industrial enzymes.

Curr Sci 77: 149-62.

Pandey A, Soccol C R and Mitchell D (2000) New developments

in solid state fermentation: I-bioprocesses and products. Pro-

cess Biochem 35: 1153-69.

Pomeranz Y (1988) Chemical composition of kernel struc-

ture. In: Pomeranz Y (Ed) Wheat: Chemistry and Technology,

Vol I, 3

rd

Edn, St Paul, MN: Am Assoc Cereal Chem, pp. 97-

58.

Prakash B, Vidyasagar M, Madhukumar M S, Muralikrishna G

and Sreeramulu K (2009) Production, puri cation, and char-

acterization of two extremely halotolerant, thermostable and

672 UTILIZATION OF DAMAGED AND SPOILED WHEAT GRAINS FOR BIOETHANOL PRODUCTION BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Nadia Razdan and G.S. Kocher

alkali-stable amylases from Chromo halobacter sp. TVSP 101.

Process Biochem 44: 210-15.

Prakasham R S, Subba Rao C, Rao R and Sarma P N (2007)

Enhancement of acid amylase production by an isolated

Aspergillus awamori. J Appl Microbiol 102 (1): 204-11.

Qader S A U, Bano S, Aman A, Syed N and Azhar A (2006)

Enhanced production and extracellular activity of commer-

cially important amylolytic enzyme by a newly isolated strain

of Bacillus. sp. AS-1. Turk J Biochem 31(3): 135-40.

Ramprakash B and Muthukumar K (2014) Comparative study

on the production of biohydrogen from rice mill wastewater.

Int J Hydrogen Energy 39: 14613-21.

Raplong H H, Odeleye P O, Hammuel C, Idoko M O, Asanato J

I and Odeke E H (2014) Production of alpha amylase by Bacil-

lus cereus in submerged fermentation. Aceh Int J Sci Technol

3(3): 124-30.

Rehman A and Saeed A (2015) Isolation and screening of

amylase producing Bacillus species from soil. Int J Adv Res