Standardisation of recipe for batter and breaded

product Acetes cutlet from Jawala,

Acetes indicus

Kudale, A. S.

1

, Pagarkar, A. U.

2

, Gaikwad, B. V.

3

, Ranveer, R. C.

1

, Pujari, K. H.

1

, Rathod N. B.

1

,

H. Singh

2

, Shargandhar, S.T.

3

, Swami, S. B.

1

, Shingare, P. E.

4

, Phadtare M. C.

1

and

Sawant, N. H.

2

1

Post Graduate Institute of Post Harvest Management, Killa-Roha, Dist: Raigad, Maharashtra (India)

2

Marine Biological Research Station, (Dr. B. S. Konkan Krishi Vidyapeeth, Dapoli) Ratnagiri - 415 612,

Maharashtra (India)

3

College of Fisheries, Shirgaon, (Dr. B. S. Konkan Krishi Vidyapeeth, Dapoli) Ratnagiri - 415 629,

Maharashtra (India)

4

Taraporewala Marine Biological Research Station, (Dr. B. S. Konkan Krishi Vidyapeeth, Dapoli) Mumbai -

400052, Maharashtra (India)

ABSTRACT

Acetes is a small sized shrimp, locally known as ‘Jawala’ or ‘Kolim’ is landed along the north-west coast in the states

of Gujarat and Maharashtra, India. At present the fresh utilization of Acetes is very limited. One of the most important

food product is battered and bearded product. A standardized recipe of batter and breaded Acetes product is mentioned

in the paper. Acetes cutlet having a standard size of 2.0-3.5 cm in length cm diameter, 1 cm thickness and 0.2-0.5 g

weight Acetes cutlets were standardized by using different ingredients viz., cooked potatoes, salt, green chilly (C) and

ginger (G). Prepared of cutlets were standardized by organoleptic evaluation. It was found that, Acetes cutlet prepared

with the ratio of 75:100 (w/w), 20:100 (w/w), 5.5:100 (w/w), 5.5:100 (w/w) and 2.5:100 (w/w) for potato: Acetes mince,

onion: Acetes mince, green chilly: Acetes mince, ginger: Acetes mince and table salt: Acetes mince respectively, ratios

showed highest score as compared to other ratios tried in the experiments.

KEY WORDS: ACETES, BATTER AND BREADED PRODUCT, INGREDIENTS, SENSORY EVALUATION, VALUE ADDED PRODUCTS

563

Ichthyological

Communication

Biosci. Biotech. Res. Comm. 11(4): 563-570 (2018)

ARTICLE INFORMATION:

Corresponding Authors: pagarkarau@gmail.com,

ajaykudale21@gmail.com

Received 17

th

Sep, 2018

Accepted after revision 12

th

Dec, 2018

BBRC Print ISSN: 0974-6455

Online ISSN: 2321-4007 CODEN: USA BBRCBA

Thomson Reuters ISI ESC / Clarivate Analytics USA

Mono of Clarivate Analytics and Crossref Indexed

Journal Mono of CR

NAAS Journal Score 2018: 4.31 SJIF 2017: 4.196

© A Society of Science and Nature Publication, Bhopal India

2018. All rights reserved.

Online Contents Available at: http//www.bbrc.in/

DOI: 10.21786/bbrc/11.4/5

Kudale et al.

564 STANDARDISATION OF RECIPE FOR BATTER AND BREADED PRODUCT ACETES CUTLET BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

INTRODUCTION

Acetes is widely distributed in different parts of the

world with dominance along the coast of many coun-

tries bordering the Indian Ocean. Acetes is a small sized

shrimp, belongs to family Sergestidae, genus Acetes and

scienti cally named as Acetes indicus. In India, a sub-

stantial quantity of this group locally known as ‘Jawala’

or ‘Kolim’ is landed along the north-west coast in the

states of Gujarat and Maharashtra (Zynudheen, 2004;

Mahakal et al., 2016). At present the fresh utilization of

Acetes is very limited and people locally people consume

Jawala or Kolim regularly either in fresh or dried form

in the preparation of day-to-day food dishes. Acetes

is consumed mostly in dried form due to its availabity

throught out year in market. But consumption of dry

Acetes is more during non- shing season when fresh

sh is not available (Zynudheen et al., 2004; Mahakal et

al., 2016; Shaikh et al., 2017).

Now a days consumer’s particularly urban area are

showing more and more interest in seafood products

which are available in ready-to-eat or ready-to-cook in

convenience form. Recent scenario peoples both man and

women are engaged in jobs and they hardly nd time

to cook food. This leads to reasonably increase in their

income and they become more depend on ready-to-eat,

ready-to-cook and ready-to-fry types of products avail-

able in market (Balachandran, 2001; Pagarkar et al.,

2011). One of the most important foods in ready-to-eat

and ready-to-cook group is battered and breaded prod-

ucts. The process of coating with batter and bread crumbs

increases the bulk of the product, thereby reducing the

content of costly sh (Pagarkar et al., 2012). Keeping

this in view, the present research work was undertaken

to develop a battered and breaded product from low cost

shrimp locally called as Jawala or Kolim (Acetes indicus).

MATERIAL AND METHODS

Acetes (Acetes indicus) procured from sh market of Ali-

baug, district Raigad of Maharashtra coast of India, was

brought to processing hall under iced condition. Acetes

were washed with potable water, cleaned and cooked

in boiled water for 15 min., the cooked Acetes mince

was prepared using a grinder. Prepared Acetes mince

was placed in polythene bags then it was frozen and

stored in deep freezer at a - 20ºC temperature until fur-

ther use. As and when required, Acetes mince was taken

out and thawed before use. Cooked potatoes were peeled

and mashed and made into a ne paste. Chopped onions

were fried in sun ower oil till they became brown. Bread

crumbs were used as a coating material.

Standardization in the basic recipe (Pawar, et al.,

2012) as shown in Table 1 was used by varying the ratios

of different ingredients. Firstly the Acetes mince was

mixed with boiled potatoes, turmeric powder and salt,

a mixture of these was kept aside, then chopped onions

were fried in oil until brown in colour then mixed with

green chilly, ginger and garlic paste followed by the

powdered spices (Turmeric powder, pepper powder, cin-

namon powder and clove powder) then mixing of mince

base with the fried spices and cooked. Then cutlets of

40 g were taken and attened to 1cm thickness, dipped

into batter mix (Pawar, 2011) rolled over bread crumbs

and fried in sun ower oil till they became brown in col-

our then were subjected to sensory evaluation.

Acetes cutlet were prepared keeping the constant level

of oil 10 ml (w/w), powdered spices (Turmeric powder 0.2g

(w/w), pepper powder 0.3g (w/w), cinnamon powder 0.2g

(w/w), clove powder 0.3g (w/w)] and bread crumbs 20g

(w/w) while varying quantities of cooked potatoes, onion,

green chilly (C), ginger (G), and table salt, were used for

standardising the recipe. The fried cutlet were subjected to

organoleptic evaluation by a group of ten trained panellist

using 9 point hedonic scale (

ISI, 1975) on the attributes

such as colour, taste, texture, odour and overall accept-

ability. Potato was standardised in basic recipe and Acetes

cutlet was prepared with incorporation of different ratios

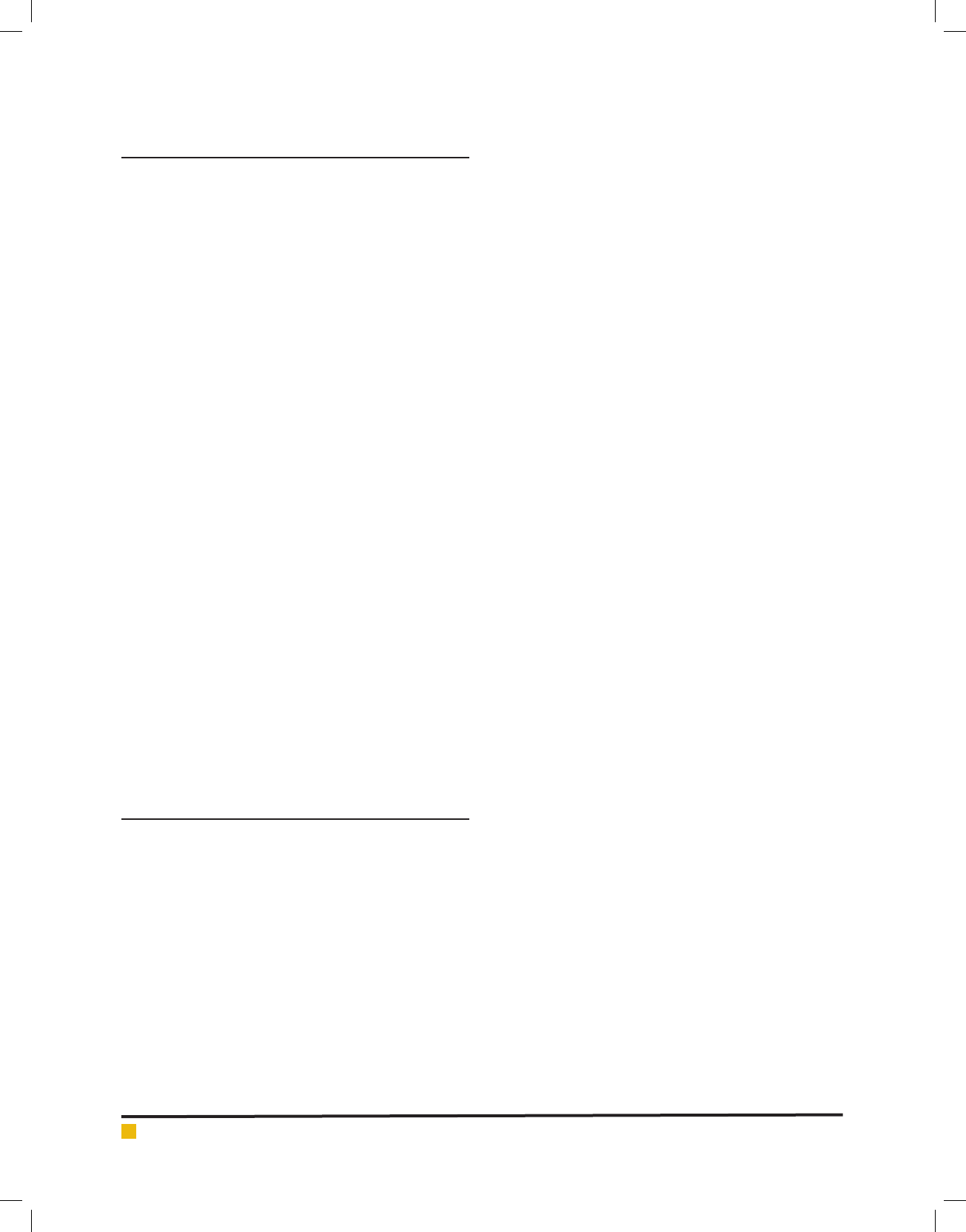

of potato to Acetes mince such as 60:100 (T1), 65:100 (T2),

70:100 (T3), 75:100 (T4) and 80:100 (T5) (w/w). All other

ingredients were kept constant. Organoleptic evaluations

were carried out to nd best ratio.

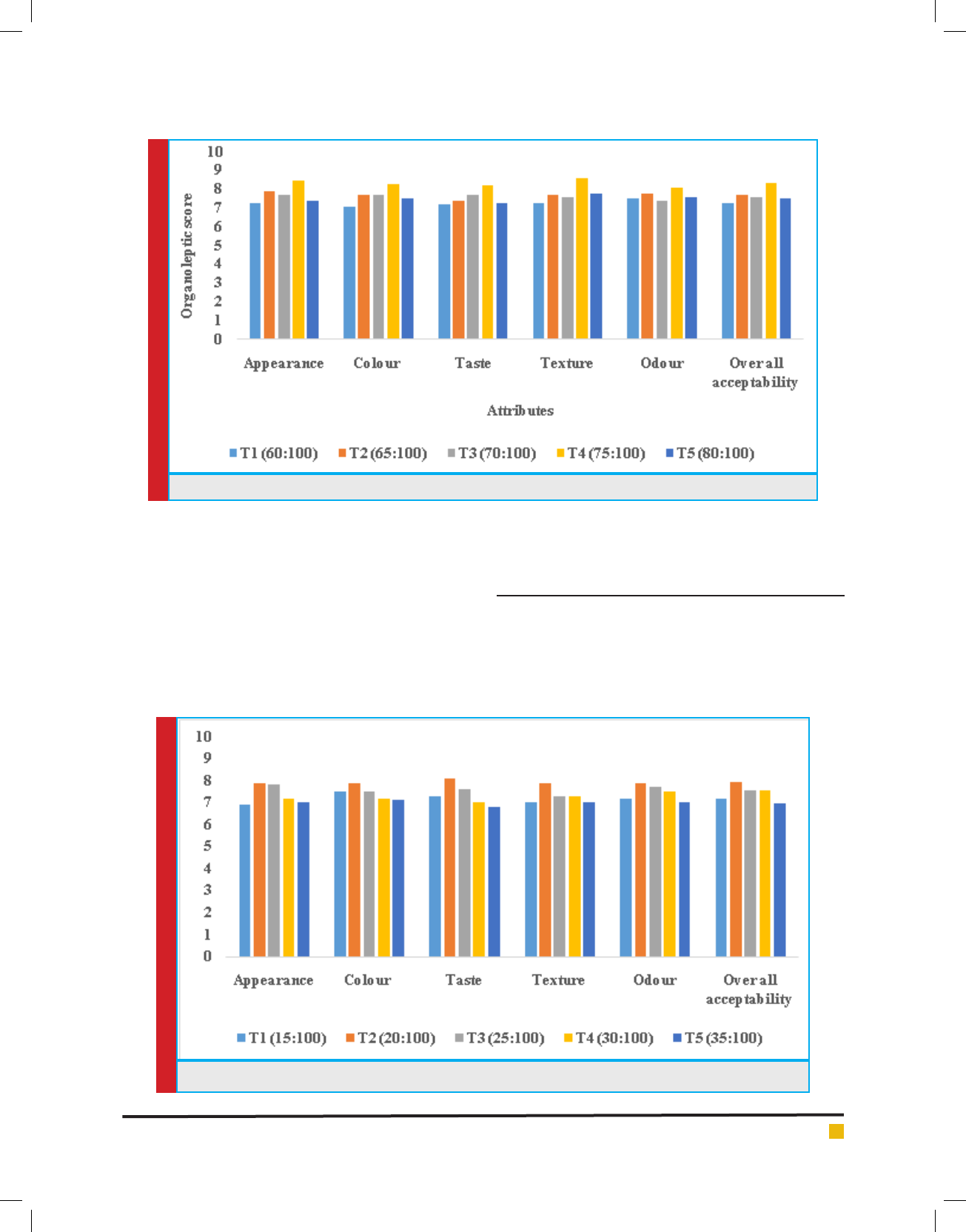

Onion was standardised in basic recipe and Acetes cut-

lets were prepared keeping the standard ratio of potato

obtained from its standardisation 75:100 (T4), with differ-

ent ratios of onion to Acetes mince, such as 15:100 (T1),

20:100 (T2), 25:100 (T3), 30:100 (T4) (w/w) and 35:100

(T5) (w/w). All other ingredients were kept constant and

prepared Acetes cutlets were organolpetically evaluated

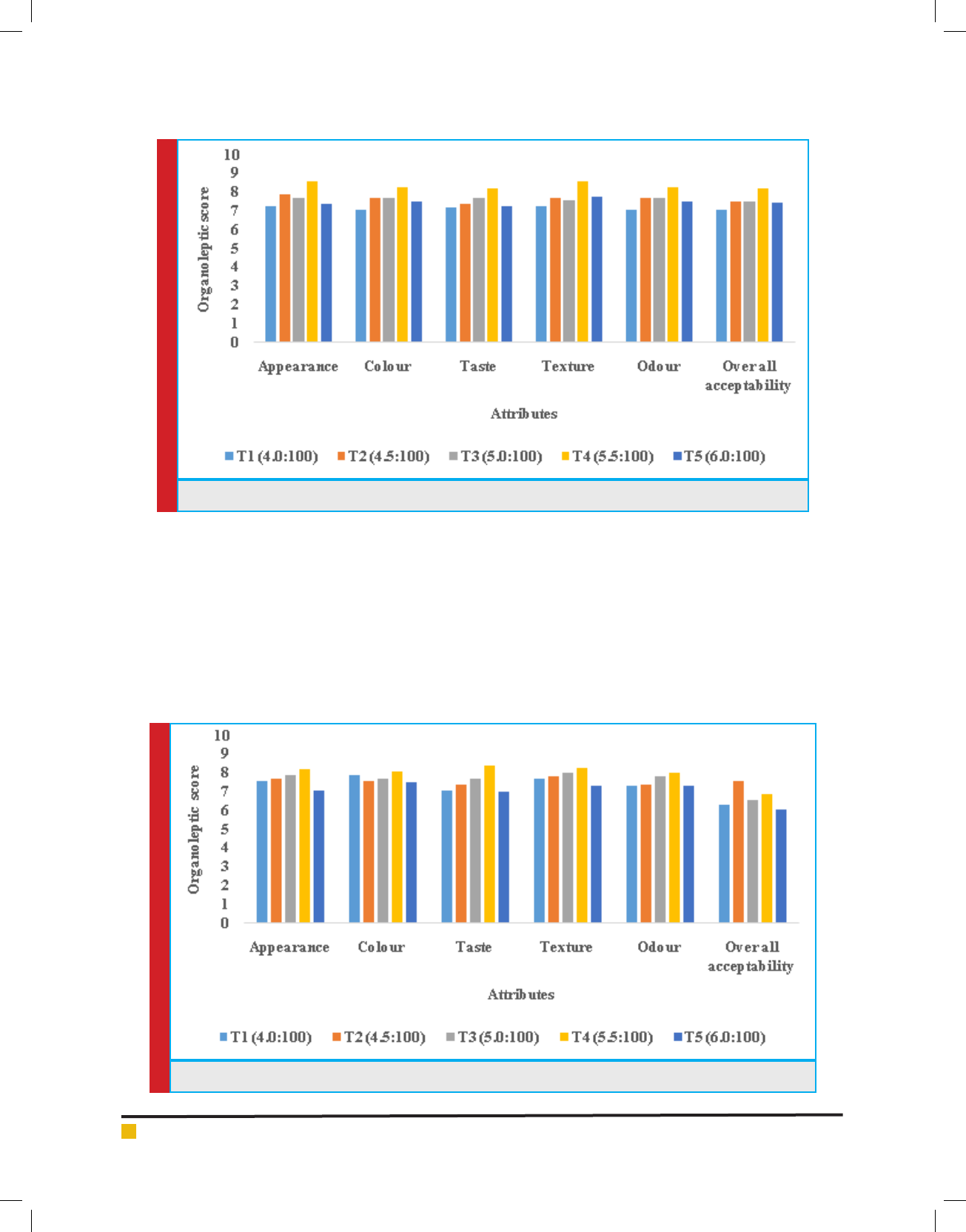

for the best combination. Raios of green chilly (C) was

standardised in basic recipe and Acetes cutlet was pre-

pared keeping standard ratio of potato 75:100 (T4) and

onion 20:100 (T2) with different ratios of green chilly (C)

to Acetes mince such as 4:100 (T1), 4.5:100 (T2), 5:100

(T3), 5.5:100 (T4) (w/w) and 6.0:100 (T5). All other ingre-

dients were kept constant. Prepared cutlets were organo-

leptically evaluated for the best combination.

Ratio of ginger (G) was standardised in basic recipe

and Acetes cutlets were prepared keeping standard ratio

of potato 75:100 (T4), onion 20:100 (T2) and 5.5:100 (T4)

with different ratios of ginger (G) to Acetes mince such as

4:100 (T1), 4.5:100 (T2), 5:100 (T3), 5.5:100 (T4) (w/w) and

6.0:100 (T5). All other ingredients were kept constant. Pre-

pared cutlets were organoleptically evaluated for the best

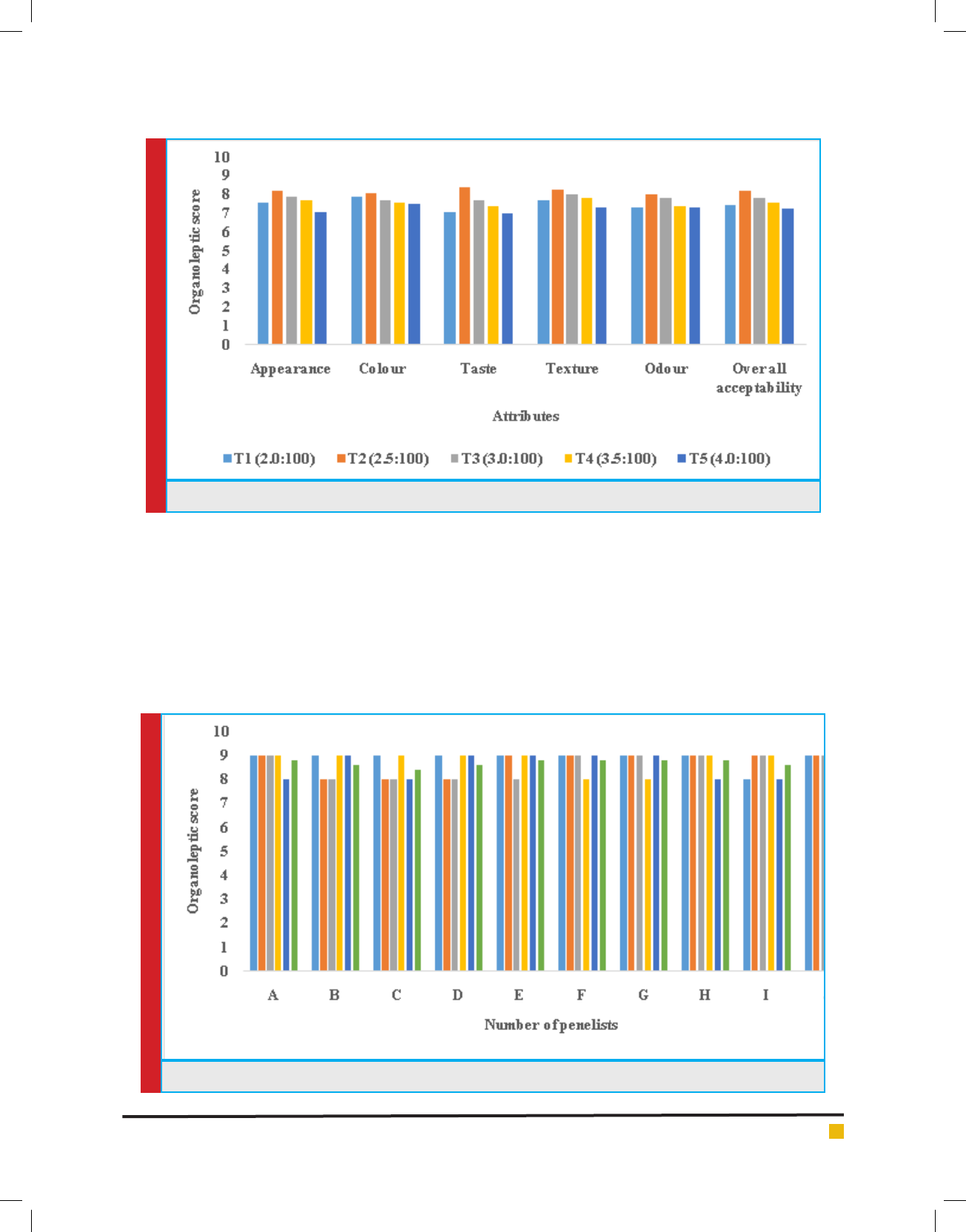

combination.Table salt was standardised as basic recipe

and Acetes cutlet was prepared keeping the standard ratio

of green chilly and ginger obtained from its standardisa-

tion 5.5:100 (T4), with different ratios of salt to Acetes

Kudale et al.

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS STANDARDISATION OF RECIPE FOR BATTER AND BREADED PRODUCT ACETES CUTLET 565

mince, such as 2:100 (T1), 2.5:100 (T2), 3:100 (T3) and

3.5:100 (T4) (w/w) and 4:100 (T5). All other ingredients

were kept constant and prepared cutlets were organolepti-

cally evaluated for the best combination.

Finally, Acetes cutlets were prepared using standard-

ised recipe (Table 1) keeping the standardised ratios of

potato 75:100 (T4), onion 20:100 (T2), ratios of green

chilly 5.5:100 (T4), ginger 5.5:100 (T4) and salt 2.5:100

(T2). Proximate composition viz. moisture, crude pro-

tein, crude fat, ash and carbohydrate (CHO) content

of Acetes cutlets were determined following standard

methods (AOAC, 2005).

RESULTS AND DISCUSSION

Standardisation of different ingredients viz., potato

75:100 (T4), onion 20:100 (T2), chilly 5.5:100 (T4), gin-

ger 5.5:100 (T4) and table salt 2.5:100 (T2), showed bet-

ter organoleptic values compared to other ratios (Fig. l,

Fig. 2, Fig. 3, Fig. 4 and Fig. 5). The organoleptic evalua-

FIGURE 1. Organoleptic evaluation of Acetescutlet prepared with different ratios of potato

FIGURE 2. Organoleptic evaluation of Acetes cutlet prepared with different ratios of onion

Kudale et al.

566 STANDARDISATION OF RECIPE FOR BATTER AND BREADED PRODUCT ACETES CUTLET BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

FIGURE 3. Organoleptic evaluation of Acetes cutlet prepared with different ratios of green chilly

FIGURE 4. Organoleptic evaluation of Acetescutlet prepared with different ratios of ginger

tion of the cutlets indicated the highest score this stand-

ardised recipe as shown in Table 2 and Fig.6.

Standardization of different ratios of potato to Acetes

mince in Acetes cutlet

Acetes cutlet prepared with 75:100 (w/w) ratio of potato

to Acetes meat was superior as compared to the other

ratios of potato to Acetes mince used for preparation of

cutlets. Joseph and Perigreen (1989) used 50:100 ratio of

potato in the cutlet prepared from horse mackerel, ribbon

sh, pola, vatta and mackerel tuna. Kamat (1999) used

50:100 ratio of potato in cutlet prepared from mackerel

(Rastrelliger kanagurta). Pawar et al. (2012) used 70:100

ratio of potato in the cutlet prepared from catla. Rathod

et al. (2012) used 70:100 ratio of potato in the cutlet

prepared from Pangassius (Pangasianodon hypothala-

mus). Species differentiation and higher ratio of potato

to mince increased more starch and taste in the cutlet

Kudale et al.

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS STANDARDISATION OF RECIPE FOR BATTER AND BREADED PRODUCT ACETES CUTLET 567

FIGURE 5. Organoleptic evaluation of Acetes cutlet prepared with different ratios of table salt

FIGURE 6. Organoleptic evaluation of Acetes cutlet prepared using standardized recipe

and bind all ingredients properly. Higher potato ratio

reduces strong odour of Acetes as well as cost of the

cutlets. Similar results with slight variation were found

by Joseph, Perigreen (1989), Kamat (1999), Pawar et al.

(2012) and Rathod et al. (2012).

Standardization of different ratios of onion to Acetes

mince in Acetes cutlet

Acetes cutlets were prepared with 20:100 (w/w) ratio of

onion to Acetes meat was superior as compared to the

other ratios of onion to Acetes meat used for prepara-

tion of cutlet. Kamat (1999) used 25:100 ratio of onion

in cutlet prepared from mackerel (R. kanagurta). Pawar

et al. (2012) used 25:100 (w/w) ratio of onion to catla

(catla) meat. Rathod et al. (2012) used 25:100 ratio of

onion in the cutlet prepared from Pangassius (P. hypo-

thalamus). Species differentiation may cause difference

in the ratio of onion to meat. In the present, study as

per the opinion of panellist, the higher ratio of onion

gave a very excellent taste to the cutlets. Therefore, the

Kudale et al.

568 STANDARDISATION OF RECIPE FOR BATTER AND BREADED PRODUCT ACETES CUTLET BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

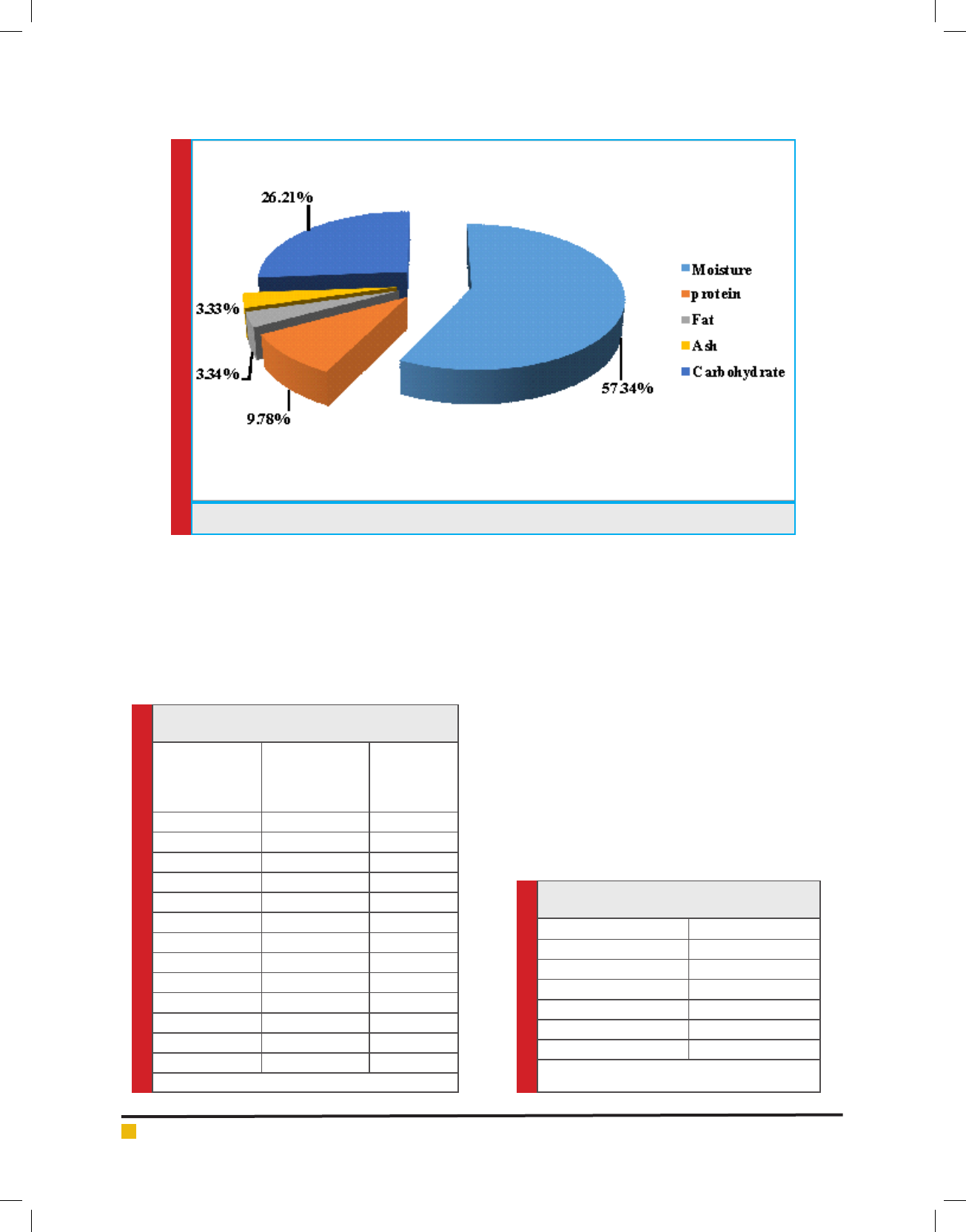

FIGURE 7. Proximate composition of Acetes cutlet

Table 1. Basic and standardized recipe of batter and

breaded Acetes cutlet

Ingredients

Basic recipe

(Pawar

et al

., 2012)

Quantity (g)

Standardized

recipe

Quantity (g)

Acetes mince 100 100

Table salt 3 2.5

Green chilly 5 5.5

Coriander leaves 5 5

Ginger 5 5.5

Garlic 5 5

Onion 25 20

Potato cooked 70 75

Pepper powder 0.3 0.3

Clove powder 0.3 0.3

Cinnamon powder 0.2 0.2

Turmeric powder 0.2 0.2

Bread powder 20 20

Note: Oil was used 10 ml for heating purpose

Table 2. Average organoleptic score of Acetes

cutlet prepared using standardized recipe

Attribute Organoleptic Score

Appearance 8.90±0.32

Colour 8.70±0.48

Taste 8.60±0.52

Texture 8.70±0.48

Odour 8.60±0.52

Overall Acceptability 8.70±0.14

1

Where number of panellist is 10 (n=10)

2

Values expressed are means + S.D. of triplicate measurements

ratio of 20:100 (w/w) onion to meat was used for better

taste.

Standardization of different ratios of green chilly to

Acetes mince in Acetes cutlet

Acetes cutlet prepared with 5.5:100 (w/w) ratio of green

chilly to Acetes meat was superior as compared to the

other ratios of green chilly to Acetes mince used for

preparation of cutlet. Kamat (1999) used 6.5:100 ratio

of green chilly in cutlet prepared from mackerel (R.

kanagurta). Pawar et al. (2012) used 5:100 ratio of green

chilly in cutlet prepared from catla and similar Rathod

et al. (2012) used 5:100 ratio of green chilly in cutlet

prepared from Pangassius (P. hypothalamus) sh. In the

present study as per the opinion of panellist, the higher

ratio of green chilly was giving a very spicy taste of

cutlet. Therefore, the ratio of 5.5:100 (w/w) green chilly

to meat was used for better taste.

Standardization of different ratios of ginger to Acetes

mince in Acetes cutlet

Acetes cutlets were prepared with 5.5:100 (w/w) ratio of

ginger to Acetes meat was superior as compared to the

other ratios of ginger to Acetes meat was used for prepa-

Kudale et al.

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS STANDARDISATION OF RECIPE FOR BATTER AND BREADED PRODUCT ACETES CUTLET 569

ration of the cutlet. Kamat (1999) used 7.5:100 ratio of

ginger in cutlet prepared from mackerel (R. kanagurta).

Pawar (2011) used 5:100 (w/w) ratio of ginger to catla

(catla) meat. Rathod et al. (2012) used 6:100 ratio of

ginger in cutlet prepared from Pangassius (P. hypothala-

mus). Species segregation may cause difference in the

ratio of ginger to meat. In the present study as per the

opinion of panellist, the higher ratio of ginger made the

cutlets little spicy. Therefore, the ratio of 6:100 (w/w)

ginger to meat were used for better taste.

Standardization of different ratios of table salt to

Acetes mince in Acetes cutlet

Acetes cutlets were prepared with 2.5:100 (w/w) ratio of

table salt to Acetes meat was superior as compared to

the other ratios of salt to Acetes meat used for prepara-

tion of cutlet.

Similar results were observed by Joseph et al. (1984)

they used 3:100 ratio of salt in the cutlet prepared from

lizard sh, thread n bream, jew sh and miscellaneous

sh (comprising mainly soles, caranx, jew sh, thread n

bream and glassy perch). Ninan et al. (2008) used 3:100

ratio of salt in cutlet prepared from tilapia (O. mossam-

bicus). Pawar et al. (2012) used 3:100 ratio of salt in the

cutlet prepared from catla (Catla catla). Rathod et al.

(2012) used 2.5:100 ratio of salt in cutlet prepared from

Pangassius (P. hypothalamus). Species differentiation

may cause difference in the ratio of salt to meat. In the

present study as per the opinion of panellist, the higher

ratio of salt was giving a more salty taste to the cutlet.

Therefore, the ratio of 2.5:100 (w/w) salt to meat was

used for better taste.

The proximate composition of Acetes cutlet showed

moisture 57.34 %, crude protein 9.78 %, fat 3.34 %

and ash 3.33 % and carbohydrate 26.21% (Fig 7). The

increase in fat and reduction in moisture content in cut-

let is due to deep frying with dehydration during chilled

storage (Ninan et al. 2008 and Pawar et al. 2012). The

reduction of protein is due to denaturation sh muscle

during chilled and frozen storage (Gopakumar, 2002;

Pawar et. al., 2013; Rathod et al., 2014). Joseph et al.

(1984) reported moisture, protein, fat and ash content

in ash fried cutlet was 62.65, 15.41, 5.92 and 1.88%

respectively. Crab cutlet prepared by Raju et al. (1997)

content and may found of moisture, protein, fat and ash

were 67.72, 17.07, 8.36 and 4.00% respectively. Kamat

(1999) reported sh cutlet prepared from bleached and

unbleached sh meat content of moisture, protein, fat

and ash were 65.01, 12.06, 6.31 and 1.39 %. Ninan et al.

(2008) reported tilapia sh cutlet content of moisture,

protein, carbohydrate, fat and ash were 65.10, 17.51,

13.47, 2.14 %. Pawar et al. (2012) reported initial mois-

ture, protein, fat and ash content in ash fried cutlets

was 65.71, 16.57, 14.50 and 3.22% respectively. Rathod

et al. (2014) reported moisture, protein, fat, ash and car-

bohydrate content in fresh ash fried cutlets was 53.34,

18.43, 21.02, 2.78 and 4.43 % respectively. Praneetha

et al. (2017) reported the moisture, protein, fat and ash

content in fresh ash fried cutlets was 57.03, 21.74, 7.61,

3.41 % respectively.

CONCLUSION

Acetes can be utilized by preparing Acetes batter and

breaded product like Acetes cutlet using standard-

ized recipe. This standardized recipe showed excellent

organoleptic characteristics. This developed technology

will be useful to prepare nutritive products from Acetes

as well as helpful to increase the income of sherman,

as well as SHG’S etc.

ACKNOWLEDGEMENT

The authors are thankful to Hon’ble, Vice-Chancellor,

other university authorities of Dr. B. S. Kokan Krishi Vid-

yapeeth, Dapoli, Maharashtra, Post-Graduate Institute

of Post-Harvest Management Killa-Roha, Dist. Raigad,

Marine Biological Research Station, Ratnagiri and Col-

lege of Fisheries, Ratnagiri, and all the staff members of

both faculties for encouragement and providing neces-

sary facilities and help for the work.

REFERENCES

AOAC (2005) Of cial Methods of Analysis, 18

th

edition. Asso-

ciation of Of cial Analytical Chemists., Washington DC, USA

246 pp.

Balachandran, K. K. (2001) Battered and breaded products In:

Post-harvest technology of sh and sh products. Daya Pub-

lishing House, New Delhi, 288-307.

Gopakumar, K. (2002) Biochemical composition of sh In:

Textbook of Fish Processing Technology. Directorate of Infor-

mation and Publishing of Agriculture, ICAR, New Delhi.

ISI, (1975) Guide for sensory evaluation of foods, Part III,Sta-

tistical Analysis of Data, Indian Standard Institute, (Part III),

IS: 6273.

Joseph, J., Perigreen, P. A. and Thampuran, N. (1984) Prepara-

tion and storage of cutlet from low-priced sh. Fishery Tech-

nol., 21(1): 70-74.

Kamat, A. H. (1999) Preparation of sh ball and sh cutlet

from mackerel mince meat. M.F.Sc. thesis submitted to Dr.

Balasaheb Sawant Konkan Krishi Vidyapeeth, Dapoli, Maha-

rashtra, India, 200 pp.

Mahakal, B. V., Pagarkar, A. U., Baug, T. E., Chaudhari, K. J.

and Kulkarni, G. N. (2016) Organoleptic and biochemical qual-

ity characteristics of Acetes chutney packed in polypropylene

packs at ambient stored temperature. J. Exp. Zool. India, 19(2):

943-946.

Kudale et al.

570 STANDARDISATION OF RECIPE FOR BATTER AND BREADED PRODUCT ACETES CUTLET BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Mahakal, B. V., Pagarkar, A. U., Baug, T. E., Shinde, K. M., Bho-

sale, B. P., Bhatkar, V. R., Shingare, P. E., Satam, S. B., Sawant,

N. H. and Shaikh, S. M. (2017) Organoleptic, microbiological,

biochemical changes of Acetes chutney (ready-to-eat) packed

modi ed atmospheric packaging with nitrogen gas stored

at ambient temperature. Biochem. Cell. Arch., 17(2): 645-

649.

Ninan, G., Bindu, J. and Joseph, J. (2008) Frozen storage studies

of mince based products developed from Tilapia, Oreochromis

mossambicus (Peters, 1852). Fishery Technol., 45(1): 35-42.

Ninan, G., Bindu, J. and Joseph, J. (2008) Frozen storage studies

of mince based products developed from Tilapia, Oreochromis

mossambicus (Peters, 1852). Fishery Technol., 45(1): 35-42.

Pagarkar, A. U., Basu, S. and Mitra, A., (2006). Storage char-

acteristics of sh-soya based ready-to-cook extruded prod-

uct. Asian Jr. of Microbiol. Bioteh. and Envir. Sc.,8 (3): 609-

614.

Pagarkar, A. U., Baug, T.E., Pawar, P. P. and Kolekar, A. D.

(2012) An approach to seafood processing: Battered and

breaded products, Journal of FISHCOOPS, 23 (4), 8-14.

Pagarkar, A. U., Joshi, V.R., Baug, T. and Kedar, J. (2011) Value

addition is need of Seafood industries, Journal of FISHCOOPS,

23 (4), 8-14.

Pawar P. P. (2011) Preparation of battered and breaded prod-

uct from freshwater sh (Catla catla). M.F.Sc. thesis submitted

to Dr. Balasaheb Sawant Konkon Krishi Vidyapeeth, Dapoli,

Maharashtra, India, 93 pp.

Pawar, P. P., Pagarkar, A. U., Rathod, N.B., Baug, T.E. and M. A.

Rather (2012) Standardisation of Recipe for Fish Cutlet Product

from fresh water sh Catla (Catla catla). European J. of Exper.

Biology, 2 (6):2043-2048.

Praneetha, S., Dhanpal, K., Reddy, G. V. S., Balsubramainan,

A. and Praveen Kumar, G. (2017) Study on the quality of sh

cutlet prepared from Rohu (R. rohita) during refrigerated stor-

age., Inter. J. Current Microbio. and Applied Sci. (IJCMAS), 12:

3262-3271.

Raju, C. V., Bhaskar, N. and Dhananjaya, S. (1997) Development

of ready-to-fry crab products. Fishery Technol., 34(2): 26-30.

Rathod, N.B., Pagarkar, A.U., Pujari, K. H., Gokhale, N. B. and

Joshi, V.R. (2012) Standardisation of recipe for sh cutlet

product from Pangasianodon hypophthalmus., Ecol. Env. and

Cons., 18 (4): 981-986.

Rathod, N, Pagarkar, A., Phadke, G., Pujari, K. and Chandra, M.

(2014) Chemical, microbial and sensory quality changes of sh

cutlets, made from Pangasius sh (Pangasianodon hypophthal-

mus), during storage in refrigerated display unit (-15 to -18°C),

Eco. Env. and Cons. 20 (3): 967-972.

Shaikh S. M., Joshi V. R., Pagarkar A. U., Pai, R. and Balange A.

K.(2017) Effect of heat penetration on quality of Acetes ball in

curry in retort pouch processed at 121.2

0

C for different dura-

tions., J. Exp. Zool. India., 20 (1), 605-610.

Zynudheen, A. A., George, N., Sen, A. and Badonia, R. (2004)

Processing and utilization of Acetes indicus (Jawala Prawn).

In: Technology Advisory Series No.15, CIFT, Cochin, 6 pp.