Chemical Engineering

Communication

Biosci. Biotech. Res. Comm. 10(1): 172-177 (2017)

Simulation study of oil production rate and water

coning in oil reservoirs using ECLIPSE software

Abdolreza Dabiri*, Mohammad Afkhami Karaei and Amin Azdarpour

Department of Petroleum Engineering, Marvdasht Branch, Islamic Azad University, Marvdasht, Iran

ABSTRACT

Oil reservoirs are usually consist of hydrocarbons (oil and gas) and bottom water. The natural depletion of the res-

ervoir occurs by the natural energy of the reservoir. Reservoirs pressures are usually high in the beginning and this

will transmit the uid from the reservoir to the surface. However, after some time of production, when the reservoir

pressure falls down, water comes into the formation and starts to produce through the wellbore. This happens because

of the disturbance in gravitational force in the reservoir, which results in water production along with oil. Reducing

well productivity, water separation and handling, corrosion and environmental issues are the major challenges asso-

ciated with water coning phenomena. In this study, the black oil model of ECLIPSE software was used to study the

water coning issue in an oil reservoir. Different production plans were studied and their effect on water coning was

investigated. In addition, the best production plan was introduced using simulation results. The simulation results

showed that pressure draw down in the reservoir decreased with decreasing oil production rate, which inherently

decreases the water production rate. Moreover, the simulation results showed that oil recovery factor can be increased

signi cantly by decreasing the amount of water production.

KEY WORDS: WATER CONING, OIL PRODUCTION, IMPROVED OIL RECOVERY, ECLIPSE

172

ARTICLE INFORMATION:

*Corresponding Author: dabiri211@yahoo.com

Received 16

th

Dec, 2016

Accepted after revision 14

th

March, 2017

BBRC Print ISSN: 0974-6455

Online ISSN: 2321-4007 CODEN: USA BBRCBA

Thomson Reuters ISI ESC and Crossref Indexed Journal

NAAS Journal Score 2017: 4.31 Cosmos IF : 4.006

© A Society of Science and Nature Publication, 2017. All rights

reserved.

Online Contents Available at: http//www.bbrc.in/

INTRODUCTION

Water production from oil wells is a common occur-

rence in oil elds. Water coning, increasing water oil

contact level, and water ngering especially in injec-

tion wells are the major reasons of waster produc-

tion in oil elds. In general, water production is not a

favorable occurrence. Reducing well productivity, water

separation and handling, corrosion and environmental

issues are the major challenges associated with water

coning phenomena (Armenta and Wojtanowicz, 2002,

Bahadori and Nouri, 2012; Mauriya et al., 2014; Carpen-

ter, 2015; Moortgat and Firoozabadi, 2016; Kamari et al.,

2016).

Dabiri, Karaei and Azdarpour

Disturbance in gravitational and viscous force around

the perforated area is the major cause of water coning

in oil elds. An upward dynamic force upon reservoir

uid is induced by the ow of oil from the reservoir

to the well. Adding the effects of pressure draw down

at the wellbore will causes the water to move upward

and be produced at the surface (Pang et al, 2008, Ansari

and Johns, 2013; Dos Santos and Oliveira, 2014; Ghane

Ezabadi, 2015; Hatzignatiou et al., 2016; Carpenter,

2016; Zeinijahromi and Bedrikovetsky, 2015; Zeinijah-

romi and Bedrikovetsky, 2016).

Different factors including mobility ratio, the extent

of penetration, vertical permeability, oil zone thick-

ness, and most importantly the production rate are the

major parameters that affect the severity of water coin-

ing. This phenomenon is more complicated in fractured

reservoirs, where dual porosity exists, which results in

the formation of two cones. In this case, two different

cones with two different rates, one in matrix and one

in fracture may form, which creates a very complicated

situation at the surface (Egbe and Appah, 2005; Lakatos

et al., 2014; Mohammed et al., 2014; Cinar et al., 2016;

Li et al., 2016; Zemtsov and Lytkin, 2016).

Permadi and Jayadi (2010) proposed a new calculation

method for determining the water coning in horizontal

wells. The post breakthrough performance in horizontal

wells was calculated and predicted using a semi empiri-

cal method in their study. They used two sets of eld

data where in the rst case no water cut was observed

and in the second case water cut occurred after produc-

tion started. Results of prediction for both cases are in

very good agreement with the eld data.

In another study by Buranatavonsom (2011), water

coning was managed successfully in a gas reservoir using

downhole water pump ood. In this method, water con-

ing is reduced signi cantly. In addition, it is not required

to produce water into surface and also to drill a well for

water production. Therefore, it can minimize cost of drill-

ing and water treatment system. Moreover, in another

study by Jin and Wojtanowics (2010), the feasibility of

water coning control installation in reservoir with down-

hole water sink (DWL) was investigated. The DWL feasi-

bility was tested with a simple analytical model derived in

this study. Also, a good match was obtained when com-

paring the model-calculated data to real production data.

Their work was comparable with the resulted presented in

the literature (Qin et al., 2014; Alblooshi and Wojtanow-

icz, 2014; Anthony and Al-Mosaileekh, 2016; Muktadir et

al., 2016; Yoshida and Hill, 2016).

In this study, different scenarios including different

oil ow rate, water cut, blocking of critical penetra-

tion intervals and drilling of new horizontal wells were

investigated and the best production plan was selected

accordingly.

MATERIALS AND METHODS

RESERVOIR CHARACTERISTICS AND SIMULATION STUDY

The oil reservoir is an under saturate oil reservoir with

no initial gas cap present. Water, oil and solution gas

are the available phases exists in the reservoir, where oil

is in contact with water in the fth layer. Table 1 rep-

resents porosity and permeability in three directions (Z,

Y, Z). On the other hand, Table 2 represents the proper-

ties of reservoir rock and uid. The reservoir is divided

into three directions of X, Y, and Z. Black oil model of

ECLIPSE software has been used to simulate water con-

Table 1. Reservoir rock characteristics

Porosity (layer 1) (ave.) 0.04425

(layer 2) (ave.) 0.01485

(layer 3) (ave.) 0.0406

(layer 4) (ave.) 0.02955

(layer 5) (ave.) 0.037

Permeability X (md) (layer 1) (ave.) 2455

(layer 2) (ave.) 11

(layer 3) (ave.) 825.26

(layer 4) (ave.) 20

(layer 5) (ave.) 1300

Permeability Y (md) (layer 1) (ave.) 2455

(layer 2) (ave.) 11

(layer 3) (ave.) 825.26

(layer 4) (ave.) 20

(layer 5) (ave.) 1300

Permeability Z (md) (layer 1) (ave.) 11

(layer 2) (ave.) 1.09

(layer 3) (ave.) 71

(layer 4) (ave.) 50.44

(layer 5) (ave.) 84

Table 2. Reservoir characteristic

Dx (ft) (ave.) 260

DY (ft) (ave.) 300

DZ (ft) (ave.) 115

Tops (ft) 2552 to 3235

Net to Gross ratio (NTG) 1.0

Pressure (psia) 5684

Temperature (F) 260

Initial Oil saturation 0.8268

Initial Gas saturation 0.0

Initial Water saturation 0.1732

Density (lb/ft3) 52.86

API 35

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS SIMULATION STUDY OF OIL PRODUCTION RATE AND WATER CONING IN OIL RESERVOIRS 173

Dabiri, Karaei and Azdarpour

ing in this reservoir. Equations were solved fully implic-

itly since the error term is minimized as compared to

Impes method. The solution method in this study was

recommended by the previous authors in the literature

(Zeinijahromi et al., 2014; Langaas and Hjellbakk, 2015;

Zhao et al., 2016; Zeinijahromi and Bedrikovetsky, 2016).

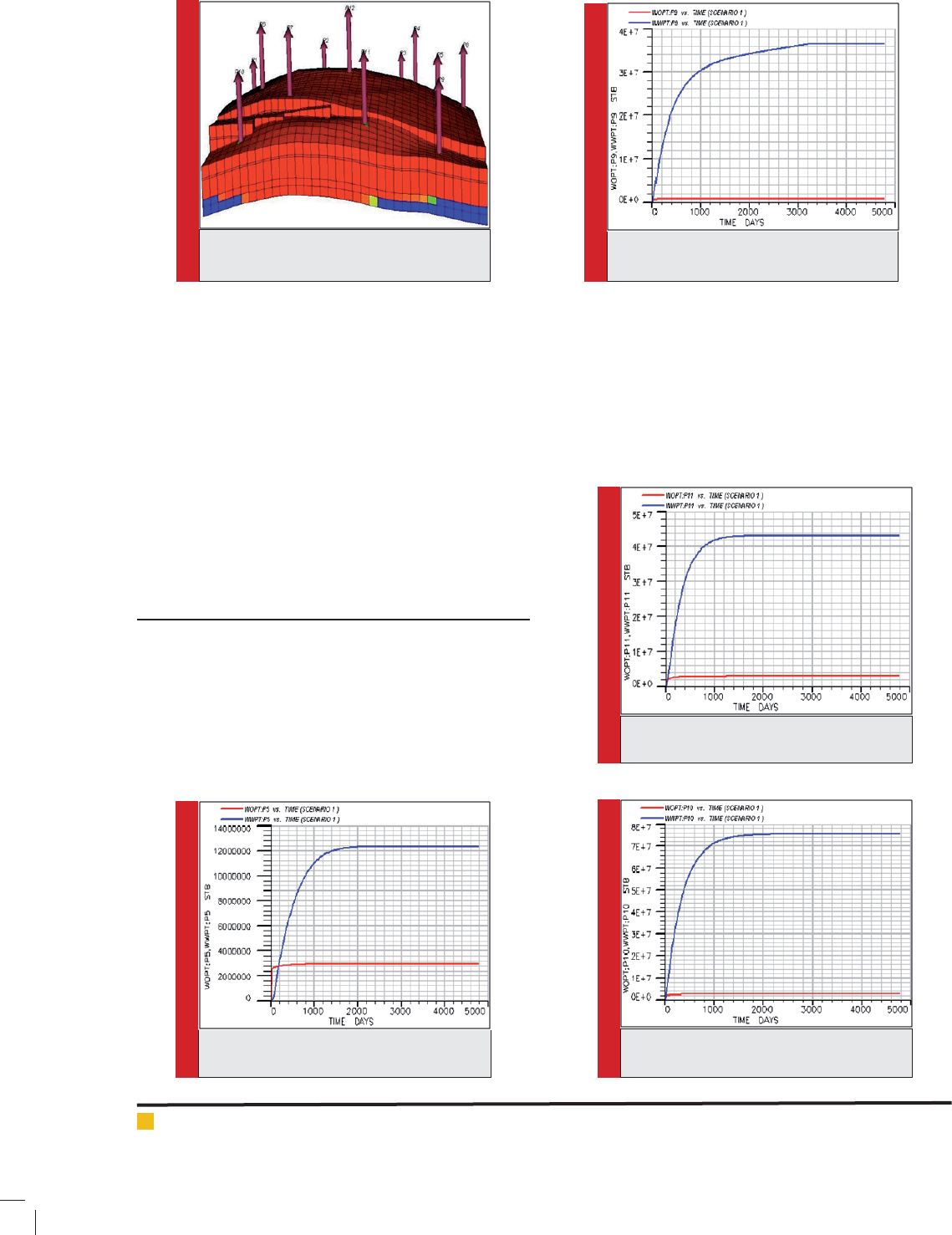

The production from this reservoir was started in

1998 using 12 production wells. Oil production rate is

the main parameters that affect water coning severity in

oil reservoirs. Figure 1 represents the three-dimensional

picture of the wells in this reservoir. Thus, ve different

scenarios were introduced and their effect on water con-

ing was investigated.

RESULTS

In the rst scenario, oil production rate from all wells

were assumed to be as default values and no limitation

on production rate was applied. The main objective of

this production scenario is to observe the productivity of

each well. As is shown in Figure 1, well number 5, 9, 10,

and 11 are near the water level in the reservoir and the

possibility of water production in these wells are higher

FIGURE 1. Three dimensional location of

production wells.

FIGURE 2. Total oil and water production

from well number 5.

FIGURE 3. Total oil and water production

from well number 9.

FIGURE 4. Total oil and water production

from well number 11.

FIGURE 5. Total oil and water production

from well number 10.

than the other wells. Thus, simulation study was focused

on the behavior of these wells. Figures 2-5 represents

the oil and water production from these four production

wells. As shown in these wells, after some time of pro-

duction from this reservoir, water starts to come to the

surface and produce along with oil.

174 SIMULATION STUDY OF OIL PRODUCTION RATE AND WATER CONING IN OIL RESERVOIRS BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Dabiri, Karaei and Azdarpour

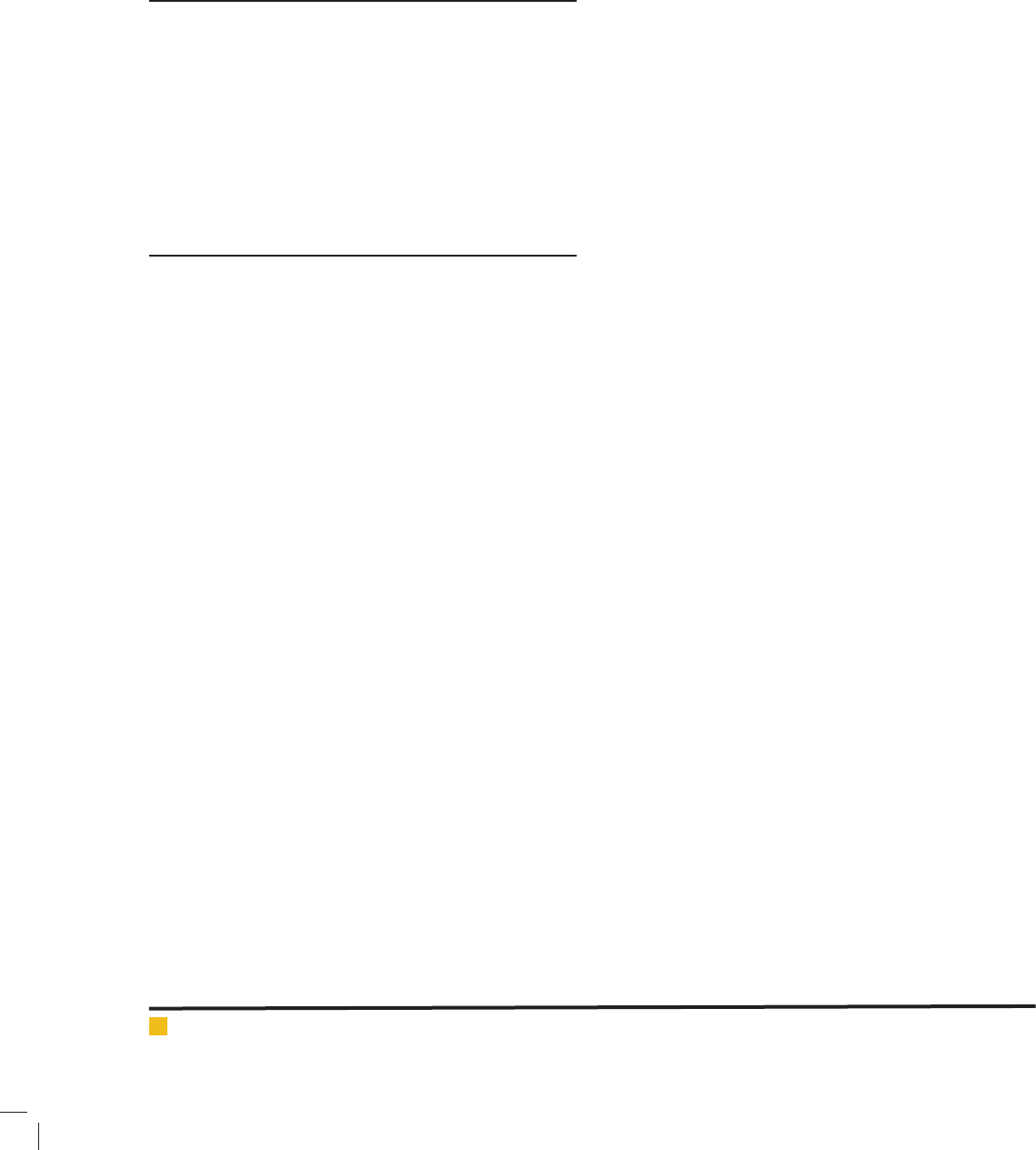

tion is increased with increasing. In the forth scenario,

production occurs from all the wells under constant

production rate of 1000 bbl/day. As shown in this g-

ure, the duration of water production is increased with

increasing. In the fth scenario, production occurs from

all the wells under constant production rate of 500 bbl/

day. The simulation results showed that water produc-

tion is decreased with oil production. In addition, a lesser

amount of water is produced at the surface as compared

to other scenarios. In addition, reducing the oil produc-

tion rate also increases recovery factor. Figure 7 repre-

sents a comparison on total amount of water production

from this reservoir under different scenarios.

Another conclusion from the simulation study is that

with decreasing oil production rate, recovery factor is

increased. In addition, the total amount of produced is

reduced as well. This happens because by lowering the

oil ow rate, pressure draw down is reduced, thus the

water movement to upper layers is delayed and reduced.

Table 3 represents a summary of the total amount of

oil and water production, recovery factor and water cut

level under these ve production scenarios.

DISCUSSIONS

Liminar ow condition exists in the wellbore when the

a well is producing with constant ow rate and pressure

gradient. In this case, viscous forces are less than the

gravitational forces in the well, which inhibit the prod-

cution of cone in the well. On the other hand, when the

pressure drop is signifcant in the wellbore, viscose forces

are dominant over the gravitational forces. This crea-

tes afavorable condition for the cone to occure. Water

coning in the wellbore continues to increase with incra-

sing the pressure drop in the wellbore (Bautista et al.,

2014; Pal and Mandal, 2015; Izwan Ismail, 2015a; Desa-

mal et al., 2015; Loh and Premanadhan, 2016). At the

optimum ow rate of the well, viscous forces are always

lower than the gravitational forces, which inhibites the

water coning to achive to the wellbore. In cases where

production ow rate is more than the optimum ow rate

FIGURE 6. Total oil adn water production in

the second scenario.

FIGURE 7. Comparison of the total water

production in the third, forth and fth sce-

nario.

Table 3. summary of production rates under different scenarios

Scenario

Recovery

factor (%)

Total water

prodcution,

FWPT (STB)

Formation

water cut,

FWCT (%)

Total formation oil

prodcution,

FOPT (STB)

Oil

prodcution

rate (bbl/day)

Number of

production wells

NO. 1 19.44 1.703×10

8

0.995 19873336 default 12

NO. 2 25.36 1.671×10

8

9.997 25924804 2000 12

NO. 3 25.59 1.660×10

8

0.991 26157852 1500 12

NO. 4 25.58 1.632×10

8

0.935 26149984 1000 12

NO. 5 25.55 26346124 0.391 26157336 500 12

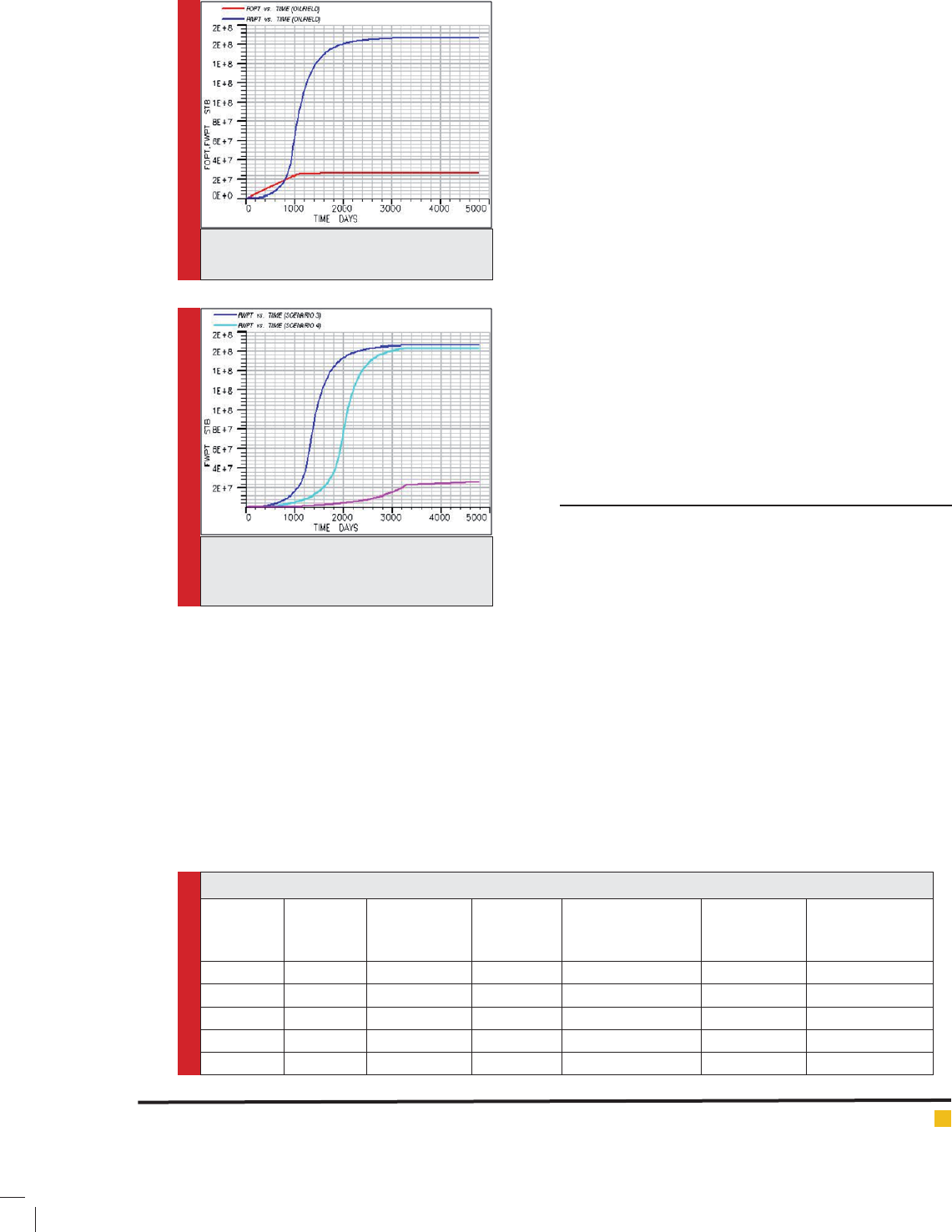

In the second scenario, production occurs from all

the wells under constant production rate of 2000 bbl/

day and the results are shown in Figure 6. As shown in

this gure, the duration of water production is reduced

with increasing. In addition, with increasing the oil pro-

duction form the reservoir, water production increases

as well.

In the third scenario, production occurs from all the

wells under constant production rate of 1500 bbl/day.

As shown in this gure, the duration of water produc-

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS SIMULATION STUDY OF OIL PRODUCTION RATE AND WATER CONING IN OIL RESERVOIRS 175

Dabiri, Karaei and Azdarpour

of the well this water coning occurs, which results in

water prodcution at the surface (Izwan Ismail, 2015b;

Liu and Bai, 2015; Hatzignatiou et al., 2016; Rozhko,

2016; Cazarez-Candia and Piedra-González, 2017). The

same pohenomenon happend in this study as shown in

Figures 2-7.

CONCLUSIONS

Water production is affected by the pressure draw down

in the wellbore. Decreasing oil prodcution rate decreases

the pressure draw down in the formation, thus decreases

the amount of water production at the surface. Changing

oil production rate is only effective when no water con-

ing is occurs. In addition, oil recovery factor is increased

by decreasing the total amount of water production

from the formation.

ACKNOWLEDGMENT

The authors would like to appreciate the Department

of Petroleum Engineering, Marvdasht Branch, Islamic

Azad University, Marvdasht, Iran for the provision of

the laboratory facilities necessary for completing this

work.

REFERENCES

Alblooshi, Y.A., Wojtanowicz, A.K. (2014) Multi-Lateral Wells

with Downhole Water Control and Disposal in Heavy Oil Res-

ervoirs with Bottom Water – A Case Study. Abu Dhabi Interna-

tional Petroleum Exhibition and Conference, 10-13 November,

Abu Dhabi, UAE.

Ansari, R.Z., Johns, R.T. (2013). Superposition of steady-

stateconingsolutions for multiple wells with reservoir bound-

aries. Journal of Petroleum Science and Engineering, 108:

362–369.

Anthony, E., Al-Mosaileekh, S. (2016). Downhole Water Sink

Technology Improves Recovery and Rates from Strong Water

Drive Reservoirs in North Kuwait – A Pilot Case Study. Inter-

national Petroleum Technology Conference, 14-16 November,

Bangkok, Thailand.

Armenta, M., Wojtanowicz, A. (2002). Severity of Water Con-

ing in Gas Wells. SPE Gas Technology Symposium, Alberta,

Canada.

Bahadori, A., Nouri, A. (2012). Prediction of critical oil rate for

bottom water coning in anisotropic and homogeneous forma-

tions. Journal of Petroleum Science and Engineering, 82-83:

125–129.

Bautista, E.V., Meneses Barillas,J.L., Dutra Jr, T.V., da Mata,

W. 2014. Capillary, viscous and gravity forces in gas-assisted

gravity drainage. Journal of Petroleum Science and Engineer-

ing, 122: 754–760.

Buranatavonsom, B. (2011). Water Coning Management in Gas

Reservoir via Downhole Water Dump Flood. SPE Annual Tech-

nical Conference and Exhibition, Colorado, USA.

Carpenter, C. (2015). Optimized Design of Autonomous In ow-

Control Devices for Gas and Water Coning. Journal of Petro-

leum Technology, 67(12): 70-71.

Carpenter, C. (2016). Optimization of Upper Burgan Reser-

voir Multilateral Well With In ow-Control Device. Journal of

Petroleum Technology, 68(2):68-69.

Cazarez-Candia, O., Piedra-González, S. (2017). Modeling of

heavy oil-water core-annular upward ow in vertical pipes

using the two- uid model. Journal of Petroleum Science and

Engineering, 150: 146–153.

Cinar, Y., Shehab, M.A., Dallag, M.M., Jama, A.A. (2016). Auto-

mated Surveillance and Diagnostic Work ow for the Manage-

ment of Water Production in Naturally-Fractured Carbonate

Reservoirs. SPE Annual Technical Conference and Exhibition,

26-28 September, Dubai, UAE.

Desamala, A.B., Dasmahapatra, A.K., Mandal, T.K. (2015). An

appraisal of viscous oil–water two-phase ow through an

undulated pipeline in peak con guration. Experimental Ther-

mal and Fluid Science, 68, 177–186.

Dos Santos, M.D.L., Oliveira, F.R. (2014) Fault Reactivation

as Mechanism of Early Water Production in Unconsolidated

Sandstones Reservoirs. SPE Annual Technical Conference and

Exhibition, 27-29 October, Amsterdam, The Netherlands.

Egbe, T., Appah, D. (2005). Water Coning Diagnosis Using

Spectral Analysis. Nigeria Annual International Conference

and Exhibition, Nigeria.

Ghane Ezabadi, M., Ramli, A.S., Ataei, A., Tg Othamn, T. R.

(2015). Challenges in Modeling of High Clay Volume Gas Res-

ervoir with No Water Production. SPE/IATMI Asia Paci c Oil

& Gas Conference and Exhibition, 20-22 October, Nusa Dua,

Bali, Indonesia.

Hatzignatiou, D.G., Askarinezhad, R., Giske, N.H., Stavland, A.

(2016). Laboratory Testing of Environmentally Friendly Sodium

Silicate Systems for Water Management Through Conformance

Control. SPE Production & Operations, 31(4): 337-350.

Izwan Ismail,A.H., Ismail, I., Zoveidavianpoor, M., Mohsin,

R., Piroozian,A., Misnan, M.S., Sariman, M.Z. (2015) Experi-

mental investigation of oil–water two-phase ow in horizon-

tal pipes: Pressure losses, liquid holdup and ow patterns.

Journal of Petroleum Science and Engineering, 127: 409–

420.

Izwan Ismail,A.H., Ismail, I., Zoveidavianpoor, M., Mohsin,

R., Piroozian,A., Misnan, M.S., Sariman, M.Z. (2015). Review

of oil–water through pipes. Flow Measurement and Instru-

mentation, 45: 357–374.

Jin, L., Wojtanowicz, A.K. (2010). An Analytical Model for

Water Coning Control Installation in Reservoir With Bot-

tomwater. Journal of Canadian Petroleum Technology, 49 (5):

65-70.

Kamari, A., Mohammadi, A.H., Bahadori, A. (2016). On the

determination of breakthrough time for water coning phenom-

176 SIMULATION STUDY OF OIL PRODUCTION RATE AND WATER CONING IN OIL RESERVOIRS BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Dabiri, Karaei and Azdarpour

enon in oil reservoirs. Petroleum Science and Technology, 34

(1): 44-49.

Lakatos, I., Lakatos-Szabo, J., Szentes, G., Vago, A. (2014).

Restriction of Water Production in Gas Wells by Induced Phase

Inversion: Field Case Studies. SPE International Symposium

and Exhibition on Formation Damage Control, 26-28 Febru-

ary, Lafayette, Louisiana, USA.

Langaas, K., Hjellbakk, A. (2015). Integrated Reservoir Model-

ling of the Alvheim Field. SPE Bergen One Day Seminar, 22

April, Bergen, Norway.

Li, K., Liu, C., Zhang, C., Jiang, P., Lei, X., Gao, H., Jing, F.

(2016). A New Method for Estimating the Production Perfor-

mance of Water Flooding. SPE Asia Paci c Oil & Gas Confer-

ence and Exhibition, 25-27 October, Perth, Australia.

Liu, W., Bai, B. (2015). Swirl decay in the gas–liquid two-

phase swirling ow inside a circular straight pipe. Experi-

mental Thermal and Fluid Science, 68: 187–195.

Loh, W.L., Premanadhan, V.K. (2016). Experimental investiga-

tion of viscous oil-water ows in pipeline. Journal of Petro-

leum Science and Engineering, 147: 87–97.

Maurya, A.K., Mahto, V., Sharma, V.P., Laik, S. (2014) Study

of the Potential of Amino Resin to Control Excessive Water

Production in the Indian Oil elds. Petroleum Science and

Technology, 32 (12): 1443-1447.

Mohammed, S.A., Aggour, M., Fraim, M., Aboegila, A.,

Farooqui, M., Al-Kharaz, H., Ashkanani, M., Marmoush, M.

(2014) Development of an Online, Non-Intrusive Means for

Detecting Onset of Formation Water Production in Gas Flow

Lines. International Petroleum Technology Conference, 19-22

January, Doha, Qatar.

Moortgat, J.B., Firoozabadi, A. (2016). Water Coning, Water,

and CO

2

Injection in Heavy-Oil Fractured Reservoirs. SPE Res-

ervoir Evaluation & Engineering. Article in press: http://dx.

doi.org/10.2118/183648-PA.

Muktadir, G., Amro, M., Schramm, A. (2016). Review and

Applicability of Downhole Separation Technology. SPE Middle

East Arti cial Lift Conference and Exhibition, 30 November-1

December, Manama, Kingdom of Bahrain.

Pal, D., Mandal, G. (2015). Mixed convection–radiation on

stagnation-point ow of nano uids over a stretching/shrink-

ing sheet in a porous medium with heat generation and vis-

cous dissipation. Journal of Petroleum Science and Engineer-

ing, 126: 16–25.

Pang, Z., Cheng, L.S., Xu, J.F., Feng, R.Y. (2008). Application of

material balance method to nitrogen anti-water-coningtech-

nology. Petroleum Exploration and Development, 35 (2): 234-

238.

Permadi, P., Jayadi, T. (2010). An Improved Water Coning Cal-

culation for Horizontal Wells. SPE Russian Oil and Gas Confer-

ence and Exhibition, Moscow, Russia.

Qin, W., Wojtanowicz, A.K., Li, H. 2014. Improved Thermal

Heavy Oil Recovery from Strong Bottom-Water-Drive Res-

ervoir by Combining SAGD with Downhole Water Sink. SPE

International Heavy Oil Conference and Exhibition, 8-10

December, Mangaf, Kuwait.

Rozhko, A.Y.(2016). Two-phase uid- ow modeling in a dila-

tant crack-like pathway. Journal of Petroleum Science and

Engineering, 146: 1158–1172.

Yoshida, N., Hill, A.D. (2016) Comprehensive Modeling of

Downhole Temperature in a Horizontal Well with Multiple

Fractures. SPE Asia Paci c Hydraulic Fracturing Conference,

24-26 August, Beijing, China.

Zeinijahromi, A., Bedrikovetsky, P. (2016). Water Production

Control Using Low-Salinity Water Injection. SPE Asia Paci c

Oil & Gas Conference and Exhibition, 25-27 October, Perth,

Australia.

Zeinijahromi, A., Bedrikovetsky, P. (2015). Controlling Exces-

sive Water Production Using Induced Formation Damage. SPE

European Formation Damage Conference and Exhibition, 3-5

June, Budapest, Hungary.

Zeinijahromi, A., Al-Jassasi, H., Zhang, Y., Begg, S.H., Bedrik-

ovetsky, P. (2014). Edge-Water Drive Recovery Enhance-

ment by Induced Fines Migration. SPE Asia Paci c Oil &

Gas Conference and Exhibition, 14-16 October, Adelaide,

Australia.

Zemtsov, Y.V., Lytkin, A.E. (2016). Supplementary evaluation

of the ef ciency of water shutoff in production wells (Russian).

Oil Industry Journal, 2016(3): 102-104.

Zhao, H., Kang, Z., Zhang, X., Sun, H., Cao, L., Reynolds, A.C.

(2016) A Physics-Based Data-Driven Numerical Model for Res-

ervoir History Matching and Prediction With a Field Applica-

tion. SPE Journal, 21(6): 2175-2194.

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS SIMULATION STUDY OF OIL PRODUCTION RATE AND WATER CONING IN OIL RESERVOIRS 177