Medical

Communication

Biosci. Biotech. Res. Comm. 10(1): 109-113 (2017)

A comparative analysis of splinted and non-splint in open-

tray impression techniques on different angled implants

Ezatollah Jalalian

1

, Fariba Balouch

2

, Nazanin Samiei

3

, Hadi Kaseb Ghane

4

*,

Babak Iranpoor

5

and Kamilia Ebrahimian

6

1

Associate Professor, Department of Fix Prostodontics, Dental Branch, Islamic Azad University, Tehran, Iran

2

Faculty member, Department of Fix Prostodontics, Dental Branch, Islamic Azad University, Tehran, Iran

3

Assistant Professor, Department of Periodontology, School of Dentistry, Alborz University of Medical

Sciences, Tehran, Iran

4

Assistant Professor, Department of Fix Prostodontics, Dental Branch, Islamic Azad University, Tehran, Iran

5

Assistant Professor, Department of Periodontology, Dental Branch, Islamic Azad University, Tehran, Iran

6

Dentist, Private Of ce, Iran

ABSTRACT

Due to the effect of various impression techniques on accuracy of nal cast dimensions and controversies about the best tech-

niques, this study was performed to compare the Splinted and non-splint in open-tray impression techniques on 15 and 25º

angled implants. At rst steel model in 8 cm diameter and 3 cm height were made with 4 holes to stabilize 4 implants. Two central

implants had 12 cm interspace from each other and 17 mm from angled implants. Central implants were perpendicular and the

other implants had the divergence of 15 and 25º. The implants and Teries were fabricated using acrylate and polymeric acryl. A

total of 30 tery were fabricated (n= 15 in each group). In group A, Open tray with splinted impression copings and group B with

splinted impression copings non-splinted. Then, Splinted and non-splint in open-tray impression techniques were evaluated.

Each casts were measured by coordinated measuring machine device for implant position. The content of dimensional changes

in transfer of implant positions was reported in for the four interspaces (A

1

, A

2

, A

3

and A

4

). According to the results, changes in

transfer of implant in A

1

, A

2

, A

3

and A

4

positions were 19.014±0.04, 15.763±0.01, 62.619±0.05 and 54.019±0.05mm, respectively

in Splinted group. In the non-splinted group changes in transfer of implant positions were 18.896±0.05, 15.772±0.01, 62.664±0.02

and 54.063±0.02mm for A

1

, A

2

, A

3

and A

4

positions, respectively. According to the results, signi cant difference detected in in

dimensional accuracy of the resultant casts made from Splinted and non-Splinted impression techniques (P<0.05). These results

suggested splinted impression technique is recommended for angulated implants.

KEY WORDS: IMPRESSION TECHNIQUE, DIMENSIONAL CHANGES, IMPLANT

109

ARTICLE INFORMATION:

*Corresponding Author:

Received 27

th

Nov, 2016

Accepted after revision 26

th

March, 2017

BBRC Print ISSN: 0974-6455

Online ISSN: 2321-4007 CODEN: USA BBRCBA

Thomson Reuters ISI ESC and Crossref Indexed Journal

NAAS Journal Score 2017: 4.31 Cosmos IF : 4.006

© A Society of Science and Nature Publication, 2017. All rights

reserved.

Online Contents Available at: http//www.bbrc.in/

110 A COMPARATIVE ANALYSIS OF SPLINTED AND NON-SPLINT IN OPEN-TRAY IMPRESSION TECHNIQUES BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Ezatollah Jalalian et al.

INTRODUCTION

A variety of impression techniques for the fabrication of

implant supported prosthesis have evolved in the past

decade. Selection of a speci c technique depends on the

evaluation of a particular patient and the clinical situa-

tion present. In the fabrication of implants, the primary

objective of impression making is to record and transfer

the relationship between the non-yielding, osseointe-

grated xture abutments and reproduce the relationship

in the master cast (Nayar et al. 2014). Prosthesis mis t

may lead to mechanical and biological problems in sup-

porting implants. Mechanical complications that might

arise from prosthesis mis t include screw loosening,

abutment or implant screw fracture and occlusal inac-

curacy (Ebadian et al. 2015).

The rst step to ensure the passive t of the implant-

supported framework is accurate recording of the

implants’ positions and distances through the impression

procedure (Conrad et al. 2007). There are many poten-

tial factors which in uence the accuracy of implant-

supported superstructures such as mandibular exure,

impression technique, impression material and t tol-

erance between intra-oral abutments using the impres-

sion copings (Assuncao et al. 2004). Various techniques

have been suggested to achieve an accurate master cast

(Assuncao et al. 2004). Dental impression is used to pro-

duce a positive replica of the structure for use as a per-

manent record or in the production of a dental restora-

tion or prosthesis (Alikhasi et al. 2013). Most of implant

impression techniques, such as, pick-up, and transfer

techniques and splint and non-splint techniques, have

been introduced, in search of the most accurate tech-

nique. In certain clinical situation, some of the factor

such as the angulations or depth of implants, may affect

the accuracy of the implant impressions (Prakash and

Chowdhary, 2016).

An inaccurate impression may result in prosthe-

sis mis t, which may cause biological and mechanical

complications. Various mechanical complications such

as loosening of screw, fracture of screw or implant and

occlusal inaccuracy may have been arisen from prosthe-

sis mis t (Prithviraj et al. 2011). Along with the evolution

of acrylic resin metal implant supported xed complete

denture for an edentulous jaw, the splint technique for

an implant impression was introduced (Lee et al. 2011).

It is reported the splint technique have greater accuracy

as compared to the non-splint technique (Prakash and

Chowdhary, 2016).

Some of problems faced with the splint technique

are fracture of the connection between the splint mate-

rial and the impression copings and distortion of the

splint materials. The metal-splinted direct technique

produced the most accurate casts, then the acrylic resin-

splinted direct, indirect and unsplinted direct techniques

(Papaspyridakos et al. 2011).Despite researches were

done on accuracy of Splinted and non-splint in open-

tray impression techniques, scarce information exist on

accuracy of these techniques on angled implants. Due to

the effect of various impression techniques on accuracy

of nal cast dimensions and controversies about the best

techniques, this study was performed to compare the

Splinted and non-splint in open-tray impression tech-

niques on 15 and 25º angled implants.

MATERIAL AND METHODS

At rst steel model in 8 cm diameter and 3 cm height

were made with 4 holes to stabilize 4 implants. Two

central implants had 12 cm interspace from each other

and 17 mm from angled implants. Central implants were

perpendicular and the other implants had the divergence

of 15 and 25º. The implants and Teries were fabricated

using acrylate and polymeric acryl. A total of 30 tery

were fabricated (n= 15 in each group). In group A, Open

tray with splinted impression copings and group B with

splinted impression copings non-splinted. Polyether

impression material (3m ESPE Impregum, USA) with 4

mm thickness was used to make the impression. In order

to make the main casts, stone plaster type IV were used.

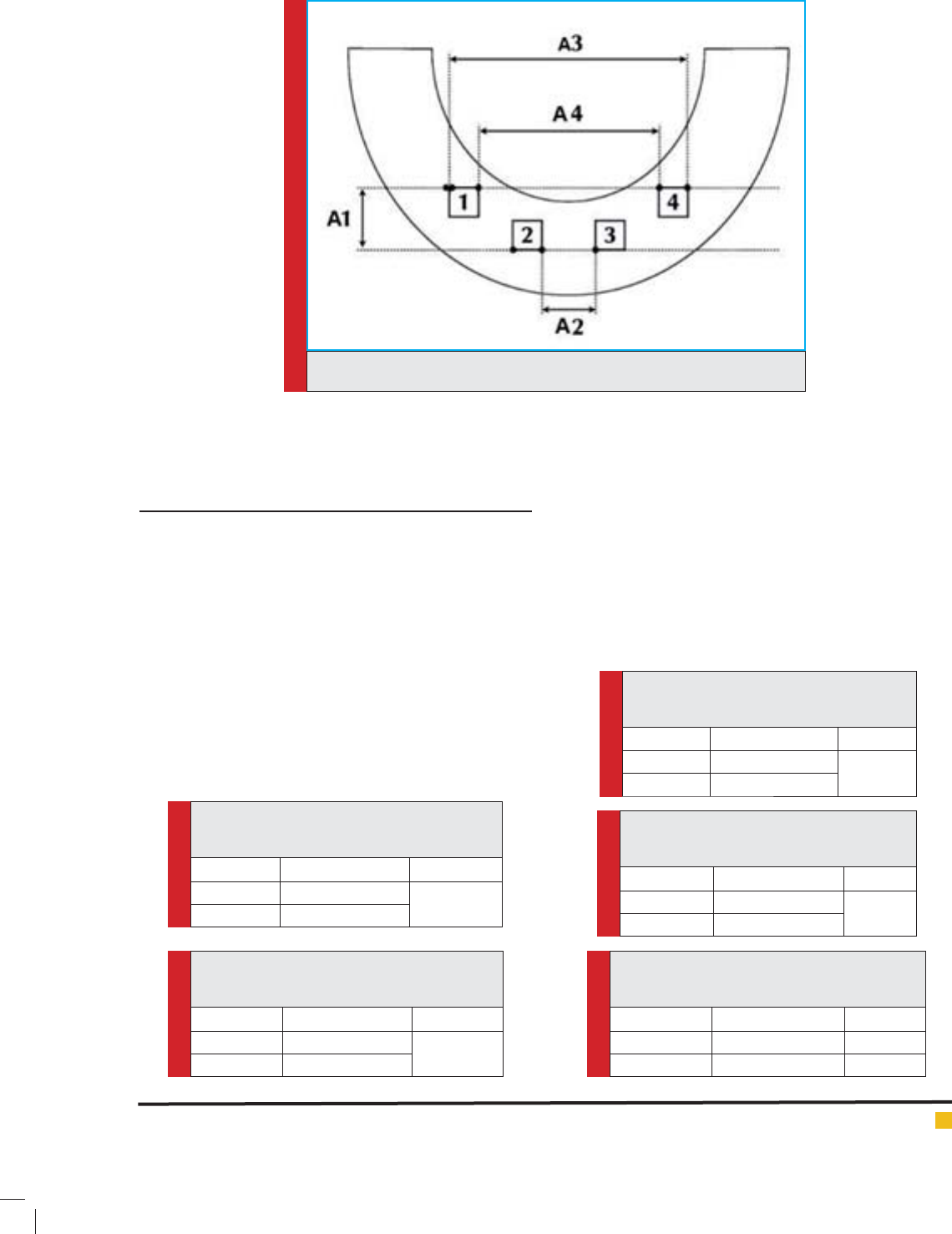

THE POSITIONING OF THE INTERSPACES

A

1

: distance between anteroposterior analogous

A

2

: distance between distal-lateral proximal left and right

analogous

A

3

: distance between mediolateral distal left and right anal-

ogous

A

4

: distance between mediolateral distal left and right anal-

ogous

Then, Splinted and non-splint in open-tray impres-

sion techniques were evaluated. Each casts were meas-

ured by coordinated measuring machine (CMM) device

for implant position. (Zeiss, Industrial Mess Technique,

Oberkochen, Germany). The accuracy of CMM for the x,

y and z axes was <0.0001 mm. The same operator used

probe head and single probe in all measurements. Umess

software (SW, Umess UNIX/ LINUX, Zeiss, Oberkochen,

Germany) was used for geometric transformation and

data collection. The content of dimensional changes in

transfer of implant positions was reported in for the four

interspaces (A

1

, A

2

, A

3

and A

4

).

STATISTICAL ANALYSIS

The operator was blind about test groups. Multivariate

two-way analysis of variance (ANOVA) was undertaken

to determine whether signi cant differences existed

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS A COMPARATIVE ANALYSIS OF SPLINTED AND NON-SPLINT IN OPEN-TRAY IMPRESSION TECHNIQUES 111

Ezatollah Jalalian et al.

between groups and one sample t-test was used to com-

pare the test groups with master model (P<0.05).

RESULTS

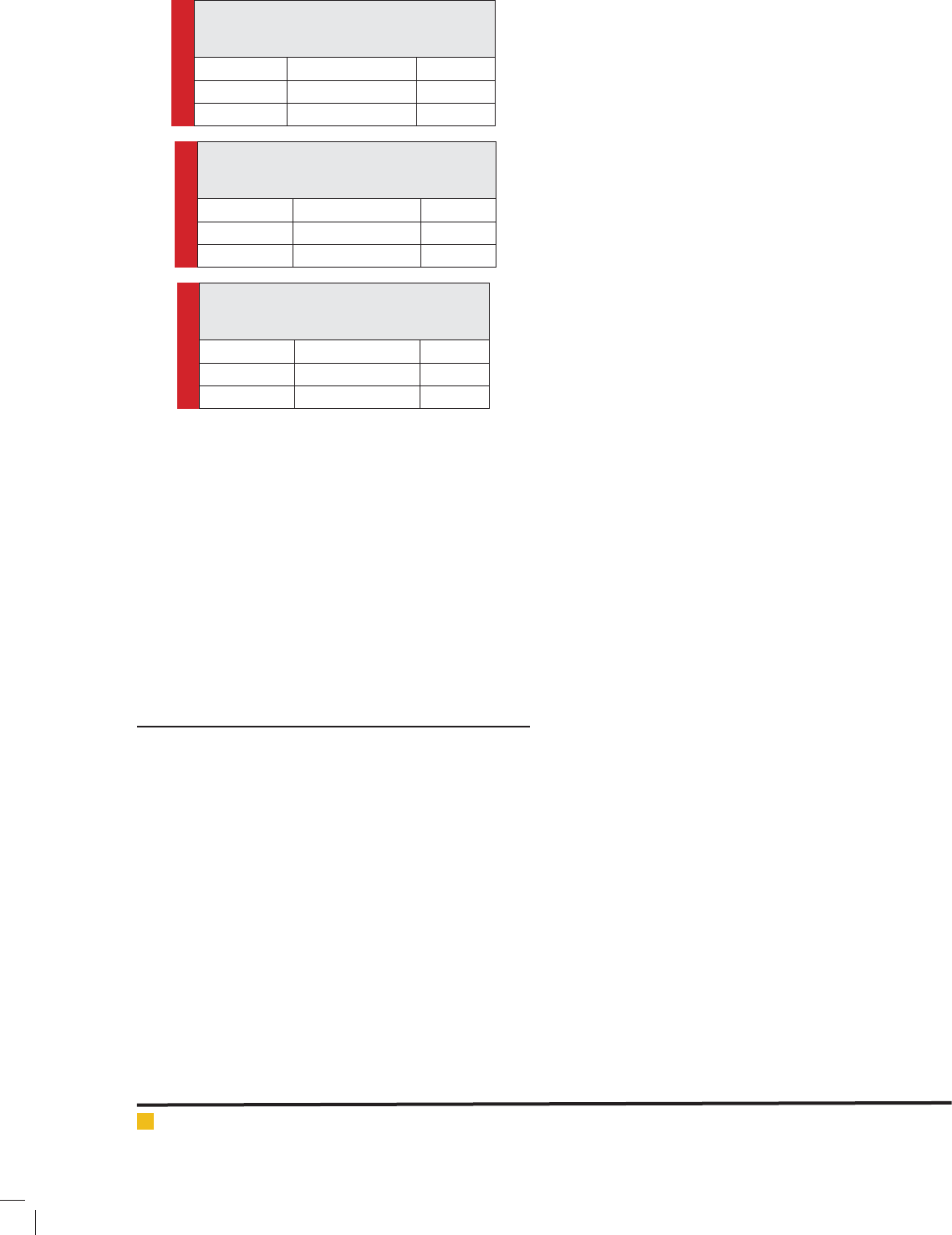

According to the results (table 1), signi cant differ-

ence detected in interspace of perpendicular and angled

implant during casting by Splinted (19.014±0.04) and

non-Splinted (18.896±0.05) impression techniques in A

1

position (P=0.0001).

As seen in table 2, no signi cant difference detected

on interspace of perpendicular implant during casting by

Splinted (15.763±0.01) and non-Splinted (15.772±0.01)

impression techniques in A

2

position (P=0.143).

Based on the results (table 3), interspace of 15 and

25º angled implant during casting by Splinted and non-

Splinted impression techniques in A

3

position were

62.619±0.05 and 62.664±0.02, respectively (P=0.005).

A signi cant difference detected for interspace of

15 and 25º angled implant during casting by Splinted

(54.019±0.05) and non-Splinted impression (54.063±0.02)

techniques in A

4

position (P=0.005) (table 4).

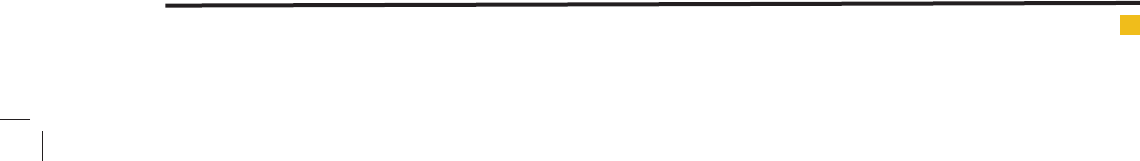

The results (table 5) of the changes in interspace of

perpendicular and angled implant using Splinted and

non-Splinted impression techniques in A

1

position is

presented in table 5. No signi cant difference detected

using splinted (0.01 mm) impression technique in A

1

position (P=0.13) while signi cant change observed

using non-Splinted (0.999 mm) impression (P=0.0001).

FIGURE 1. The positioning of the interspaces

Table 1. interspace of perpendicular and angled

implant during casting by Splinted and non-Splinted

impression techniques in A1 position

Mean ± SD (mm) P. Value

splinted 19.014±0.04

0.0001

Non-splinted 18.896±0.05

Table 2. interspace of perpendicular implant during

casting by Splinted and non-Splinted impression

techniques in A2 position

Mean ± SD (mm) P. Value

splinted 15.763±0.01

0.143

Non-splinted 15.772±0.01

Table 3. interspace of 15 and 25º angled implant

during casting by Splinted and non-Splinted

impression techniques in A3 position

Mean ± SD (mm) P. Value

splinted 62.619±0.05

0.005

Non-splinted 62.664±0.02

Table 4: interspace of 15 and 25º angled implant

during casting by Splinted and non-Splinted

impression techniques in A4 position

Mean ± SD (mm) P. Value

splinted 54.019±0.05

0.005

Non-splinted 54.063±0.02

Table 5. the changes in interspace of perpendicular

and angled implant using Splinted and non-Splinted

impression techniques in A1 position

Difference (mm) P. Value

splinted 0.01 0.13

Non-splinted 0.999 0.0001

Ezatollah Jalalian et al.

112 A COMPARATIVE ANALYSIS OF SPLINTED AND NON-SPLINT IN OPEN-TRAY IMPRESSION TECHNIQUES BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

As seen in table 6, no signi cant difference detected

on implant position using splinted (0.2 mm) and non-

Splinted impression (0.3 mm) techniques in A

2

position

(P=0.45).

Furthermore, no signi cant difference detected on

changes in interspace of 15 and 25º angled implant

using splinted (0.02 mm) and non-Splinted (0.03 mm)

impression techniques in A

3

position

No signi cant differences detected on interspace changes

of 15 and 25º angled implant using Splinted (0.01 mm)

impression (P=0.45) while signi cant difference detected

using non-Splinted impression (0.054 mm) (P=0.0001).

DISCUSSION

Based on the results, it seems, splinted impression tech-

nique is recommended for angulated implants. Many

clinical studies emphasize the passive t of implant-

supported superstructures for the long-term success of

treatment. The mean change in distances between ana-

logues in samples in the anteroposterior direction was

more than mediolateral direction compared with the

original model (Lee et al. 2008). Some studies reported

a higher accuracy for open impression technique than

closed impression technique when impression was

made from 4 or more implants (Papaspyridakos et al.

2012). Many studies have recommended splinting of

implants to increase the accuracy of the impression,

although the success of this technique is questionable

(Lee et al. 2008). Splinting can be done with different

materials such as autopolymerized acrylic resins, light-

polymerized acrylic resins or dental stones (Holst et al.

2007). Splinting with acrylic resin may be dif cult and

time-consuming and distortion of this material may be a

problem (Holst et al. 2007).

In a study, Balouch (2013) in a study, based on their

report dimensional changes were 129 ± 37 and 143.5 ±

43.67μ in closed tray and open tray, while coef cient of

variation in closed-tray and open tray were reported to

be 27.2 and 30.4%, respectively. Closed impression tech-

nique had less dimensional changes in comparison with

open tray method, so this study suggests that closed tray

impression technique is more accurate (Balouch 2013).

Among the impression making methods presented in

the literature, the splinted technique has gained popu-

larity and has proven to be the most accurate (Assun-

ção et al. 2008). The splinted direct techniques use

square transfer copings, connected to each other with

a rigid material, in a customized open impression tray.

Although different materials have been tested to splint

impression copings, such as composite resin, impression

plaster, and stainless steel pins; acrylic resin, alone or

in combination with dental oss, is the material used

most often to prevent individual coping movements

during the impression-making procedure (Del Acqua et

al. 2010). Even though there was no consistent result

for higher accuracy with any one technique as opposed

to the other, splint or non-splint, more number of stud-

ies has reported increased accurate implant impressions

with the splint technique than with the non-splint tech-

nique (Vigolo et al. 2005).

The accuracy of a splinted impression technique

depends upon its resistance to deformation under the

forces of impression material. Thus, theoretically, a tech-

nique that uses a more rigid splint material would pro-

duce a more accurate master cast. Therefore, the rigid-

ity and dimensional stability of a metal framework in

combination with impression plaster might make it a

good choice for splinting the impression copings (Lee

et al. 2008). The splinting technique using light cured

acrylic resin was signi cantly less accurate than by

using autopolymerizing resin or by impression plaster.

This may be caused by the incomplete polymerization of

the light cured acrylic resin; another reason may be that

the shrinkage during polymerization of the light cured

acrylic resin creates stresses at the impression coping

acrylic resin interface (Assunção et al. 2008). Also,

Daoudi et al. (2004) compared the closed tray technique

at the implant level with the open tray technique at the

abutment level for single tooth implants and found the

open tray technique to be superior and more predictable.

Furthermore, Carr (1992) compared the open and closed

tray techniques with a 5 implant mandibular cast where

the interabutment divergence angles were all less than

15 degrees. The open tray technique was found to be

superior as it provided the most accurate working cast.

Table 6. the changes in interspace of perpendicular

implant using Splinted and non-Splinted

impression techniques in A2 position

Difference (mm) P. Value

splinted 0.2 0.45

Non-splinted 0.3 0.45

Table 7. the changes in interspace of 15 and 25º

angled implant using Splinted and non-Splinted

impression techniques in A3 position

Difference (mm) P. Value

splinted 0.02 0.45

Non-splinted 0.03 0.45

Table 8. the changes in interspace of 15 and 25º

angled implant using Splinted and non-Splinted

impression techniques in A4 position

Difference (mm) P. Value

splinted 0.01 0.45

Non-splinted 0.054 0.0001

Ezatollah Jalalian et al.

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS A COMPARATIVE ANALYSIS OF SPLINTED AND NON-SPLINT IN OPEN-TRAY IMPRESSION TECHNIQUES 113

Some of the studies that advocated the splinting tech-

nique over the non-splinted technique have shown fur-

ther that splinting with autopolymerized acrylic resin,

sectioned post-setting, and rejoined, yielded the best

results within the various splinting group combinations.

However, this nding was not applicable to all studies

that examined the effect (Rustum Baig, 2014). Splinted

direct technique was found to be the most accurate for

multi-unit situations with two highly unparallel (20-

to 25-degree divergence) implants. This nding was,

however, in disagreement with a few other studies that

showed no correlation between direct splint and non-

splint (Filho et al. 2009). With regards to the tray type

and material, rigid custom trays81 or modi ed metal

stock trays82 produced more accurate impressions in

comparison with the polycarbonate (plastic) stock trays.

On the reuse of impression copings, it has been shown

recently that the impression accuracy is unaffected

when copings were reused up to ten times (Alikhasi

et al. 2013). Some non-splint techniques have shown

improved accuracy in comparison to splinted methods,

achieved through impression coping modi cation prior

to impression making (Lee et al. 2008). In conclusion,

these results suggested splinted impression technique is

recommended for angulated implants.

REFERENCES

Alikhasi M, Bassir S, Naini R.(2013) Effect of multiple use of

impression copings on the accuracy of implant transfer. Int J

Oral Maxillofac Implants ;28: 408–414.

Alikhasi M, Siadat H, Rahimian S.(2013) The Effect of Implant

Angulation on the Transfer Accuracy of External-Connection

Implants. Clin Implant Dent Relat Res. Dec 3. doi: 10.1111/

cid.12185

Assunção WG, Cardoso A, Gomes EA, Tabata LF, dos Santos

PH. (2008) Accuracy of impression techniques for implants.

Part 1 – in uence of transfer copings surface abrasion. J Pros-

thodont. 17: 641-7.

Assuncao WG, Filho HG, Zaniquelli O. (2004) Evaluation of

transfer impressions for osseointegrated implants at various

angulations. Implant Dent 13:358-66.

Balouch F., Jalalian E., Nikkheslat M., Ghavamian R., Toop-

chi Sh., Jallalian F., Jalalian S.(2013) Comparison of Dimen-

sional Accuracy between Open-Tray and Closed- Tray Implant

Impression Technique for 15° Angle Implants. J Dent Shiraz

Univ Med Sci, Sept. 14(3): 96-102.

Carr AB. (1992) Comparison of impression techniques for a

two-implant15-degree divergent model. Int J Oral Maxillofac

Implants. 7:468-75.

Conrad HJ, Pesun IJ, DeLong R, Hodges JS. (2007) Accuracy of

two impression techniques with angulated implants. J Prosthet

Dent 97:349-56.

Daoudi MF, Setchell DJ, Searson LJ. (2004) An evaluation

of three implant level impression techniques for single tooth

implant. Eur J Prosthodont Restor Dent. 12:9-14.

Ebadian B, Rismanchian M, Dastgheib B, Bajoghli F. (2015).

Effect of different impression materials and techniques on

the dimensional accuracy of implant de nitive casts. Dental

Research Journal 12(2): 136-143.

Filho HG, Mazaro J, Vedovatto, E, Assuncao W, Santos P.(2009)

Accuracy of impression techniques for implants. Part 2: Com-

parison of splinting techniques. J Prosthodontics 18:172–176.

Holst S, Blatz MB, Bergler M, Goellner M, Wichmann M.(2007)

In uence of impression material and time on the 3-dimensional

accuracy of implant impressions. Quintessence Int 38: 67-73.

Lee H, Ercoli C, Funkenbusch PD, Feng C.(2008) Effect of sub-

gingival depth of implant placement on the dimensional accu-

racy of the implant impression: an in vitro study. J Prosthet

Dent 99:107–113.

Lee H, So JS, Hochstedler JL, Ercoli C.(2008) The accuracy

of implant impressions: A systematic review. J Prosthet Dent

100:285-91.

Lee YJ, Heo SJ, Koak JY, Kim SK. (2009) Accuracy of different

impression techniques for internalconnection implants. Int J

Oral Maxillofac Implants. 24(5):823-30.

Mirza Rustum Baig. (2014) Multi-unit implant impression

accuracy: A review of the literature. Quintessence Int 45:39–51

Nayar S, Rathinavel PM, Bhuminathan S, Raghavendra jayesh

S, Vidhya J. (2015) Impression technique in implantology: A

Review. RJPBCS. 5(2): 1934- 1940.

Papaspyridakos P, Benic GI, Hogsett VL, White GS, Lal K,

Gallucci GO. (2012)Accuracy of implant casts generated with

splinted and non-splinted impression techniques for edentu-

lous patients: An optical scanning study. Clin Oral Implants

Res 23:676-81.

Papaspyridakos P, Lal K, White GS, Weber HP, Gallucci GO.

(2011) Effect of splinted and nonsplinted impression tech-

niques on the accuracy of t of xed implant prostheses in

edentulous patients: a comparative study. Int J Oral Maxillofac

Implants. 26(6):1267-72.

Prakash S, Chowdhary R. (2016). Impression techniques and

impression materials in dental implant supported restorations-

a systematic review. International Journal of Recent Scienti c

Research. 7(4): 10285-10295.

Prithviraj DR, Pujari LM, Garg P, Shruthi DP (2011) Accuracy

of the implant impression obtained from different impression

materials and techniques: review. J Clin Exp Dent 3(2):e106–

e1118.

Vigolo P, Fonzi F, Majzoub Z, Cordioli G.(2005) Master cast

accuracy in single-tooth implant replacement cases: an in vitro

comparison. A technical note. Int J Oral Maxillofac Implants.

20:455-60.

Del Acqua MA, Chavez AM, Castanharo SM (2010) The effect

of splint material rigidity in implant impression techniques. Int

J Oral Maxillofac Implants. 25:1153-1158.