Medical

Communication

Biosci. Biotech. Res. Comm. 10(3): 551-556 (2017)

Effect of dynamic loading on removal torque value of

one-piece and two-piece abutments

Farnaz Firouz

1

, Bijan Heidari

2

, Sara Alijani

3

and Sara Khazaei

4*

1

DDS, MS, Assistant Professor, Department of Prosthodontics, School of Dentistry, Hamadan University of

Medical Sciences, Hamedan, Iran

2

DDS, MS, Assistant Professor, Department of Prosthodontics, School of Dentistry, Shahid Beheshti

University of Medical Sciences, Evin, Tehran, Iran

3

DDS, MS, Assistant Professor, Department of Orthodontics, School of Dentistry, Hamadan University of

Medical Sciences, Hamedan, Iran

4

*DDS, MS, Assistant Professor, Department of Prosthodontics, School of Dentistry, Hamadan University of

Medical Sciences, Hamedan, Iran

ABSTRACT

The aim of this study was to assess the effect of dynamic loading and abutment type on removal torque value. Thirty-two analogs

of xtures with internal taper connections were divided into two groups of 16. The one-piece (OP) group received solid (one-piece)

abutments and the two-piece (TP) group received two-piece abutments. Each group was further subdivided into subgroups C

(control) without mechanical loading and T (test) with mechanical loading. The screw of abutments in OPC and TPC groups, were

tighten and then removed to record the removal torque value (RTV). In OPT and TPT groups, abutments were tighten, mechani-

cally loaded (300,000 cycles), removed, and the RTV were recorded. Two-way ANOVA and Tukey’s HSD post-hoc testwere used

for data analysis.The signi cance threshold was set at 0.05. The mean torque loss of OPC group was signi cantly lower than both

TPC and OPT groups (P < 0.05). But there was not signi cant different in torque lossvalues between abutments in TPC and TPT

groups.Under mechanical loading, theremoval torque of both one-piece and two-piece groups decreased and this reduction was

only signi cant for one-piece group. Also, the abutment type has signi cant effect on removal torque value.

KEY WORDS: TORQUE, DENTAL ABUTMENT, CYCLIC LOADING

551

ARTICLE INFORMATION:

*Corresponding Author: sarakhazaei_83@yahoo.com

Received 29

th

June, 2017

Accepted after revision 19

th

Sep, 2017

BBRC Print ISSN: 0974-6455

Online ISSN: 2321-4007 CODEN: USA BBRCBA

Thomson Reuters ISI ESC and Crossref Indexed Journal

NAAS Journal Score 2017: 4.31 Cosmos IF: 4.006

© A Society of Science and Nature Publication, 2017. All rights

reserved.

Online Contents Available at:

http//www.bbrc.in/

DOI: 10.21786/bbrc/10.3/32

INTRODUCTION

Failure and complications with implant-supported pros-

theses still occur, despite the high clinical success rates

in long-term. These complications include biological

and mechanical problems. Screw loosening is the most

commonly reported mechanical complication for sin-

gle implant-supported prostheses. Different factors may

552 EFFECT OF DYNAMIC LOADING ON REMOVAL TORQUE VALUE BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Farnaz Firouz et al.

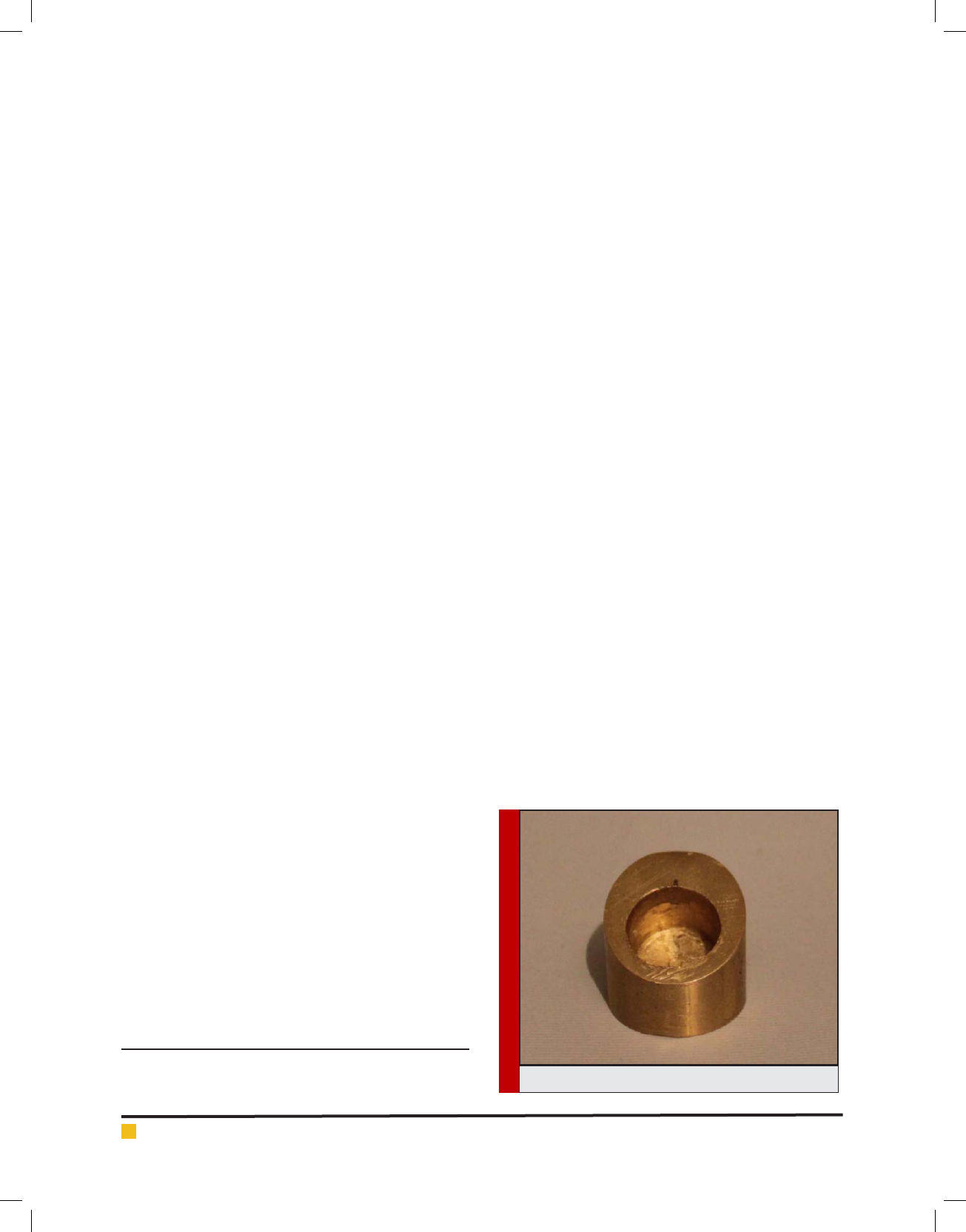

FIGURE 1. Brass mold

contribute to loss or decrease in abutment screw torque

such as fatigue, inappropriate tightening torque, failure

in screw retightening after initial placement, settling

effect, vibrating micro movements and excessive bend-

ing. The mis t of abutment or implant-supported crown,

occlusal loading and structural design of implant con-

nection are among other factors playing a role in this

respect (Norton (1997, Jörnéus et al., 1992, Coelho et al.,

2007 De Boever et al., 2006, Theoharidou et al., 2008).

The implant-abutment interface design can be roughly

divided into two groups namely (I) butt-joints or slip t

joints with a passive t and (II) conical interface with fric-

tional t between mating surfaces of abutment-implant

complex; the latter type of interface also known as lock-

ing or Mores taper connection. In most previous studies,

internal taper connections showed superior performance

and were thought to minimize screw loosening and frac-

ture, which commonly occur external hexagon butt-joint

connections. An internal tapered abutment, based on the

speci c system used, may be attached to implant body by

an external screw, orwith threads machined directly on

the abutment body itself, which are calledone-piece (solid

abutment) and two-piece abutments, respectively, (Finger

et al., 2003 Budynas et al., 2008, Hansson 2000, Dittmer et

al., 2011, Ricciardi et al., 2009, Cehreli et al., 2004 Aguir-

rebeitia et al., 2013 Rabelo et al., 2015).

It has been proven that both types are highly resist-

ant to fatigue under dynamic loads and could function

without any mechanical problems. One concern regarding

the internal taper connection system is the possibility of

cold welding of the abutment inside the implant. This was

also mentioned by Sutter et al; whereas, other authors

concluded that cold welding is presumably neutralized by

a phenomenon called embedment relaxation. Clinically,

it seems that One-piece abutments may be removed from

the xture more easily than two piece abutments, due to

the nature of their design,which may causeless problems

during removal, (Bozkaya et al., 1995, Weiss et al., 2000,

Pintinha et al., 2013, Rabelo et al., 2015).

As mentioned earlier, screw loosening is the most com-

mon complication in single implant -supported restora-

tions. This is important, particularly, incemented prosthesis,

in which loosening or fracture of the abutment screw may

lead to failure of prosthesis. Therefore, this study aimed to

evaluate the effect of dynamic loading on removal torque

value (RTV) of two types of internal taperabutments namely

one-piece and two-piece abutments. The null hypothesis

was that the RTV of one-piece and two-piece abutments

would not decrease under dynamic loading.

MATERIALS AND METHODS

In this in vitro experimental study, 32 analogs of xtures

(Ø 4.8 mm* 10 mm L, Simple line II, Dentium, Korea)

with internal taper hexagon were chosen. In addition, 32

abutments (11-degree taper, Ø 4.5 mm* 5.5 mm L, Simple

line II, Dentium, Korea) of two different types (one-piece

and two-pieces) were used. Each analog was mounted

in a mold containing auto-polymerizing acrylic resin.

The customized molds were fabricated from brass and

measured 20 mm in height and 25 mm indiameter, in

addition, their upper surfaces were cut so that this sur-

face had 30˚ angle relative to the horizontal plane. Then,

on the upper ramp, ahole was drilled perpendicular to

the surface for placement of implant analog (Figure 1).

This design of the mold allowed for the fatigue tester to

apply load to the abutment at a 30 ° angle relative to the

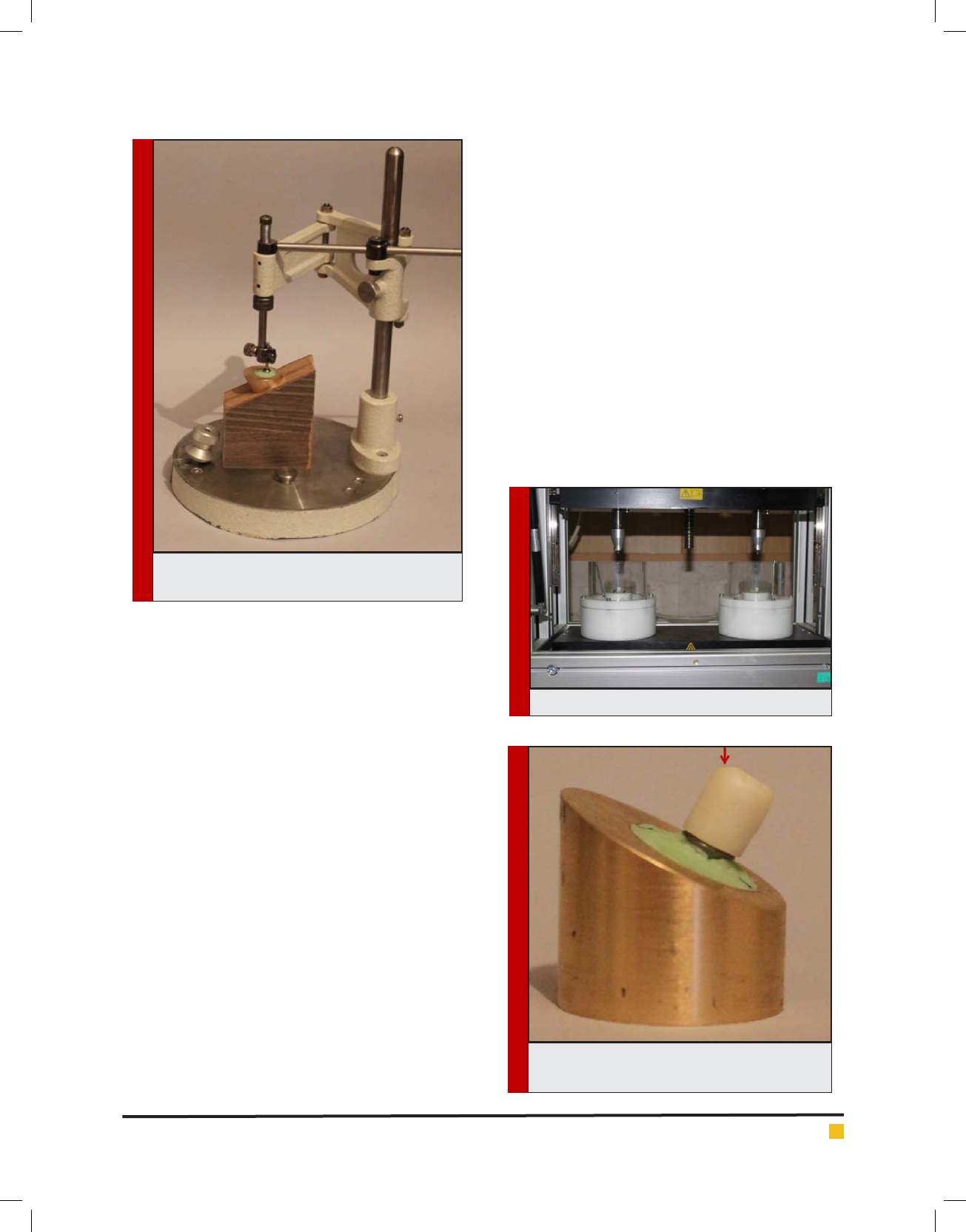

long axis. A wooden jig was used for correct positioning

of the molds on the surveyor. The jig was a ramp with

a 60 ˚ angle relative to the horizontal plane. Therefore,

by assembling the mold on the jig its upper surface was

positioned parallel to the horizon. Next, analogs were

placed inside the hole perpendicular to the ramp of mold

using a surveyor. The hole was lled with auto-polym-

erizing acrylic resin in doughy stage right before analog

insertion (Figure 2). Then, analogs were divided into two

groups according to the type of abutment they would

receive. The study groups were as follows:

OPC group: One-piece abutments that were not

subjected to dynamic loading (control group, n=8).

TPC group: Two-piece abutments that were not

subjected to dynamic loading (control group, n=8).

OPT group: One-piece abutments that were sub-

jected to dynamic loading (test group, n=8).

TPT group: Two-piece abutments that were sub-

jected to dynamic loading (test group, n=8).

To measure the tightening and removal torques, a

digital torque meter (TQ-8800; Lutron electronic, Tai-

wan) with an accuracy of precision of 0.1 Ncm was used.

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS EFFECT OF DYNAMIC LOADING ON REMOVAL TORQUE VALUE 553

Farnaz Firouz et al.

FIGURE 2. Wooden jig for correct positioning of

molds on the surveyor

Torque meter was positioned on top of a torque delivery

device and the cylinder-analog-abutment assembly was

xed into a socket at the bottom of the device.

Before screw tightening, all abutments were lubri-

cated with arti cial saliva (Saliva Substitute; Roxane

Laboratory Inc, USA). Then, all abutments in the con-

trol groups were tightened to 35 Ncm torque. After a

10-minute interval, abutments were retightened to the

same torque to compensate for the loss of preload due

to settling of surface at the interface. Ten minutes later,

the RTV of abutments in the control groups was meas-

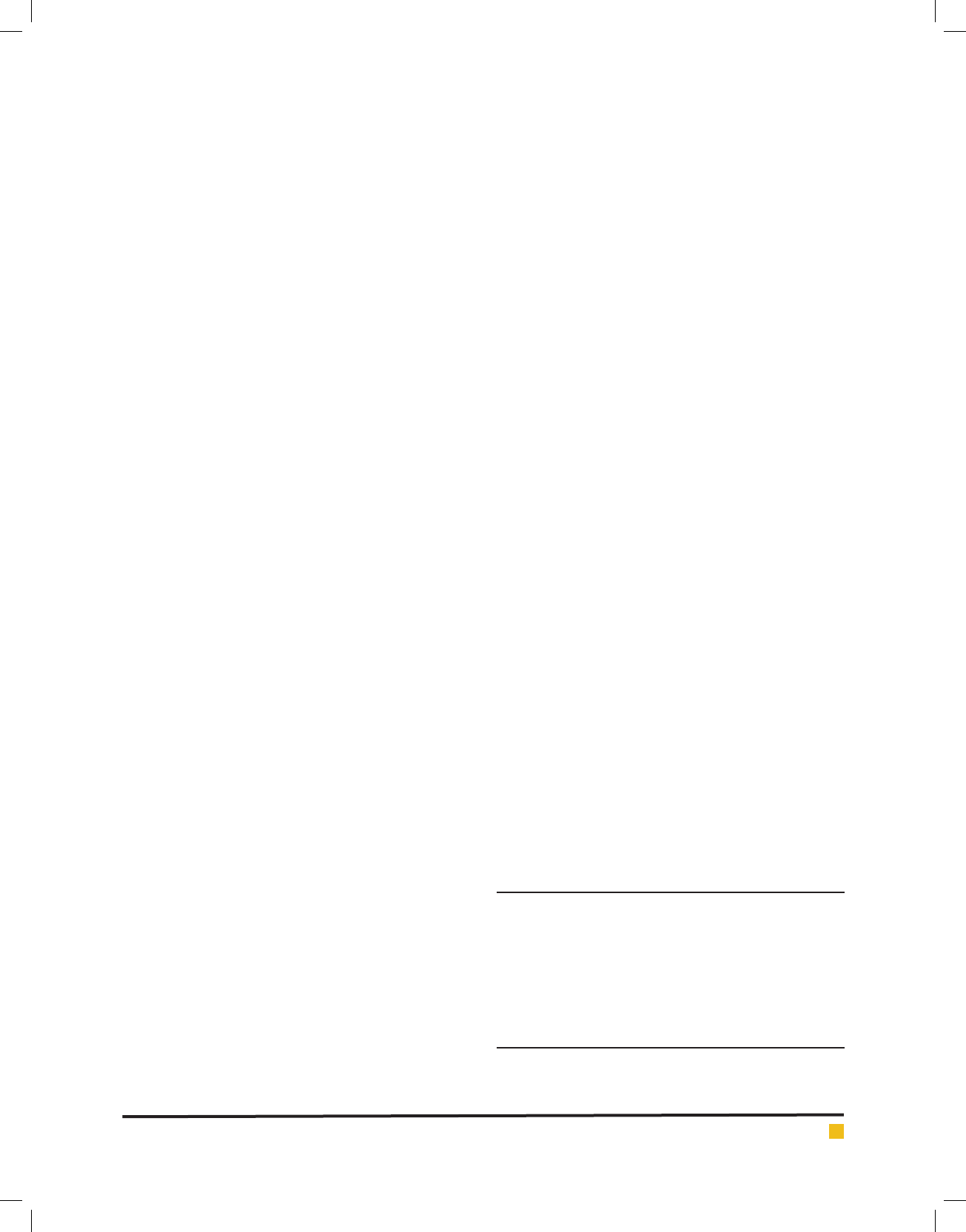

ured and recorded. For the test groups, 16 ceramic cop-

ings (e.max*Zir CAD, ivoclarvivodent) were fabricated

with the same size and shape by computer aided design/

computer aided manufacturing (CAD/CAM) technology

(Sirona in Lab MCXL, Germany).

Since these abutments were cement-retained, for

measurement of the RTV, the copings had to be removed

from the abutment. For this reason, the coping were

designed such that they had a hole in place of the abut-

ment screw. Therefore, we hada direct accessto the cop-

ing hole, and there was no need to remove the crown

after loading. Then, the adaptation of copings was veri-

ed and con rmed using light body silicone (Speedex,

condensation polysiloxane, low consistency, Colten,

Switzerland).

In the test groups, as well as the control groups, the

abutments were torqued to 35 Ncmby digital torque

meter in two cycles with 10-minutes intervals. Then, the

crowns were placed on the abutments and cemented by

a temporary cement (Temp bond, Kerr, Italy). During the

experiment, the hole of crown was covered with com-

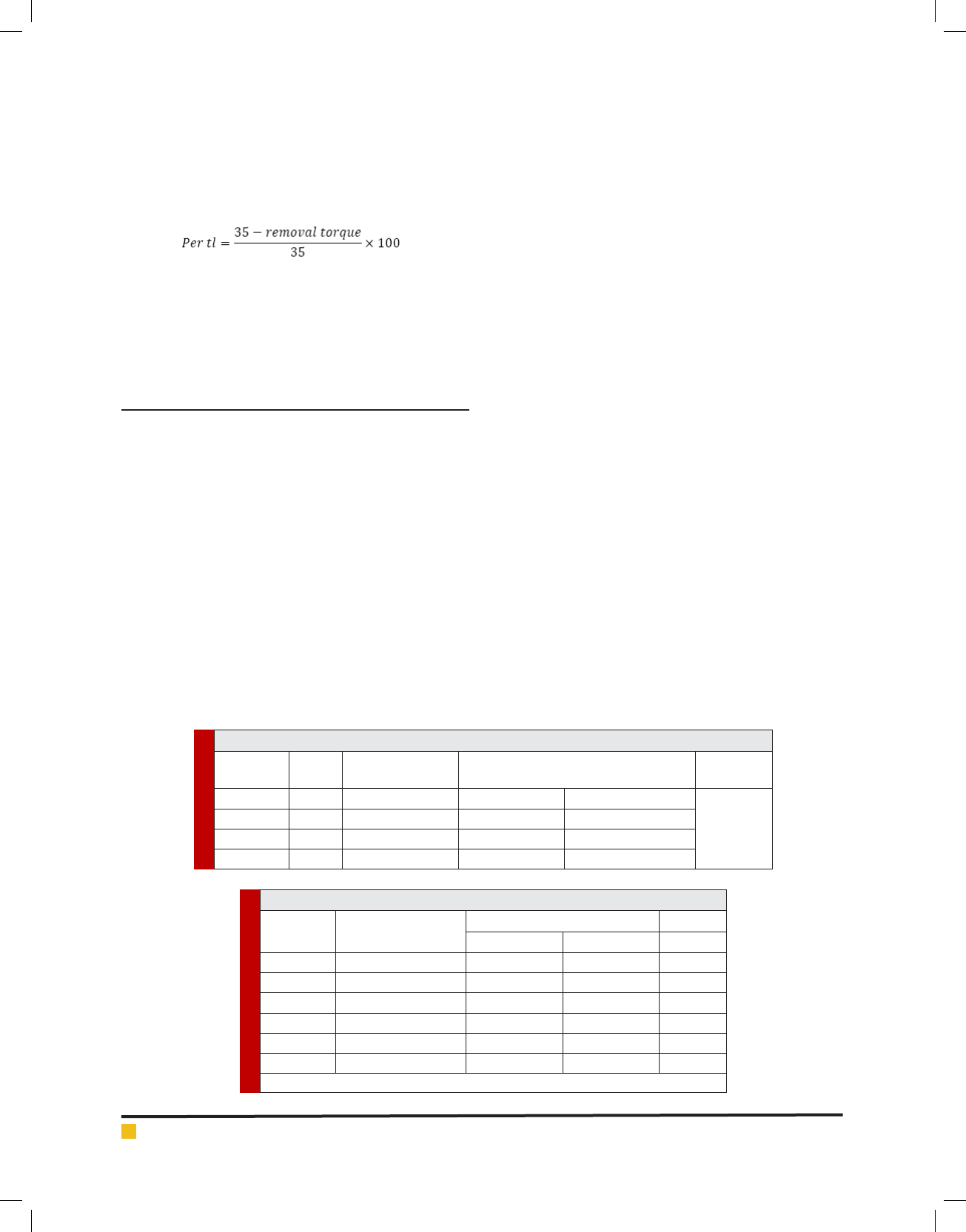

posite. Afterward, each assembly of mold-analog-abut-

ment-cap from the test groups was mounted and xed

to the electromechanical fatigue testing machine (CS-4,

SDM echatronik, Germany) (Figure 3). The device has

two lever arms that simultaneously apply force. The arm

of device was so that the force was applied to the upper

most part of the coping (Figure 4).

The fatigue tester was calibrated so that the lever

arm soperated for 300,000 cycles (nearly corresponding

toone year of chewing function) at a speed of 1Hz (60

rpm) [19].the position of load was Oblique load (withan

angle of 30˚) of 100±5N was applied to each coping [19].

FIGURE 3. Dynamic fatigue tester

FIGURE 4. Ceramic coping and position of apply-

ing force

554 EFFECT OF DYNAMIC LOADING ON REMOVAL TORQUE VALUE BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Farnaz Firouz et al.

After each test, the specimens were transferred to the

torque delivery device and the RTV was measured and

recorded. The following formula was used to calculate

the percentage of torque loss (Per tl):

SPSS software version 21 was used for statistical

analysis. The Per tl were statistically analyzed by Two-

way ANOVA and Tukey’s HSD post-hoc test. The signi -

cance threshold was set at 0.05.

RESULTS AND DISCUSSION

None of the tested samples showed abutment or screw

fracture; there was no sign of crown loosening either

after loading. Two-way ANOVA indicated that abut-

ment types, dynamic loadingand their interaction had

signi cant effects (P<0.05) on Percentage of torque loss.

Table 1 shows the mean and standard deviations of Pertl

inall study groups. There moval torque of abutments

decreased in both groups (control and test group). The-

OPC group presented the lowest torque loss. The highest

torque loss was observed in OPT group. Pair wise com-

parisons of Pertl were then performed with Tukey’s HSD

post-hoc test (Table 2). The mean Pertl in abutments of

OPC group was signi cantly lower than that in TPC and

OPT groups (P<0.05). Also, the difference between OPT

and TPT groups was signi cant (P<0.05), But there was

no signi cant different in Per tl of abutments between

TPC and TPT groups (P>0.05). In our study, all abut-

ments in both control and test groups showed reduc-

tion in removal torque value compared to the insertion

torque. Thisindicated that no cold welding occurred in

any implant-abutment interface, which was consistent

with the results of previous studies (Norton 1999, Ric-

ciardi et al, 2009 Pintinha et al., 2013, Kim et al 2014).

Norton showed that cold welding occurs only at the

highest level of torque, right before the component fail-

ure and when plastic deformation is expected. In addi-

tion, cold welding does not occurin clinical levels of

torque, and the removal torque is expected to be 10 to

20 % less than the initial torque. However, Sutter and

colleagues stated that following torque application, the

removal torque increases from 10 to 15 % compared to

the initial torque in internal taper connections. They

argued that probably, the effect of axial component of

the simulated occlusal force surpasses other oblique and

tensile forces that interact negatively with retention of

abutments. But, other authors have reported different

results, indicating that the cold welding, if occurs, is

compensated by the settling effect, (Ricciardi et al., 2009

Cehreli et al., 2004).

The results from One-piece abutments showed that

the mean torque loss Inthe test group was signi cantly

higher than that in control group (8.93% in the control

and 51.02 % in the test group). In One-piece systems,

abutment serves asa screw; therefore, in the test group,

with application of dynamic load, these forcesare directly

transferred to the threads and decrease the removal

torque. In addition, the bending and tensile stresses are

produced at the interface andlead to greater reduction

Table 1. Mean and standard deviation of per tl for all groups (n=8)

Group N

Mean±standard

deviation

95% con dence interval for the mean

Lower boundUpper bound P value

OPC 8 8.93±4.76 4.9533 12.9167

.000

OPT 8 51.02 ±4.61 47.1711 54.8839

TPC 8 22.8±8.00 16.1642 29.5408

TPT 8 23.2± 8.97 15.8487 30.5538

Table 2. Results of Tukey’s HSD post-hoc test for pairwise comparisonsper tl

Mean Difference (I-J)

95% Con dence Interval

Lower Bound Upper Bound P value

OPC& OPT -42.092* -51.3843 -32.8007 .000

OPC&TPC -13.917* -23.2093 -4.6257 .002

OPC&TPT -14.266* -23.5581 -4.9744 .001

OPT&TPC 28.175* 18.8832 37.4668 .000

OPT&TPT 27.826* 18.5344 37.1181 .000

TPC&TPT -0.34875 -8.9431 9.6406 1.000

*The mean difference is signi cant at the 0.05 level.

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS EFFECT OF DYNAMIC LOADING ON REMOVAL TORQUE VALUE 555

Farnaz Firouz et al.

oftorque. The results of a previous study showed various

ranges of torque loss in One-piece abutments. Pinhata et

al. reported the mean torque loss values of 18.35% for

the control group and 15% for the test group, Pintinha

et al. (2013). This value was between 15 and 20% in the

study by Norton et al. and between 10.5 and 5.4% in the

study by Ricciardi et al. (2013).

A mean torque reduction of 8% by Cehreli et al.

(2004) and 25% by Seol et al. (2015) has been reported

in test groups. Different results of studies can partly be

related to differences in the types of implant systems

used. In addition, differences in experimental condi-

tions should be considered. There are signi cant differ-

ences between our study and others in number of cycles,

intensity, position, angle and rate of applied force. In

two-piece abutments, the difference between the con-

trol (with 22.8% torque loss) and test group (with 23.2%

torque loss) was not statistically signi cant.

Pinhata et al. (2013) reported a mean torque loss

of 36% and 40.85% for the control and test groups,

respectively. Similarly, Ricciardi et al. 2013 found the

mean values of 32% forthe control group and 37.2%

for the test group.Also, Seol et al. (2015) reported a

mean torque loss of 48% for test group.Based on the

results of our study, in the control groups, one-piece

abutments showed signi cantly higher removal torque

value than two-pieceabutments. When opening one-

piece abutments, the retention caused by the tapered

part of the abutment as well as retention caused by the

threads should be overcome. But intwo-piece abutments,

the removal torque recorded by torque meter is mainly

spent to overcome the retention friction generated by

the threads because in two-piece abutments, the abut-

ment screw passes through the abutment andat the time

of opening, this unit is removed from the abutment.

Therefore, in these types of abutments, a large amount

of torque required by the tapered part of the abutment is

not registered by the torque meter (particularly inabut-

ments that have anti-rotation feature). Thus, it seems

logical that two-piece abutments show less removal

torque than one-piece abutments.

After applying force, the torque loss of one-piece abut-

ments was signi cantly higher than that of two-piece

abutments. In two-piece abutments, since the screw and

abutment are in two distinct parts (yet related), smaller

amount of force exerted on the abutment is transferred

to thescrew; whereas, in one-piece abutments, as men-

tioned earlier, the abutment serves as a screw and trans-

fers dynamic forces directly to the threads and decreases

the required removal torque.

In this study, we tried to establish conditions to simu-

late clinical masticatory conditions. Each sample under

went 300,000 cycles of dynamic force, which corre-

sponded to one year of normal chewing function. Inad-

dition, the abutments were lubricated by arti cial saliva

before applying torque because it has been suggested

that greater initial preload can be achieved underwet

conditions, Jaarda et al., (1993). Siamos et al., 2002 Lee

et al., 2002, Winkler et al., 2003)

Applying proper torque recommended by the manu-

facturer is very important to prevent screw loosening

and screw fracture. Jaarda et al. reported 15 to 48% error

when closing the abutment screw by hand. Therefore,

the abutments were tightened to 35 Ncm torque by a

digital torque meter. Ten minutes later, the same torque

was applied to compensate the loss of preload due to set-

tling effect. Siamos et al. suggested that in order tomini-

mize the loss of preload caused by the settling effect, the

initial torque should beapplied again 10 minutes after

initial tightening torque, (Siamos et al., 2002).

Considering the fact that biteforce actually acts on

the super structure, it was appropriate to perform anex-

periment in which dynamic forces are applied on the

abutment after cementation of crown. Before cemen-

tation, precise and passive t of caps was assessed by

light-body silicon. Prostheses with active t or improper

adaptation can exertun desirable forces on the abut-

ment, (Lee et al. 2002).

The limitations of this study included small sample

size and short-term loading. In addition, our study had

an in vitro design and had the limitation of in vitro

studies in simulating the complex nature of mastication

cycles. In the oral environment, forces are applied in

different directions and angles to the axis of abutments;

moreover, the intensity of these forces is variable in dif-

ferent situations. The maximum biting force has been-

reported in the range of 200 to 3500 N, (Winkler et al.

2003). But in the present study, a force of 100 N was

applied, which is at the low end of this range. Also, the

rate of force in this study was one hit per second, which

was continuously applied within 3 to 4 days, but in nor-

mal oral function, 300,000 cycles of force are applied in

a much longer period (aboutone year). All these factors

can affect the behavior of screw and its loosening.

CONCLUSION

Under mechanical loading, RTV of both groups (one-

piece and two-piece) decreased and this reduction was

signi cant for one-piece group. However, there was no

signi cant difference in RTV between one-piece and

two-piece abutments under dynamic loading.

ACKNOWLEDGEMENTS

I would like to express my sincere gratitude to my sta-

tistical advisor Dr. Saiid Mousavi for the continuous

Farnaz Firouz et al.

556 EFFECT OF DYNAMIC LOADING ON REMOVAL TORQUE VALUE BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

support and immense knowledge. This research received

no speci c grant from any funding agency in the public,

commercial, or not-for-pro t sectors.

Con ict of Interest “None declared”

REFERENCES

Aguirrebeitia J, Abasolo M, Vallejo J, Ansola R. 2013 Dental

implants with conical implant-abutment interface. In uence of

the conical angle difference on the mechanical behavior of the

implant. Int J Oral Maxillofac Implants Mar-Apr; 28(2): 72-82.

Bozkaya D, Müftü S. 1995 Mechanics of the taper integrated

screwed-in (TIS) abutments used indental implants. J Prosthet

Dent 74:270-8.

Budynas RG, Nisbett JK. 2008 Shigley’s mechanical engineer-

ing design. 8th ed. New York McGraw-Hill, 2008: 830-1.

Cehreli M, Duyck J, De Cooman M, Puers R, NaertI.2004

Implant design and interface force transfer. A photoelastic and

strain-gauge analysis. Clin Oral Implants Res 15:249–57.

Coelho AL, Suzuki M, Dibart S, DA Silva N, Coelho PG. 2007

Cross sectional analysis of the implant-abutment interface. J

Oral Rehabil Jul;34:508–16.

De Boever AL, Keersmaekers K, Vanmaele G, Kerschbaum G,

Theuniers G, De Boever JA. 2006 Prosthetic complications in

xed endosseous implant-bone reconstructions after an obser-

vation period of at least 40 months. J Oral Rehabil 33: 833–9.

Dittmer S, Dittmer MP, Kohorst P, Jendras M, Borchers L, Sti-

esch M. 2011. Effect of implant-abutment connection design

on load bearing capacity and failure mode of implants. J Pros-

thodont 20:510-6.

Finger IM, Castellon P, Elian N. 2003 The evolution of external

and internal implant/abutment connections. Pract Proced Aes-

thet Dent 15(8):625–34.

Hansson S. 2000 Implant-abutment interface: biomechanical

study of at top versus conical. Clin Implant Dent Relat Res

2:33-41.

Jaarda MJ, Razzoog ME, Gratton DG. 1993 Providing opti-

mum torque to implant prostheses: A pilot study. Implant Dent

2:50-2.

Jörnéus L, Jemt T, Carlsson L. 1992 Loads and designs of

screw joints for single crowns supported by osseo integrated

implants. Int J Oral Maxillofac Implants 7:353-9.

Keating K. 2001 Connecting abutments to dental implants: “an

engineer’s perspective”. Irish Dent: 43-6.

Khraisat A, Hashimoto A, Nomura S, Miyakawa O. 2004 Effect

of lateral cyclic loading on abutment screw loosening of an

external hexagon implant system. J Prosthet Dent 91:326–324.

Kim KS, Han JS, Lim YJ.2014 Settling of abutments into

implants and changes in removal torque in ve different

implant-abutment connections. Part 1: Cyclic loading. Int J

Oral Maxillofac Implants. Sep-Oct; 29(5):1079-84.

Lee J, Kim YS, Kim CW, Han JS. 2002 Wave analysis of implant

screw loosening using an air cylindrical cyclic loading device.

J Prosthet Dent Oct; 88(4):402-8.

Nigro F, Sendyk CL, Francischone CE. 2010 Removal Torque

of Zirconia Abutment Screws under Dry and Wet Conditions.

Braz Dent J 21(3): 225-8.

Norton MR. 1997 An in vitro evaluation of the strength of an

internal conical interface compared to a butt joint interface in

implant design. Clin Oral Implants Res 1997; 8(4):290–8.

Norton MR. 2000 In vitro evaluation of the strength of the

conical implant-toabutment joint in two commercially avail-

able implant systems. J Prosthet Dent 83(5):567-71.

Norton MR.1999 Assessment of cold welding properties of

the internal conical interface of two commercially available

implant systems. J Prosthet Dent 81:159-66.

Pintinha M, Camarini ET, Sábio S, Pereira JR. 2013 ection

abutments for dental implants. J Prosthet Dent 110:383-8.

RabeloSC, Omonte SV, Vieira SP, Jansen WC, Seraidarian

PI2015. Morse taper internal connection implants: would abut-

ment reseating in uence retention? Braz. J. Oral Sci;14(3):2015.

Ricciardi Coppede A, Faria ACL, Shibli JA, de Mattos MGC,

Ribeiro RF, Rodrigues RC. Mechanical Comparison of Experi-

mental Conical-Head Abutment Screws with Conventional

Flat-Head Abutment Screws for External-Hex and Internal Tri-

Channel Implant Connections: An In Vitro Evaluation of Loos-

ening Torque. Int J Oral Maxillofac Implants 2013; 28:321–9.

Ricciardi,Copeddê A, de Mattos Mda G, Rodrigues RC, Ribeiro

RF. 2009 Effect of repeated torque/mechanical loading cycles

on twodifferent abutment types in implants with internal

tapered connections: an in vitro study. Clin Oral Implants Res

Jun; 20(6):624-32.

Seol HW, Heo SJ, Koak JY, Kim SK, Kim SK. 2015 Axial dis-

placement of external and internal implant-abutment con-

nection evaluated by linear mixed model analysis. Nov-Dec;

30(6):1387-99

Siamos G, Winkler S, Boberick KG. 2002 The relationship

between implant preload and screw loosening on implant-sup-

ported prostheses. J Oral Implanto l28(2):67–73.

Sutter F, Weber HP, Sorensen J, Belser U. 1993 The new restor-

ative concept of the ITI dental implant system: design and

engineering. Int J Periodont Rest Dent13:409-31.

Theoharidou A, Petridis HP, Tzannas K, Gare s P. 2008 Abut-

ment screw loosening in single-implant restorations: A sys-

tematic review. Int J Oral Maxillofac Implants Jul-Aug;

23:681–90.

Weiss EI, Kozak D, Gross MD. 2000 Effect ofrepeated closures

on opening torque values in seven abutment-implant systems.

J Prosthet Dent 84:194-9.

Winkler Sh, Ring K, Ring JD, Boberick K. 2003 Implant screw

mechanics and the settling effect : An overview. Journal of

Oral Implantology 29(5);242