Agricultural

Communication

Biosci. Biotech. Res. Comm. 10(3): 536-541 (2017)

Comparative studies on cooking qualities of aged

brown and polished rice,

Oryza sativa

V. K. Tiwari

1

, Neha Pachlasiya

2

and H. L. Sharma

3

Department of Post-Harvest Process and Food Engineering, Faculty of Agricultural Engineering, Jawaharlal

Nehru Krishi Vishwa Vidyalaya, Jabalpur 482004 (MP) India

ABSTRACT

A comparative study of cooking quality of brown rice and polished rice (i.e. volume, length, breadth, thickness

expansion ratio, water uptake ratio and optimum cooking time) with respect to different time was carried out in

the laboratory of Post-Harvest Process and Food Engineering College of Agricultural Engineering, JNKVV, Jabalpur.

Brown rice and polished rice was procured from Singhai Rice Mill village Panagar, Jabalpur and kept for three months

at ambient condition. Sample from aged raw and polished rice were withdrawn and cooked for 3, 5 and 7 minutes for

evaluation of cooking quality. It was observed that the length expansion ratio (LER) of polished rice was maximum

(1.46) as compared to brown rice for all type of cooking, breadth expansion ratio was maximum (1.45), thickness

expansion ratio (TER-1.22), volume expansion ratio of polished rice (VER-2.6), the water uptake of polished rice was

maximum (1.78) as compared to brown rice. However cooking time was minimum for polished rice when cooked for

3, 5 and 7 minutes as compared to brown rice.

KEY WORDS: BROWN RICE, POLISHED RICE LENGTH, BREADTH, VOLUME EXPANSION RATIO, WATER UPTAKE RATIO, OPTIMUM COOKING TIME

536

ARTICLE INFORMATION:

*Corresponding Author: iitkgp84@yahoo.co.in

Received 21

st

July, 2017

Accepted after revision 25

th

Sep, 2017

BBRC Print ISSN: 0974-6455

Online ISSN: 2321-4007 CODEN: USA BBRCBA

Thomson Reuters ISI ESC and Crossref Indexed Journal

NAAS Journal Score 2017: 4.31 Cosmos IF: 4.006

© A Society of Science and Nature Publication, 2017. All rights

reserved.

Online Contents Available at: http//www.bbrc.in/

DOI: 10.21786/bbrc/10.3/30

INTRODUCTION

Rice (Oryza sativa L ) is a cereal grain and an important

staple food for a large part of the world’s human popu-

lation. Among cereals, rice is even more nutritious than

wheat. India is the world’s largest producer of rice. India

produced 105 million tonnes rice in the year 2017 (www.

fci.gov.in). Brown rice is unpolished whole rice grain

that is produced by removing only the husk using the

rubber rolls. Distinguish factor is its unpolished features

and not the colour. Post-harvest researchers reported

that the milling recovery in brown rice is 10% higher

than polished rice. It contain minerals (prevents beriberi)

and high fat (energy source). Also it has been reported

that brown rice contains high phytic acid (antioxidant,

anti-cancer); it decreases serum cholesterol (prevents

Tiwari, Pachlasiya and Sharma

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS COMPARATIVE STUDIES ON COOKING QUALITIES OF AGED BROWN AND POLISHED RICE 537

cardio-vascular diseases) and is considered a low glyce-

mic index food (low starch, high complex carbohydrates

which decrease risk to type 2 diabetes). Moreover, brown

rice contains large amount of insoluble bre, which may

prevent a variety of cancers. There are many bene ts

of brown rice. The fuel savings in milling process is

50-60% because the polishing and whitening steps are

eliminated. In this way the milling time is also shortened

with less labour requirements, also, the enhancement in

output volume and the economy in milling indicated

the business opportunity in brown rice (Rogelio, 2003

Kumar et al., 2017).

Brown rice when being cooked, becomes a sticky or

pasty mass, swells only slightly and leaves a thick gruel.

All these cooking properties may not be accustomed to

most consumers who prefer uffy and hard texture. The

desired cooking properties can normally be obtained by

storing freshly-harvested rice for at least 3-6 months

(Swamy et al. 1978). Ageing involves changes in physi-

cal and chemical properties of the rice grain. Starch,

protein and lipids are the main grain components which

affect cooking and eating quality (Villareal et al.1976).

An unusual property of rice is that its cooking quality

depends on its age after harvest. New rice swells poorly

during cooking. This undesirable property gradually

changes during storage for few months (Patindol, et al.

2005 and Sowbhagya 2001).

MATERIALS & METHODS

Brown rice and polished rice were procured from mod-

ern rice mill. The rice was stored at ambient condition

for four month in the laboratory Post Harvest Process

and Food Engineering Department, College of Agricul-

tural Engineering, JNKVV, Jabalpur. Then the samples

were withdrawn from the stored rice stock and cooked in

the laboratory for different time to evaluate the cooking

quality including optimum cooking time.

MOISTURE CONTENT DETERMINATION

Moisture content of sample was determined by standard

air oven method (AOAC method). The samples were dried

in hot air oven maintained at 103±1ºC for 24 hours.

COOKING QUALITY

Rice expands length wise, breadth wise and thickness

wise during cooking by absorbing water. To determine

rice length after cooking and rice breadth after cooking

20 milled grains are pre-soaked to 10-30 minute and

placed directly into boiling water by directly dropping

until its optimum cooking time .The length, breadth and

thickness are measured and the average worked out. The

experiment was aimed to determine cooking properties.

Rice is considered to have good cooking quality if it

has high length expansion ratio (VER), volume expan-

sion ratio (LER), water uptake ratio (WUR) and minimum

Cooking time (CT) (Juliano, 1985). Length and volume

expansion ratio (VER) and water absorption are desir-

able for the food service industry as they lead to a fuller

plate for the same amount of rice. Length expansion

ratio i.e. the ratio of the length of cooked rice to that of

raw rice was calculated

Breadth expansion ratio i.e. the ratio of the breadth of

cooked rice to that of raw rice was calculated

Thickness expansion ratio i.e. the ratio of the thickness

of cooked rice to that of raw rice was calculated

VOLUME EXPANSION RATIO

Volume expansion ratio (VER) was calculated i.e. the

ratio of the volume of the cooked rice to the initial vol-

ume of the raw rice, using toluene displacement method.

WATER UPTAKE RATIO

Water uptake ratio (WUR) as ratio of water absorbed

during cooking to cooked rice weight was calculated by

weight of cooked rice and weight raw rice.

OPTIMUM COOKING TIME (OCT)

It is the time taken by a predetermined weight of rice

to cook completely. Brown rice and polished rice (2g)

samples were taken in test tube and cooked in 100ml

distilled water in a hot water bath at 100ºC. The cook-

ing time was determined by taking out 20 grains at dif-

ferent time intervals during cooking and pressing them

between two glass plates until atleast 90% of rice had no

longer centres, which is considered as optimum cooking

time.

Tiwari, Pachlasiya and Sharma

538 COMPARATIVE STUDIES ON COOKING QUALITIES OF AGED BROWN AND POLISHED RICE BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

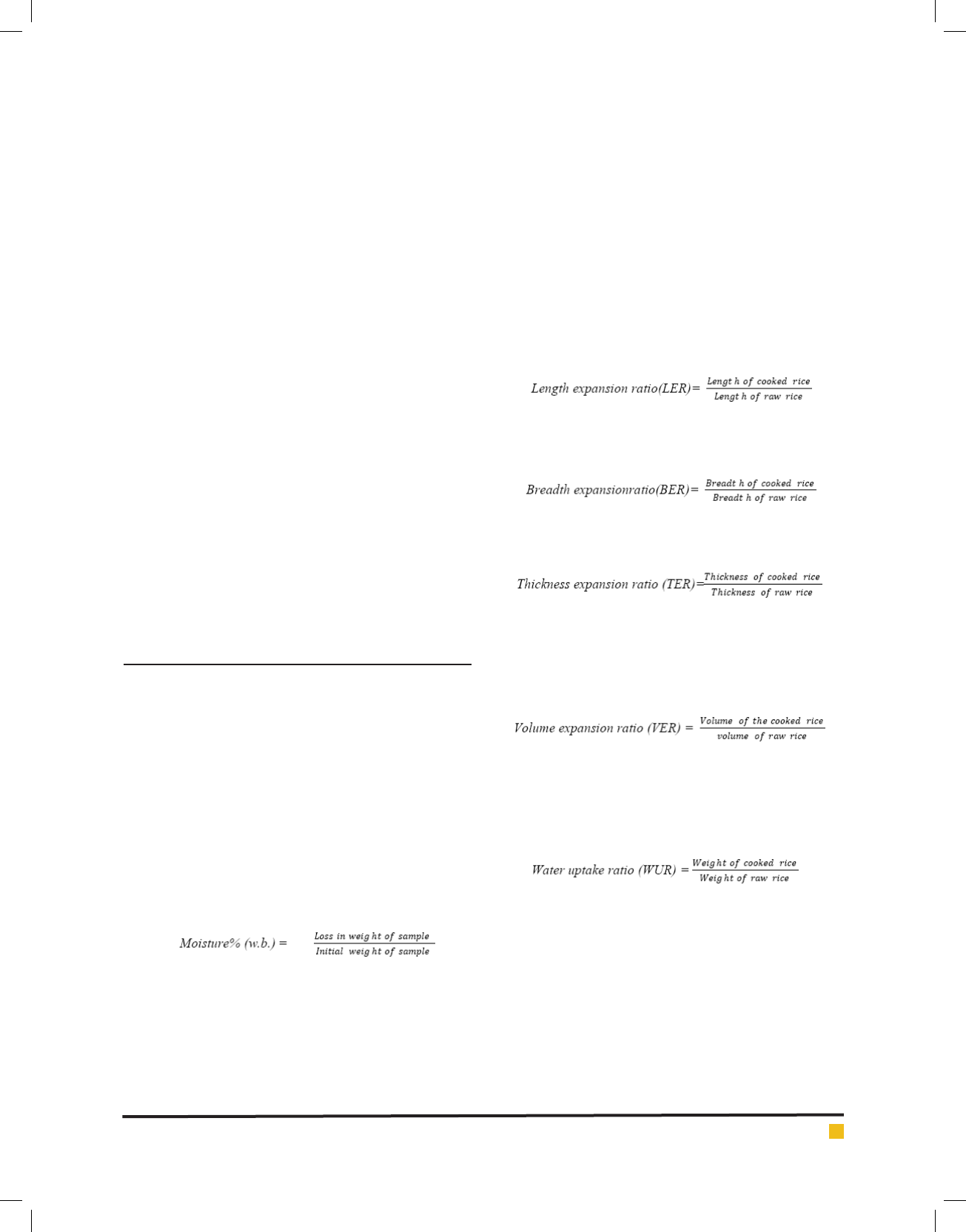

FIGURE 1. Length expansion ratio of Polished and Brown rice

RESULTS AND DISCUSSION

A comparative study of cooking quality of brown rice

and polished rice was initiated to nd out signi cance

of polishing of rice. Three aged brown and polished rice

was cooked for three minute and 1.135 times increases in

length were observed with linear expansion. The graph

reveals about the forecast value of length expansion of

polished rice at the time of cooking. The linear relation

line will always provide the best result for the relation

between time of cooking and expansion of polished rice.

The maximum value of R observed as 97% and this vari-

ability was explained in the expansion of polished rice

through the cooking time.It shows that the expansion of

polished rice is certainly dependent on the cooking time

means the cooking time is one of the best factor. The

length expansion ratio for polished and brown rice is

represented by models

Y= 0.0677x + 0.98 (1)

Y = 0.0286x + 0.99 (2)

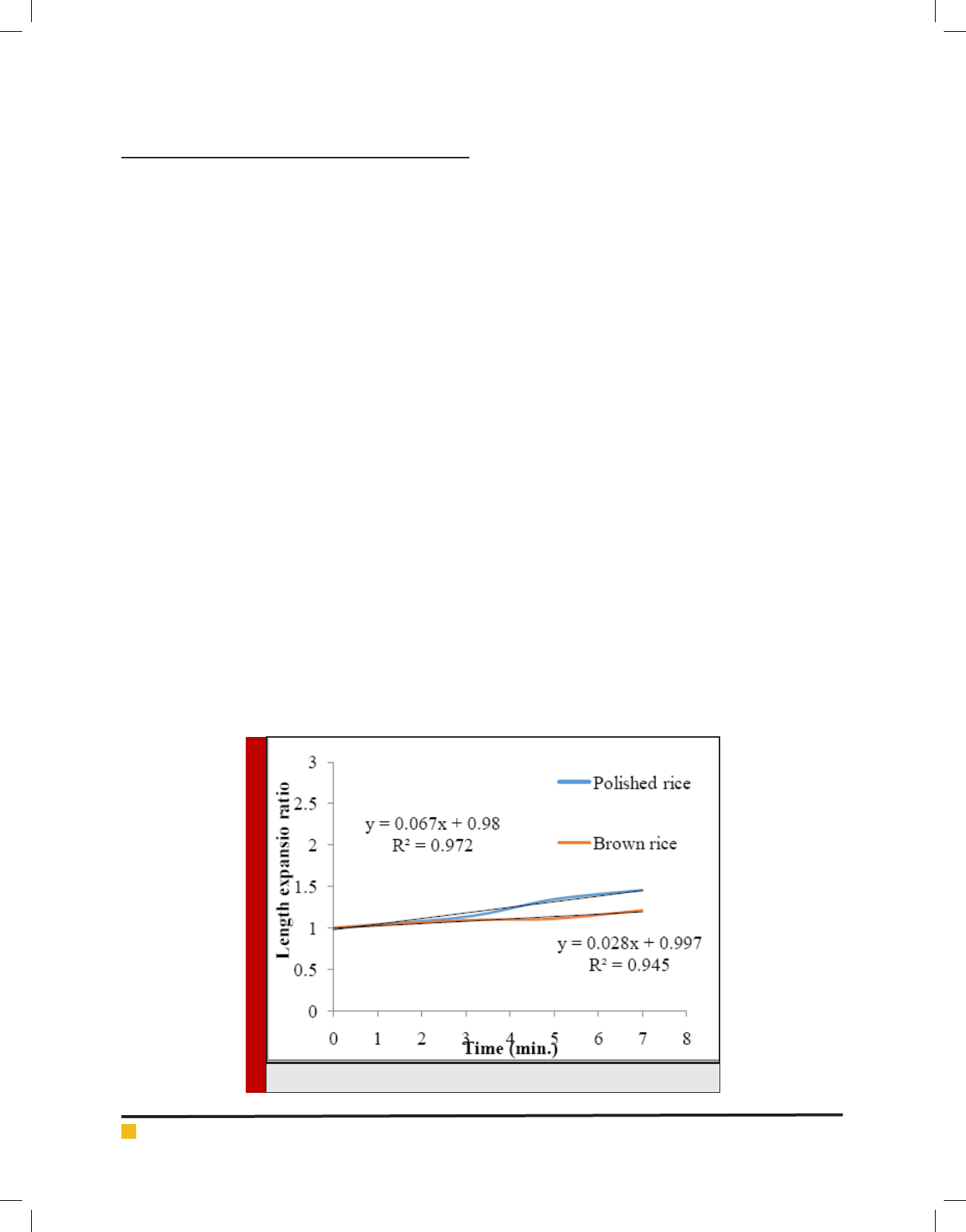

The results of breadth expansion of polished rice (for

5 minute cooking) showed 1.42 times increase as shown

in g. 2. It is observed that the polished rice expand at

faster rate. The maximum value of R observed as 99%

and this variability was explained in the expansion of

polished rice through the cooking time and the breadth

expansion ratio for polished rice and brown rice are rep-

resented by models

Y = 0.0781x + 1.0013 (3)

Y = 0.054x + 0.9862 (4)

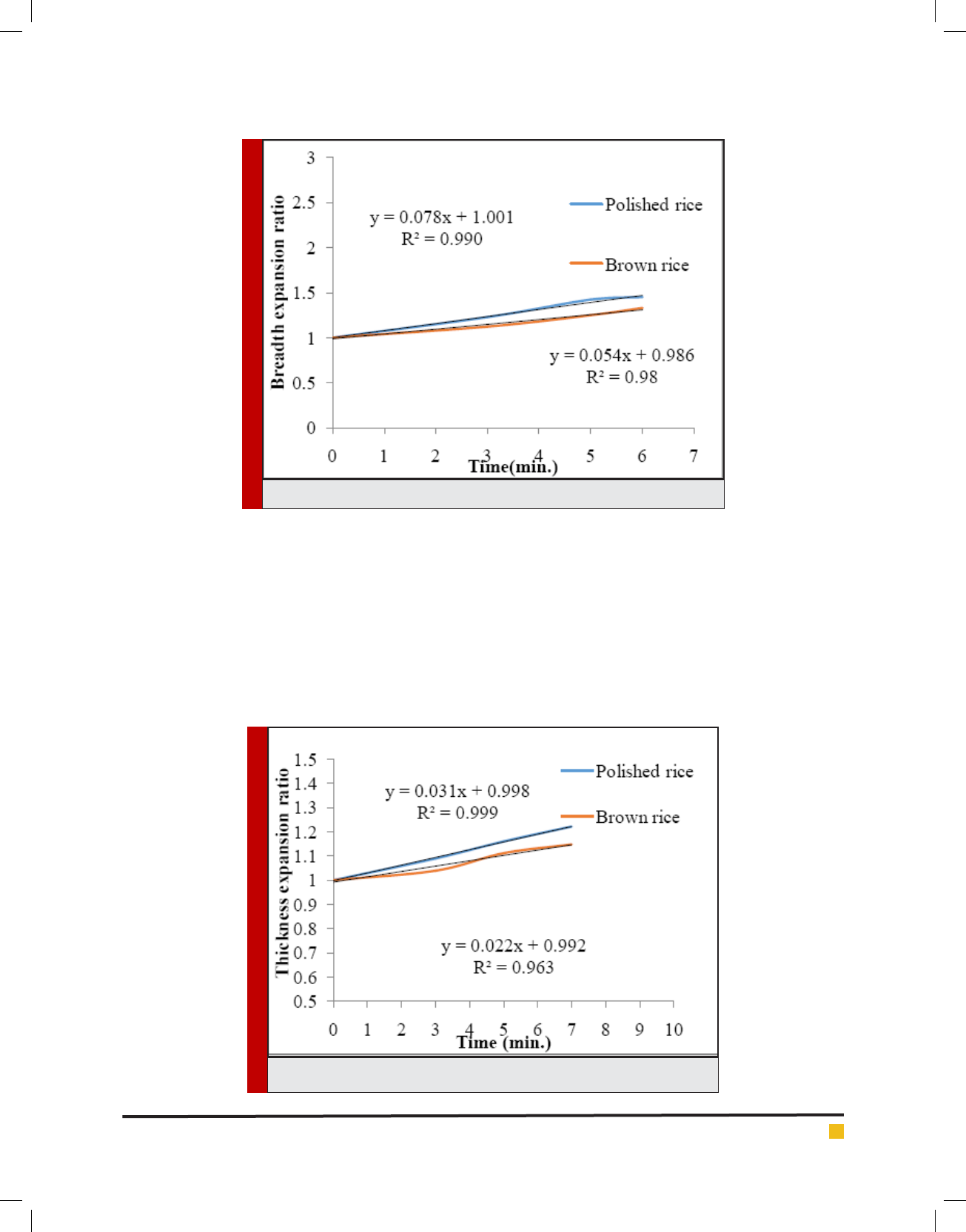

The graph shows thickness expansion of polished rice

increases at faster rate for 7 minute cooking time with

1.22 times increase in thickness. The linear behaviour

is shown in g. 3. The maximum value of Robserved as

99% and this variability was explained in the thickness

expansion of polished rice through cooking time. The

thickness expansion ratio for polished rice and brown

rice are represented by models.

Y = 0.0318x + 0.9985 (5)

Y = 0.0221x + 0.9638 (6)

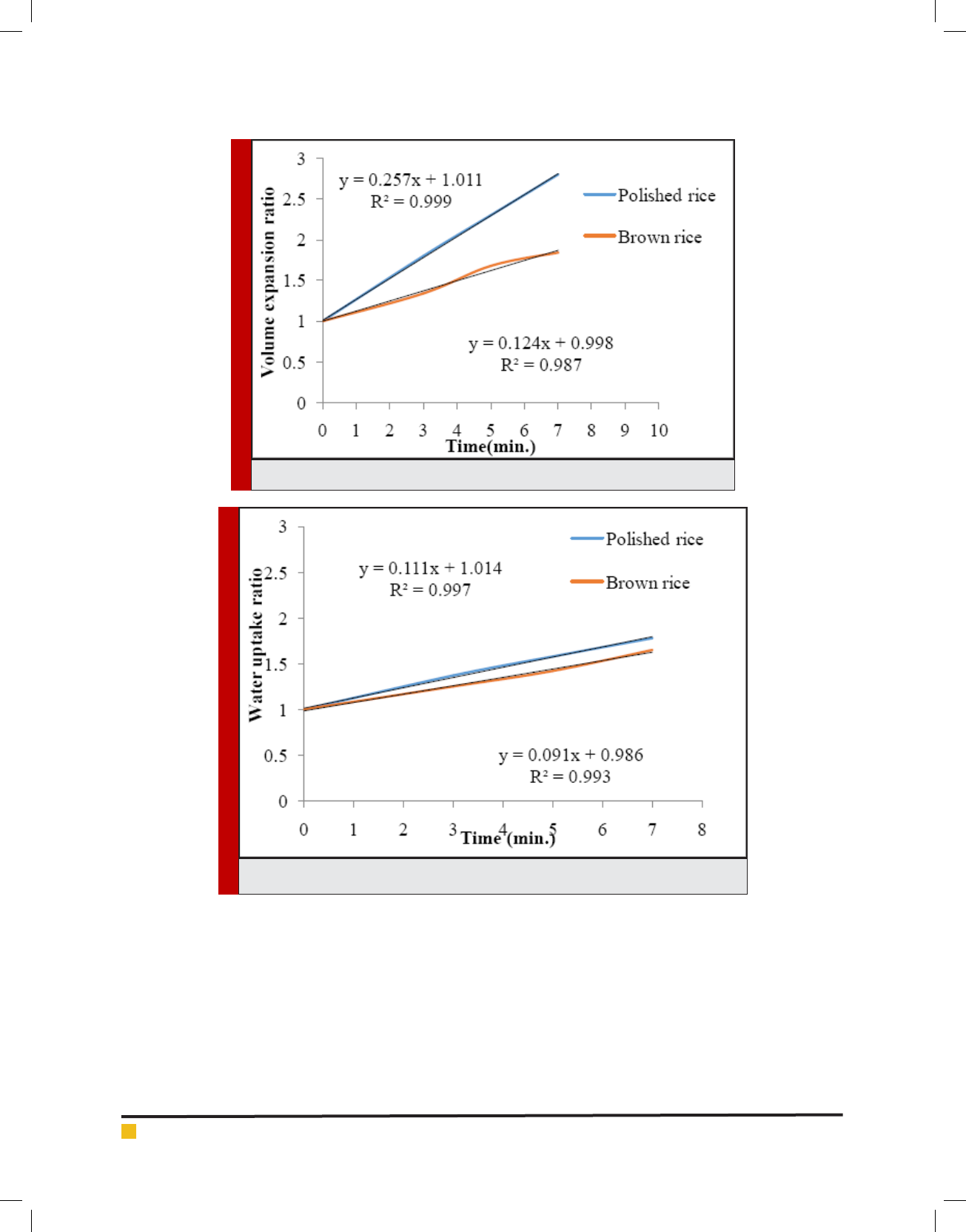

The volume expansion of polished rice was higher

(for 3 minute cooking time) with1.8 times increase in

volume as shown in g. 4. It is observed that the pol-

ished rice expand at faster rate. The maximum value

Robserved as 99% and this variability was explained in

the expansion of polished rice through the cooking time.

The expansion behaviour can be expressed by following

models:

Y = 0.257x + 1.0112 (7)

Y = 0.1234x + 0.9989 (8)

The water uptake ratio increased linearly for polished

rice (for 5 minute cooking time) with 1.58 times increase

as shown in g. 5. The maximum value of R observed as

99% and this variability was explained in the expansion

of polished rice and the water uptake ratio of polished

and brown rice behaviour can be shown by following

models

Y = 0.1066x + 1.0225 (9)

Y = 0.0916x + 0.9865 (10)

Tiwari, Pachlasiya and Sharma

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS COMPARATIVE STUDIES ON COOKING QUALITIES OF AGED BROWN AND POLISHED RICE 539

FIGURE 2. Breadth expansion ratio of Polished and Brown rice

FIGURE 3. Thickness expansion ratio of Polished and Brown rice

Less expansion is observed in brown rice in all three

dimensions (length. breadth and thickness) because the

kernel is covered with thin layer of bran which con-

tains oil so that expansion ratio was less in brown rice,

Although the brown rice takes more time in cooking but

water uptake ratio is high in polished rice. In this study

length expansion ratio, width expansion ratio, thick-

ness expansion ratio, volume expansion ratio and water

uptake ratio of brown and polished rice were determined.

Rice is considered to have good cooking quality if it has

high expansion ratio. Water to rice ratio affected chewi-

ness of cooked rice. Ratio of water to rice also affected

the eating quality rice (Daomukda 2011).

Length expansion ratio of brown and polished rice is

shown in gure 1. Cooking time of rice varied from 3-7

minutes (with 2 min interval). Polished rice had highest

LER as compared to brown rice. This shows the positive

correlation of LER with time of cooking (Gujral 2003).

Tiwari, Pachlasiya and Sharma

540 COMPARATIVE STUDIES ON COOKING QUALITIES OF AGED BROWN AND POLISHED RICE BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

FIGURE 4. Volume expansion ratio of Polished and Brown rice

FIGURE 5. Water uptake ratio expansion of Polished and Brown rice

Similar results of BER, VER and WUR were also obtained

in brown and polished rice. A greater elongation ratio of

polished rice is due to absence of bran layer which allows

water to enter inside the kernel as compared to brown

rice. The results are in agreement with Kumar et al. (2017).

REFERENCES

AOAC (1980) Association of Of cial Analytical Chem-

ists, Of cial methods of analysis, 13

th

Edition, Washing-

ton, DC, USA.

Juliano B.O. (1985) Rice: Chemistry and Technology. 2

nd

ed.,

American Association of cereal Chemists, St. Paul, M.N

Rogelio VC (2003) The National Campaign to Combat Hidden

Hunger through Brown In: Consultative Meeting on Nutri-

tional Aspect of Brown Rice, September 2003, Food and Nutri-

tion Research Inst., Manila, Philippines .

Swamy YM, Sowbhagya CM and Bhattacharya KR (1978)

Changes in the physiocochemical properties of rice with

aging. Journal of the science of Food and Agriculture 29: 625-

627.

Tiwari, Pachlasiya and Sharma

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS COMPARATIVE STUDIES ON COOKING QUALITIES OF AGED BROWN AND POLISHED RICE 541

Villareal CP, Maranville JW and Juliano BO (1991).Nutrient

content and retention during milling of brown rice from the

international Rice Research Institute. Cereal Chem.68:437-440.

Patindol, J., Wang, Y.J. and Jane, J. I. 2005 Structure-function-

ality changes in starch following rough rice storage. Starch/

Starke, 2005,57,197e207.

Sowbhagya, C.M. and Bhattacharya, K.R. 2001 Changes in

pasting behaviour of rice during ageing. Journal of Cereal

Science.2001,34:115e124.

Daomukda, M., Moongngarm,A., Payakapol, L. and Noisu-

wan, A. 2011 Effect of cooking methods on physicochemical

properties of brown rice. 2

nd

international conference on Envi-

ronment Science and Technology, IACSIT Press, Singapore,

2011,6(2),1-4.

Gujral, H.S. and Kumar,V. Effect of accelerated ageing on the

physicochemical and textural properties of brown and milled

rice. Journal of Food Engineering, 2003,59,117-121.

Kumar, A.,Bhople,S.,Kumar,N.,and Tiwari,V.K.2017 Effect of

ageing, moisture contents and storage structures on nutri-

tional and cooking characteristics of brown rice during stor-

age, J. Food Corporation of India 6 (22),793-800.www.fci.

gov.in