Environmental

Communication

Biosci. Biotech. Res. Comm. 10(2): 287-296 (2017)

On the analysis of phenol removal from drinking water

by batch reactor using powdered eggshell

Giti Kashi

Department of Environmental Health, Tehran Medical Branch, Islamic Azad University, Tehran, Iran

ABSTRACT

Phenol is a known prejudicial exotoxin and nds place in the environment due to intense activity of petrol industry.

The aim of this applied-analytical study is to investigate phenol removal from urban drinking water using batch

reactor with using powdered eggshell. Various operating variables are tested for their effects on phenol removal;

these include pH, contact time, adsorbent doses, initial phenol concentration, reaction kinetics, and powdered egg-

shell characteristics. Sample of urban drinking water is prepared containing 5-15 mg/L phenol. Powdered eggshell

is prepared in a laboratory oven at 105˚C for 12 h. The phenol-containing water enters batch reactor and phenol

removal ef ciency is studied in different cases of the variables pH (3-11), contact time (0-120 min), and adsorbent

doses (3-5 gr/dl). Characteristics of the eggshell powder show that the average diameter size of eggshell powder is 2

μm. The main component of eggshell powder is calcium carbonate (CaCO

3

). The best conditions for phenol removal

are obtained to be pH 3, contact time 80 min, and adsorbent dose 4 gr, and phenol concentration 5 mg/L. The adsorp-

tion of phenol on powdered eggshell is obtained from Langmuir isotherm.

KEY WORDS: ADSORPTION, ISOTHERM, PHENOL, POWDERED EGGSHELL, URBANE DRINKING WATER

287

ARTICLE INFORMATION:

*Corresponding Author: gitikashani11@gmail.com

Received 12

th

April, 2017

Accepted after revision 28

th

June, 2017

BBRC Print ISSN: 0974-6455

Online ISSN: 2321-4007 CODEN: USA BBRCBA

Thomson Reuters ISI ESC and Crossref Indexed Journal

NAAS Journal Score 2017: 4.31 Cosmos IF : 4.006

© A Society of Science and Nature Publication, 2017. All rights

reserved.

Online Contents Available at: http//www.bbrc.in/

INTRODUCTION

Chemically, phenol is acidic because of the in uence of

the aromatic ring. Phenol is an organic pollutant that

nds in the industrial wastewater. Phenol has been

measured in ef uents (up to 53 ppm), ambient water (1.5

- >100 ppb), groundwater (1.9 - >10 ppb), rain (0.075-

1.2 ppb), sediment (>10 ppb), and ambient air (0.03-44

ppb) (Al-Khalid, 2012 and American Public Health Asso-

ciation, 2015). The increase in phenol levels in ground-

water has been mainly attributed to pro igate utilization

of phenolic pesticides, municipal and industrial sew-

age treatment systems such as oil re nery, and decay-

ing organic matter or producing toxic poly chlorinated

288 ON THE ANALYSIS OF PHENOL REMOVAL FROM DRINKING WATER BY BATCH REACTOR BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Giti Kashi

phenols during water chlorination process (Bazrafshan,

2016).

Phenol and its derivatives like Dinitrophenol and pen-

tachlorophenol are very toxic substances with a toxicol-

ogy rating of 4 (Cabaj, 2016). Phenol is famous due to

its high toxicity for human life and aquatic life (Chand

Meena, 2015). Phenol-laced water may lead to liver, kid-

ney, and respiratory disorders in humans (Dakhil, 2013).

Phenol-contaminated water above the permissible drink-

ing water limit leads to phenolic tastes and doors prob-

lem, may be a cause of lethal to humans, and the drink-

ing water standard have been promulgated as >1 μg/l at

point of chlorination (Daraei, 2013). Processes such as

activated carbon adsorption, ion exchange, liquid-liquid

extraction, and chemical oxidation methods are effec-

tive for removing phenol and phenolic compounds from

water (Dehghani, 2016).

The main disadvantage of ion exchange technique

is low selectivity against anions. The main disadvan-

tage of these techniques is high capital and operational

cost (Fan, 2011). The advantages of adsorption technol-

ogy are applicable in batch and continue arrangements,

easier accessibility, designing exibility, economical,

and retain very effectiveness on high concentration and

low of phenolic industrial wastewater. Many natural

adsorbents are experimented as removal phenol agents

including sawdust Yeast (Liao, 2010), and almond shell

(Hsieh, 2008, Loganathan, 2013, Kashi, 2015 and Giti,

2015). The potential of annual egg, as biosorption of

organic materials, production in 2011 is estimated to be

5.2 million tons in Iran country. The aim of this applied-

analytical study is to investigate feasibility of phenol

removal from drinking water using the batch reactor

with using eggshell powder. The variables under study

involve pH, contact time, adsorbent doses, initial phenol

concentration, reaction kinetics, and eggshell powder

characteristics.

MATERIAL AND METHODS

Phenol-contaminated water samples used for adsorp-

tion experiments are obtained from urbane distribution

system situated the site of a laboratory in Islamic Azad

University Tehran Medical Sciences Branch, in Tehran

city. The samples are tested for the main physicochemi-

cal characteristics. The mean values of these water char-

acteristics are presented in Table 1. All the reagents used

are of analytical grade. A solution of 5, 10, and 15 mg/L

phenol is prepared by dissolving appropriate amount of

phenol (Merck, Germany) in deionized water.

After collecting chicken eggshells from local markets

of Tehran city, removing waste matters such as colour

and fat, boiling in deionized water for 30 minutes, and

washing with deionized water, eggshell powder is pre-

pared by heating the collected eggshells in a hot air

oven (Dena, Iran) at 105˚C for 12 h, maybe, temperature

higher than 105˚C leads to decreasing phenol removal

due to damaging calcium carbonate structure, while

temperature below 105˚C leads to developing bad taste

and odour in nished water. Heat pre-treatment removes

the organic matter, cause of taste and colour problems

in water. After heating, the eggshells are crushed by a

laboratory electrical crusher (AIKA, Germany) for 20-30

second and are sieved several times to get a uniform

fraction of eggshell in a speci c size (60-100 mesh/

0.25-0.104 mm), according to ASTM standard (Mijan,

2014). The powdered eggshell is stored in the desicca-

tor after pre-treating with a solution of sodium hypo

chloride (NaOCl) (Merck, Germany), to eliminate the dust

particles (Mourão, 2011).

Scanning Electron Microscopy (SEM) image (Philips,

XL 30, Holand) is prepared from powdered eggshell.

X-ray diffraction patterns are measured using RINT

2000 (Rigaku Instrument Corp.) with Cu K radiation

for con rming the structure and mineral composition

of powdered eggshells (Philips, Xpert, Holand). Pow-

dered eggshell composition is obtained by energy dis-

persive X-ray (EDX) analysis. The surface area of pow-

dered eggshell is analysed through nitrogen adsorption

measurements at 77 K using Micromeritics Gemini 2370

equipment. The zeta potential is analysed with a Nano

Zetasizer (Philips, Holand).

The batch reactor is a 250 ml glass rectangular con-

tainer (10×6×6 cm). To evaluate the effect of adsorption,

on the phenol removal process, samples undergo with

different pH (ca. 3-11), different times (0-120 min), dif-

ferent concentrations of F (5-15 mg/L), and adsorbent

dosage (3-5 gr/dl). The sample number is obtained 192.

Magnetic stirrer (AIKA, Germany) is used for homogene-

ous mixing of water samples (120 rpm). For each test,

200 ml of sample water is poured into the reactor. All

tests are performed at laboratory temperature (20˚C).

Chloride acid and sodium hydroxide solutions (0.1 N)

(Merck, Germany) are used for pH adjustment.

All tests were performed in triplicate, and the mean

data values are reported. The water samples are tested

for phenol after adsorption process by using spectropho-

tometer (Hach DR5000, America) at a wavelength of 500

nm. Phenol is determined by standard method 5530D

(Ngah, 2011). The percentage phenol removal is calcu-

lated according to the following equation (1):

(1)

Where the percentage of phenol removal (R, percent-

age) and the phenol value before and after treatment (C

t0

and C

t

, mg/L) expressed.

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS ON THE ANALYSIS OF PHENOL REMOVAL FROM DRINKING WATER BY BATCH REACTOR 289

Giti Kashi

The removal phenol capacity of the regenerated pow-

dered eggshell is calculated according to the following

equation (2):

(2)

Where the removal phenol capacity of the regener-

ated powdered eggshell (DC

FC

, mg/g) and the phenol con-

centration before and after treatment (S

0

and S

t

, mg/L)

expressed. To optimize runs and data analysis, based on

Taguchi model, is used to study vestiges of the selected

variables and minimize the number of experimental runs

(Tzvetkova, 2016).

RESULTS AND DISCUSSION

The reduction of phenol from urbane drinking water is

investigated in an adsorption reactor with ller particles

made of charring chicken eggshells in batch mode. Sev-

eral operational variables are examined for the effects

on process reduction ef ciency. The following results

are obtained from the experiments.

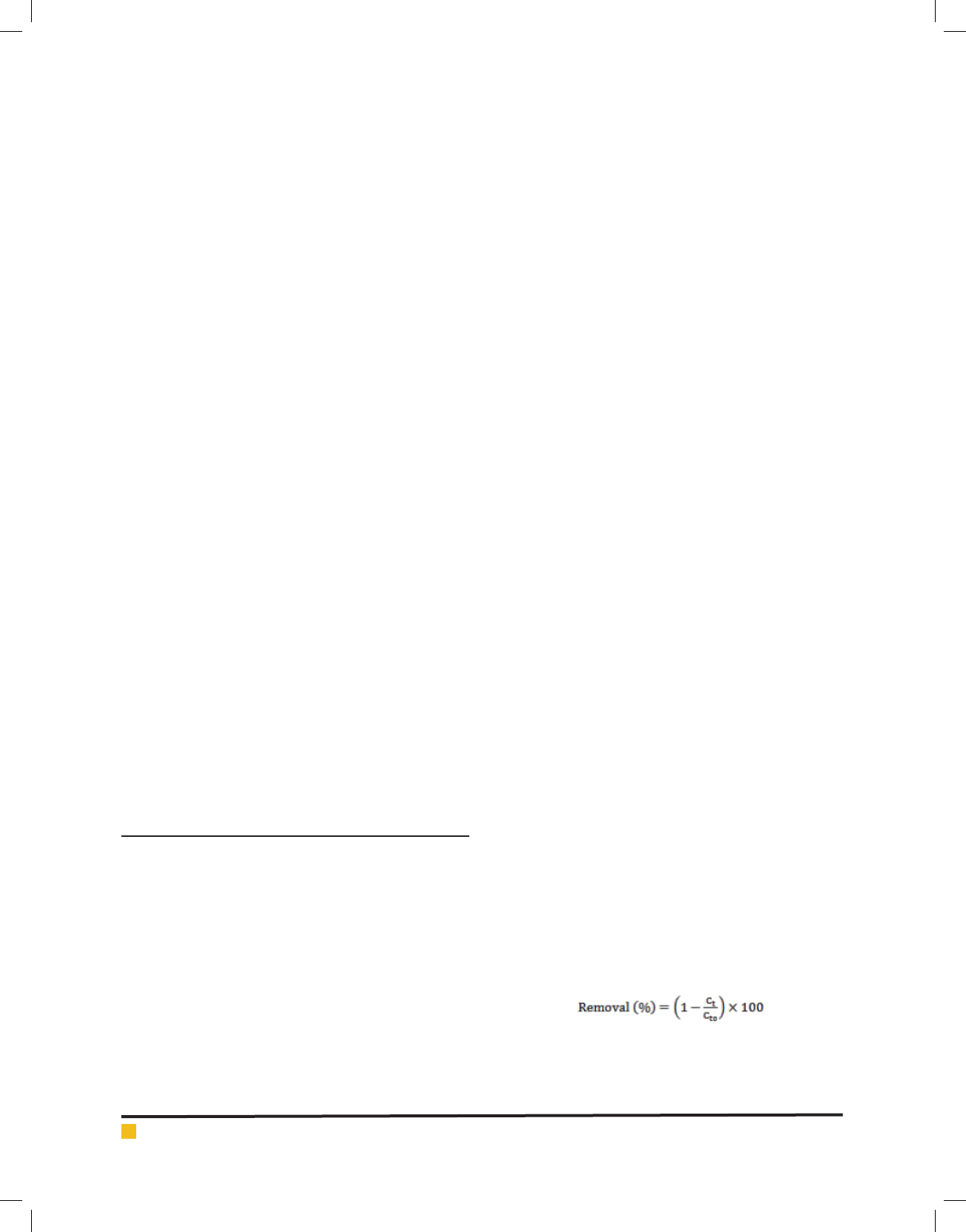

Figure 1 illustrates SEM images of the eggshell pow-

der. As is observed that, the average diameter size of

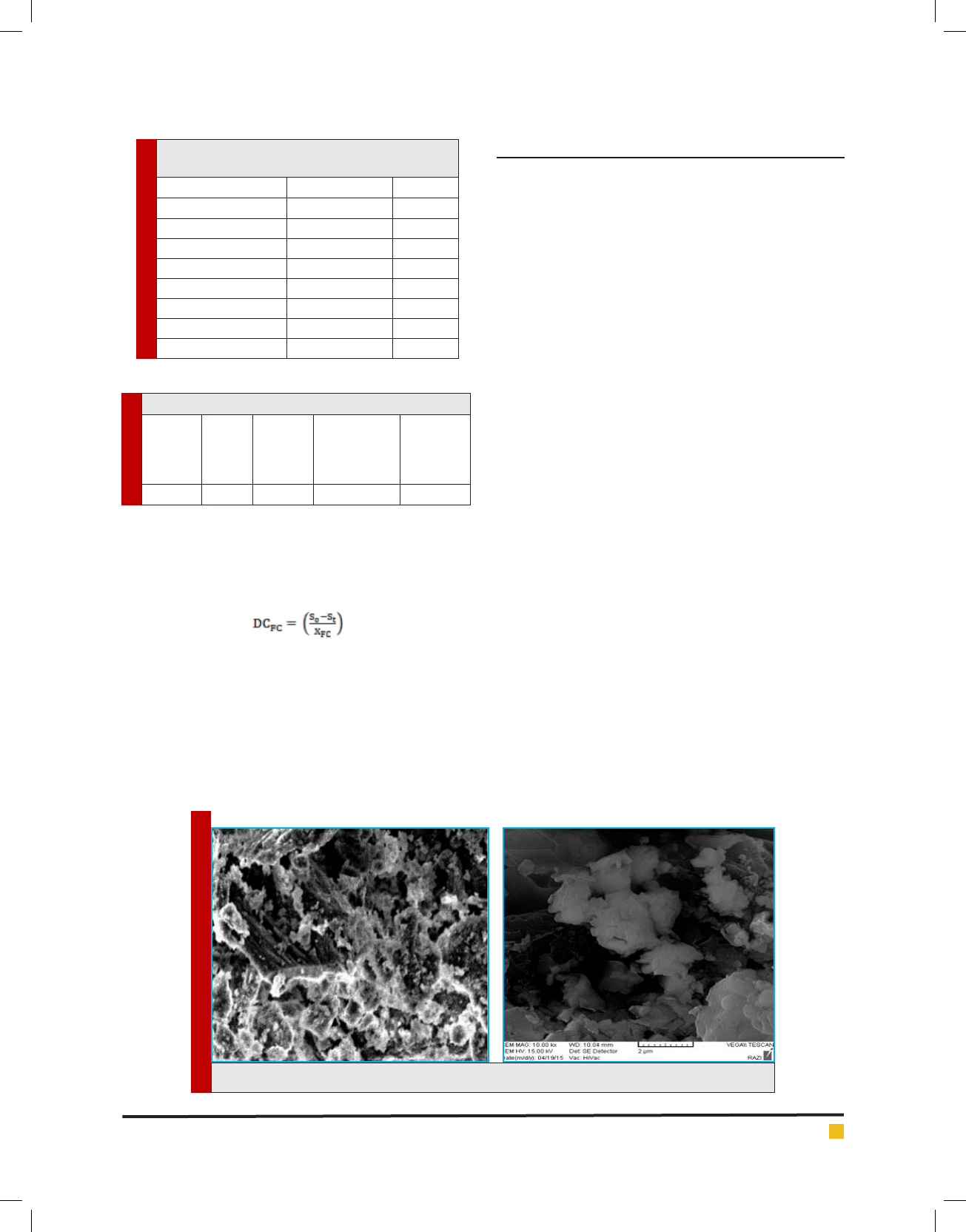

eggshell powder is 2 μm. Figure 2 illustrates X-ray dis-

persive (XRD) analysis of the eggshell powder. As is

found in gure 2, the analysed eggshell powder is com-

posed of the elements including calcium (Ca) and phos-

phor (P) as the main and partial elements respectively.

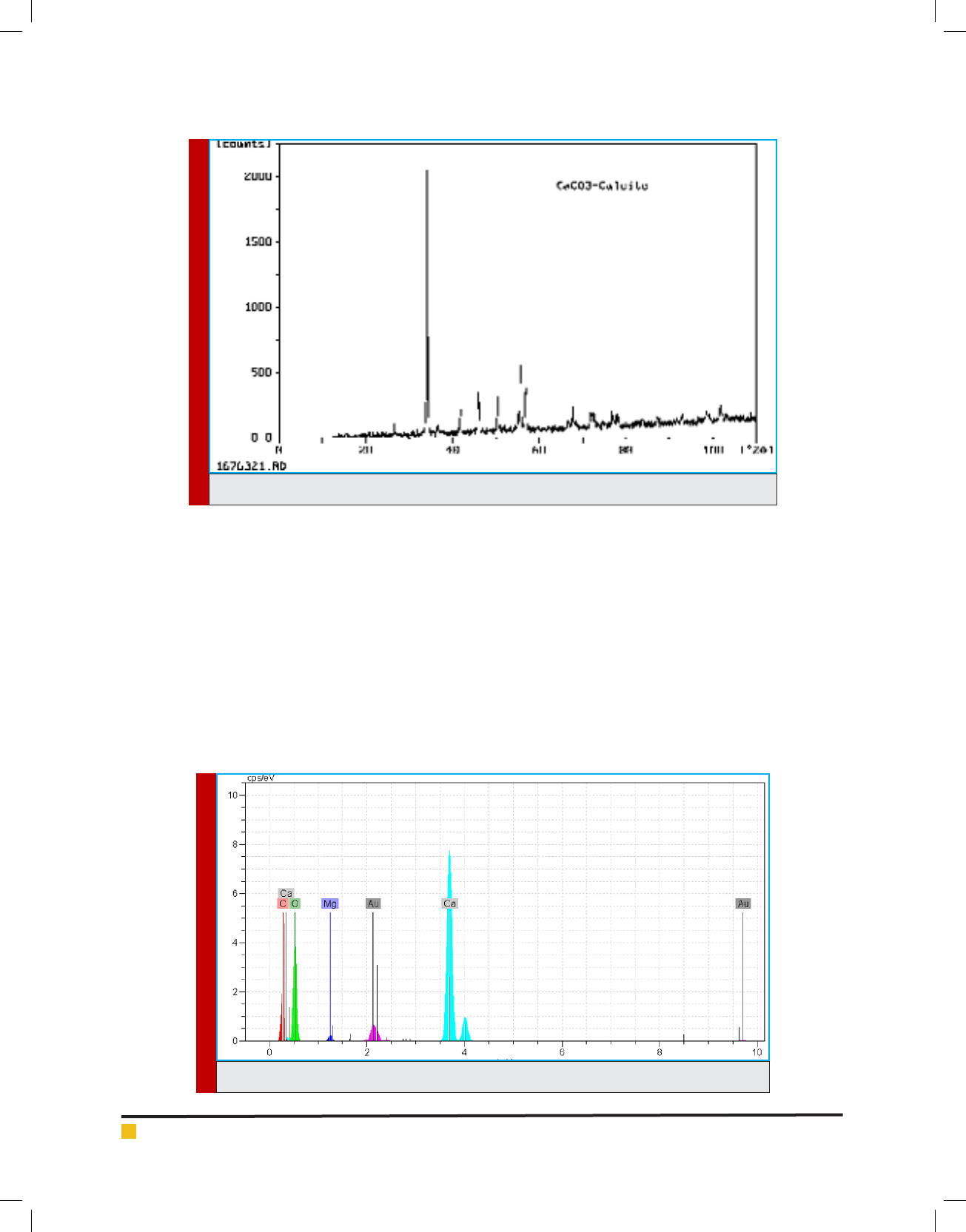

Figure 3 illustrates EDX analysis of the eggshell powder.

As is found in gure 3, the analysed eggshell powder is

composed of elements including calcium (Ca), oxygen

(O), magnesium (Mg), carbon (C), and so on.

The characteristics of eggshell powder are showed in

Table 2. Speci c surface area, BET measurements has

also been performed, and the highest BET is obtained for

eggshell powder 7.43 m

2

/g. The spectrum of the analysed

eggshell powder is adapted to 2370 standards. Therefore

these peaks con rmed that the main component of egg-

shell powder is calcium carbonate (CaCO

3

). The calcium

to carbon (Ca/C) ratio of eggshell powder is 2.9. SEM

analysis is another helpful instrument for the analysis of

the surface morphology of an adsorbent. The agglomer-

ate, non-adhesive, porous and irregular surface structure

of the adsorbent can be distinctly shown in SEM image

indicates in gure 1a. Furthermore, the pores on the sur-

face of the adsorbent are regular, adhesive, and very het-

erogeneous as indicates in gure 1b. The heterogeneous

pores leads to producing a lager exposed surface area

for the adsorption of phenol. In other hand the hetero-

Table 1. The Main Physicochemical Characteristics

of Phenol-Contaminated Urbane Water

Parameter Unit Value

Calcium mg/L as CaCO

3

162

Dissolved oxygen mg/L 8.05

Nitrate mg/L 9.5

ORP mV 272

pH - 7.19

Sulphate mg/L 93.8

Temperature ˚C 20

Total Alkalinity mg/L as CaCO

3

122

Table 2. Characterization of Eggshell Particles

Particle pHZPC

Density

(g/cm

3

)

Speci c

Surface

Area, BET

(m

2

/g)

Diameter

(μm)

Eggshell 8.2 1.148 7.43 2

(a) (b)

FIGURE 1. SEM image of eggshell powder (a) before treatment, (b) after treatment

290 ON THE ANALYSIS OF PHENOL REMOVAL FROM DRINKING WATER BY BATCH REACTOR BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Giti Kashi

FIGURE 2. XRD analysis of eggshell powder

FIGURE 3. EDX analysis of eggshell powder

geneous pores leads to producing a large af nity for the

adsorption of phenol.

Mijan et al. (2014) report that the eggshell pow-

der particles are irregular in shape and their surface is

rough. The diameter of pore is symptom of the antici-

pated adsorption of phenol molecule onto the surface of

the adsorbent. It distinctly indicates the porous surface

formation which supports the adsorbent with enhanced

surface area and very adsorption capacity. The SEM

analysis shows that the removal of phenol affects the

orientation of the eggshells powder. The treated sample

illustrates regular, adhesive appearance causing higher

adsorption of phenol. Bhaumik et al report that the par-

ticle size of eggshell powder is 150-350 μm. Zul kar

et al. (2013) report that BET of eggshell powder is 3.23

m

2

/g. Gaonkar and Chakraborty report that composition

of eggshell consists of calcium carbonate (91%). Agarwal

and Gupta report that the most compound in the egg-

shell powder is calcium carbonate. Functional groups of

eggshells are diagnosed by infrared analysis. The peaks

at about 710, 875, 1420, 1807, and 2520 cm

-1

adopt

with those of pure CaCO

3

. The XRD pattern displays six

characteristic peaks at 2=34.5°, 42.2°, 46°, 50.9°, 56°,

and 57.8° in crystalline structure and corroborates the

Giti Kashi

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS ON THE ANALYSIS OF PHENOL REMOVAL FROM DRINKING WATER BY BATCH REACTOR 291

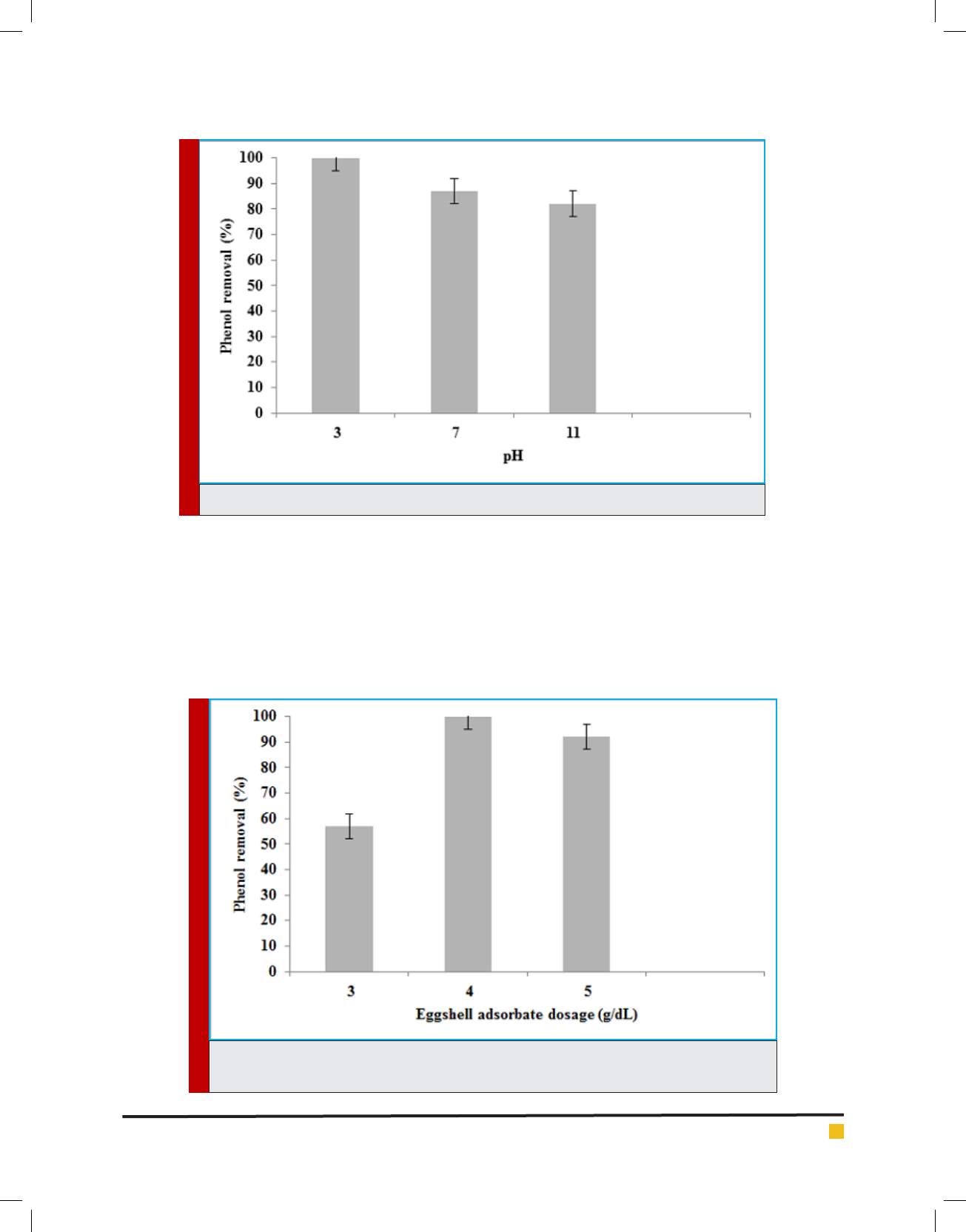

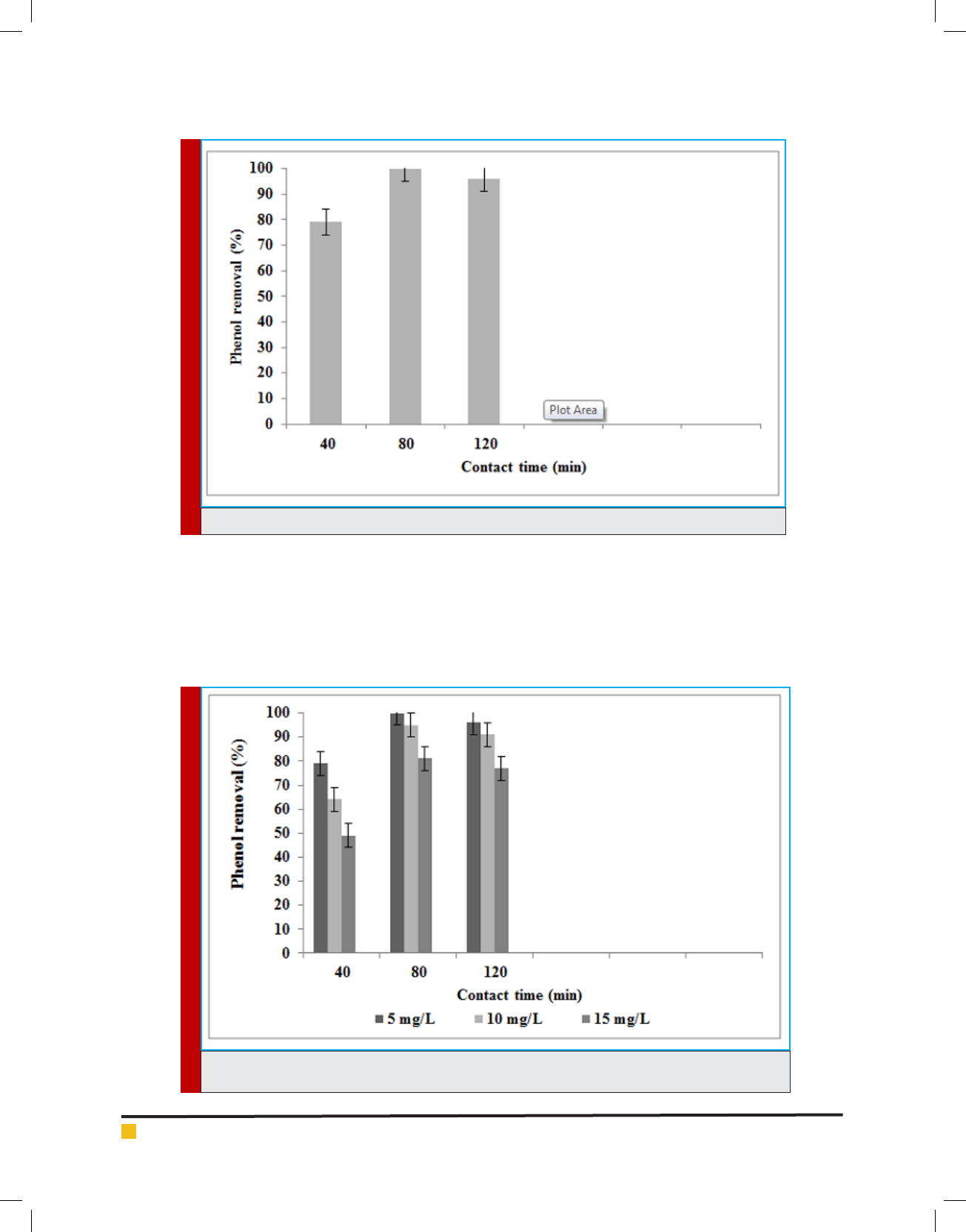

FIGURE 4. The effect of water pH on the phenol removal in the batch adsorption reactor

FIGURE 5. The effect of eggshell powder adsorbent dosage on the phenol removal in the batch

adsorption reactor

presence of calcite (CaCO3) in the eggshell (Zul kar,

2013).

Adsorption experiments are carried out an initial

pH values in the range of 3 to 11 at the experimen-

tal conditions such as contact time (80 min), phenol

concentration (5 mg/L) and amount of eggshell powder

adsorbent (4 g). The mean phenol removal decreases

from 100% to 87% when the pH increased from 3 to

7 (Figure 4). Phenol removal in the adsorption reactor

is mainly in uenced by the water pH. The pH has a

signi cant effect on phenol reduction due to surface

charge of the absorbent, with the highest reduction

obtained at pH 3. It is related to phenol ionization, and

adsorbent surface. Phenol is a weak acid and produces

phenoxide ions. Due to more exchangeable ion rate,

and better adsorbent, the optimum pH for reaching to

Giti Kashi

292 ON THE ANALYSIS OF PHENOL REMOVAL FROM DRINKING WATER BY BATCH REACTOR BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

FIGURE 6. The effect of contact time on the phenol removal in the batch adsorption reactor

FIGURE 7. The effect of initial phenol concentration on the uoride removal in the batch adsorption

reactor

phenol standard (>1 μg/L) is pH 3. The phenol removal

of in alkaline condition diminishes which can be due to

increasing turbidity.

This is in agreement with Daraei et al. (Daraei, 2013),

who report that the fastest removal rate occurs at pH

equal to 3.5. The pH of point of zero charge (pHZPC) is

an important parameter in phenol sorption, for it is the

pH in which the sorbent has a neutral charge. When pH

is increased above the pHZPC, phenol sorption decreases

due to electrostatic repulsion between the surface and

phenoxide ions as well as a result of competition with

hydroxides in solution.

Giti Kashi

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS ON THE ANALYSIS OF PHENOL REMOVAL FROM DRINKING WATER BY BATCH REACTOR 293

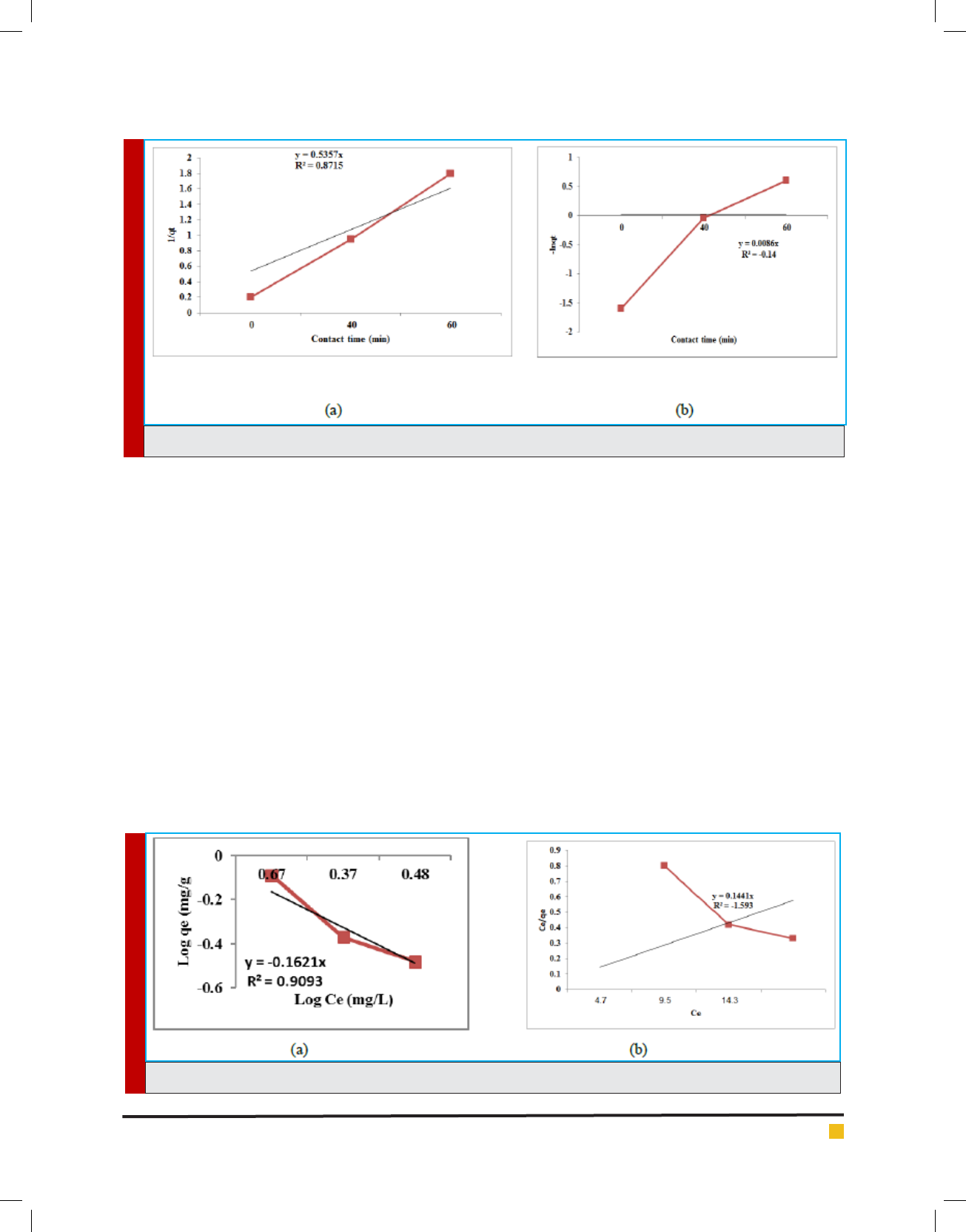

FIGURE 8. Kinetic models: (a) rst order (b) second order

FIGURE 9. Conceptual model of DPSIR framework

Adsorption experiments are carried out an ini-

tial adsorbent dosage in the range of 3 to 5 g at the

experimental conditions such as contact time (80 min),

phenol concentrations (5 mg/L) and pH value (3). The

mean phenol removal increases from 57% to 100%

when the adsorbent dosage increases from 3 to 4 (Fig-

ure 5). Enhancing the adsorbent dosage increases the

percentage of phenol that is attributed to enhancing of

sportive surface area, and sorption capacity since more

active adsorption sites, more exchangeable sites, and

more proper porosity are available. The optimum dos-

age of eggshell powder adsorbent is 4 g. It is seen that

4 g is a better adsorbent dosage than 3 g. This phe-

nomenon can be due to exposure of the active sites of

adsorbent which allow phenoxide ions of water to have

a direct contact with eggshell powder, therefor increas-

ing adsorption capacity. Increasing the adsorbent dosage

also leads to decreasing surface area between eggshell

powder adsorbent and phenol adsorbate due to the for-

mation of aggregates. Any change in the adsorbent dos-

age will increase pH. Zul kar et al (2013) reported that

the optimum dosage of eggshell is 5.0 g. At constant

pH, activity of phenoxide is directly proportional with

the concentration of Ca

+2

and thereby increasing the

adsorption of phenol over eggshell surface signi cantly

(Zul kar, 2013).

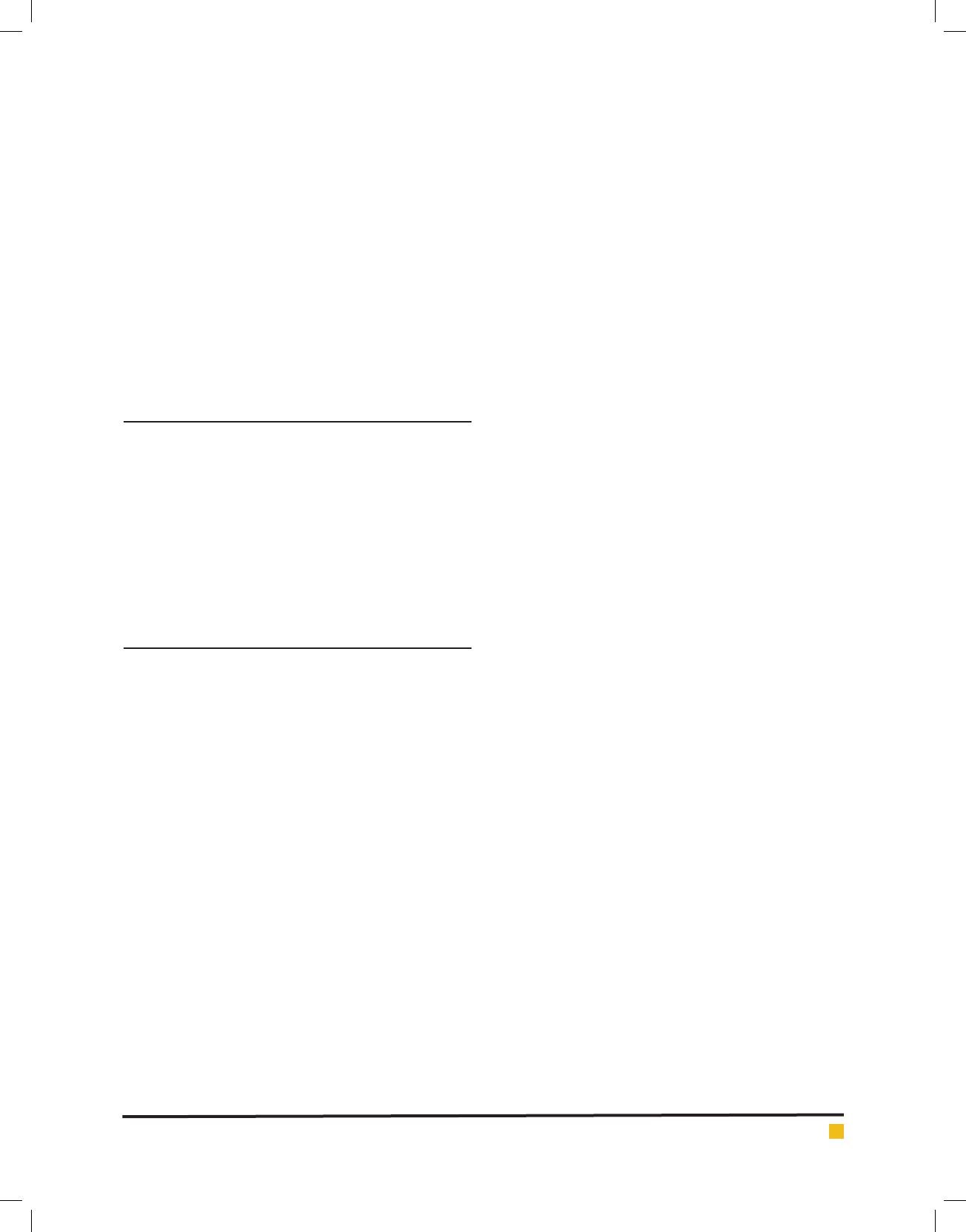

Adsorption experiments are carried out as a func-

tion of the time levels in the range of 0 to 120 min

at the experimental conditions such as amount of egg-

shell powder adsorbent (4 g/dL), phenol concentration (5

mg/L) and pH value (3). The ef ciency of phenol removal

increases as the contact time increases. The mean phe-

nol removal increases from 79% to 100% when the con-

tact time increases from 40 to 80 min (Figure 6). The

ef ciency of phenol removal initially increases as the

contact time increases, but then gradually approaches

Giti Kashi

294 ON THE ANALYSIS OF PHENOL REMOVAL FROM DRINKING WATER BY BATCH REACTOR BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

FIGURE 10. Effect of contact time and initial concentration on the phenol removal (Sorbent dosage 4

g; pH 3)

a more or less constant value, indicating obtain-

ment of equilibrium. As there is no enhance in phenol

removal ef ciency between 80 and 120 minute, equilib-

rium time of 80 minute is selected for eggshell powder

adsorbents.

These variations can be due to the fact that initially,

all absorbent sites are empty and active, the solute con-

centration gradient is high and attraction of active func-

tional groups towards phenol which results in stronger

surface binding is high. Then, the phenol adsorption rate

on to eggshell powder adsorbent noticeably diminishes

due to decreasing in absorbent sites. This phenomenon

indicates a monolayer of phenoxide ions on the external

surface and pores of eggshell powder and pore diffu-

sion on to the internal surface eggshell powder through

the lm due to continues turbulent maintains during the

experiments. During this period residual phenol uctu-

ates from a maximum value of 1.05 mg/L at 40 min

contact time to a minimum value of 0.0 mg/L for a con-

tact time of 80 min. The highest removal capacity of

eggshell powder (4 mg/g) is obtained for duration of 80

min, respectively. An equilibrium time of 60 minute is

selected for chitosan-H

2

SO

4

beads by Ngah et al., (2011).

An equilibrium time of 120 minute is selected for car-

bonate hydroxyapatite are extracted from eggshell waste

by Liao (Liao, 2010). If the phenoxide ion is more than

absorbent sites, adsorption decreases due to saturating

absorbent sites at a constant concentration.

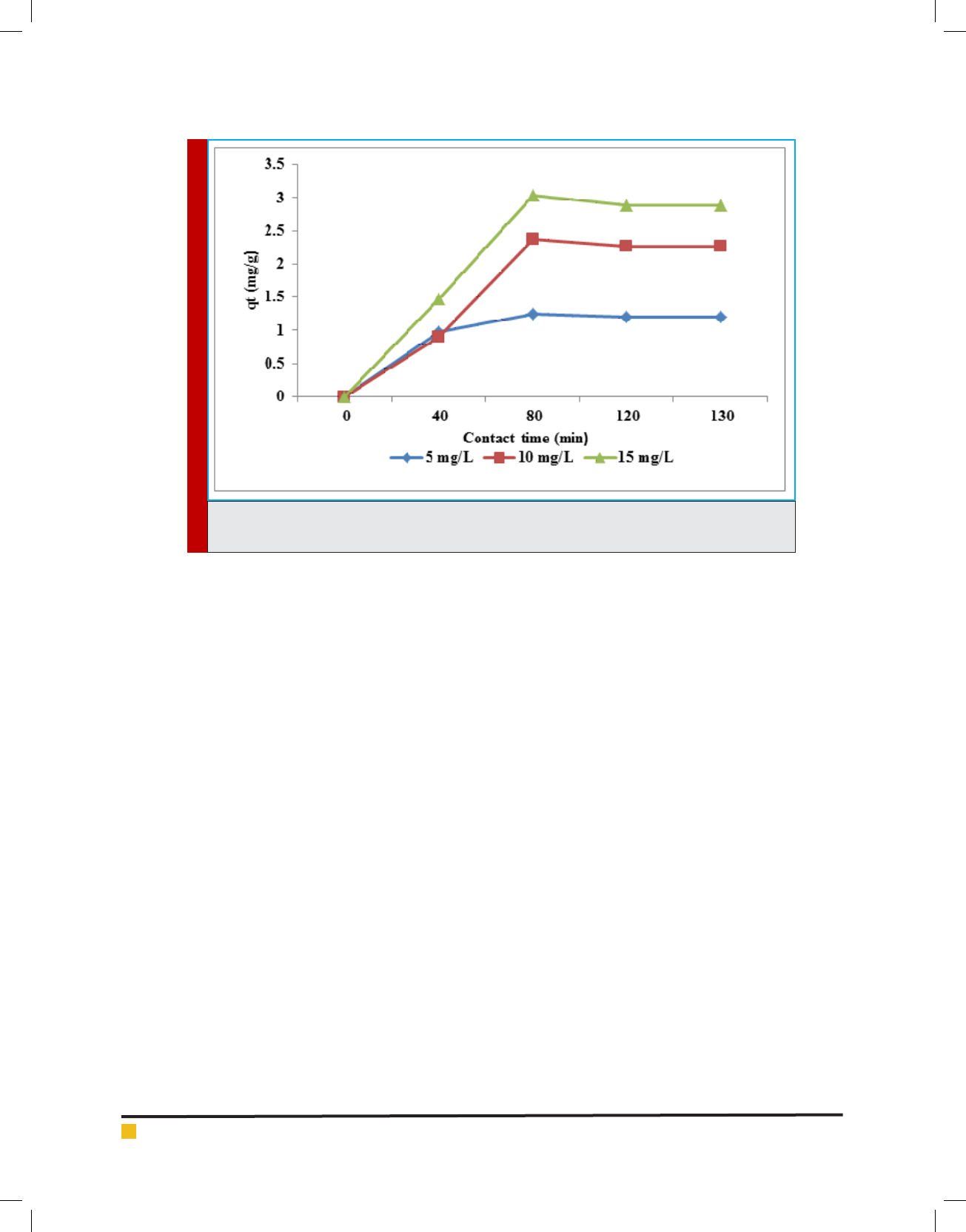

Adsorption experiments are carried out an initial

phenol concentration in the range of 5 to 15 mg/L at

the experimental conditions such as contact time (40-

120), amount of eggshell powder adsorbent (4 g/dL)

and pH value (3). The mean phenol removal decreases

from 100% to 81% when the initial phenol concentra-

tion increases from 5 to 15 mg/L

for duration 80 minute

(Figure 7). The phenol removal as a function of con-

tact time is proportional to the phenol ions in water. At

higher concentration, due to saturating active adsorp-

tion sites by phenol the mass transfer rate decreases.

Due to enhancing concentration gradient, performed as

enhancing driving force to predominant all mass trans-

fer resistances of the phenol between the solution and

solid phase, resulting in an enhancing equilibrium sorp-

tion until sorbent saturation is obtained. This is in agree-

ment with Balasubramani and Sivarajasekar who report

that the removal rhodamine B ef ciency decreases when

the initial rhodamine B concentration increases. In other

hands, increasing concentration of phenol leads to shift-

ing the pH

ZPC

to lower value and decreasing the electro-

static attraction between sorbent surfaces and phenox-

ide ions.

The proposed mechanism of phenol uptake rate onto

eggshell powder surface involves the replacement (ion

exchange adsorption) of calcium of the eggshell pow-

der, by phenoxide ion to form an insoluble matter. The

regression coef cient for the tted line is calculated to

Giti Kashi

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS ON THE ANALYSIS OF PHENOL REMOVAL FROM DRINKING WATER BY BATCH REACTOR 295

be R

2

= 0.8715 for phenol. The apparent rate constant,

K

1

and the half-life time, t

1/2

are calculated to be 0.5357

min

-1

and 1.29 min. Phenol reduction follows a rst

order kinetic model. Phenol reduction follows a Freun-

dlich isotherm model (R

2

>0.9). This is agreement with

Kumaraswamy et al who report that chromium by egg-

shell powder follows a Langmuir isotherm model. There-

fore, the eggshell powder adsorption reactor, in batch

mode, is showed to be an ef cient and viable process for

meeting a high degree of phenol reduction from drink-

ing water and be considered as a promising technology

for treating phenol-polluted drinking water in develop-

ing countries (Figure 8, Figure 9).

CONCLUSION

The experimental results suggest that batch chicken

eggshell powdered reactor is a practical and promis-

ing method for the phenol-contaminated water. Phenol

removal is affected by pH, the concentration of phenol,

the concentration of adsorbent, and reaction time. This

reactor are capable of phenol removal at the pH value

(3) investigated, with a reaction time 80 min. It is pur-

posed that performance of process is studied the other

material.

ACKNOWLEDGMENTS

The authors thank the Department of Environmental

Health of Islamic Azad University, Tehran Medical Sci-

ences Branch for nancial and instrumental supports.

REFERENCES

Al-Khalid, T. and El-Naas, M.H., 2012. Aerobic biodegrada-

tion of phenols: a comprehensive review. Critical reviews

in environmental science and technology, 42(16), pp.1631-

1690.

American Public Health Association, American Water Works

Association, Water Pollution Control Federation and Water

Environment Federation, 2015. Standard methods for the

examination of water and wastewater(Vol. 2). American Pub-

lic Health Association..

Bazrafshan, E., Amirian, P., Mahvi, A.H. and Ansari-

Moghaddam, A., 2016. Application of adsorption process for

phenolic compounds removal from aqueous environments: a

systematic review.Global NEST Journal,18(1), pp.146-63.

Cabaj, J., J

e

˛drychowska, A., Zajłc, D., Krawiec, S. and

Sołoducho, J., 2016. Phenolic Compounds Determination

Using Laccase-based Electrode Modi ed with Conducting Pol-

ymer Support. International Journal of Electrochemical Sci-

ence,11(1), pp.609-620.

Chand Meena, M., Band, R. and Sharma, G., 2015. Phenol

and Its Toxicity: A Case Report. Iranian Journal of Toxicol-

ogy,8(27), pp.1222-1224.

Dakhil, I.H., 2013. Removal of phenol from industrial wastewa-

ter using sawdust.

International Journal of Engineering And

Science,

3(1), pp.25-31.

Daraei, H., Mittal, A., Noorisepehr, M. and Daraei, F., 2013.

Kinetic and equilibrium studies of adsorptive removal of phe-

nol onto eggshell waste.

Environmental Science and Pollution

Research,

20(7), pp.4603-4611.

Dehghani, M.H., Mosto , M., Alimohammadi, M., McKay,

G., Yetilmezsoy, K., Albadarin, A.B., Heibati, B., AlGhouti,

M., Mubarak, N.M. and Sahu, J.N., 2016. High-performance

removal of toxic phenol by single-walled and multi-walled

carbon nanotubes: Kinetics, adsorption, mechanism and opti-

mization studies.Journal of Industrial and Engineering Chem-

istry,35, pp.63-74.

Fan, J., Zhang, J., Zhang, C., Ren, L. and Shi, Q., 2011. Adsorp-

tion of 2, 4, 6-trichlorophenol from aqueous solution onto

activated carbon derived from loosestrife.Desalination,267(2),

pp.139-146.

Giti, K. and Narges, J., 2015. Optimization electrophotocata-

lytic removal of acid red 18 from drinking water by the Tagu-

chi model.

Hsieh, F.M., Huang, C., Lin, T.F., Chen, Y.M. and Lin, J.C., 2008.

Study of sodium tripolyphosphate-crosslinked chitosan beads

entrapped with Pseudomonas putida for phenol degrada-

tion.

Process Biochemistry,43(1), pp.83-92.

Kashi, G., Mehree, A., Zaeimdar, M., Khoshab, F. and Madaree,

A.M., 2015. Removal of uoride from urban drinking water by

eggshell powder.

Liao, D., Zheng, W., Li, X., Yang, Q., Yue, X., Guo, L. and Zeng,

G., 2010. Removal of lead (II) from aqueous solutions using

carbonate hydroxyapatite extracted from eggshell waste.Jour-

nal of Hazardous Materials,177(1), pp.126-130.

Loganathan, P., Vigneswaran, S., Kandasamy, J. and Naidu, R.,

2013. De uoridation of drinking water using adsorption pro-

cesses.Journal of Hazardous materials,248, pp.1-19.

Mijan, M.A., Kim, D.H. and Kwak, H.S., 2014. Physicochemical

properties of nanopowdered eggshell.International Journal of

Food Science & Technology,49(7), pp.1751-1757.

Mourão, P.A.M., Laginhas, C., Custódio, F., Nabais, J.V., Car-

rott, P.J.M. and Carrott, M.R., 2011. In uence of oxidation

process on the adsorption capacity of activated carbons from

lignocellulosic precursors.Fuel Processing Technology,92(2),

pp.241-246.

Ngah, W.W., Fatinathan, S. and Yosop, N.A., 2011. Isotherm

and kinetic studies on the adsorption of humic acid onto chi-

tosan-H 2 SO 4 beads.Desalination,272(1), pp.293-300.

Tzvetkova, P.G., Nickolov, R.N., Tzvetkova, C.T., Bozhkov,

O.D. and Voykova, D.K., 2016. Diatomite/carbon adsorbent for

phenol removal.Journal of Chemical Technology and Metal-

lurgy,51(2), pp.202-209.

Giti Kashi

296 ON THE ANALYSIS OF PHENOL REMOVAL FROM DRINKING WATER BY BATCH REACTOR BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Zazouli, M.A., Taghavi, M. and Bazrafshan, E., 2012. In u-

ences of Solution Chemistry on Phenol Removal From Aque-

ous Environments by Electrocoagulation Process Using Alu-

minum Electrodes.Health Scope,1(2), pp.66-70.

Zul kar, M.A., Mariske, E.D. and Djajanti, S.D., 2012.

Adsorption of lignosulfonate compound using powdered

eggshells. Songklanakarin Journal of Science and Technol-

ogy,34(3), pp.309-316.

Zul kar, M.A., Novita, E., Hertadi, R. and Djajanti, S.D., 2013.

Removal of humic acid from peat water using untreated pow-

dered eggshell as a low cost adsorbent.International Journal of

Environmental Science and Technology,10(6), pp.1357-1366.