Biotechnological

Communication

Biosci. Biotech. Res. Comm. 9(4): 769-775 (2016)

Synthesis of green ZnO/SiO

2

nanocatalyst and its

application to reduce acenaphthylene from re nery

waste water

Rajani Bharati and S. Suresh*

Green Catalysis and Process Technology Research laboratory, Department of Chemical Engineering, Maulana

Azad National Institute of Technology, Bhopal-462 051

ABSTRACT

Plants extract have a vital role for the synthesis of different nanocatalysts like TiO

2

, ZnO, Fe

2

O

3

etc. due to its non-

toxicity, low cost. Many of these nanocatalysts have been used for the degradation of water pollutants. Some of the

plants extract are used as reducing and stabilizing agent in the synthesis of nanoparticles. No work has been found

on Butea monosperma (Palash) ower extract with ZnO nanoparticles. Phenol is found in many industrial ef uents

and excessive exposure of its may cause coma, cyanosis and even death. This research work focuses on the syn-

thesis of ZnO/SiO

2

with palash ower extract nanocatalyst by using single pot process for degradation of phenol

from aqueous solution. The synthesized nanocatalyst of ZnO/SiO

2

palash ower extract was characterized by using

BET surface area, FEG-SEM, EDAX, XRD, and FTIR. BET surface area of nanocatalyst is 157.23 m2/g and FEG-SEM

micrograph shows that spot of nanorange particles. Optimum percent removal of acenaphthylene was found to be

81% at 0.5g/500ml catalyst loading, 30oC temperature and 4h reaction time. Synthesis of ZnO/SiO

2

nanocatalyst with

palash ower extract by single-pot process is eco-friendly and cost effective method than other chemical methods.

KEY WORDS: SYNTHESIS, ZNO/SIO

2

, NANOCATALYST, PALASH, FLOWER, EXTRACT, ACENAPHTHYLENE, DEGRADATION

769

ARTICLE INFORMATION:

*Corresponding Author: rajniem000@yahoo.co.in

Received 27

th

Nov, 2016

Accepted after revision 27

th

Dec, 2016

BBRC Print ISSN: 0974-6455

Online ISSN: 2321-4007

Thomson Reuters ISI ESC and Crossref Indexed Journal

NAAS Journal Score 2015: 3.48 Cosmos IF : 4.006

© A Society of Science and Nature Publication, 2016. All rights

reserved.

Online Contents Available at: http//www.bbrc.in/

INTRODUCTION

Palash tree is also known as Butea monosperma, is

a very use full tree which is easily available in India

(Hegde et al., 2014). From literature it has been found

that palash ower has many biomolecules some are trit-

erpene, avonoids, glycosides carbohydrate and protein

(Jamkhade et al., 2013). It has been found that solubility

of palash ower is more in water than other solvents for

extractive value (Hegde et al., 2014). It has been found

770 SYNTHESIS OF GREEN ZNO/SIO

2

NANOCATALYST AND ITS APPLICATION BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Rajani Bharati and S. Suresh

that using plants extract as reducing and stabilizing

agents for nanocatalysts synthesis is eco-friendly and

cheap method than other methods which use chemicals

(Dizaji et al., 2015).

Single pot method also known as one step method

is the bioreduction processes in which plant extracts are

used as reducing and stabilizing agent to reduce metal

ions in nano range (Gdikandula et al., 2016). Palash

ower extract contains a broad variability of biomole-

cules so this method is faster than other methods (Kumar

and Yadav, 2012).

No research article has been found in the literature

for the synthesis of ZnO/SiO

2

based nanocatalyst by

using an aqueous palash ower extract as reducing

and stabilizing agent. This work is different from other

works because palash ower extract contains many

metals naturally which increases catalysts photocata-

lytic activity. SiO

2

has been found naturally in palash

ower extract. Incorporation of ZnO with SiO

2

increases

its photocatalytic activity for visible light. So ZnO/SiO

2

nanocatalyst synthesized by this method will be more

effective under sunlight to remove pollutant than ZnO

nanocatalyst synthesized by other methods. We can

use this nanocatalyst to treat ef uents from industries

under sunlight also. ZnO/SiO

2

with palash ower extract

nanocatalyst was used for acenaphthylene removal from

re nery wastewater in an annular reactor. We have

found Hexagonal crystal structure of ZnO nanocatalyst

which is the most stable in the environment. Synthe-

sized nanocatalysts were characterized by Brunauer-

Emett-Teller (BET), energy dispersive atomic X-ray

(EDAX), Field Emission Gun-Scanning electron micro-

scope (FEG-SEM), and X-ray diffraction (XRD) and Fou-

rier transform infrared spectroscopy ( FTIR) to determine

their Surface area, size, shape, particle distribution and

functional group.

MATERIALS AND METHODS

ZnO bulk material (Molychem from Mumbai, 99.5%

purity), acenaphthylene (Ranbaxy ne chemicals from

New Delhi, 99% purity),Sodium hydroxide (A. B. Enter-

prises, Mumba,, 98% purity),HCL (Central drug house

Ltd. From Delhi, 35% purity), Palash owers, (Butea

monosperma) were collected from MANIT Bhopal cam-

pus, Double distilled water. ZnO bulk material was used

as a precursor to make 1mM ZnO aqueous solution; HCL

acid was used to making 1 M solution to dissolve ZnO in

water. NaOH to make the 1N solution to maintained pH.

Phenol was used to make aqueous solution of Phenol

to remove by catalyst and nd Percentage removal of

Phenol by HPLC.

All chemicals used for the experimental work were

analytical grade (AR). Palash owers were collected

from the Campus of MANIT Bhopal, Madhya Pradesh,

India. The collected owers were cleaned by washing

many times with double distilled water and then dried

in sunlight. Dried ower were powdered in a mixer and

stored in a container to prevent from moisture and this

powder was preserved for experimental work. 250 mL

Erlenmeyer ask has been taken for boiling 10 g of

palash ower powder and 200 mL of double distilled

water for 1 h (Yadav and Khurana, 2015). Whatman l-

ter paper (pore size >0.5μm) has been used for ltration

of extract and it has been stored at 4°C in a deep freezer

which was used later for experimental work. We have

chosen water for extracting agent due to an extractive

value of palash ower in water is 17.5 ± 0.5% which is

comparatively maximum than other solvents.

ZnO has been bought from Molychem, Mumbai, and

the aqueous palash ower extract has been used for

the bioreduction process. To make nanoparticles from

palash ower 35 mL of the aqueous ower extract was

carefully added to 90 mL of 1 mM aqueous ZnO solution

in 250 mL Erlenmeyer asks. Colour of the solutions has

changed from brownish yellow to dark brownish, con-

rming the green synthesis of ZnO. We have performed

this experiment at pH 9.30; at this pH we got more pre-

cipitate of ZnO nanocatalyst. After the reaction, nano-

particles in the form of the precipitate had been settled

at the bottom of the conical asks. We separated ZnO

nanoparticles in the form of precipitate by centrifuging

it at 10000 rpm for 15 min (Awwad et al., 2013). Then we

have used these nanoparticles for characterization and

experimental work.

Characterization of ZnO nanocatalyst with palash

ower extract was done by standard methods (Sarma

and Sarma, 2014). Brunauer–Emmett–Teller (BET) sur-

face area of the nanoparticle was found by nitrogen

adsorption at 77.15K using an automatic pulse chem-

isorptions system (Micromeritics Chemisorb 2720) using

the software available with the instrument. To determine

the surface morphology and chemical composition, SEM

and EDAX tests were done in the SAIF, IIT Mumbai. The

phase identi cation and crystal structure have been

analysed by X-ray powder diffraction (XRD) test. Func-

tional groups present in synthesized nanocatalyst were

found by FTIR test. The XRD and FTIR tests have been

done in central laboratory of North Maharashtra Univer-

sity, Jalgaon, India.

Removal of acenaphthylene by synthesized nanocatalyst

Concentric Annulus photocatalytic reactor has been

used for acenaphthylene removal from re nery waste-

water by synthesized nanocatalyst. In this batch reac-

tor, which we have used for experiment; two coaxial

cylinders are there. The inner with reaction zone and

lamp is placed on the symmetry axis. The total volume

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS SYNTHESIS OF GREEN ZNO/SIO

2

NANOCATALYST AND ITS APPLICATION 771

Rajani Bharati and S. Suresh

of the reactor is 1 litre and working volume is 0.7 litres.

Practically, all the photons emitted by UV lamp reach

the reaction medium if the outer walls of the reactor

are re ective. This geometry has been selected for the

photoreactor used in this study and offers a number

of advantages viz. ef cient photon captures, practical

to uidize the photocatalyst in a cylindrical geometry

and an outer jacket can be used for meeting the cooling

requirements of UV lamp. At the bottom of the reactor,

the magnetic stirrer is tted for uniform mixing. The

temperature was maintained around 28±2

o

C.

Acenaphthylene is one of the polycyclic aromatic

hydrocarbons that is found as pollutant in re nery

wastewater (Uddeen et al., 2011). In this experimental

work for treatment of re nery waste water, 500 ml re n-

ery wastewater has been treated in concentric annular

reactor with 1000 ml capacity. For this 0.5/500 ml cata-

lyst loading was used for photocatalytic reaction. The

solution of 500 ml was used to treat in a 1000ml of the

total volume of the reactor. The mixture solution was

placed into an annular reactor and started the UV light

(6W) to study the degradation or removal for duration of

6 h. The temperature was maintained at 30

o

C. The sam-

ples were withdrawn from annular reactor periodically

in an interval of 0.5, 1.5, 1, 2, 3, 4, 5, 6 hrs. After appro-

priate degradation, the samples were ltered and then

obtained residual concentrations of acenaphthylene

were analysed with the help of high performance liquid

chromatography (HPLC) (Waters Pvt. Ltd., India) C-18

column.The removal of acenaphthylene (%) was deter-

mined by following relationships (Hassan et al.,2015).

Acenaphthylene degradation (%) = 100 (C

i(0)

-C

f(t)

)/C

i(0)

Where, C

i(o)

is the initial acenaphthylene concentra-

tion (mg/l), C

f(t)

is the nal acenaphthylene concentration

(mg/l) at times t.

RESULTS AND DISCUSSION

The mechanism of ZnO nanocatalyst synthesis with

palash ower extract is that we have taken 1mM ZnO

solution for synthesis ZnO particles in nano range. Ini-

tially, ZnO (Bulk powder) was insoluble in water but

when we added few drops of one molar HCL acid, it

was completely soluble in water. The ZnO was degraded

by acid and formed ZnCl

2

. ZnCl

2

salt worked here as

precursor of Zn

+2

ions.Zn

+2

ions were reduced in nano

range by biomolecules present in palash ower extract.

Than functional groups present in palash ower extract

naturally worked as the capping agent for stabilization

of synthesized nanoparticles (Akhtar et al., 2013). The

mechanism and role of palash ower extract to synthe-

size ZnO/SiO

2

nanocatalyst in nanorange is shown in

Fig. 1. And SiO

2

was obtained from palash ower extract

which is present in palash ower naturally.

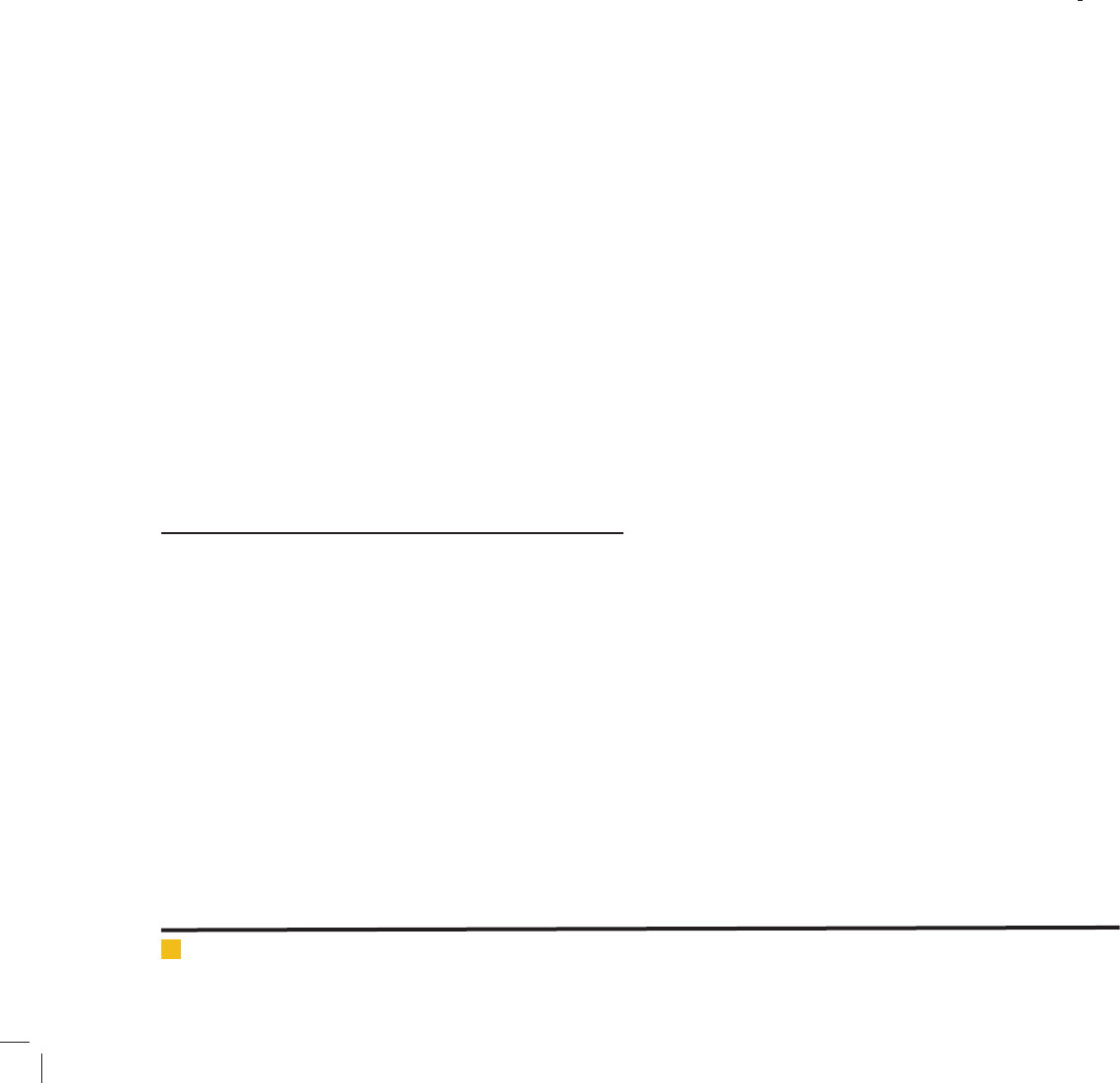

Intensity

Range in energy (KeV)

FIGURE 1. EDAX spectra of ZnO/SiO

2

palash ower extract nanoparticles.

ZnO(Powder) + 2HCL ZnCl

2

+ H

2

O

Zn

+2

+ 2OH

-

Zn(HO)

Zn(HO)

2

ZnO(nanocatalyst) + H

2

O

BET surface area of nanocatalyst has been found

157.23 m

2

/g. Reduction of Zn

+2

ions into nanorange

by palash ower extract can be seen by colour change.

When we added palash ower extract and mixed it

with the aqueous solution of the ZnO, the change in

colour of solution from brownish yellow to dark brown-

ish was observed and it has been con rmed that for-

mation of ZnO nanocatalyst has been occurred (Shukla

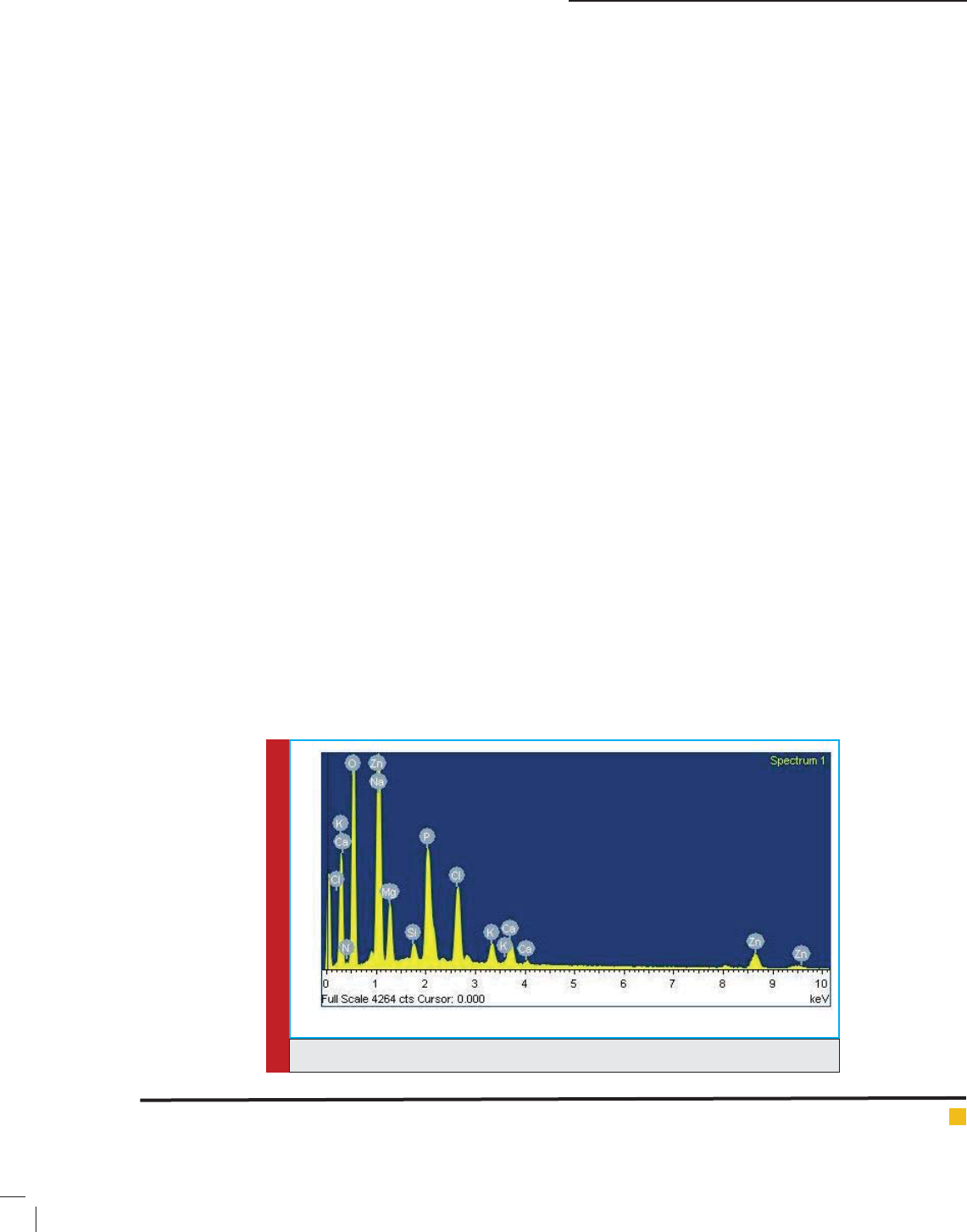

and Vankar, 2012). Figs.1-2 shows the EDAX spectra and

FEG-SEM images of synthesised ZnO/SiO

2

with palash

ower extract. The Hexagonal Crystal structure of ZnO

nanoparticles has been found by XRD pattern. The FEG-

SEM image shown in Fig.2 Shows spherical shape of

772 SYNTHESIS OF GREEN ZNO/SIO

2

NANOCATALYST AND ITS APPLICATION BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

Rajani Bharati and S. Suresh

nanoparticles has been formed and Fig2-3 shows that

nanocatalysts have been found in the range of 3 nm to

45 nm with 23 nm mean particle diameter (Khalil et al.,

2014). At some places aggregation of nanoparticles have

been shown in FEG-SEM image Fig.2.

EDAX test has been done to nd chemical compo-

sition of ZnO/palash ower extract nancatalyst .EDAX

spectra found for a sample of ZnO/palash ower extract

nanoparticles and the weight percentage of Zn and O are

found to be 15.79 % and 38.05% respectively (Khalil et

al., 2014). From EDAX it can be seen that Si is also pre-

sent palash ower extract. It con rms that we have got

ZnO/SiO

2

with Palash ower extract nanocatalyst. It has

been shown in EDAX spectra that we have got strong

Diameter

No. of particles

FIGURE 2. FEG-SEM image of ZnO/SiO

2

palash ower extract nanocatalyst.

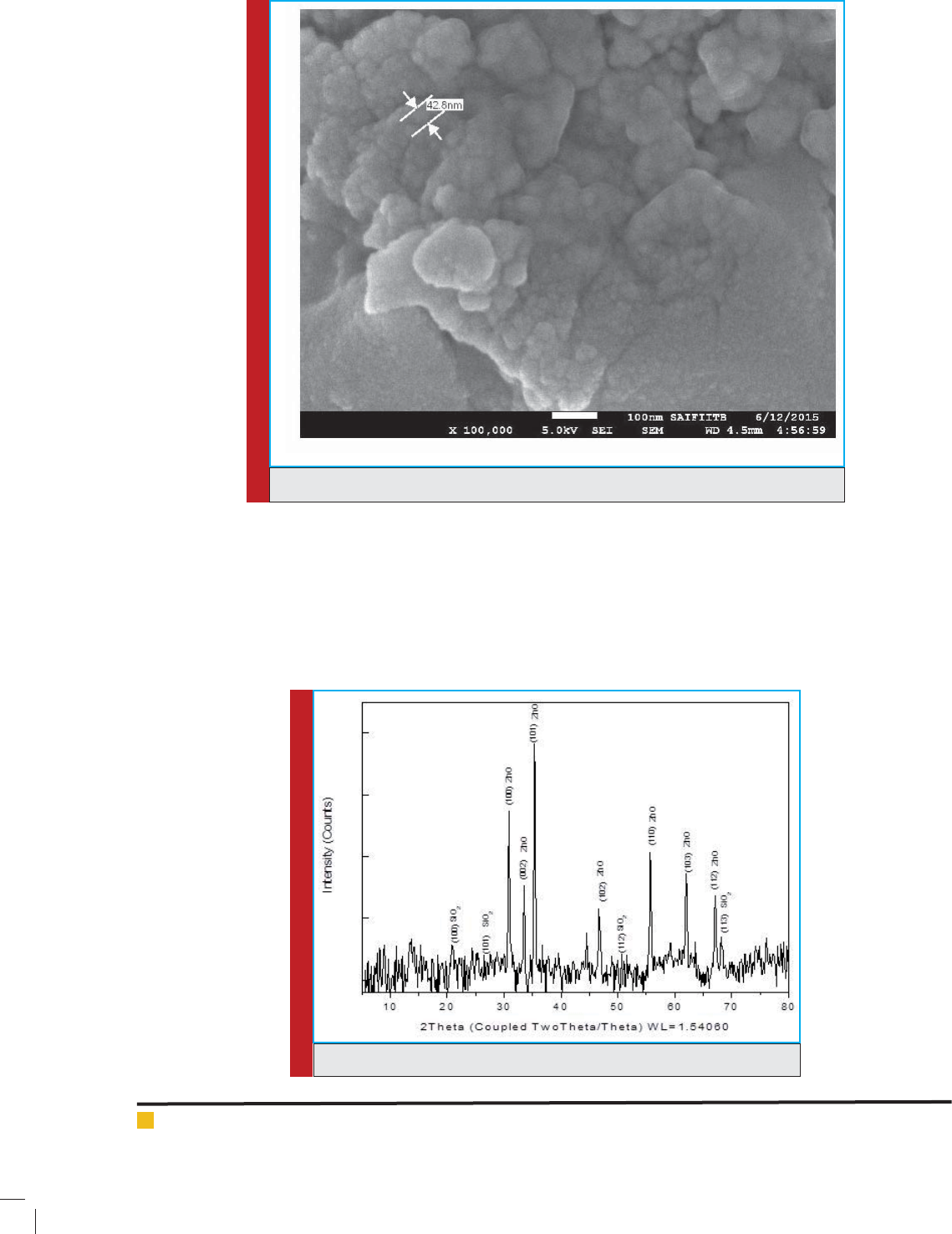

FIGURE 3. XRD pattern of ZnO/ palash ower extract nanocatalyst.

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS SYNTHESIS OF GREEN ZNO/SIO

2

NANOCATALYST AND ITS APPLICATION 773

Rajani Bharati and S. Suresh

Percent Transmittance

IR Frequency

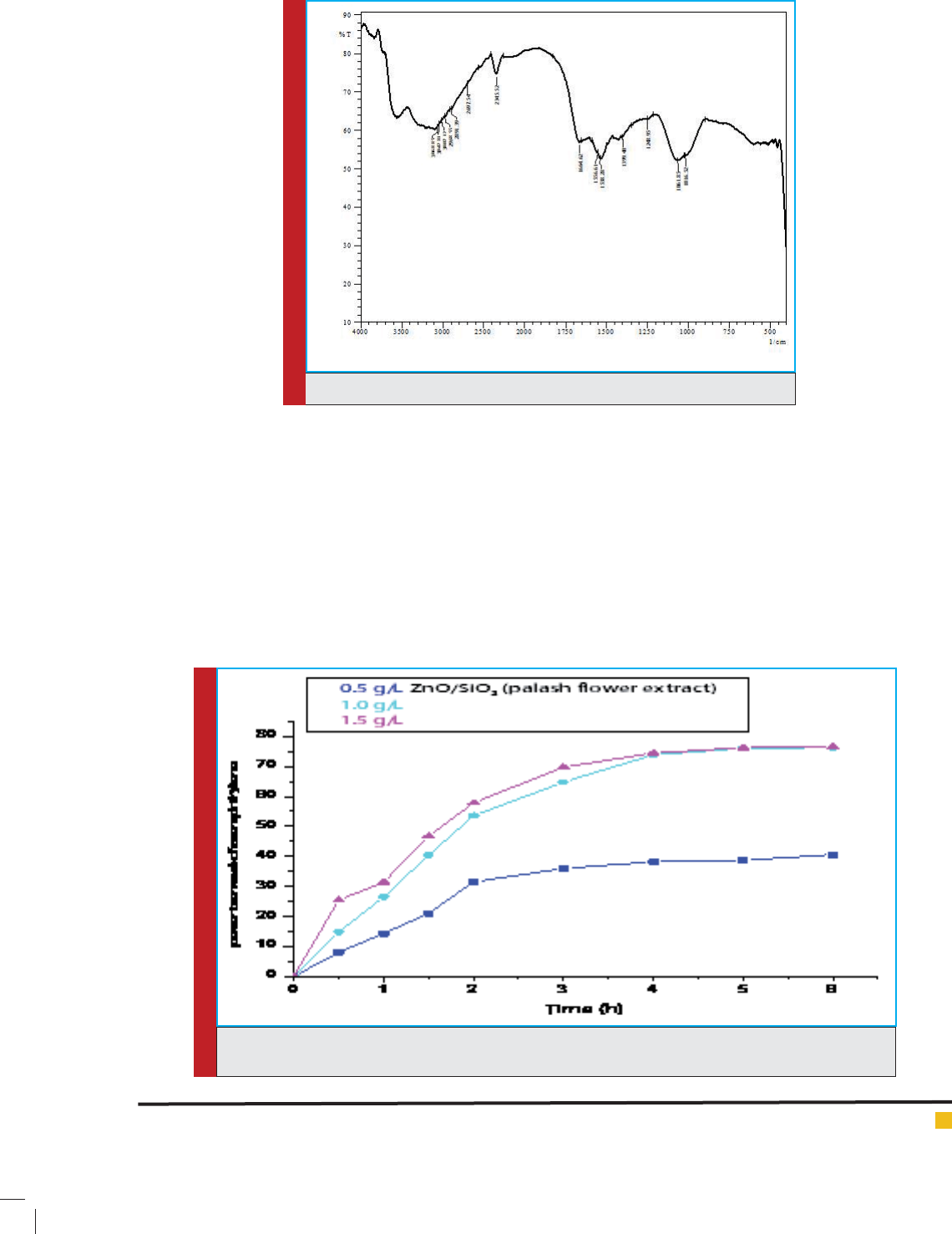

FIGURE 4. FTIR spectra of ZnO/palash ower extract nanocatalyst.

FIGURE 5. Degradation of acenaphthylene from re nery wastewater with time by ZnO/SiO

2

with palash

ower extract nanocatalyst.

signal of energy peaks for Zn and O atoms in the range

0.5–1.5 keV and weaker signals for Zn atoms in the

range 8-10 keV (Khalil et al., 2014; Sarma et al., 2014).

It has been also found that we have got weaker signals

for N, Mg, Si, P, Cl, K, and Ca, which were present in

palash ower extract and due to presence of many met-

als naturally in palash ower extract it increases photo-

catalytic activity of ZnO/SiO

2

with palash ower extract

nanocatalyst.

XRD peaks shown in Fig.3 con rmed the presence

of ZnO corresponding to PDF No. 80-0075. The lattice

parameters a and c were calculated to be about 3.25 A

0

and 5.209 A

0

respectively. The minor amount of Si (SiO

2

)

was also found in the XRD pattern. The crystal structure

of the SiO

2

was found to be matching with low quartz.

The peaks of Si, as well as ZnO, were found to be broad-

ened indicating nanocrystalline or amorphous nature

of the crystal. In our experiment, the X-ray pattern of

synthesized ZnO nanoparticles matches the hexagonal

structure of the ZnO nanoparticles with the broad peaks

at 2 = 36.243, 56.568. These are corresponding to (101),

(110) and (103), respectively. Similar peaks were found in

774 SYNTHESIS OF GREEN ZNO/SIO

2

NANOCATALYST AND ITS APPLICATION BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS

the ZnO based nanoparticles (Rekha et al., 2010, Khalil et

al., 2014 and Sarma and Sarma, 2014).

Fig. 4 Shows FTIR spectra of ZnO/palash ower

extract nanocatalyst , which has been done to nd vari-

ous functional groups present in nanocatalyst .IR fre-

quency from 2697.54 to 3068.85 is due to O-H stretch-

ing , 1061.85 and 1248.95 for Si-O-Si starching ,1538.28

to 1664.62 for C=O stretching ,1016.52 for ZnO stretch-

ing , this stretching is slightly shifted from 1000 which

is for metal oxide due to the presence of other functional

groups(Uddeen et al.,2011).

Hence XRD pattern con rms that ZnO nanoparticles

have been formed by this bioreduction process. Phases of

the sample were matched with standard XRD pattern of

ZnO nanoparticles. From EDAX, XRD and FTIR test it has

been found that SiO

2

has been also found in the sample

which increases photocatalytic activity of this catalyst.

Percentage removal of pollutant

ZnO/SiO

2

nanocatalyst made by biosynthesis or green

single pot method are very good nanocatalyst for degra-

dation of acenaphthylene from re nery wastewater. Fig.

5 shows the degradation of phenol from aqueous solu-

tion by using ZnO/SiO

2

palash ower extract. Acenaph-

thylene degradation from re nery wastewater has been

done in an annular photocatalytic reactor and it has

been found that optimum percent removal of acenaph-

thylene was found to be 81% at 0.5g/500ml, 30

o

C and

4h of catalyst loading, temperature and reaction time

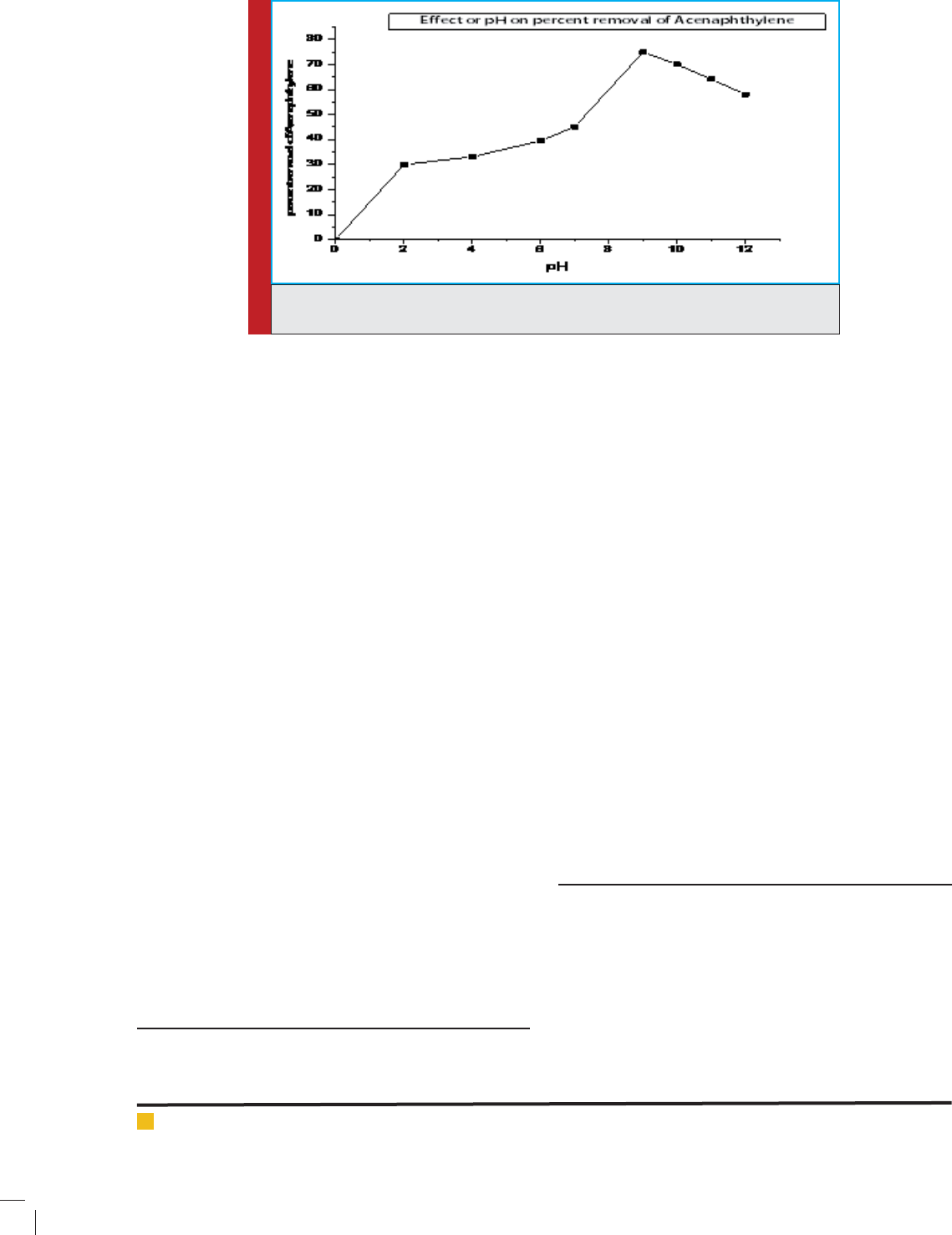

respectively. Fig. 6 shows optimum percent removal of

acenaphthylene with pH at 9.5 pH.

CONCLUSION

In present research work the characterization of nano-

catalyst shows that we have synthesized ZnO/SiO

2

nano-

catalyst with palash ower extract in nanorange. We

have used palash ower extract as reducing and sta-

bilizing agent in place of chemical to synthesize ZnO

nanocatalyst so it is eco-friendly method. Palash ower

contains many biomolecules which are responsible for

reduction and stabilization of Zn

+2

ions in nanorange so

it is more fast method than other methods. It contains

SiO

2

naturally catalyst synthesized by palash ower

extract is more ef cient to remove pollutant than other

methods. So Palash ower is easily available in India at

low cost and we need very simple techniques to synthe-

size nanocatalyst by this method so it is cheap process

than other processes. We have found from EDAX and

XRD test that many metals present naturally in palash

ower extract so incorporation of these metals with

ZnO nanocatalyst increases its photocatalytic activity

.Results shows that ZnO/palash ower extract nanocata-

lyst is very good photocatalyst to remove phenol from

an aqueous solution of phenol. The percent removal of

phenol can be optimized by controlling affecting param-

eters such as reaction time, catalyst size, catalyst load-

ing, pH and temperature. The optimum percent removal

of phenol has been found 81% at 0.5/500ml catalyst

loading at 30

o

C temperature and 4h reaction time.

ACKNOWLEDGMENT

The authors wish to thank Ministry of Human Resource

Development, Government of India (MHRD) and Maul-

ana Azad National Institute of Technology (MANIT)

Bhopal, India to provide fund and facilities to carry out

experimental work.

REFERENCES

Ahmed, S.; Ahmad, M.; Swami, B. L.; Ikram, S. (2016): A review

on plants extract mediated synthesis of silver nanoparticles

FIGURE 6. Degradation of acenaphthylene from re nery wastewater at different pHby

ZnO/SiO

2

with palash ower extract nanocatalyst.

BIOSCIENCE BIOTECHNOLOGY RESEARCH COMMUNICATIONS SYNTHESIS OF GREEN ZNO/SIO

2

NANOCATALYST AND ITS APPLICATION 775

for antimicrobial applications. A green expertise, Journal of

Advanced Research, 7(1), 17–28.

Akhtar, M. S.; Panwar, J.; Yun, Y.S. (2013): Biogenic Synthesis

of Metallic Nanoparticles by Plant Extracts. American Chemi-

cal Society Sustainable Chemistry & Engineering, 1, 591−602.

Awwad, A. M.; Salem, N. M. and Abdeen, A. O. (2013): Green

synthesis of silver nanoparticles using carbon leaf extract and

its antibacterial activity. International Journal of Industrial

Chemistry, 4(1):29, 1-6.

Balachandran, Y. L.; Peranantham, P.; Selvakumar, R.; Arno,

C.; Girija, G. S. (2012): Size-Controlled Green Synthesis of Sil-

ver Nanoparticles using Dual Functional Plant Leaf Extract at

Room Temperature. International Journal of Green Nanotech-

nology, 4(1), 310–325.

Dizaji, A. N.; Yilmaz, M.; Piskin, E. (2015): Silver or gold depo-

sition onto magnetite nanoparticles by using plant extracts as

reducing and stabilizing agents. Arti cial Cells, Nanomedicine,

and Biotechnology, Early Online, 1–7.

Gudikandula, K. and S. C., Maringanti (2016): Synthesis of

silver nanoparticles by chemical and biological methods and

their antimicrobial properties. Journal of experimental nano-

science, doi: 10.1080/17458080.2016.1139196.

Hassan, S. E. D.; Desouky, S. E.; Fouda, A.; Mamdouh, S. E.

and Ahmed A. (2015): Biodegradation of Phenanthrene by

Klebsiella sp Isolated from Organic Contaminated Sediment.

Journal of Advances in Biology & Biotechnology, 4(4), 1-12.

Hegde, S. V.; Hegde, G. R.; Mannur, S.; Poti, S. S. (2014):

Pharmacognostical studies on Butea monosperma (Lam.) Taub

(Faboideae) ower. International Journal of Pharmaceutical

and Phytopharmacological Research, 4(1), 2250-1029.

Jamkhande, P. G.; Patil, P.H.; Tidke, P. S. (2013): In Vitro Anti-

oxidant activity of Butea monosperma Flowers Fractions. Inter-

national Journal Drug, Delivery& Research, 5 (3), 245-255.

Khalil, M. I.; M. Qunaibit, M. A.; Zahem, A. M. A.; Labis, J. P.

(2014): Synthesis and characterization of ZnO nanoparticles by

thermal decomposition of a curcumin zinc complex. Arabian

Journal of Chemistry, 7(1), 1178–1184.

Kumar, V. and S. K., Yadav (2012): Characterization of gold

nanoparticles synthesized by leaf and seed extract of Syzygium

cumini L. Journal of Experimental Nanoscience , 7(4), 440–451.

Rekha, K.; Nirmala, M.; Nair, M. G.; Anukaliani, A. (2010):

Structural, optical, photocatalytic and antibacterial activity

of zinc oxide and manganese doped zinc oxide nanoparticles,

Physica B, 405 (1), 3180–3185.

Sarma, H.; Chakrabortty, D.; Sarma, K.C. (2014): Structural

and Optical Properties of Zno Nano Particles. IOSR Journal of

Applied Physics, 6 (4), 08-12.

Sarma, H.; Sarma, K.C. (2014): X-ray Peak Broadening Anal-

ysis of ZnO Nanoparticles Derived by Precipitation method.

International Journal of Scienti c and Research Publications,

4(3), 2250-3153.

Shukla, D. and P. S., Vankar (2012): Synthesis of Plant Parts

Mediated Gold Nanoparticles. International Journal of Green

Nanotechnology, 4(1), 277–288.

Uddeen, B.H.D.; Daud, W.M.A.W.; Aziz, A.R.A.(2011): Treat-

ment technologies for petroleum re nery ef uents. A review,

Process safety and environmental protection, 89(1), 95-105.

Wang, P.; Menzies, N. W.; Lombi, E.; Sekine, R.; Blamey, F. P.

C.; Soriano, M. C. H.; Cheng, M.; Kappen, P.; Peijnenburg, W. J.

G. M.; Tang, C.; Kopittke P. M. (2015): Silver sul de nanopar-

ticles (Ag

2

S-NPs) are taken up by plants and are Phytotoxic.

Nanotoxicology, Early Online: 1–9.

Yadav S. and Khurana, J. M. (2015) Cinnamomum tamala leaf

extract-mediated green synthesis of Ag nanoparticles and their

use in pyranopyrazles synthesis. Chinese Journal of Catalysis,

36 (1), 1042-1046.